Rectangular vacuum cracking washing furnace with conveniently opening and closing lid

A technology for cleaning furnaces and furnace covers, applied to furnaces, furnace components, furnace types, etc., can solve the problems of time-consuming, labor-intensive, labor-intensive, etc., and achieve the effect of good cleaning effect, short cleaning time, and improved work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Embodiments of the present invention are described in detail below in conjunction with accompanying drawings:

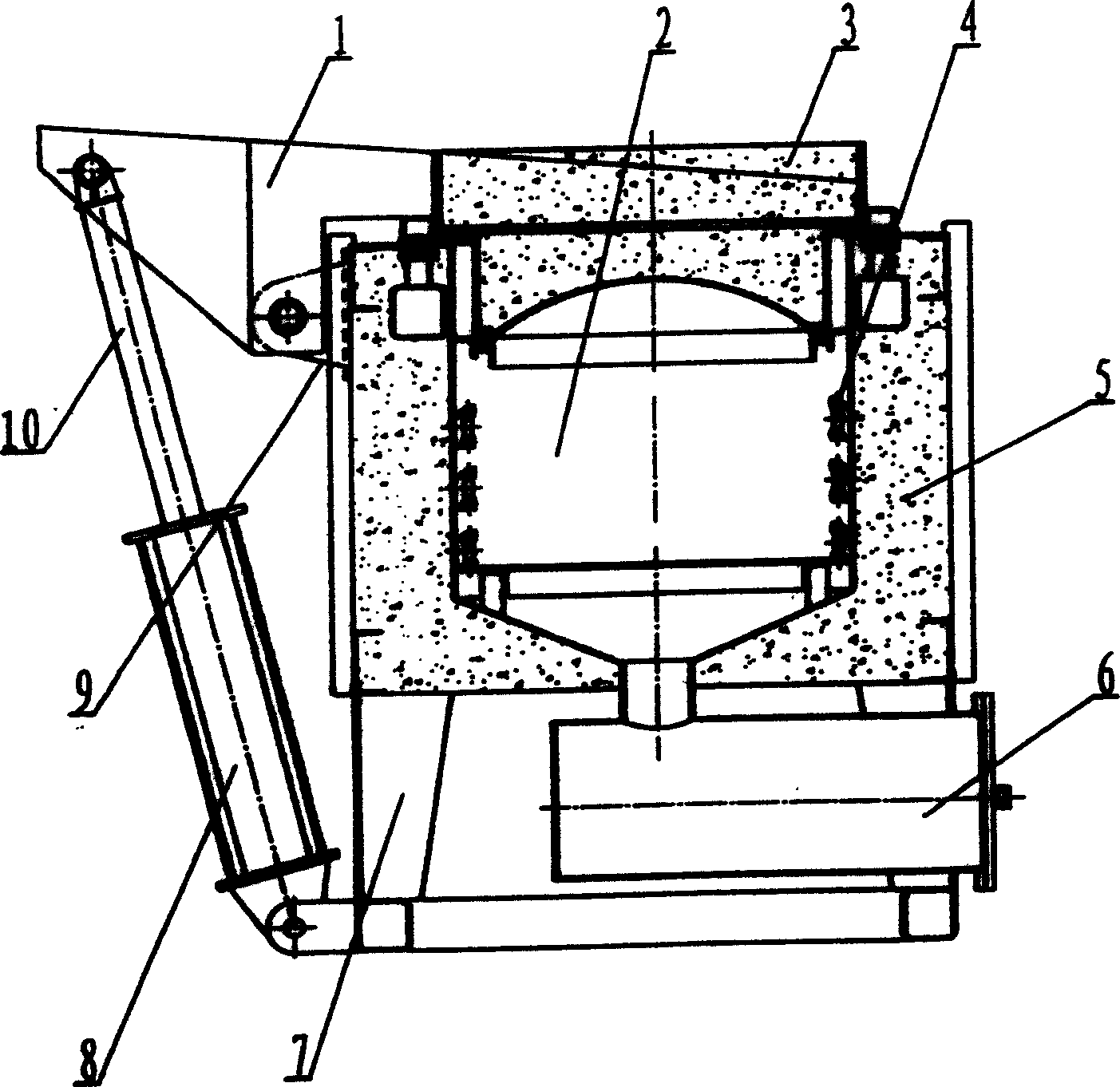

[0012] Contains a vertical furnace 2, a furnace body 5, a furnace cover 3, a heating element 4, and a waste collection tank 6, the waste collection tank 6 is placed under the furnace body 5, the vertical furnace 2 is connected to the waste collection tank 6, and the heating element 4 Placed on the inner wall of the vertical furnace 2, a support 9 is fixed on the side of the furnace body 5, the support 9 is movably connected with the lever 1, one end of the lever 1 is fixed on the cover 3, and the other end of the lever 1 is connected to the piston Rod 10 is movably connected, and the cylinder body 8 of cylinder is movably matched with piston rod 10, and one end of cylinder body 8 of cylinder is movably connected with body of heater support 7. The working size of the vertical furnace is 600mm×600mm×3800mm, and the working temperature is adjustable from room tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com