Reusable supercharging superheat steam drying method and device

A technology of superheated steam and drying method, which is applied in the direction of drying gas arrangement, heating to dry solid materials, drying solid materials, etc., can solve problems such as restricting reuse, and achieve the effect of high energy utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

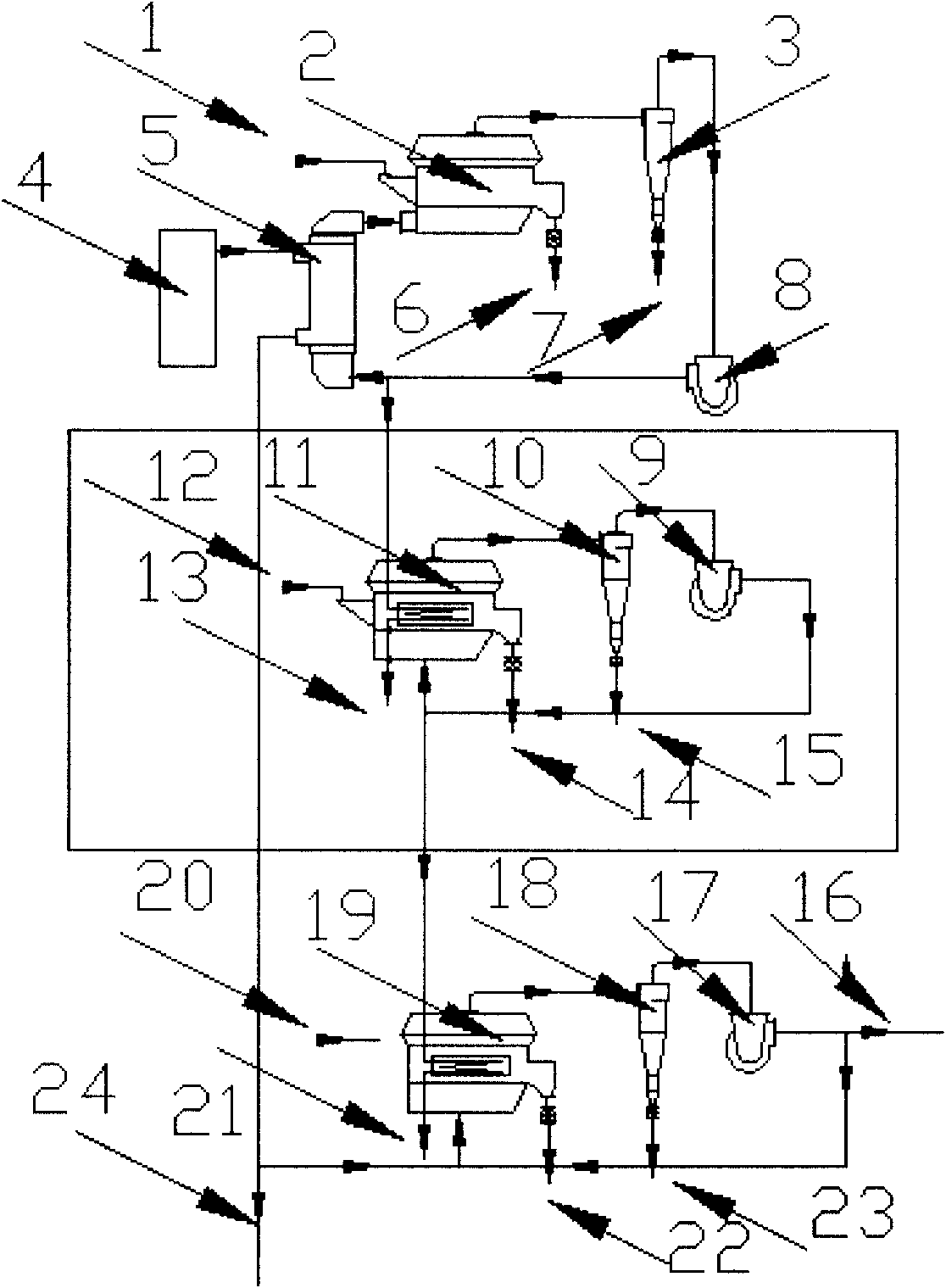

[0015] The following is an example of three-stage drying.

[0016] The first stage of drying is pressurized superheated steam drying in which wet materials are in direct contact with superheated steam.

[0017] Such as figure 1 As shown, the wet material is fed into the first-stage dryer 2 from the first-stage drying feed 1, and is heated and dehydrated by high-temperature superheated steam. The dried material is discharged from the drying system from the first-stage drying discharge 6. The steam produced by the evaporation of moisture in the wet material circulates in the first-stage drying system, passes through the first-stage drying cyclone dust collector 3, and the fine particle materials brought out are separated and discharged from the drying system by the first-stage drying cyclone discharge 7 . The dedusted gas passes through the first-stage drying and circulating fan 8 , enters the heat exchanger 5 and is heated by the high-temperature flue gas from the combustion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com