Millisecond laser processing and postprocessing process for no-recasting-layer micro-deep holes

A laser processing and micro-deep hole technology, applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve problems such as recasting layers, and achieve low cost, clear outline, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings.

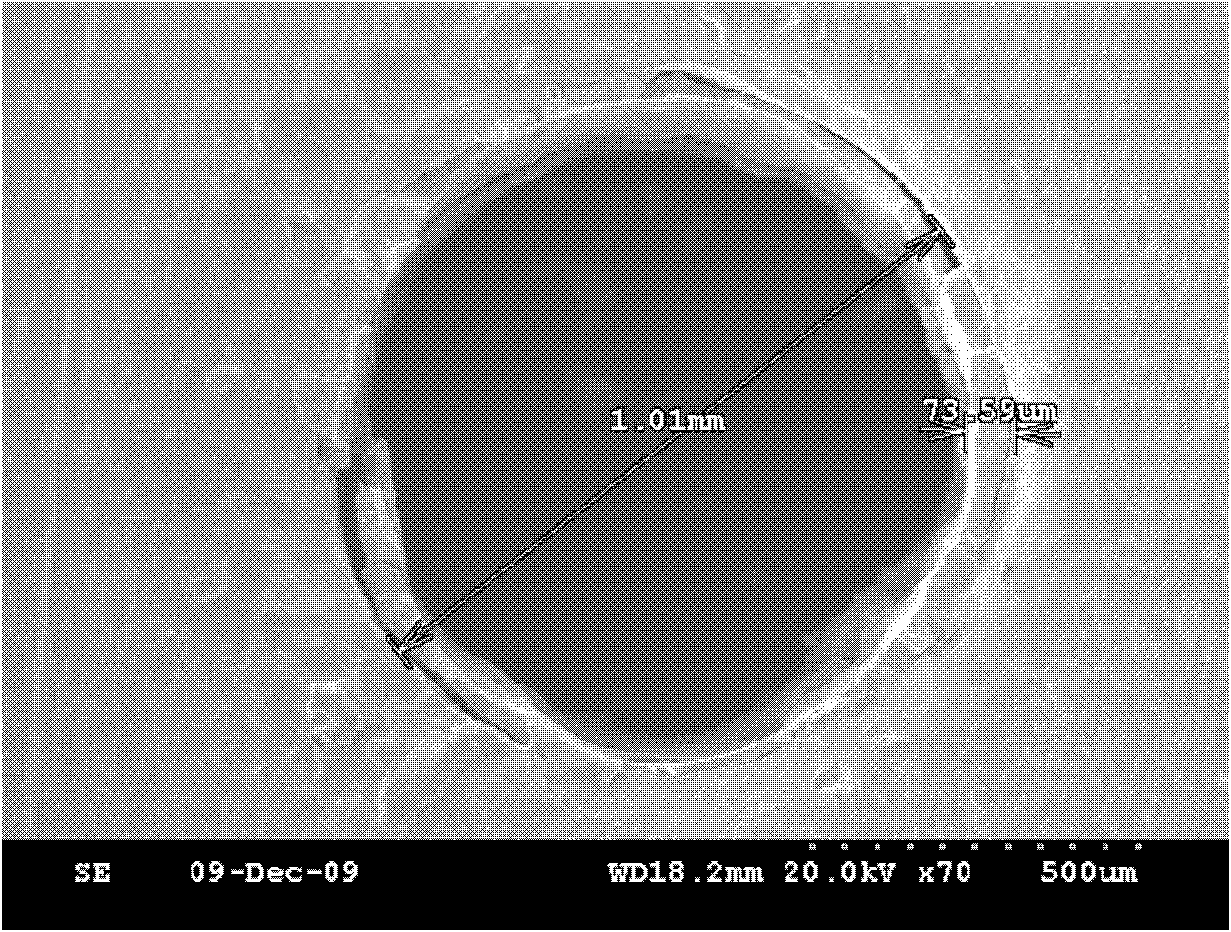

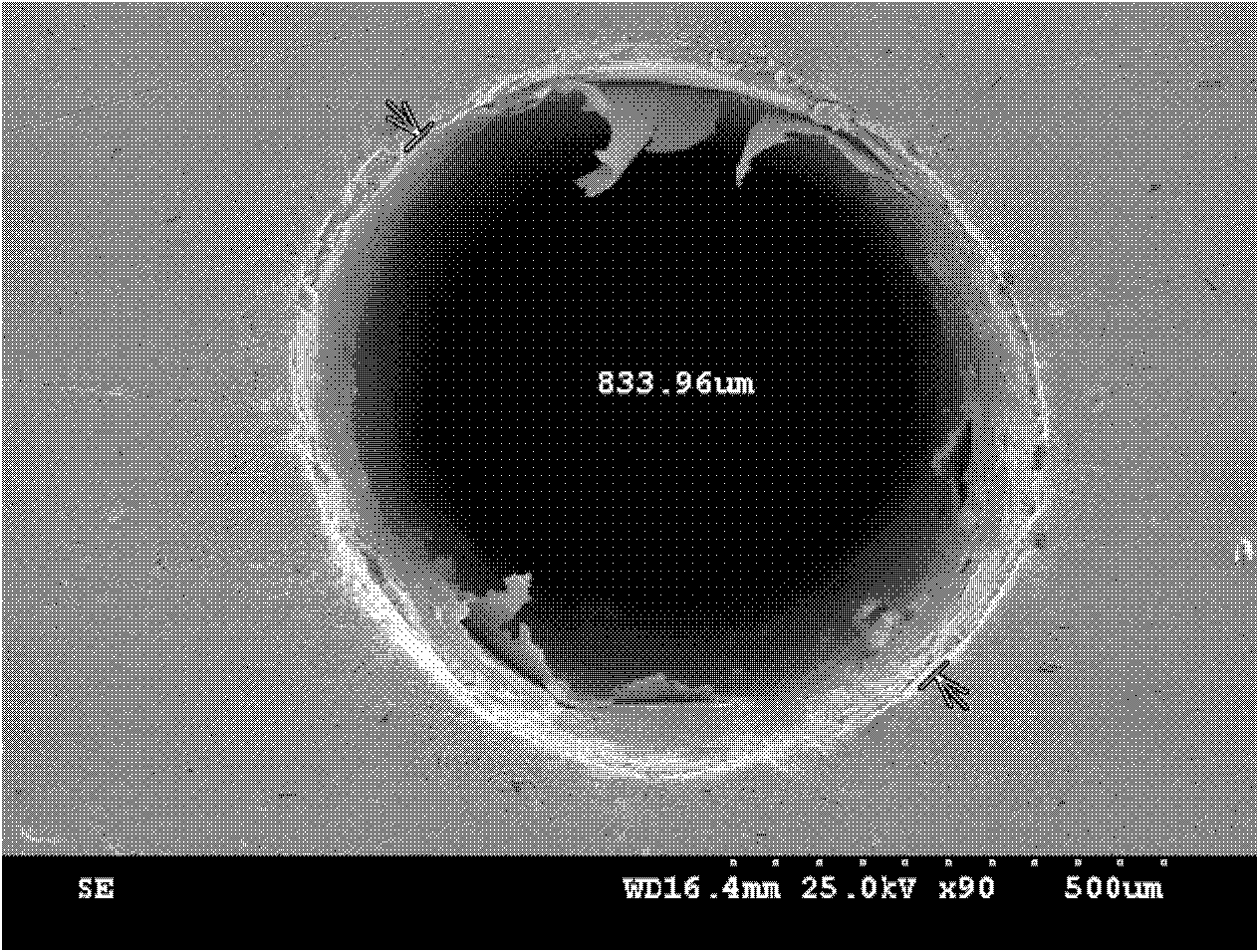

[0021] In terms of millisecond laser hole processing, many studies only focus on the influence of laser parameters on hole geometry, and study the effects of laser pulse energy, pulse width, focusing conditions, and repetition frequency on drilling quality, without comprehensive consideration of various parameters There is no in-depth study on the recasting layer specifically for the factors that affect each other. The invention aims to comprehensively consider the influence of various parameters on the hole processing quality, and finds a method that can not only retain the high efficiency of millisecond laser, but also greatly improve the processing quality.

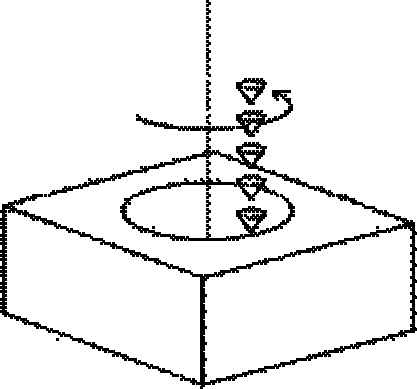

[0022] The purpose of the present invention is to provide a millisecond laser processing and post-processing technology for micro-deep holes without recasting layer, using high-power lasers and optimi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com