Reaming fixture and method of marine low speed diesel engine

A diesel engine and reaming technology, applied in broaching equipment, manufacturing tools, metal processing equipment, etc., can solve problems such as hidden safety hazards, time-consuming and labor-intensive, affecting assembly work, etc., to achieve less burrs, overall effect improvement, hole wall smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further elaborated and described below in conjunction with the accompanying drawings and embodiments, but the protection scope of the present invention cannot be limited by this.

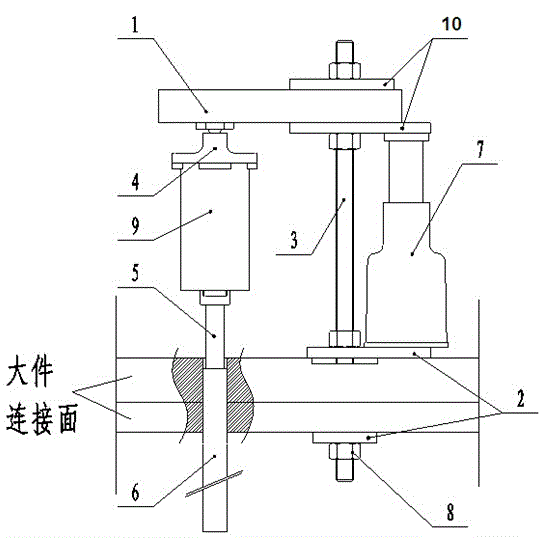

[0028] see figure 1 , figure 1 It is a schematic structural diagram of the reaming tool for a low-speed marine diesel engine of the present invention. As shown in the figure, a reaming tool for a low-speed marine diesel engine includes: a beam plate 1 with a waist-shaped hole, a first backing plate 2, and a full-threaded bolt 3 , guide rod 5, reaming broach 6, screw jack 7, hex nut 8 and oil cylinder 9 connected with hydraulic pump by oil pipe.

[0029] The bottoms of the two ends of the beam plate are respectively fixed with the top of the oil cylinder and the top of the screw jack, and the level of the beam plate is kept, and one end of the fully threaded bolt passes through the waist-shaped hole of the second backing plate 10 and the beam plate and the beam. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com