Three-dimensional evaporation mask with high iron content

A three-dimensional and mask technology, applied in the field of OLED production, can solve the problem that the light-emitting display cannot meet high requirements, and achieve the effects of good opening quality, broad market prospects and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

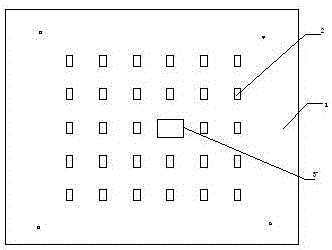

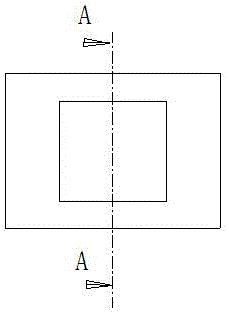

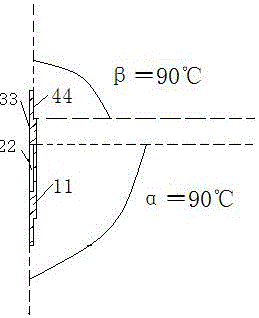

[0030] Such as Figure 1-3 Said, a three-dimensional three-dimensional evaporation mask plate 1 with high iron content, including a pattern opening 2 in the pattern opening area, has a three-dimensional structure 3, and the three-dimensional structure 3 is composed of a recessed area 22 and a raised area 11. The recessed area 22 is a recessed structure lower than the surface of the mask plate, and the raised area 11 is a raised structure higher than the surface of the mask plate. The material of the mask 1 includes iron and nickel, the iron content is 63%, and the nickel content is 37%. The depth of the depressed region 22 is ≤10 μm, and the height of the raised region 11 is ≤10 μm. The angle α formed between the recessed area 22 and the surface of the mask 1 is 90° 0 , the angle β formed between the raised area 11 and the surface of the mask 1 is 90° 0 . The thickness of the mask plate is 50 μm, and the uniformity COV of the nickel-iron alloy coating is less than 5%; the ...

Embodiment 2

[0032] A three-dimensional three-dimensional evaporation mask with high iron content, including a pattern opening in the pattern opening area, has a three-dimensional structure, and the three-dimensional structure is composed of a recessed area and a raised area, and the recessed area is lower than the surface of the mask plate The concave structure, the convex structure of which the raised area is higher than the surface of the mask template. The material of the mask includes iron and nickel, the iron content is 64%, and the nickel content is 36%. The depth of the depressed region is ≤1 μm, and the height of the raised region is ≤1 μm. The range of the included angle formed between the recessed area and the mask plate surface is 80° 0 , the angle between the raised area and the mask plate surface is 80° 0 . The thickness of the mask plate is 10 μm, and the uniformity COV of the nickel-iron alloy coating is less than 5%; the surface brightness of the nickel-iron alloy coati...

Embodiment 3

[0034]A three-dimensional three-dimensional evaporation mask with high iron content, including a pattern opening in the pattern opening area, has a three-dimensional structure, and the three-dimensional structure is composed of a recessed area and a raised area, and the recessed area is lower than the surface of the mask plate The concave structure, the convex structure of which the raised area is higher than the surface of the mask template. The material of the mask plate includes two elements of iron and nickel, the iron content is 65%, and the nickel content is 35%. The depth of the depressed region is ≤10 μm, and the height of the raised region is ≤10 μm. The range of the included angle formed between the recessed area and the mask plate surface is 85° 0 , the range of the included angle formed between the raised area and the mask plate surface is 85 0 . The thickness of the mask plate is 60 μm, and the uniformity COV of the nickel-iron alloy coating is less than 5%; th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com