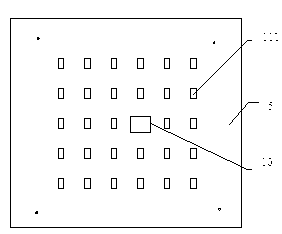

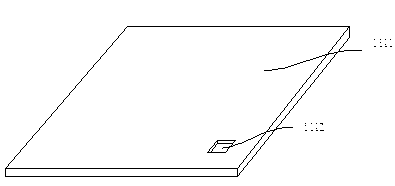

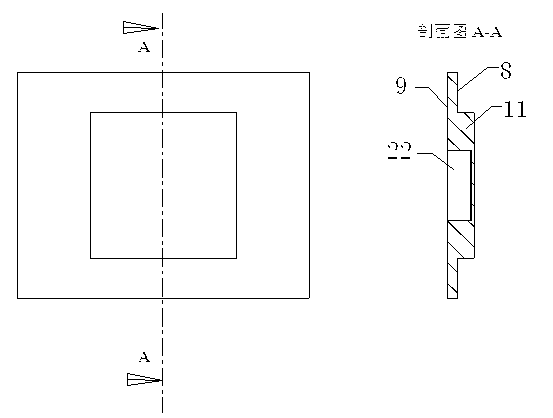

Composite preparation process of three-dimensional vapor plating mask plate

A three-dimensional three-dimensional, preparation process technology, applied in the photoplate making process of the pattern surface, vacuum evaporation plating, metal material coating process and other directions, can solve problems such as deformation and product scrap, achieve simple process, smooth hole wall, The effect of broad market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073] A specific process flow of a compound preparation process of a three-dimensional evaporation mask includes the following two steps:

[0074] A. The preparation process of the three-dimensional mandrel;

[0075] B. Preparation process of three-dimensional three-dimensional evaporation mask.

[0076] Specifically, the preparation process of the three-dimensional mandrel described in step A comprises the steps of:

[0077] Mandrel processing → pre-treatment (degreasing, pickling, sandblasting) → double-sided film coating → single-sided exposure a → single-sided development a → single-sided etching → stripping → post-treatment of core mold (degreasing, pickling)

[0078] More specifically, the technological process described in each step is as follows:

[0079] (1) Mandrel processing: select a 1.8mm thick stainless steel plate as the mandrel material, and cut the mandrel into a size of 800mm×600mm;

[0080] (2) Pretreatment: Degrease, pickle and sandblast the mandrel to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com