Patents

Literature

41results about How to "Ease of handling emissions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Reusable supercharging superheat steam drying method and device

InactiveCN101769669AWith dryImprove utilization efficiencyDrying solid materials with heatDrying gas arrangementsProcess engineeringSuperheated steam

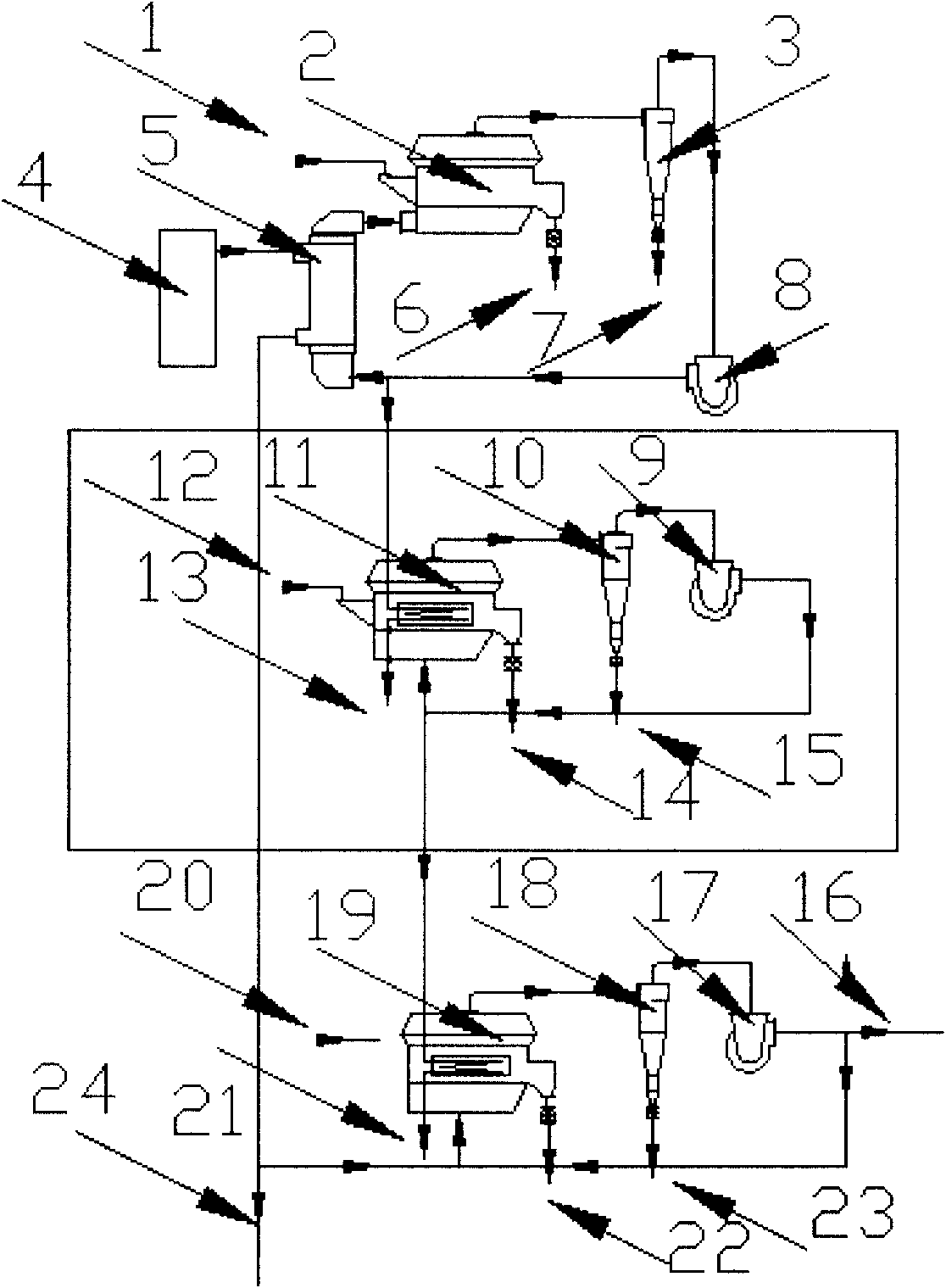

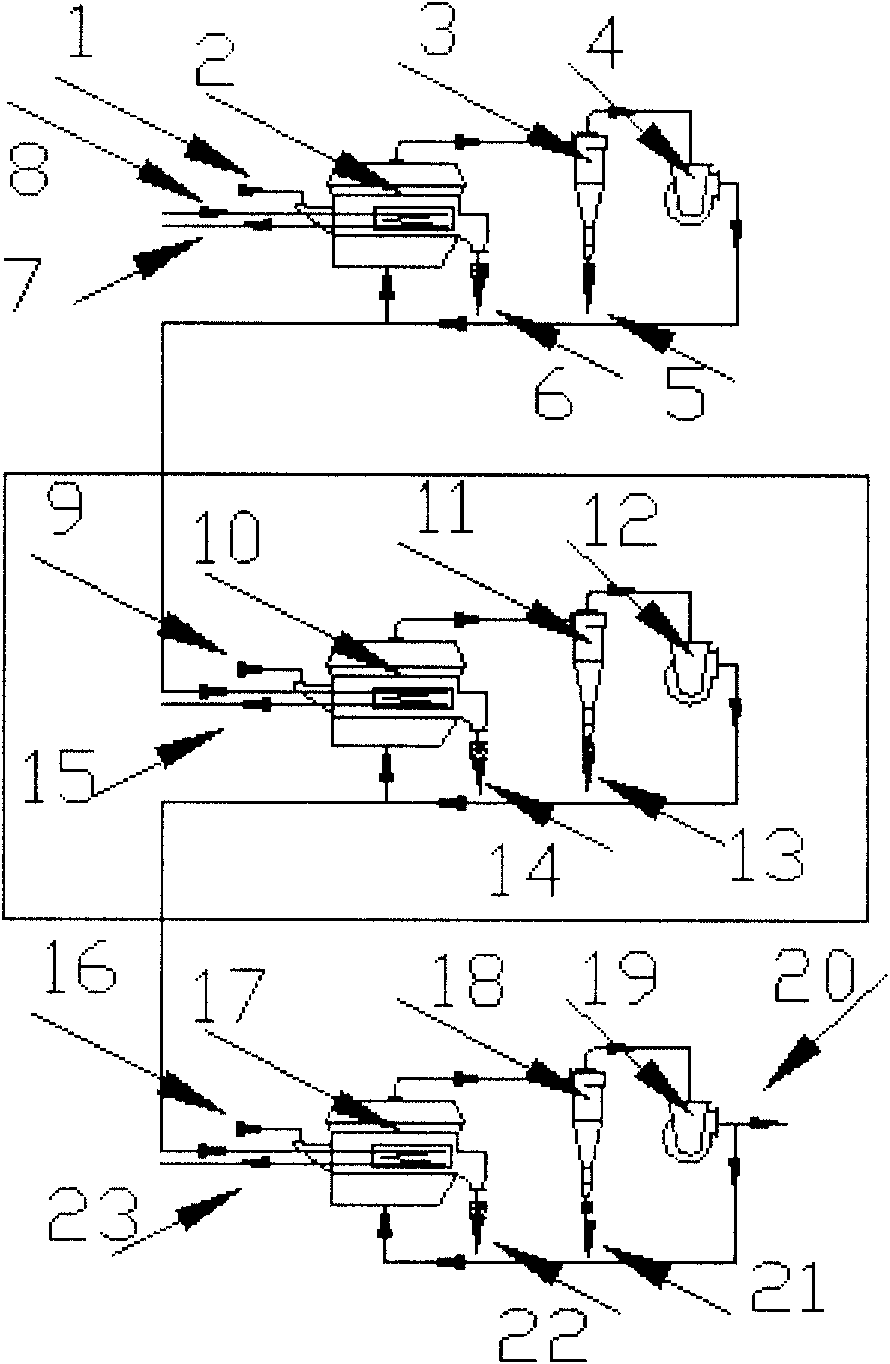

The invention relates to a reusable supercharging superheat steam drying method and a device which consists of a multi-stage drying system. The first stage drying is supercharging superheat steam drying, gas circulated in the system is superheat steam, wet materials are discharged out of the drying system after being heated and dehydrated by the superheat steam, the steam generated by moisture in the system is circulated in the system and provides heat to dry the wet materials after being heated by a heat exchanger. The superheat steam beyond the need of system circulation is discharged from the first stage drying to the next stage drying and is used as the heat source of the next stage drying. The second stage drying and each subsequent stage drying (except the last stage drying) are carried out by a supercharging indirect superheat steam drier with an internal heating device, which utilizes the superheat steam from the previous stage drying to dry the wet materials indirectly. The wet materials are discharged out of the drying system after being heated and dehydrated by the superheat steam, and the superheat steam from the previous stage drying is condensed into condensate water and then is discharged out of the drying system.

Owner:黄龙

Optics parts surface detergent

InactiveCN101368137AEasy to cleanLess corrosiveNon-ionic surface-active compoundsOrganic detergent compounding agentsSurface-active agentsCleansing Agents

The invention provides a cleaner for the surface of an optical element, comprising pH regulator, surface active agent, solubilizer, corrosion inhibitor and purified water; wherein, the weight percentage of the pH regulator is 1 percent to 22 percent, the weight percentage of the surface active agent is 1 percent to 5 percent, the weight percentage of the solubilizer is 1 percent to 5 percent, the weight percentage of the corrosion inhibitor is 1 percent to 5 percent and the rest is purified water; the cleaner is applicable to the cleaning of the dirty on the surface of the optical element, has reasonable formulation design, low cost and safe and convenient use, and meets the requirements of environment protection; and the cleaned waste liquid is convenient to be treated and discharged.

Owner:JIANGSU HAIXUN IND GROUP SHARE

Electronic instrument panel surface detergent

InactiveCN101368141AImprove permeabilityWash thoroughlyNon-ionic surface-active compoundsOrganic detergent compounding agentsOzone layerSolid particle

The invention provides a cleaner for the surface of an electronic instrument panel, comprising solubilizer, surface active agent, pH value regulator, antifoaming agent and deionized water; the weight percentage of all the components is as follows: 3 percent to 10 percent of the solubilizer, 3 percent to 12 percent of the surface active agent, 2 percent to 8 percent of the pH value regulator, 2 percent to 8 percent of the antifoaming agent and the rest is the deionized water; the cleaner is water soluble liquid and the pH value thereof is 11 to 12; the cleaner is applicable to the cleaning technique of the surface of the electronic instrument panel, can effectively remove the pollutants including rosin, soldering tin, oil stain, finger prints and solid particles and the like stained on the surface of the electronic instrument panel, has good permeability and thorough cleaning, is not easy to generate residue, has little corrosion, safe and reliable use and no damage to the ozone layer, meets the requirements of environment protection and has reasonable formulation design, simple preparation technique and low cost.

Owner:JIANGSU HAIXUN IND GROUP SHARE

Electronic instrument detergent

InactiveCN101368138AEasy to cleanEase of handling emissionsInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsOzone layerAntistatic agent

The invention provides a cleaner of an electronic instrument, comprising phosphate, surface active agent, antistatic agent, pH value regulator and deionized water; the weight percentage of all the components is: 3 percent to 12 percent of the phosphate, 3 percent to 12 percent of the surface active agent, 3 percent to 8 percent of the antistatic agent, 2 percent to 8 percent of the pH value regulator and the rest is the deionized water; the pH value of the mixing liquid is 11 to 12; the cleaner is applicable to the cleaning technique of a circuit board and parts of the electronic instrument, can effectively remove organics and dusts and the like stuck in the long time operation of the electronic instrument, can eliminate static, has low corrosion and safe and reliable use, does not damage the ozone layer, conforms to the requirements of environmental protection, etc. and has reasonable formulation design, simple preparation technique and low cost; and the cleaned waste liquid is convenient to be treated and discharged.

Owner:JIANGSU HAIXUN IND GROUP SHARE

Derusting and cleaning agent for non-ferro metal

The invention provides non ferrous metal derusting cleaning agent which includes phosphate, surface active agent, pH value regulator and de-ionized water. The weight percentage of each component is as follows: 5 to 10 percent of phosphate, 5 to 10 percent of surface active agent, 1 to 6 percent of pH value regulator and the rest is the de-ionized water. The pH value of the mixed liquid is ranged from 11 to 12; the non ferrous metal derusting cleaning agent has the effects of high efficiency and easy cleaning to non ferrous metals to lead the rusty spots on the surfaces of the non ferrous metals to be completely cleaned, can prevent the surfaces of the non ferrous metals from forming rusty spots again, can also shorten the cleaning time and improve the working efficiency; the non ferrous metal derusting cleaning agent is water-soluble cleaning agent, convenient for the processing and drainage of the wasted liquid after cleaning and accords with the requirements for environment protection; besides, the corrosion property to device is low; the production cost is effectively reduced; besides, the non ferrous metal derusting cleaning agent is safely and reliably used.

Owner:JIANGSU HAIXUN IND GROUP SHARE

Pressurizing superheat steam drying method and device with inner heater and capable of being reused

InactiveCN101776373AWith dryImprove utilization efficiencyDrying solid materials with heatHearth type furnacesFluidized bed dryingHigh energy

The invention relates to pressurizing superheat steam drying method and device with an inner heater and capable of being reused, in particular to a novel drying technology which has high efficiency and energy saving and higher energy utilization efficiency except all the advantages of superheat steam drying. The pressurizing superheat steam drying system with the inner heater and capable of being reused comprises a multi-level drying system; drying of each level is pressurizing superheat steam drying; a dryer of each level is a fluidized bed dryer with the inner heater; high-temperature and high-pressure steam needed by drying is only provided for a first-level drying system; energy needed by second-level drying and the drying of other levels is provided by superheat steam generated by previous-level drying; the steam needed by the drying of each level is condensed into condensate water by wet materials in the drying of each level and then discharged out of the drying system; only the steam generated in the last-level drying is discharged out of the drying system in a tail gas way; the steam generated in the drying of each level not only meets the need of self circulation, but also enters the inner heater of the fluidized bed dryer of a next level to provide heat for wet material drying; and steam discharged materials generated in the last-level drying not only meet the need of the self circulation, but also are discharged out of the drying system.

Owner:黄龙

Metallic aluminum material detergent

InactiveCN101311316AEase of handling emissionsMeet the protection requirementsLiquid wasteMetallic aluminum

The invention provides a cleaning agent for the aluminum material, which comprises silicate, phosphate, a surfactant, a Ph value regulator and deionized water. The weight percentage of every component is that the silicate is 3 to 10 percent; the phosphate is 5 to 10 percent; the surfactant is 5 to 10 percent; the Ph value regulator is 1 to 6 percent and the deionized water occupies the residual percentage. The Ph value of the mixed solution is 11 to 12. The cleaning agent has high effective and easy-to-clean function for the aluminum material, completely cleans the oil spot and rust spot on the surface of the aluminum material, prevents the rust spot from forming on the surface of the aluminum material again, shortens the cleaning time and improves the working efficiency. The cleaning agent is a water soluble cleaning agent, so the waste liquid left after washing is easy to discharge and accords with the environmental requirements. Furthermore, the cleaning agent has low corrosion to the equipment, which effectively reduces the production cost and is safe and reliable in using.

Owner:天津晶岭电子材料科技有限公司

Cleaning agent for semiconductor industry

ActiveCN101463295AReduce surface tensionGood water solubilityNon-ionic surface-active compoundsDetergent solventsSolubilitySurface-active agents

The invention relates to a cleansing agent for semiconductor industry. The cleansing agent comprises the following compositions according to the weight percentage: 0.2-1 portion of a main agent, 5-15 portions of a surface active agent, 3-8 portions of an antistatic agent, 3-5 portions of a synergistic agent, 3-8 portions of an organic solvent, and the rest being de-ionized water. The cleansing agent has the technical effects as follows: (1) dosage of the solvent and the surface active agent is reasonably arranged in the cleansing agent, so that surface tension of the cleansing agent is greatly reduced, while the cleansing agent has the advantages of good water solubility and strong permeability; (2) the chemical reagents adopted in the cleansing agent does not pollute environment, can not be easily combusted, and belongs to an ozone-friendly substance, and the waste liquid after cleansing is easy to treat and discharge, thereby meeting the requirements of environmental protection and the 'three wastes' discharge; and (3) the preparation process is simple, the operation is convenient, and the application is safe and reliable.

Owner:JIANGSU HAIXUN IND GROUP SHARE

Novel cleaning fluid special for diode semiconductor

InactiveCN105385518AReduce surface tensionGood water solubilityOrganic detergent compounding agentsSurface-active detergent compositionsActive agentSurface-active agents

The invention relates to novel cleaning fluid special for a diode semiconductor. The novel cleaning fluid comprises the following components in parts by weight: 2-4 parts of quaternary ammonium hydroxide, 4-14 parts of a polyacrylic anticorrosive solution, 6-8 parts of an alkyl diol aryl ether, 2-6 parts of a surfactant, 9-11 parts of alkyl benzyl dimethyl ammonium chloride, 9-11 parts of a synergist, 9-11 parts of ethanol and 37-57 parts of deionized water. The novel cleaning fluid disclosed by the invention has the advantages that the amount of various effective components and solvents is reasonably configured in the novel cleaning fluid special for the diode semiconductor disclosed by the invention, and the surface tension of the cleaning fluid can be rapidly and completely reduced at room temperature, so that the cleaning fluid has the characteristics of high water solubility and high seepage force; and moreover, each selected formula component does not pollute the environment and does not have any risk, the atmosphere is not damaged, the cleaned waste solution is convenient to treat and emit, and the environment friendliness is guaranteed.

Owner:RUGAO DACHANG ELECTRONICS

Zinc-nickel alloy trivalent chromium black passivation solution and preparation method thereof

InactiveCN108707887ASimple compositionFacilitate waste water treatment and dischargeMetallic material coating processesIonHexavalent chromium

The invention provides a zinc-nickel alloy trivalent chromium black passivation solution and a preparation method thereof. The preparation method comprises the following steps of 1, preparing a solution A; 2, preparing a solution B; and 3, preparing a working solution. In the step 1, chromium sulfate or chromium nitrate, cobalt nitrate, malonic acid and citric acid are provided, the balance of water is added into the mixed solution formed by the components to carry out reaction, and the solution A is obtained; and in the step 2, nitric acid, formic acid and glycine are provided, the balanceof water is added into the mixed solution formed by the components for stirring and dissolving so as to obtain the solution B; and in the step 3, the deionized water is mixed with the obtained solution A and the solution B, and is uniformly stirred to obtain the zinc-nickel alloy black trivalent chromium passivation solution. The passivation solution is simple in composition, and no hexavalent chromium, no fluorine and phosphorus are contained in the whole production process, the passivation solution is more environment-friendly, and wastewater treatment and emission are facilitated.

Owner:江苏秀博新材料有限公司

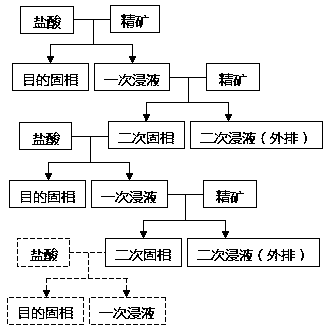

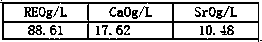

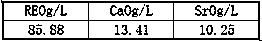

Method for leaching calcium and strontium by using low concentration hydrochloric acid to chemically separate Weishan Lake rare earth concentrate

ActiveCN108559842ARealize efficient chemical selectionReduce loss rateProcess efficiency improvementPregnant leach solutionStrontium carbonate

The invention provides a method for leaching calcium and strontium by using low concentration hydrochloric acid to chemically separate Weishan Lake rare earth concentrate. The method comprises the following steps: immersing the Weishan Lake rare earth concentrate in the low concentration hydrochloric acid, and heating the obtained solution to perform a reaction; adding the Weishan Lake rare earthconcentrate to a filtered leachate, heating the obtained solution to perform a reaction, carrying out solid-liquid separation, discharging the obtained liquid, and reusing the obtained solid phase. The grade of the Weishan Lake rare earth concentrate is improved to 50% from 40%, 90% of calcium carbonate and 85% of strontium carbonate in the Weishan Lake rare earth concentrate are efficiently leached out, the rare earth loss rate of below 1% is ensured, a discharged acid leaching waste liquid only contains calcium chloride, strontium chloride and a small amount of iron chloride, and wastewatertreatment is easy.

Owner:中稀(寿光)资源科技有限公司

Waterborne antirust agent

InactiveCN108251197AAnti-rust for a long timePrevent rust spotsLubricant compositionAntistatic agentEmulsion

The application discloses a waterborne antirust agent, which is prepared from the following raw materials in parts by weight, 15-95 parts of alkyd resin, 25-76 parts of cycloalkyl base oil, 25-70 parts of acrylic resin, 24-85 parts of waterborne acrylic emulsion, 34-75 parts of fatty acid amide, 35-95 parts of a silane coupling agent, 25-85 parts of polyisobutene, 20-45 parts of polyvinyl chlorideresin, 15-75 parts of glutamic acid and 10-85 parts of an antistatic agent. Therefore, the antirust agent is longer in rust protection time, and can prevent rusty spots from forming on the surface ofa material again after being used; the waste antirust agent can be conveniently disposed and discharged; the waterborne antirust agent meets the environmental protection requirements, is free from pollution to equipment, is non-corrosive, effectively lowers the production cost, and is safe and reliable to use.

Owner:丁春香

Metal aluminum material cleaning agent

The invention provides a metal aluminum material cleaning agent. The metal aluminum material cleaning agent comprises, by weight, 3-10% of a silicate, 5-10% of a phosphate, 5-10% of a surfactant, 1-6%of a pH adjusting agent and the balance of deionized water. The mixed solution has pH of 11-12, has efficient effects of easily cleaning the metal aluminum material, thoroughly cleans oil stain and rust on the surface of the metal aluminum material, prevents rust pots on the surface of the metal aluminum material, shortens cleaning time and improves work efficiency. The metal aluminum material cleaning agent is a water-soluble cleaning agent. The cleaning waste liquid is easy to treat and discharge, satisfies the environmental protection requirements, has low corrosion of equipment, effectively reduces the production cost and is safe and reliable in use.

Owner:张翠华

Metal equipment cleaning agent

InactiveCN103898544AEase of handling emissionsMeet the protection requirementsPhosphatePhosphoric acid

The present invention discloses a metal equipment cleaning agent, which is prepared from the following raw materials by weight: 5.3-8.5 parts of tetrahydroxy ethylenediamine, 2.5-5.8 parts of polyol polyoxyethylene ether carboxylic ester, 3.5-8.6 parts of sodium hydroxide, 1.8-2.5 parts of a penetrating agent, 5.5-6.8 parts of nonylphenol ether methyl phosphate ethanolamine salt, 3.3-5.6 parts of a stabilizer, and 6.2-9.5 parts of lysine. According to the present invention, the formula is scientific and reasonable, the production process is simple, and the raw materials are only required to be mixed at a room temperature without the special equipment; characteristics of strong cleaning ability, short cleaning time, manpower saving, working hour saving, work efficiency improving, rust removing and rust resistance are provided; the metal equipment cleaning agent is alkaline, and has characteristics of low corrosion on equipment, safe and reliable use, and easily equipment cost reducing; and the metal equipment cleaning agent is a water-soluble liquid, the waste liquid after cleaning is easily treated and discharged, and environmental protection requirements are met.

Owner:QINGDAO SHUAIWANG OIL CHEM

Water-soluble printed circuit board cleaning agent and preparation method thereof

InactiveCN103540434ANot easy to damageEasily damagedNon-ionic surface-active compoundsOrganic detergent compounding agentsPhosphorous acidSucrose

The invention provides a water-soluble printed circuit board cleaning agent. The cleaning agent is prepared from the following raw materials in parts by weight: 30-34 parts of methanol, 20-25 parts of acetone, 30-40 parts of butanediol, 10-15 parts of sucrose fatty acid ester, 40-50 parts of ethanol, 3-4 parts of fatty alcohol-polyoxyethylene ether sodium sulfate, 4-5 parts of dibutyl phosphite, 1-2 parts of menthol, 4-5 parts of auxiliary and 100-120 parts of deionized water. The cleaning agent has the beneficial effects that the cleaning agent is weakly alkaline, has good inhibitory effects on tension of circuit chip surface cleaning agents, excellent removal effects on organic and inorganic matters and low corrosivity, does not corrode equipment, does not damage surfaces of circuit chips easily, is convenient for treatment and discharge of waste cleaning agents, and meets the requirement of environmental protection; the auxiliary can form a protective film on the surface of the circuit board to isolate air to prevent water and other molecules in the air from corroding the circuit board; the cleaning agent is resistant to oxidation, prevents short circuit and is convenient for operation of the next preparation process.

Owner:合肥市华美光电科技有限公司

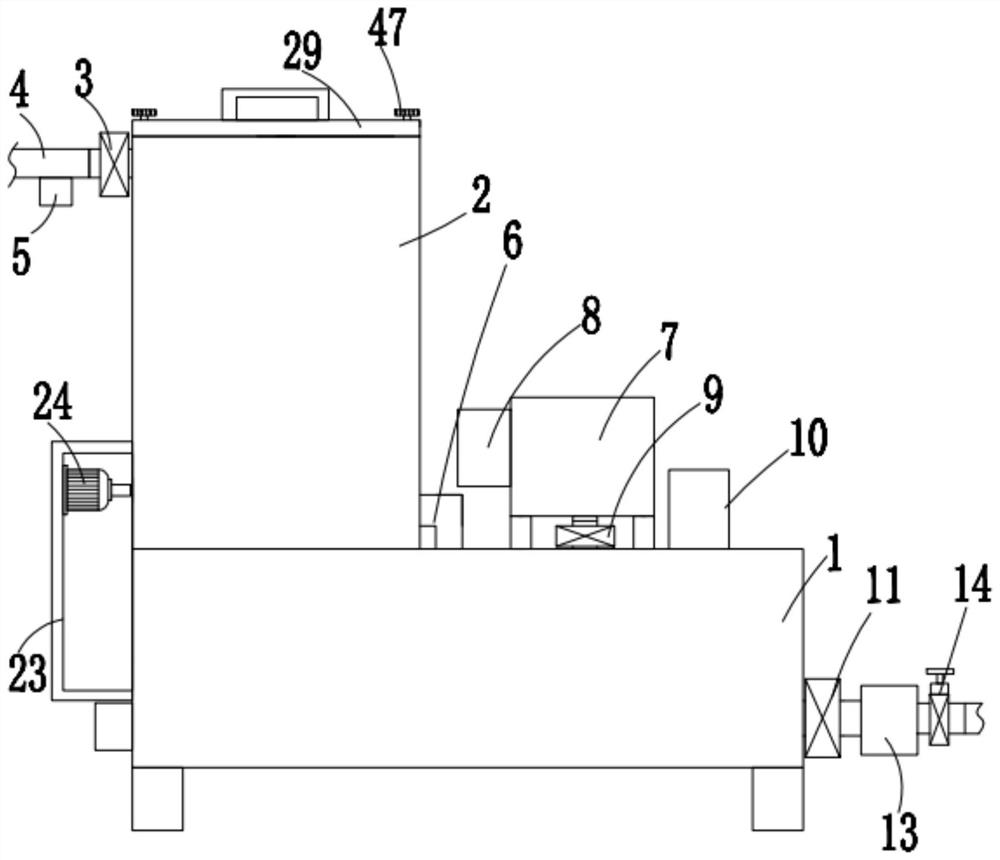

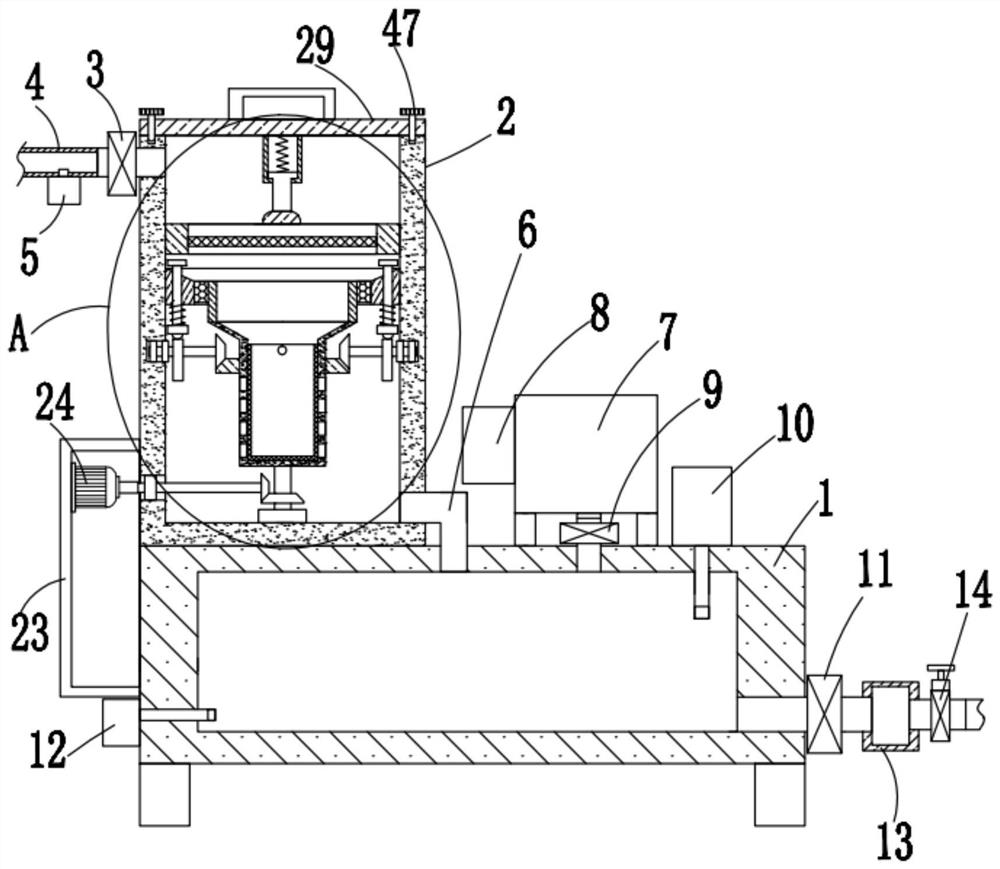

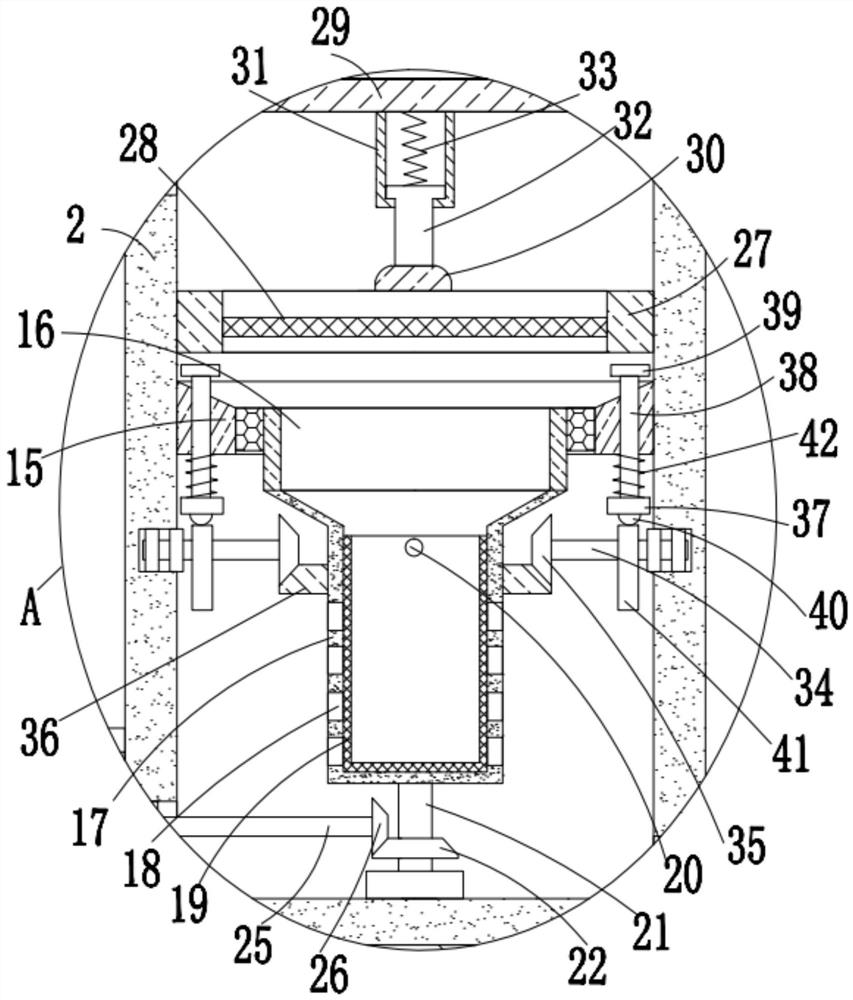

Water-saving device for secondary utilization of water resources and use method of water-saving device

InactiveCN113121042AEasy to detectImprove mixing uniformityWater/sewage treatment by centrifugal separationWater treatment parameter controlWater savingWater resources

The invention provides a water-saving device for secondary utilization of water resources and a use method of the water-saving device, and provides the following scheme aiming at the problems that an existing water-saving device for secondary utilization of the water resources is inconvenient for rapid and stable filtration, automatic detection of water quality, automatic and intelligent dosing and rapid mixing treatment. The water-saving device for secondary utilization of water resources comprises a treatment box and a filter box, the filter box is fixedly mounted at the top of the treatment box, the same automatic dosing treatment mechanism is arranged on the filter box and the treatment box, and a centrifugal quick filtration mechanism and a vibration coarse filtration mechanism matched with the centrifugal quick filtration mechanism are arranged on the filter box. The device is convenient for automatically detecting the water quality and automatically and intelligently adding a treatment agent, is convenient for automatically and intelligently controlling, treating and discharging, is convenient for realizing vibration rough filtration, centrifugal rotation fine filtration dehydration and stirring mixing through single driving, and improves the filtration treatment efficiency, the filtration stability and the water-agent mixing uniformity. The purposes of rapid and stable filtration and rapid mixing treatment and recovery are achieved, and automation is high.

Owner:NANJING HYDRAULIC RES INST

Cleaning agent for metal parts of environment-friendly machines

The invention discloses a cleaning agent for metal parts of environment-friendly machines and relates to the field of cleaning agents for metal parts. Rust and oil stains on the surfaces of the metal parts can be effectively removed, rust-proof corrosion-resisting layers can be formed on the surfaces of the metal parts, cleaned metal is not damaged and is invariant in color, the cleaning agent is safe and reliable and is water-soluble liquid, and waste liquid left after cleaning is convenient to treat and discharge and meets the requirement for environment protection.

Owner:ANHUI XINRUI HEAVY IND

Cleaning liquid special for prepared solar water heater

InactiveCN105695174ALow costNo pollution in the processSoap detergents with organic compounding agentsSoap detergents with inorganic compounding agentsChemical reactionPhosphate

The invention relates to cleaning liquid special for a prepared solar water heater. The cleaning liquid is prepared from, by weight, 2-4 parts of quaternary ammonium hydroxide, 4-14 parts of a polyacrylic corrosion inhibition solution, 6-8 parts of alkyl diol aryl ether, 9-11 parts of alkyl benzyl dimethyl ammonium chloride, 12-20 parts of phosphate, 3-7 parts of sodium hydroxide, 9-11 parts of a synergist, 9-11 parts of ethyl alcohol and 37-57 parts of deionized water. The cleaning liquid special for the prepared solar water heater has the advantages that all the effective components and the dosage of solvent are reasonably proportioned, and therefore the cleaning liquid is low in cost, free of pollution and capable of improving the surface smoothness of the product and meeting the environmental protection standard; in addition, the phosphate is added, a phosphorus element in the phosphate easily generates a chemical reaction with various impurities on the surface of the prepared solar water heater, and then the effect of cleaning the surface of the prepared solar water heater is achieved.

Owner:JIANGSU SHUANGNENG SOLAR ENERGY

Washing agent used for metal parts

InactiveCN104651863AEase of handling emissionsMeet the protection requirementsStearic acidCleansing Agents

The invention discloses a washing agent used for metal parts, which is prepared from following raw materials, by weight: 10-12 parts of 3,3-dimethylpentane, 9-13 parts of a surface inhibitor, 5-10 parts of sodium hydroxide, 5-10 parts of sodium bichromate, 7-9 parts of deionized water, 2-3 parts of glycol stearic acid diester, 1.5-3 parts of oleamide and 1-2 parts of a hydrophobic modification alkali-swelling thickening agent. The washing agent is scientific and reasonable in formula, is simple in preparation technology and is free of requirement of special devices. The washing agent can be prepared just by mixing the raw materials above at the room temperature. The washing agent is strong in washing performance, is short in washing time, can save labor intensity and working time, can increase work efficiency and has functions of removing and preventing rust. The washing agent is alkaline and is low in corrosion on equipment, is safe and reliable to use and can reduce the equipment cost. The washing agent is a water-soluble liquid so that waste liquid after washing is convenient to treat and discharge in conformity with an environmental protection.

Owner:QINGDAO DESHENGTAI CONSTR INSTALLATION ENG

Strong cleaning compound used for equipment

The invention discloses a strong cleaning compound used for equipment, which comprises the following raw materials by weight part: 1.2-3.4 parts of nonylphenol ethoxylate sodium silicate, 1.5-3.2 parts of polyether modified silicone, 2.3-5.7 parts of valine, 3.2-5.5 parts of cypermethrin, 6.5-8.7 parts of lemon oil, 6.3-8.4 parts of alcohol polyoxyethylene ether phosphate, 1.2-2.5 parts of adsorbent, and 3.5-5.5 parts of emulsifier. The strong cleaning compound has strong decontamination capability, can rapidly and thoroughly remove the impurities such as oil stain, dust and copper cuttings on the surface of the copper pipe; has moderate volatilization speed, can satisfy twining requirement, and can prevent waste due to fast volatilization of the cleaning compound; the cleaning compound can be thoroughly volatilized without residues, thoroughly volatilization can be ensured in time from cleaning step to annealing step, and damage of the external surface of the copper pipe and equipment due to annealing can be avoided.

Owner:王璐

Corrosion-free cleaning agent for metal surfaces

The invention discloses a corrosion-free cleaning agent for metal surfaces. The corrosion-free cleaning agent is prepared from the following raw materials in parts by weight: 1.5-2.8 parts of chloro-m-xylenol, 0.8-2.3 parts of defoamer, 1.2-3.4 parts of potassium diphosphate, 1.2-1.5 parts of deionized water, 1.5-2.8 parts of hydrocarbyl acetic acid, 3.1-6.4 parts of sodium thio-succinate, 3.5-6.7 parts of polyvinyl pyrrolidone and 4.5-5.8 parts of hydrophobic modified thickener. The corrosion-free cleaning agent has the beneficial effects that the surface tension of water can be remarkably lowered, so that the surface of a workpiece can be easily wetted and is strong in seepage force; the interface condition between oil stains and the workpiece can be more effectively changed, so that oil-in-water type granules are formed by the oil stains through emulsifying, dispersing, rolling and solubilization and are cleaned; the formula is scientific and reasonable, the foam is little during cleaning, the cleaning capability is strong, the continuity is good, the speed is high, and the service life is long.

Owner:王璐

Copper pipe outside surface cleaning agent

InactiveCN104928700AImprove decontamination abilityModerately volatileChloroacetic acidsCleansing Agents

The invention discloses a copper pipe outside surface cleaning agent. The copper pipe outside surface cleaning agent is composed of the following raw materials including 80-120 parts of acetic acid, 25-30 parts of ethyl alcohol, eight-nine parts of sodium hydroxide, 10-15 parts of butanone, 12-13 parts of xylene, 10-12 parts of ethylene glycol monomethyl ether, five-eight parts of ethyl acetate, 20-25 parts of trichloroacetic acid, 25-28 parts of chloroacetic acid, 20-25 parts of dichloromethane, five-eight parts of 8-hydroxyquinoline, three-five parts of potassium pyrophosphate, 6-10 parts of methyl benzotriazole, five-10 parts of phosphonic acyl glycolic acid and five-eight parts of myristyl dimethyl benzyl ammonium chloride. The copper pipe outside surface cleaning agent is strong in dirt-removing ability, moderate in volatilization, thorough in volatilization, free of corrosive effect on copper metal, clean in cleaning, high in cleanliness, convenient to treat and discharge after cleaning, capable of according with the environmental protection standard and safe in use.

Owner:陈新棠

Cleaning agent for semiconductor industry

ActiveCN101463295BReduce surface tensionGood water solubilityNon-ionic surface-active compoundsDetergent solventsSolubilitySurface-active agents

Owner:JIANGSU HAIXUN IND GROUP SHARE

Environment-friendly automobile hub antirust agent

The invention discloses an environment-friendly automobile hub antirust agent. The environment-friendly automobile hub antirust agent comprises, by weight, 20-95 parts of calcium stearate, 10-60 partsof oxalic acid, 25-55 parts of phytosterol, 15-70 parts of 1-hydroxybenzotriazole, 20-70 parts of chlorhexidine hydrochloride, 20-75 parts of barium sulfate, 35-110 parts of chlorinated paraffin, 15-40 parts of calcium hydroxide, 10-80 parts of sodium acetate and 15-60 parts of sodium alga acid. Accordingly, the antirust agent is long in antirust time, and rust spots can be prevented from being formed on the material surface again after usage; and treatment and discharging of the waste antirust agent are convenient, the environment protection requirement is met, no pollution and no corrosionare caused to equipment, the production cost is effectively reduced, and usage is safe and reliable.

Owner:丁春香

Environment-friendly cleaning agent

The invention discloses an environment-friendly cleaning agent. The environment-friendly cleaning agent is prepared from the following raw materials in parts by weight: 5.3-8.5 parts of acetyl tributyl citrate, 2.5-5.8 parts of tetraethyl lead, 3.5-8.6 parts of dialkyl succinate sulfonate, 1.8-2.5 parts of a penetrant, 5.5-6.8 parts of EDTA (Ethylene Diamine Tetraacetic Acid), 3.3-5.6 parts of a stabilizer and 6.2-9.5 parts of sulfoxide. According to the environment-friendly cleaning agent, the formula is scientific and reasonable, the production process is simple, special equipment is not required, and only the raw materials are required to be mixed at normal temperature; the cleaning capability is strong, the cleaning time is short, labor and working hours are saved, the working efficiency is increased, and the cleaning agent has derusting and antirust effects; the cleaning agent is relatively low in equipment corrosiveness and safe and reliable in use and is beneficial to equipment cost reduction; the cleaning agent is water-soluble liquid, so that cleaned waste liquid is convenient to treat and drain, and the requirements on environmental protection are met.

Owner:QINGDAO KERUN PLASTIC MACHINERY

High temperature-resistant textile product

InactiveCN108691197AImprove toughnessEnvironmentally friendly flame retardant performanceHeat resistant fibresHalogenMagnesium

The invention relates to a high temperature-resistant textile product. The high temperature-resistant textile product comprises a textile product body and a flame-resistant arrangement material, wherein the flame-resistant arrangement material is cured in fiber gaps and fiber surfaces of the textile product; the flame-resistant arrangement material comprises a magnesium hydroxide flame retardant and a crosslinking agent; 5 to 8wt% of magnesium hydroxide flame retardant is cured into the textile product; the crosslinking agent is dicumyl peroxide, and 0.8 to 2wt% of dicumyl peroxide is cured into the textile product. A preparation method comprises the following steps of adding the magnesium hydroxide flame retardant and the dicumyl peroxide crosslinking agent into pure water according to acertain ratio, so as to prepare an arrangement liquid; putting the textile product into the arrangement liquid, and padding; drying by a special method, drying, cleaning, and the like. The high temperature-resistant textile product has the advantages that the flame-retardant ability is realized and is lasting, the washing-resistant property is realized, and the adding of halogen, organophosphor orformaldehyde is avoided in the production process.

Owner:RUGAO WANLONG GARMENT FACTORY

Environment-friendly antirust agent for bicycle chains

InactiveCN108129932AAnti-rust for a long timePrevent rust spotsAnti-corrosive paintsSulfonateAcrylic resin

The invention discloses an environment-friendly antirust agent for bicycle chains. The environment-friendly antirust agent for bicycle chains comprises the following components in parts by weight: 15to 80 parts of sulfur, 30 to 120 parts of a potassium nitrite solution with the concentration of 30%, 25 to 80 parts of acrylic resin, 20 to 90 parts of boron nitride, 30 to 90 parts of sodium sulfonate, 40 to 80 parts of glycerol methyl ether, 50 to 120 parts of ammonium phosphate, 20 to 80 parts of silicon dioxide, 10 to 50 parts of a flatting agent and 20 to 55 parts of sodium nitrite. Therefore, the antirust agent is relatively long in antirust time, and rust can be prevented from being formed on the surface of the material again after the antirust agent is used; a waste antirust agent ismore convenient to treat and discharge, the environmental requirement is met, the antirust agent is free of pollution to equipment and free of corrosion, the production cost is effectively reduced, and the antirust is safe and reliable to use.

Owner:丁春香

Cleaning agent for magnetic head

ActiveCN101463300BImprove solubilityGuaranteed surface tensionNon-ionic surface-active compoundsCleaning recording headsOrganic solventActive agent

The present invention provides a cleansing agent for a computer disk head. The cleansing agent comprises the following compositions according to weight percentage: 3-8 percent of a solubilizing agent, 3-10 percent of a non-ionic surface active agent, 3-10 percent of an anionic active agent, 1-5 percent of foam suppressor, 3-10 percent of 2, 3-dihydro-decafluoropentane, and the rest being de-ionized water. The cleansing agent is a water soluble cleansing agent, has perfect cleansing effect on organic solvent and solid particles remained on the surface of a polished disk head with small corrosion, is convenient for treating and discharging of waste cleansing agent, and accords with the requirement of environmental protection. The cleansing agent has the advantages of reasonable formulation design, simple preparation process and low cost without special production equipment.

Owner:JIANGSU HAIXUN IND GROUP SHARE

Environment-friendly rust inhibitor applied to surfaces of bending machines

InactiveCN108148490AAnti-rust for a long timePrevent rust spotsAnti-corrosive paintsPolyether coatingsSodium acetateSodium molybdate

The invention discloses an environment-friendly rust inhibitor applied to surfaces of bending machines. The rust inhibitor is prepared from the following raw materials in parts by weight: 15-75 partsof calcium stearate, 20-60 parts of nonylphenol polyoxyethylene ether, 25-95 parts of sodium molybdate, 25-80 parts of alkylbenzyloxyamine, 20-75 parts of sodium sulfonate, 20-75 parts of barium sulfate, 25-80 parts of potassium tetraborate, 15-70 parts of anionic surfactants, 10-80 parts of sodium acetate and 25-55 parts of 2,3-dihydrodecafluoropentane. The rust inhibitor is long in rust inhibition time; after the rust inhibitor is applied to the surface, the rust inhibitor is capable of preventing the surface of the material from forming rusty spots again; the waste rust inhibitor can be conveniently treated and discharged; the requirement of environmental protection is met; the rust inhibitor is free of pollution and corrosion to equipment, can effectively reduce the production cost, and is safe and reliable to use.

Owner:丁春香

Antirust agent for carbon steel

The invention discloses an antirust agent for carbon steel. The antirust agent comprises, by weight, 15-85 parts of hydroxyethyl oleoimidazoline, 25-65 parts of sodium molybdate, 25-60 parts of sodiumcitrate, 38-85 parts of oleoyl sarcosine, 34-75 parts of tri-n-butylamine, 35-85 parts of silane coupling agent, 25-85 parts of polyisobutene, 20-45 parts of polyvinyl chloride resin, 15-75 parts ofglutamic acid and 10-85 parts of power increasing agent. Therefore, the antirust time of the antirust agent is long, and rust spots can be prevented from being formed on the surface of the material again after the antirust agent is in use; the waste antirust agent is convenient to process and discharge, environmental protection requirements are met, no pollution or corrosion is caused to equipment, the production cost is effectively reduced, and use is safe and reliable.

Owner:仪征锐翼机械科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com