Polyacrylonitrile preoxidized fiber skin-core structure detection method

A technology of pre-oxidized fiber and polyacrylonitrile, which is applied in the direction of measuring devices, test sample preparation, sampling, etc., can solve the problems of poor curing effect of collodion liquid, rough hole wall, affecting accuracy, etc., and achieves guaranteed treatment Efficiency and effect, avoiding fiber lodging, and ensuring the effect of flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

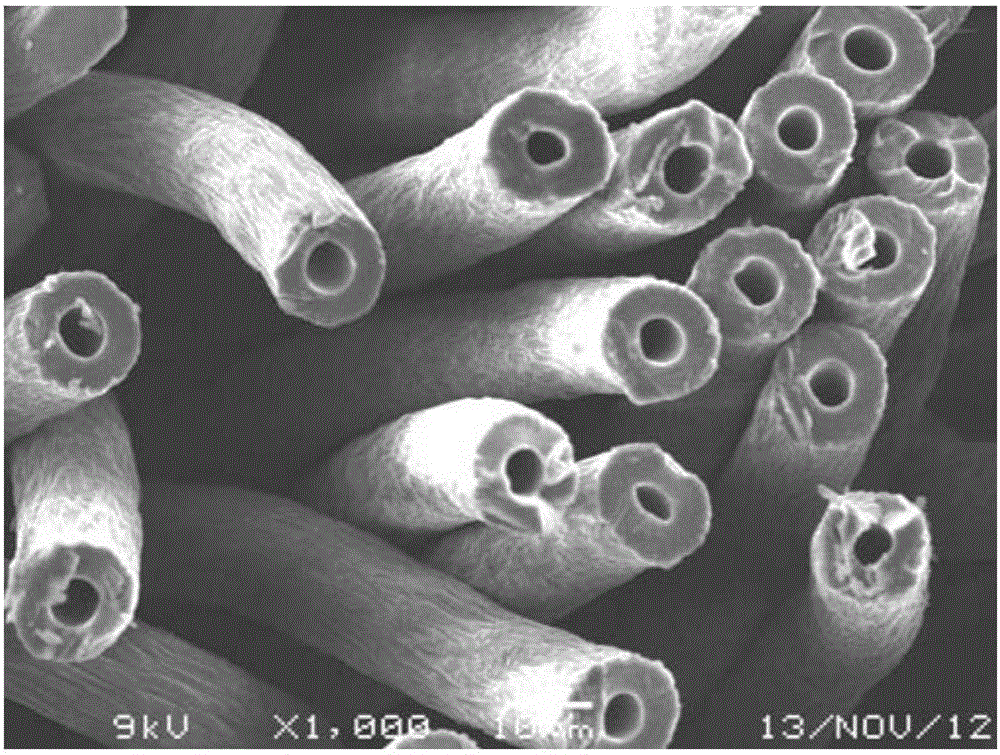

[0022] 1g3cm long 1KPAN pre-oxidized short fiber is immersed in a flask filled with sulfuric acid solution, the concentration of sulfuric acid solution is 20wt%, the sulfuric acid solution is heated to boiling, and the treatment time is 2h. Stir and wash the treated pre-oxidized short fibers in a beaker filled with deionized water until neutral to remove residual sulfuric acid solution. After filtering with filter paper, collect the pre-oxidized short fibers in a watch glass, put Dry in a blast oven at 120°C for 1.5h, and cool to room temperature naturally in a desiccator. Take the treated pre-oxidized short fiber, place the pre-oxidized short fiber in parallel, wrap the pre-oxidized short fiber tightly with strip-shaped double-sided conductive tape, and then quickly cut off the two ends of the wrapped tape with a blade, Keep a 0.5cm long section in the middle, stick one end of it firmly with double-sided conductive tape and stand it upright on the SEM sample stage, use SEM to...

Embodiment 2

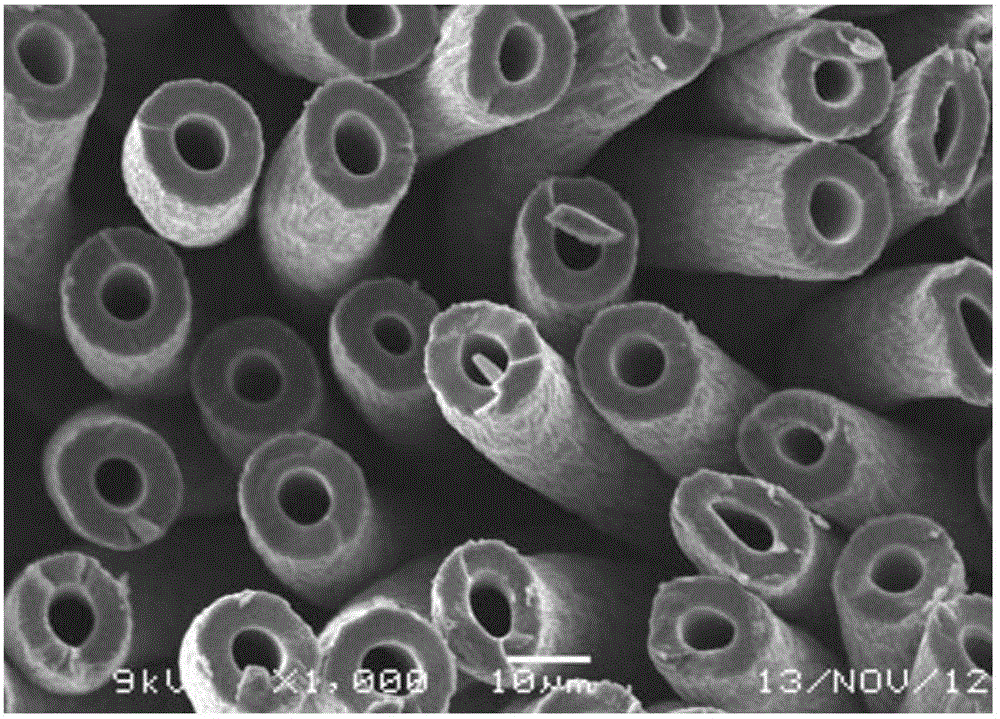

[0028] 1g of 3cm long 3KPAN pre-oxidized fiber short filaments are immersed in a flask filled with sulfuric acid solution, the concentration of sulfuric acid solution is 40wt%, and the sulfuric acid solution is heated to boiling for 0.8h. Stir and wash the treated pre-oxidized short fibers in a beaker filled with deionized water until neutral to remove residual sulfuric acid solution. After filtering with filter paper, collect the pre-oxidized short fibers in a watch glass, put Dry in a blast oven at 120°C for 1.5h, and cool to room temperature naturally in a desiccator. Take the processed pre-oxidized short fiber, place the short pre-oxidized fiber in parallel, wrap the short pre-oxidized fiber tightly with strip-shaped double-sided conductive tape, and then quickly cut off the two ends of the wrapped tape with a blade , keep a 0.5cm-long section in the middle, stick one end of it firmly with double-sided conductive tape and stand it upright on the SEM sample stage, use SEM t...

Embodiment 3

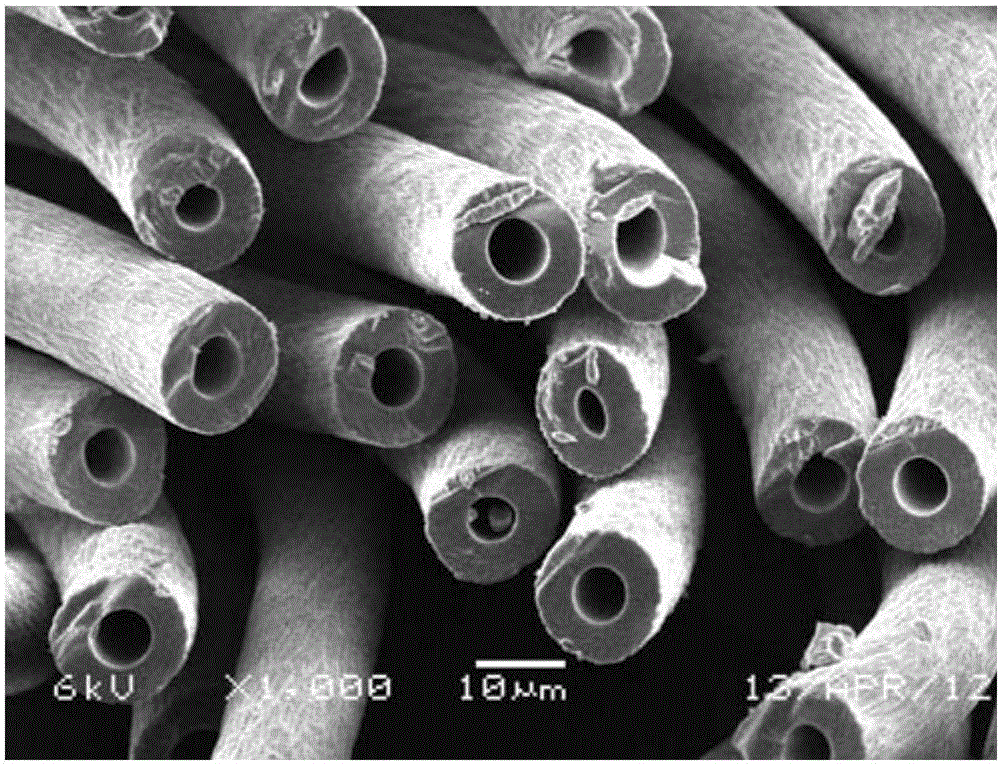

[0034] 1g of 3cm long 6KPAN pre-oxidized fiber short filaments are immersed in a flask filled with sulfuric acid solution, the concentration of sulfuric acid solution is 60wt%, the sulfuric acid solution is heated to boiling, and the treatment time is 0.1h. Stir and wash the treated pre-oxidized short fibers in a beaker filled with deionized water until neutral to remove residual sulfuric acid solution. After filtering with filter paper, collect the pre-oxidized short fibers in a watch glass, put Dry in a blast oven at 120°C for 1.5h, and cool to room temperature naturally in a desiccator. Take the treated pre-oxidized short fiber, place the pre-oxidized short fiber in parallel, wrap the pre-oxidized short fiber tightly with strip-shaped double-sided conductive tape, and then quickly cut off the two ends of the wrapped tape with a blade, Keep a 0.5cm long section in the middle, stick one end of it firmly with double-sided conductive tape and stand it upright on the SEM sample ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com