Preparation of small pore diameter carbon foam

A foamed carbon, small pore size technology, used in sustainable manufacturing/processing, climate sustainability, chemical industry, etc. The effect of narrow pore size distribution and smooth pore wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

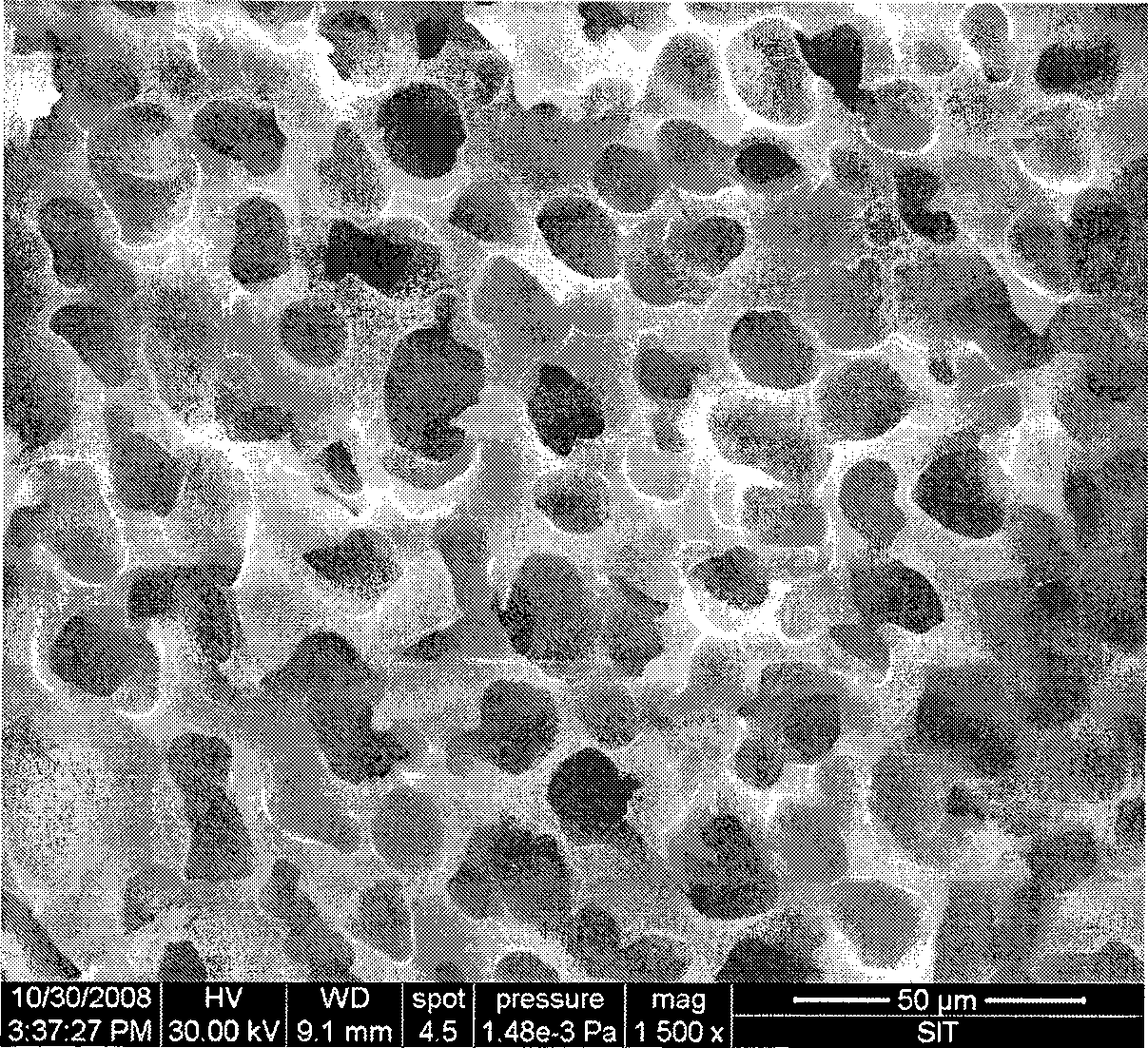

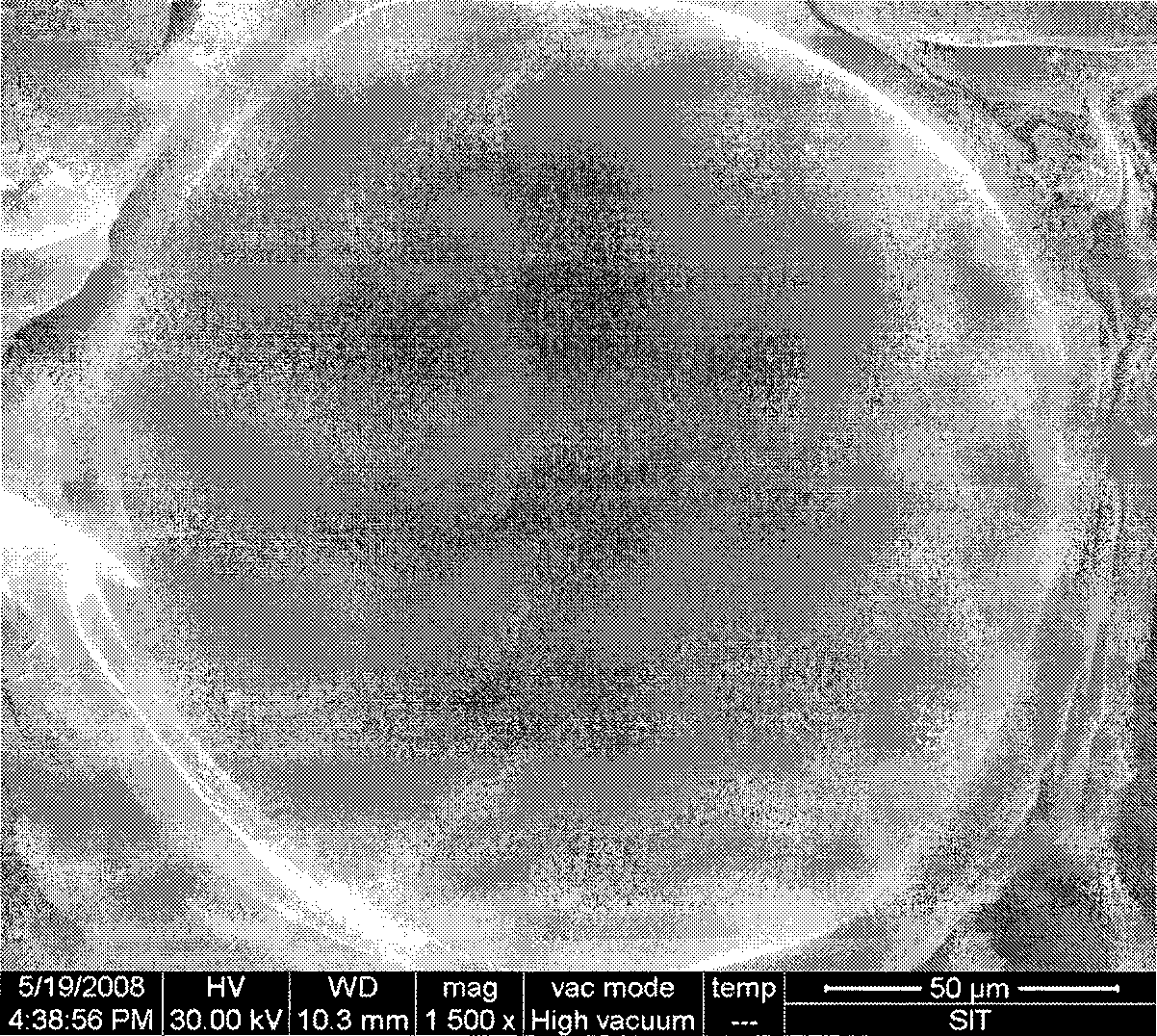

[0023] Weigh 20g of 50μm mesophase pitch (softening point is 275℃) and 240ml of toluene into a 250ml autoclave. After sealing, heat it up to 320℃ at a heating rate of 3℃ / min and keep it at constant temperature for 2h. At this time, the pressure reaches 9MPa. . Decrease to normal pressure at a pressure relief speed of 10 MPa / sec to obtain foamed mesophase pitch. Put the foamed mesophase pitch in an oxidation stabilization reaction furnace, heat it up to 280°C at a temperature increase rate of 0.05°C / min in an air atmosphere and keep it at a constant temperature for 3h, and then directly switch to N 2 Atmosphere, the temperature was raised to 850°C at a heating rate of 5°C / min and kept at a constant temperature for 2h for carbonization heat treatment. After natural cooling and cooling, samples were taken to obtain mesophase pitch-based foamed carbon with a compressive strength of 3.8MPa and an average pore size of 20μm. Place the mesophase pitch-based foamed carbon in a graphitizati...

Embodiment 2

[0025] Weigh 20g of 50μm mesophase pitch (softening point is 275℃) and 180ml of toluene into a 250ml autoclave. After sealing, heat it up to 320℃ at a heating rate of 3℃ / min and keep it at constant temperature for 2h. At this time, the pressure reaches 14MPa. . Decrease to normal pressure at a pressure relief speed of 10 MPa / sec to obtain a foamed mesophase pitch with an average pore diameter of 100 μm. Put the foamed mesophase pitch in an oxidation stabilization reaction furnace, heat it up to 280°C at a temperature increase rate of 0.05°C / min in an air atmosphere and keep it at a constant temperature for 3h, and then directly switch to N 2 Atmosphere, the temperature was raised to 850°C at a heating rate of 5°C / min and kept at a constant temperature for 2h for carbonization heat treatment. After natural cooling and cooling, samples were taken to obtain mesophase pitch-based foamed carbon with a compressive strength of 3.2MPa and an average pore diameter of 100μm.

Embodiment 3

[0027] Weigh 20g of 50μm coal-based high-softening point pitch (softening point is 285℃) and 180ml of toluene in a 250ml autoclave. After sealing, heat it up to 320℃ at a heating rate of 3℃ / min and keep it constant for 2h. The pressure reaches 14MPa. Decrease to normal pressure at a pressure relief rate of 10 MPa / sec to obtain a foamed mesophase pitch with an average pore diameter of 200 μm. Put the foamed mesophase pitch in an oxidation stabilization reaction furnace, heat it up to 280°C at a temperature increase rate of 0.05°C / min in an air atmosphere and keep it at a constant temperature for 3h, and then directly switch to N 2 Atmosphere, the temperature was raised to 850°C at a heating rate of 5°C / min and kept at a constant temperature for 2h for carbonization heat treatment. After natural cooling and cooling, samples were taken to obtain mesophase pitch-based foamed carbon with a compressive strength of 3.2MPa and an average pore diameter of 200μm. Put the pitch-based foamed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com