Construction method of cast-in-place box girder based on composite mobile formwork

A technology of mobile formwork and construction method, which is applied to the composite mobile formwork of cast-in-place box girders, based on the construction field of composite mobile formwork cast-in-place box girders, which can solve the problems of low construction efficiency, poor adaptability, and formwork And formwork brackets need to be removed repeatedly, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below with reference to the accompanying drawings and examples. The following examples are explanations of the present invention and are not limited to the following examples.

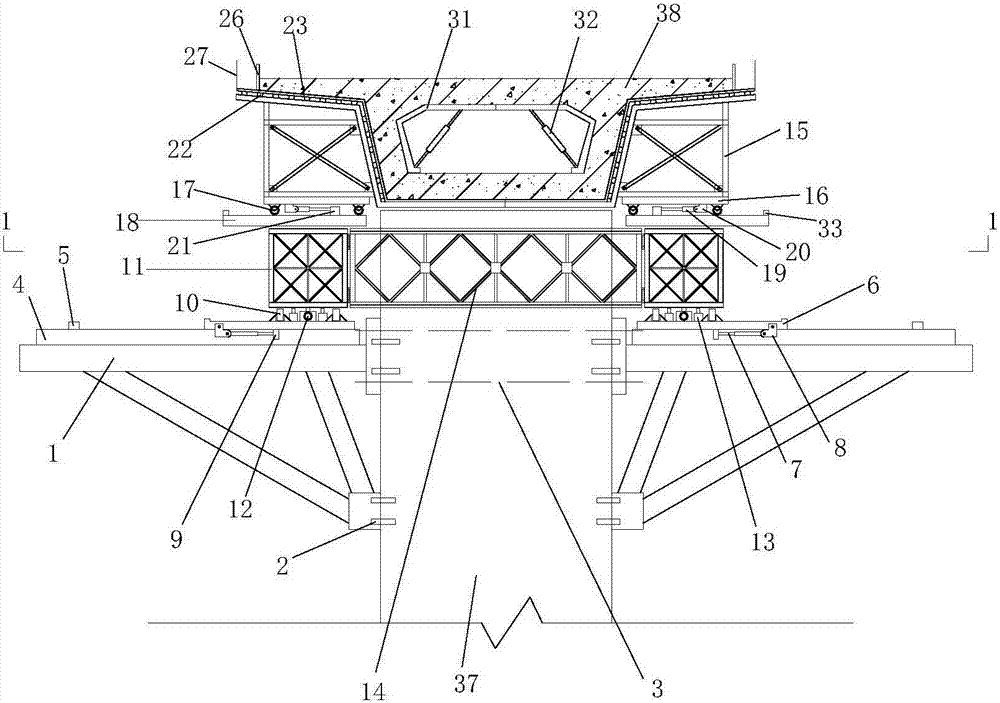

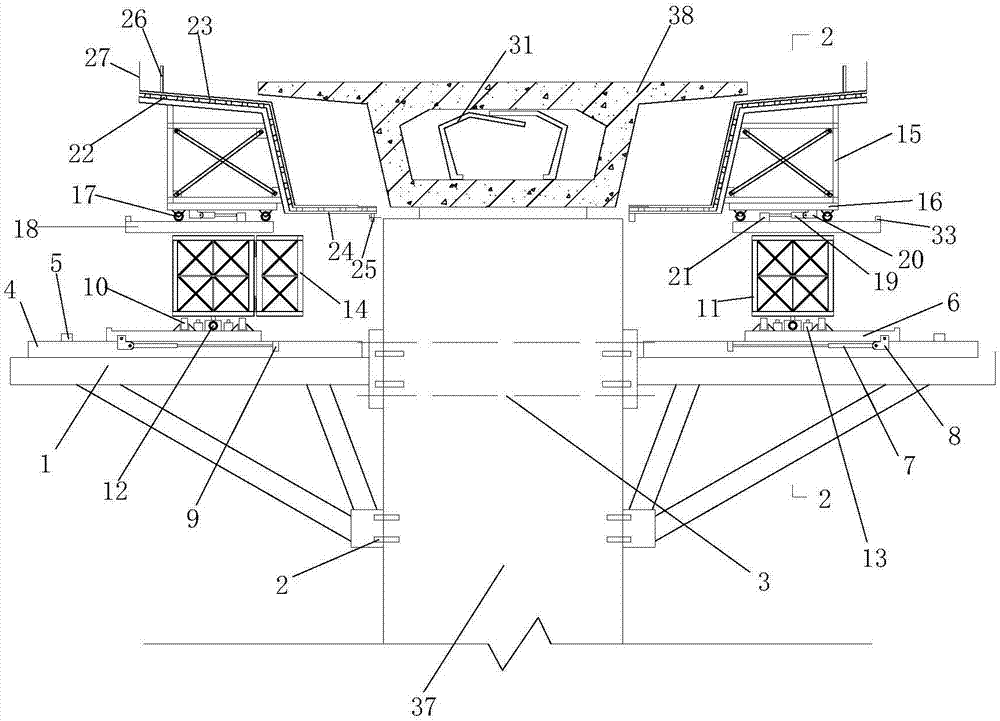

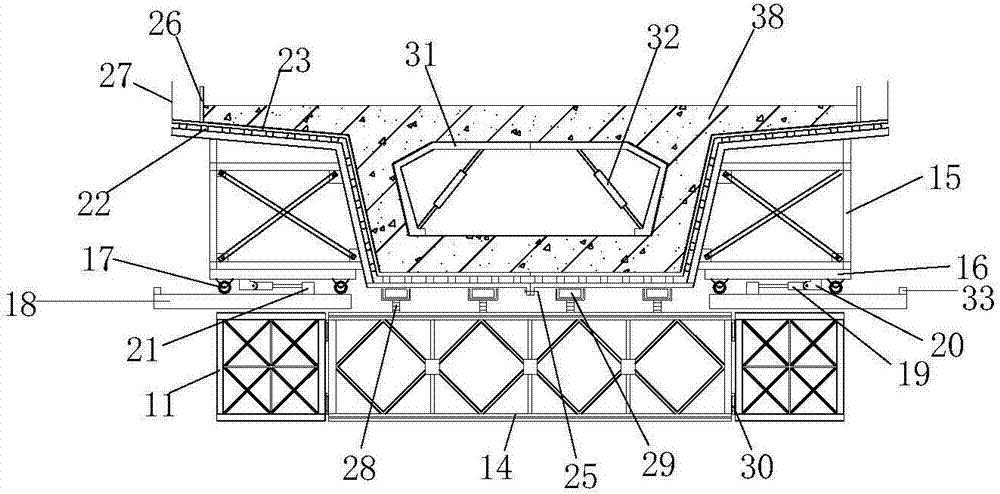

[0036] figure 1 It is a cross-sectional view of the construction state of the cast-in-place box girder based on the composite mobile formwork. like figure 1 The composite mobile formwork shown mainly includes: corbel support bracket 1, traversing track 4, pulley block platform 6, longitudinal Bailey beam 11, transverse Bailey beam 14, outer mold support 15, traversing platform 16, Traverse jack A7, longitudinal jack 35, traverse jack B19, baffle mold 26 and guardrail 27.

[0037] The traversing track 4 is set on the corbel support bracket 1, and the limit block A5 is set on the outside of the traversing track 4; the pulley block platform 6 is placed on the traversing track 4, and the longitudinal pulley A10 is set on the pulley block pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com