Patents

Literature

92results about How to "Meet the quality standard requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

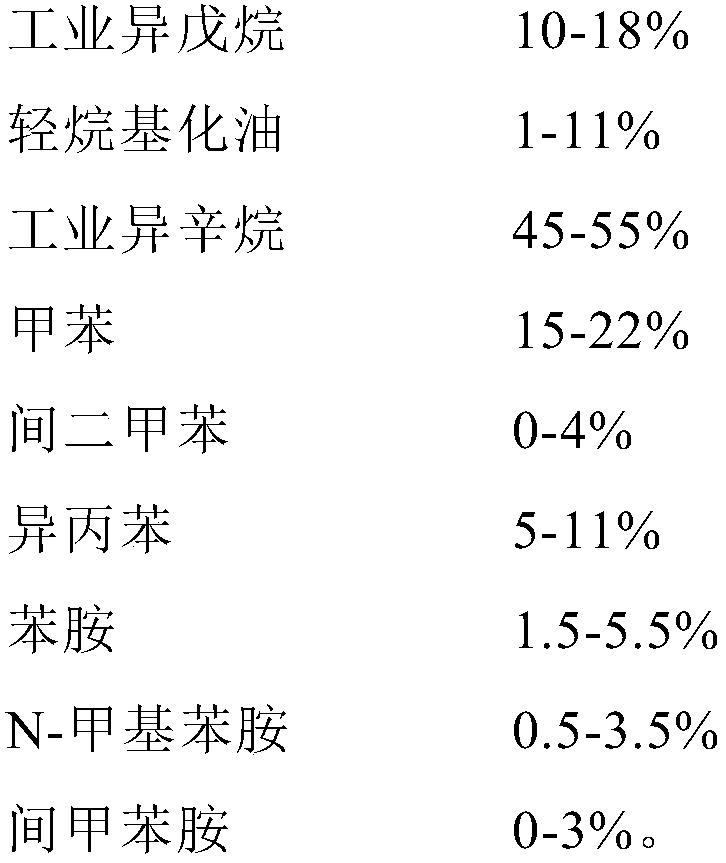

100# lead-free aviation gasoline and preparation method thereof

ActiveCN106398783AMeet the quality standard requirementsTackling lead pollutionLiquid carbonaceous fuels2-methylbutaneAviation

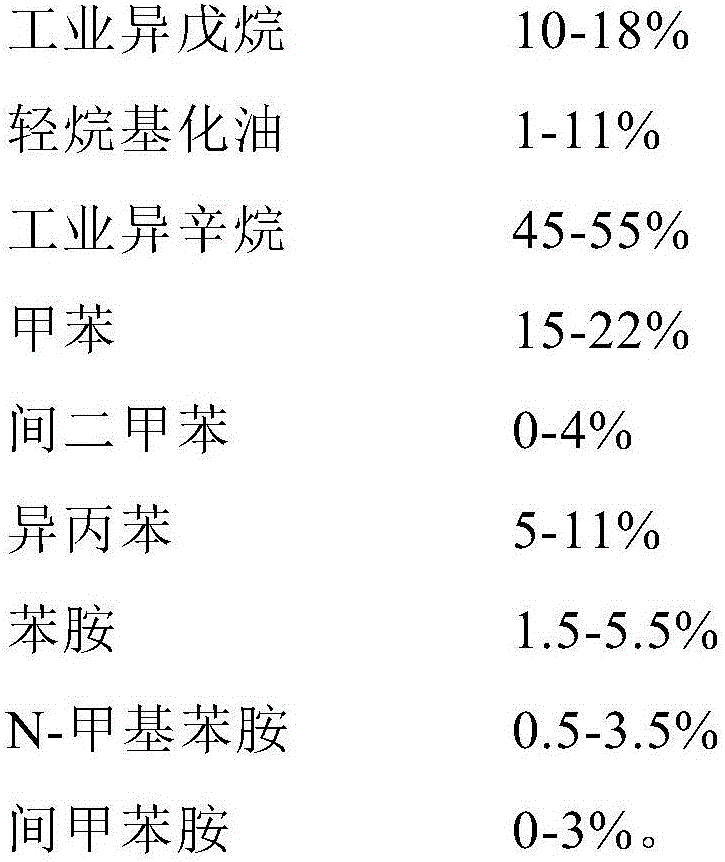

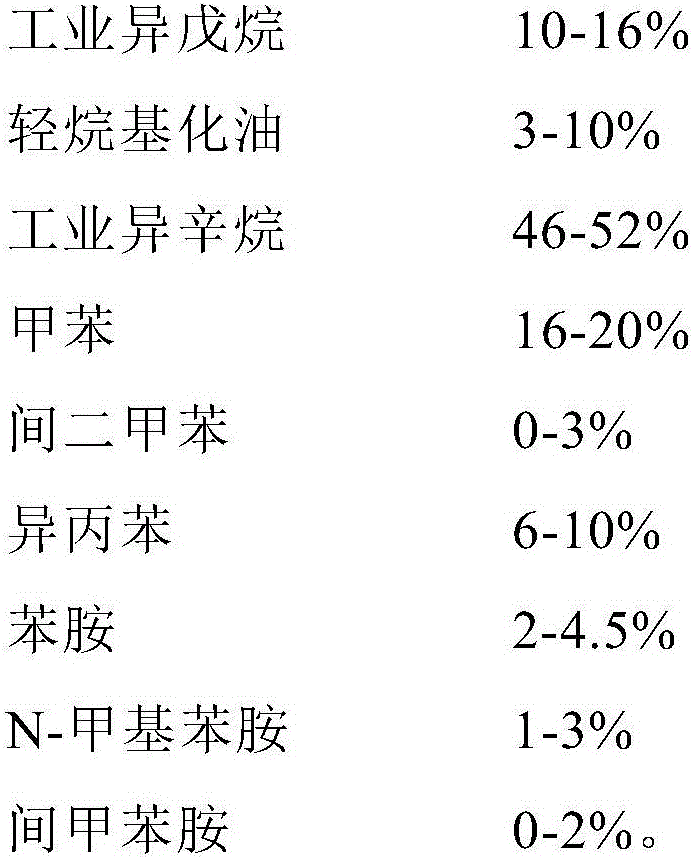

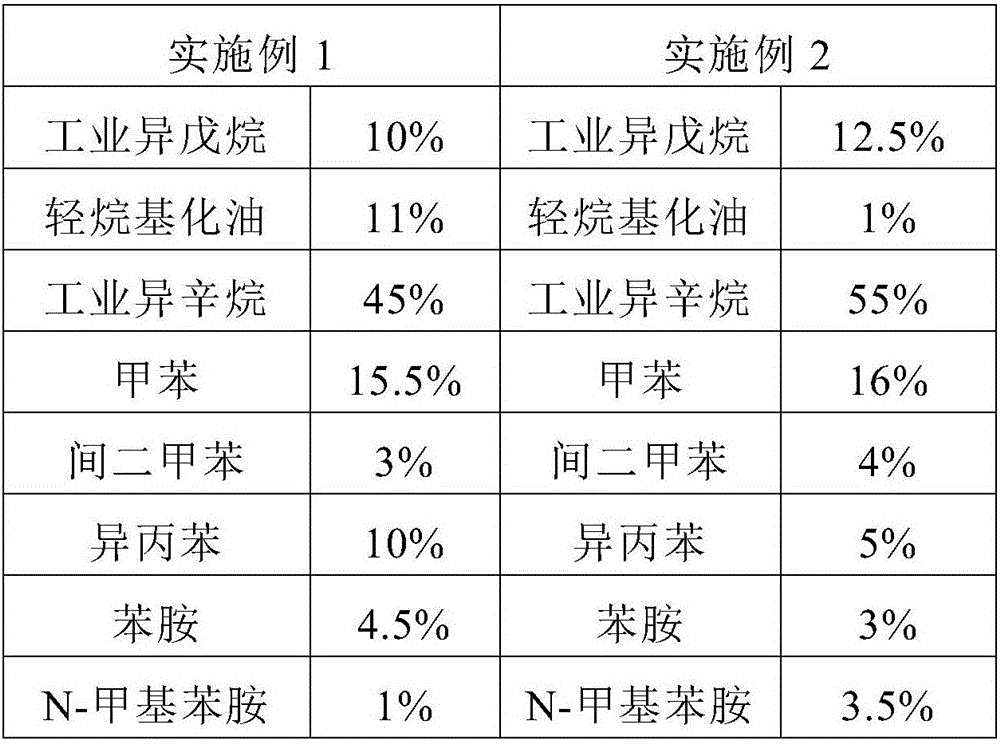

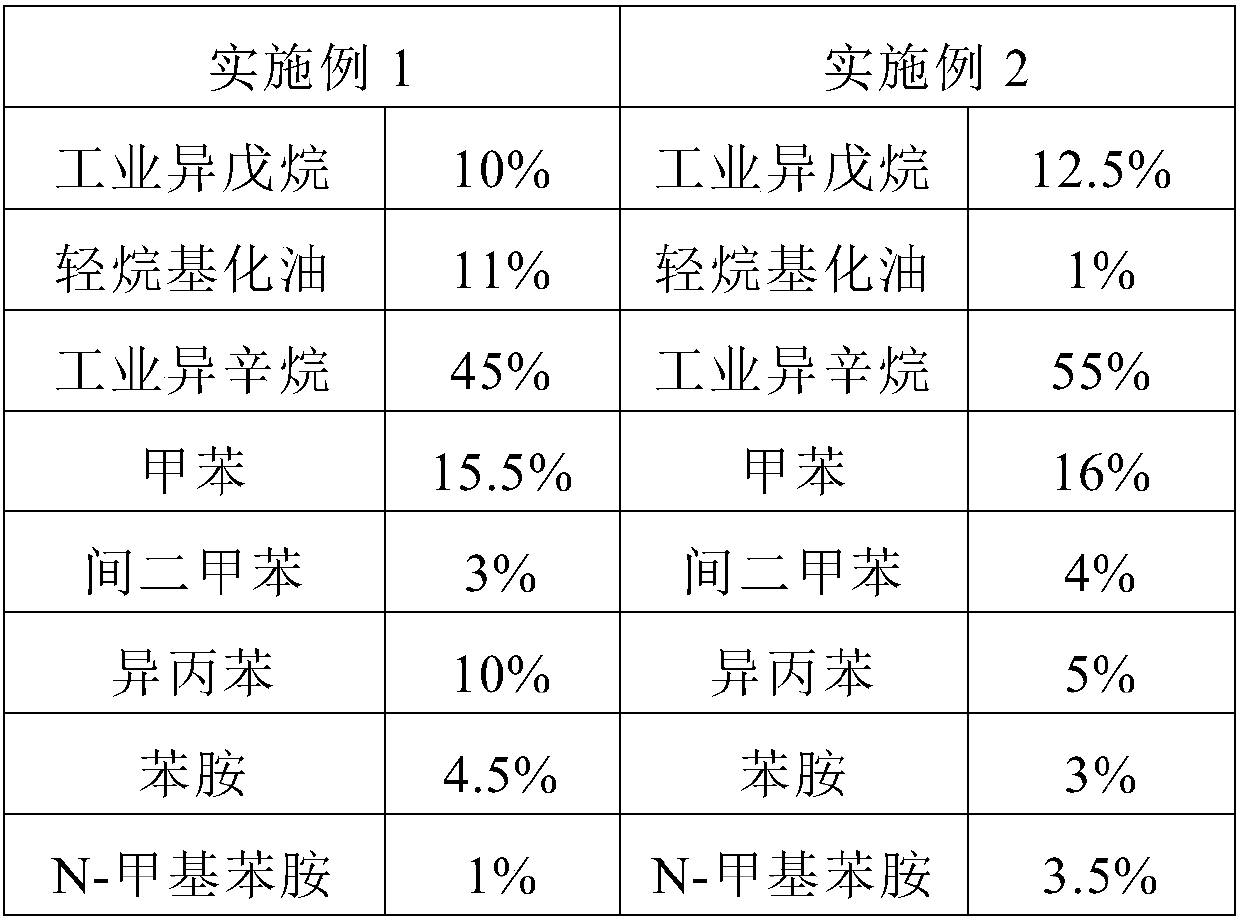

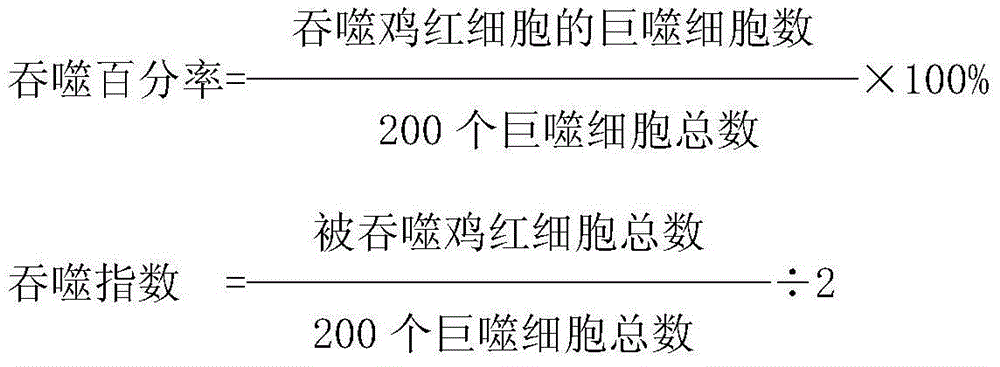

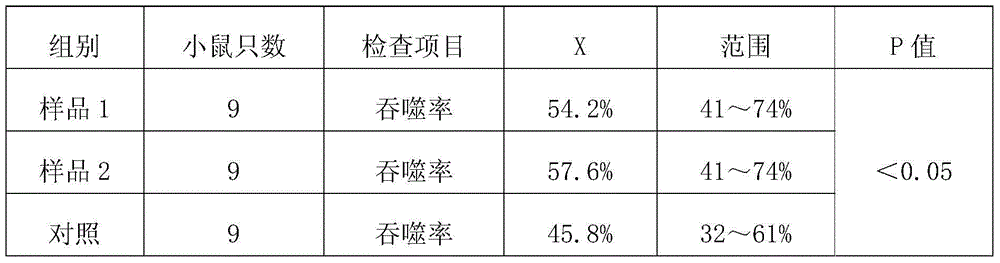

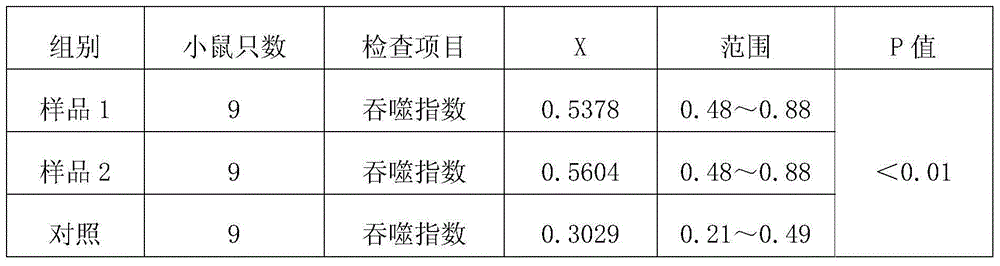

The invention relates to 100# lead-free aviation gasoline and a preparation method thereof. The 100# lead-free aviation gasoline comprises, by volume, 10-18% of industrial isopentane, 1-11% of light alkylated oil, 45-55% of industrial isooctane, 15-22% of toluene, 0-4% of m-xylene, 5-11% of cumene, 1.5-5.5% of aniline, 0.5-3.5% of N-methyl aniline and 0-3% of m-toluidine. The components are blended to form the finished product. Compared with the prior art, the 100# lead-free aviation gasoline does not contain lead and solves the problem of lead pollution of aviation gasoline. Through the optimized combination of the components, the 100# lead-free aviation gasoline quality is high and the 100# lead-free aviation gasoline satisfies the quality index requirements. The 100# lead-free aviation gasoline has a high economic value. The 100# lead-free aviation gasoline blending process is simple and is conducive to industrial production.

Owner:EAST CHINA UNIV OF SCI & TECH

Low-sugar or cane-sugar-free yoghourt and preparation method thereof

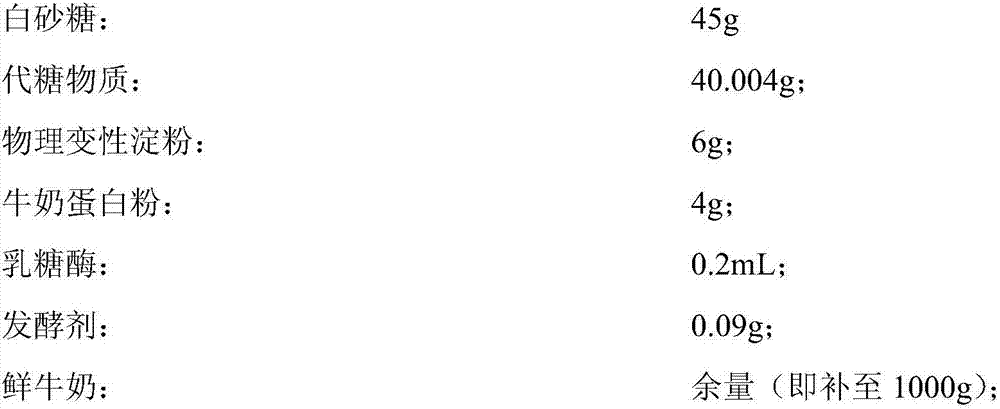

The invention provides low-sugar or cane-sugar-free yoghourt and a preparation method thereof. The yoghourt consists of the following raw materials of 0-45 parts by weight of white granulated sugar, 0.001-90 parts by weight of sugar substitute substances, 0.1-5 parts by weight of lactase, 0-6 parts by weight of a stabilizing agent, 3-10 parts by weight of milk protein, 0.07-0.1 part by weight of a fermenting agent and the balance of milk, so that the total parts by weight of the raw materials are 1000. The preparation method of the yoghourt comprises the following steps of standardizing the milk, performing blending, performing deaeration, performing homogenizing and sterilizing, performing enzymolysis and fermentation, and performing filling. According to the yoghourt disclosed by the invention, an appropriate natural sweetener is selected for increasing the sweet degree; the lactase is added, and lactose is decomposed into glucose and galactose, so that the sweet degree of the yoghourt is further increased; besides, the stuffing type sweetening agent is added for complementing the mouth feel loss caused by no addition of cane sugar; and under the condition of no addition of the stabilizing agent, the compounding ratio of several sweetening agents is reasonably adjusted, so that the problems that existing low-sugar or cane-sugar-free yoghourt products are bad in mouth feel, low in viscosity, crude in state and the like are solved.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

Method for producing matured honey

InactiveCN102763791ASolve defects in the production processMeet the quality standard requirementsFood preparationHoneycombActive value

The invention relates to a method for producing matured honey. The method comprises the following steps of: collecting and brewing nectar, taking a honeycomb out, shaking honey, melting the honey, crystallizing, performing multistage filtering, inspecting an intermediate, metering, filing, sealing, sterilizing, inspecting a finished product, warehousing the finished product, storing at the appropriate temperature. The natural matured honey produced by the method is pure honey which is brewed to be matured by honey, is thick, mellow and rich of nutrition, the active value of amylase is high, and the content of natural content is below 20 percent.

Owner:JIANGSU JIANGDAYUAN ECOLOGICAL BIOLOGICAL TECH

Smelting manufacturing method for high temperature ferric alloy

A technology for smelting the refractory Fe-base alloy includes such steps as primary smelting in ordinary electric arc furnace by return oxygen blowing method and smelting the qualified refractory Fe-base alloy in AOD furnace. Said second step includes blowing the mixture of argon gas and O2 in ratio of 4:1 for decarbonizing, heating, blowing the mixture of argon gas and O2 in ratio of 1:1 when C content is 0.1%, sampling and analyzing, regulating contents of its components, blowing argon gas when C content is 0.03%, adding prereducing slags, prereducing, sampling and analyzing, adding reducing slags, blowing argon for dissolving slags, blowing argon for 3 min, adding Ti in ladle, tapping, and casting rod electrodes.

Owner:宝钢特钢有限公司

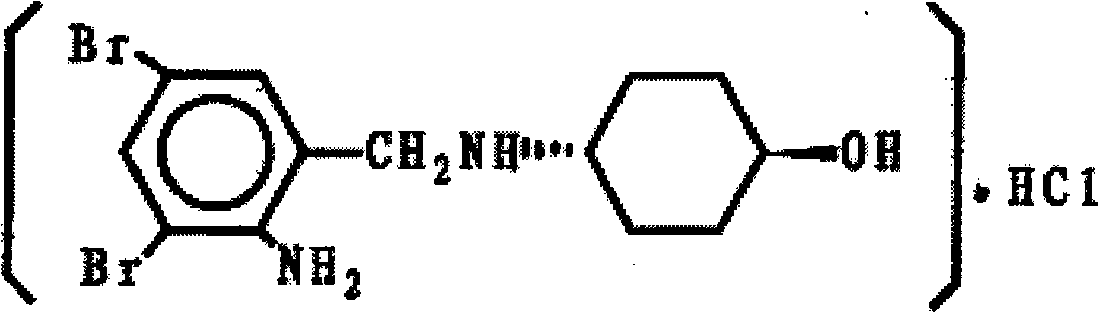

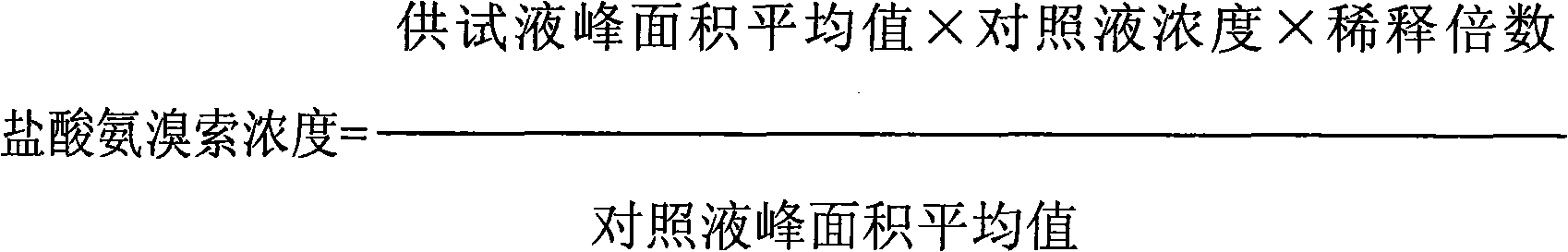

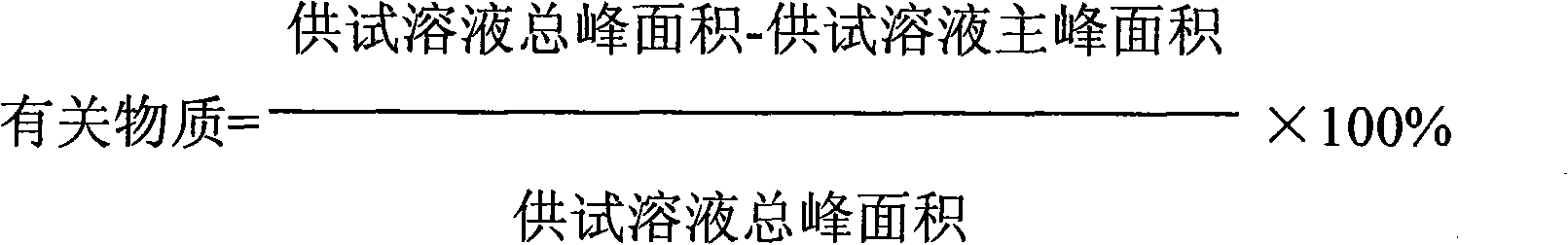

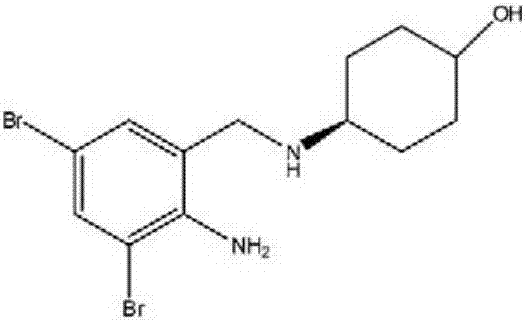

Ambroxol hydrochloride liquid preparation and preparation method thereof

ActiveCN101627967AImprove solubilityOvercome the defect of being slightly soluble in waterOrganic active ingredientsPharmaceutical delivery mechanismWater useBULK ACTIVE INGREDIENT

The invention discloses an ambroxol hydrochloride liquid preparation and a preparation method thereof. The method comprises the steps: dissolving ambroxol hydrochloride, stabilizing agent and osmotic pressure regulator into water used for injection, and evenly mixing together to obtain solution I; then, filtering the solution I, and obtaining the ambroxol hydrochloride liquid preparation. The preparation method does not introduce active carbon, so as to avoid the danger of hurting human body since active carbon particle is introduced into the preparation; meanwhile, the active ingredients in the preparation is ensured to be stable, and the safety (namely, the chemical stability of the ambroxol hydrochloride can be effectively improved, the particle content in the preparation is reduced, and the purity of the preparation is improved) of the finished product can be guaranteed.

Owner:上海华源药业(宁夏)沙赛制药有限公司

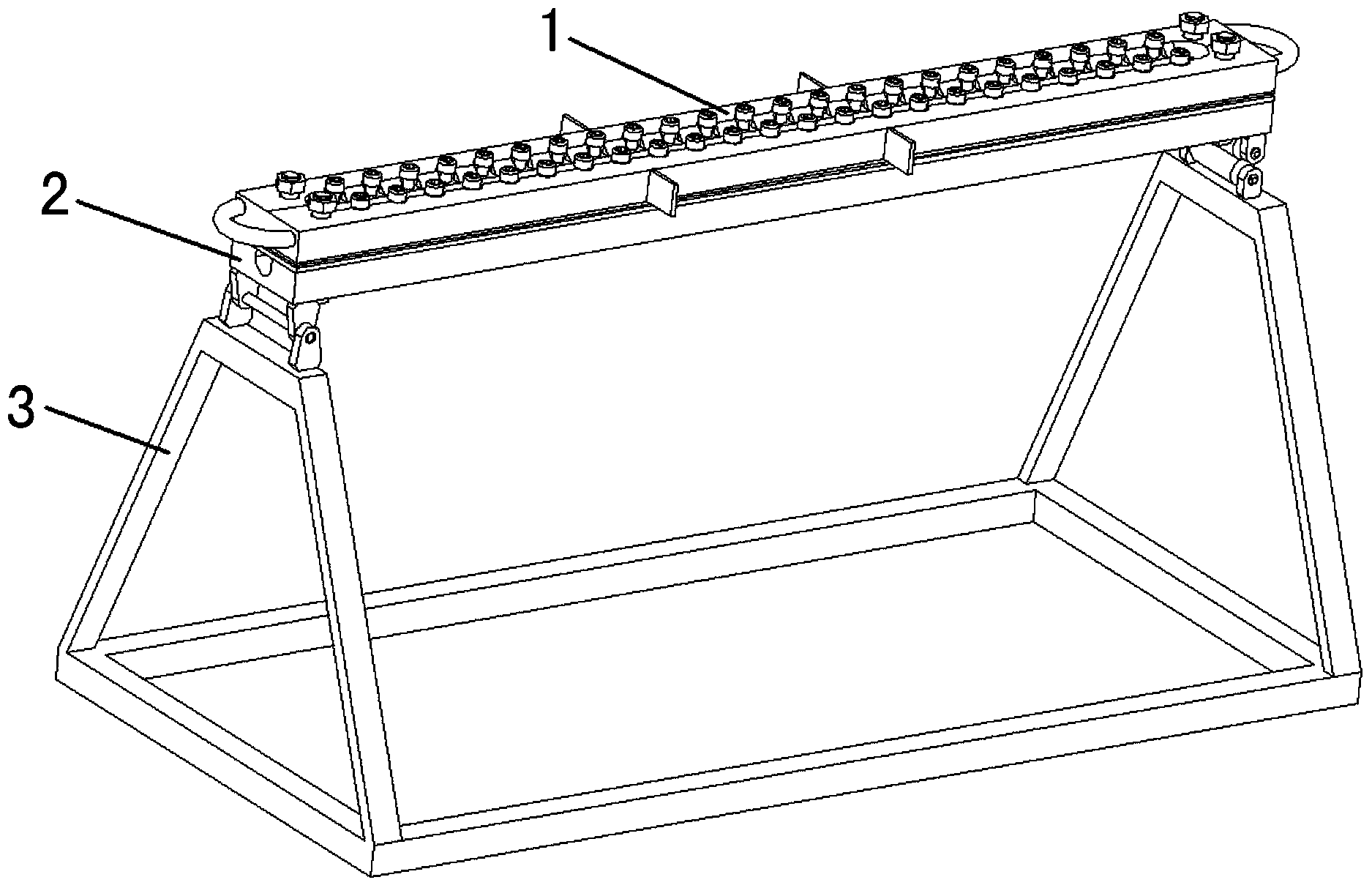

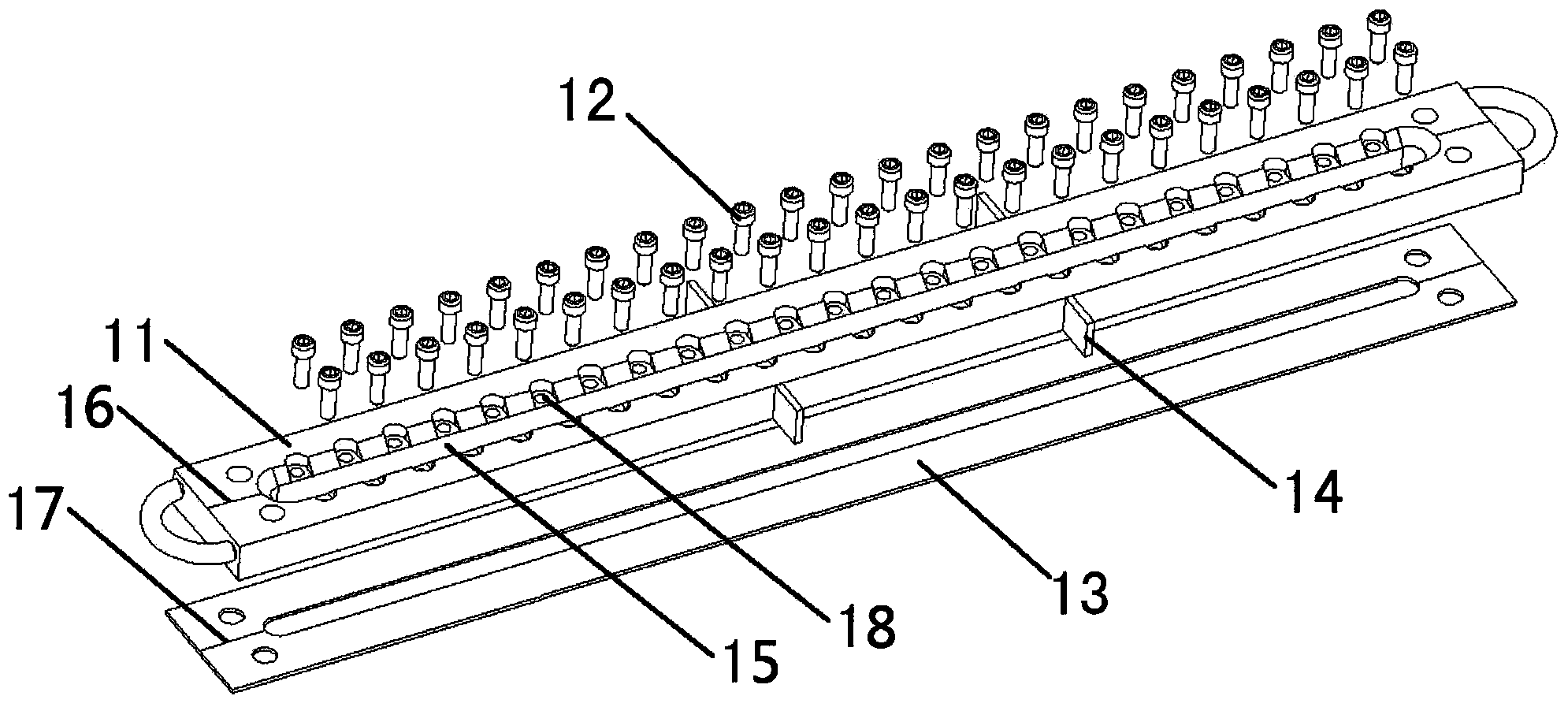

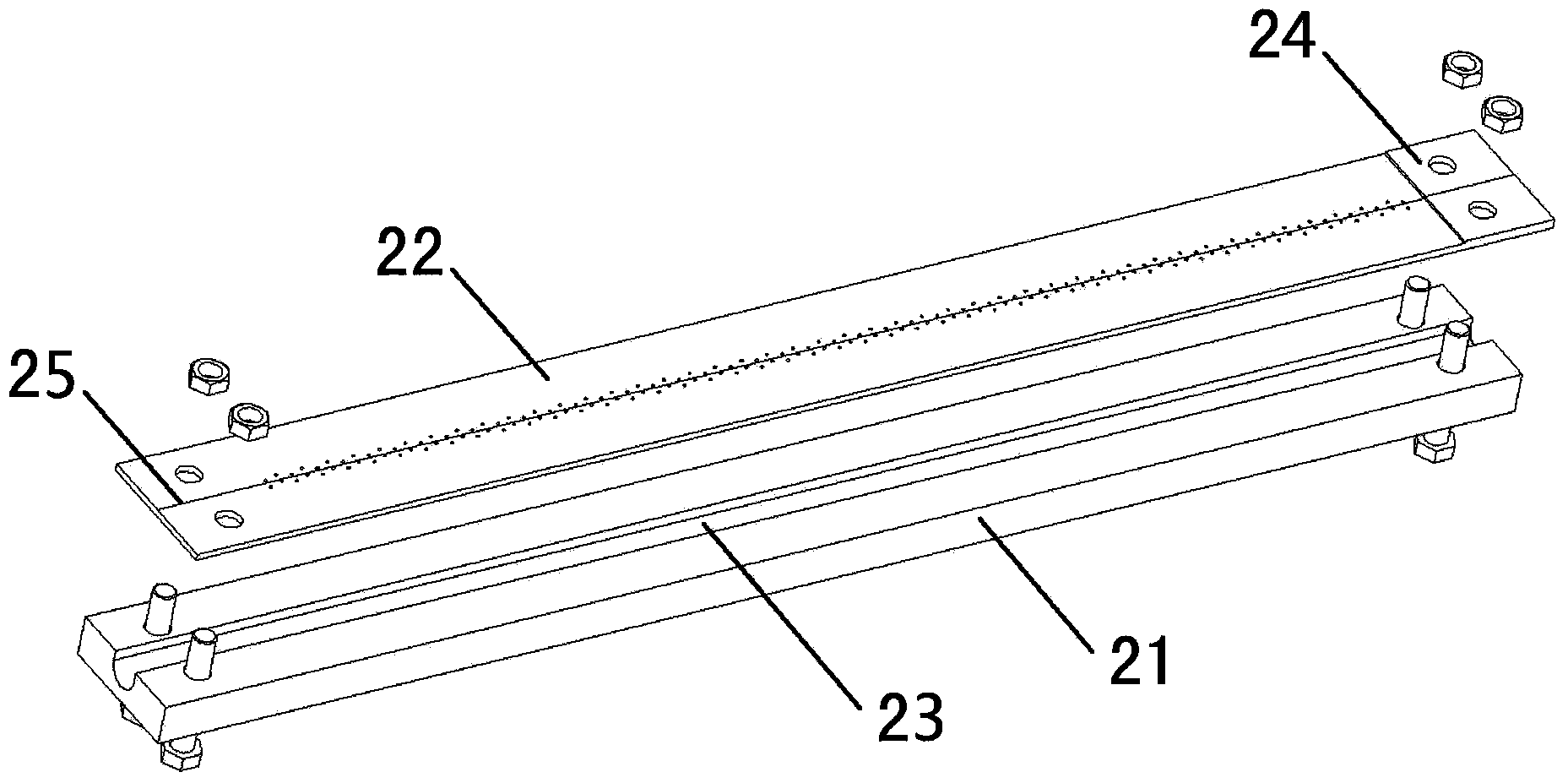

Method for manufacturing inner barrel of combustor of gas turbine and fixture

ActiveCN103862146AImprove protectionNo oxidationWelding/cutting auxillary devicesAuxillary welding devicesCombustorWelding deformation

The invention discloses a method for manufacturing an inner barrel of a combustor of a gas turbine and a welding fixture of the inner barrel. The method and the welding fixture are characterized in that an N-2-1 positioning method and a symmetrical wandering welding method are achieved through the fixture, and welding deformation of thin-walled barrels such as the inner barrel of the combustor of the gas turbine can be controlled within 1 mm.

Owner:DONGFANG TURBINE CO LTD

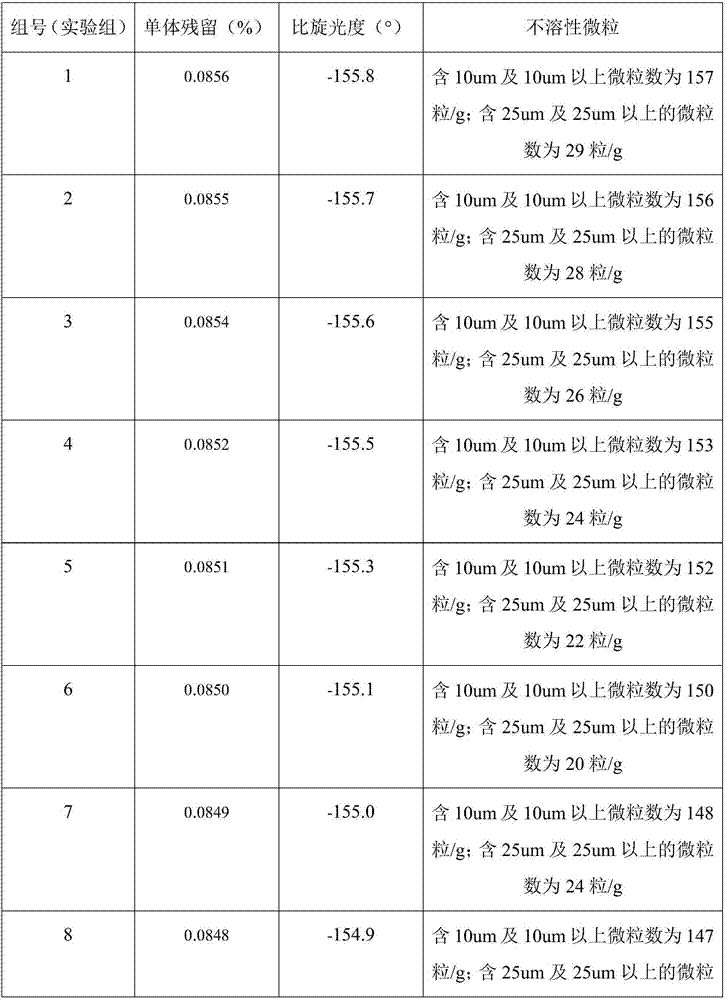

Manufacture method for surgical implant-level poly(L-lactic acid)

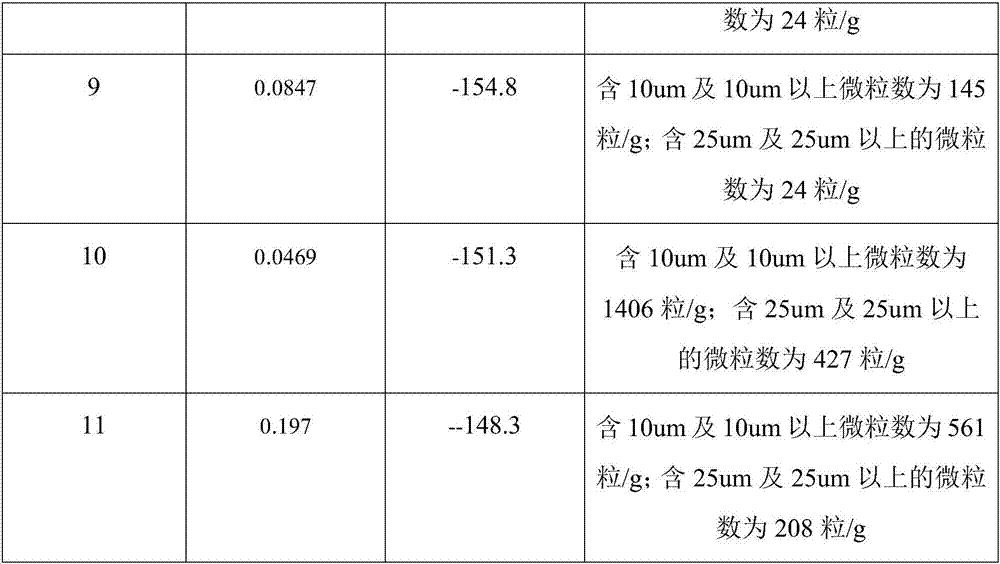

The invention relates to a manufacture method for surgical implant-level poly(L-lactic acid). The method comprises the following steps: mixing L-lactic acid and a catalyst, performing reduced-pressure distillation to obtain a crude product DL-lactide, and performing recrystallization to obtain high-purity DL-lactide; performing a reaction on the DL-lactide, a catalyst and an end-capping agent under vacuum and nitrogen introducing circulation conditions to obtain poly(L-lactic acid); and performing dissolving, performing recrystallization, and performing drying to obtain the implant-level poly(L-lactic acid) which can be supplied for surgery. According to the poly(L-lactic acid) prepared by the manufacture method, the physical and chemical properties of the poly(L-lactic acid) can fully meet a YY / T 0661-2008 (standard specification for virgin poly(L-lactic acid) resin for surgical implants), and the poly(L-lactic acid) has remarkable effects on aspects such as monomer residues, an optical rotation and microparticle control (requirements that the number of microparticles with sizes of 10 micrometers or more in 1 g is 200 at most, and the number of microparticles with sizes of 25 micrometers or more in 1 g is 100 at most are met). The high-optical-purity poly(L-lactic acid) can be better and normally metabolized by people, and biocompatibility between the poly(L-lactic acid) and people is improved; and low-insolubility microparticles are reduced, thus possibility of aseptic inflammation is reduced.

Owner:CHENGDU MEDART MEDICAL SCI CO LTD

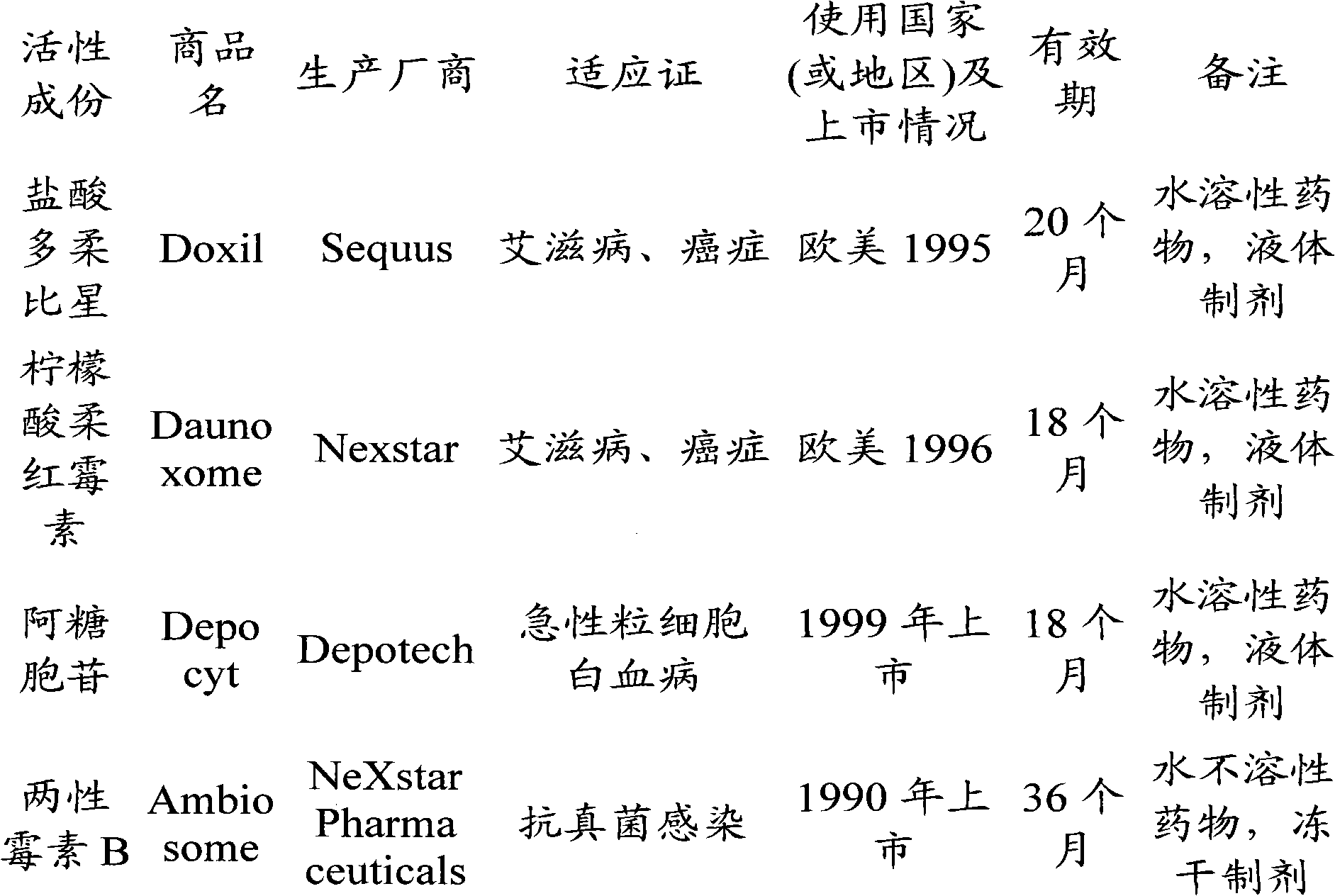

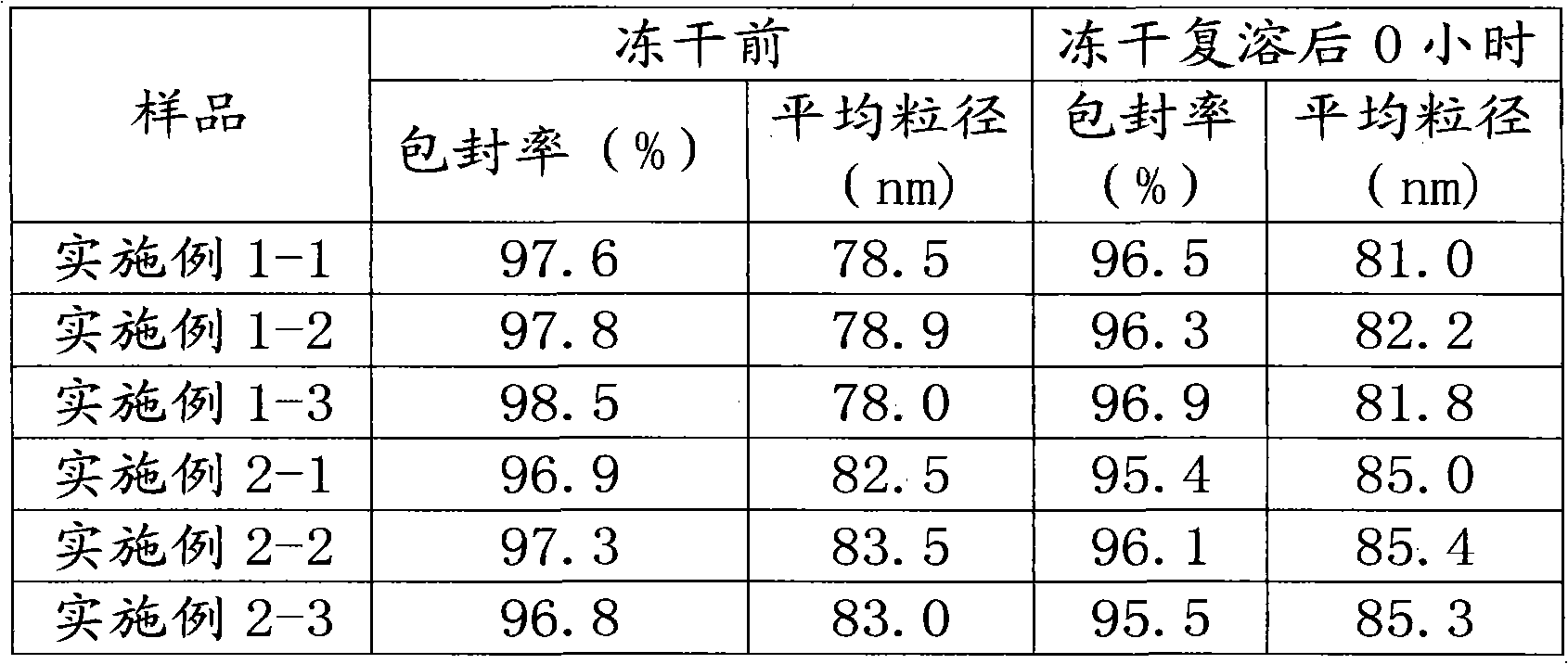

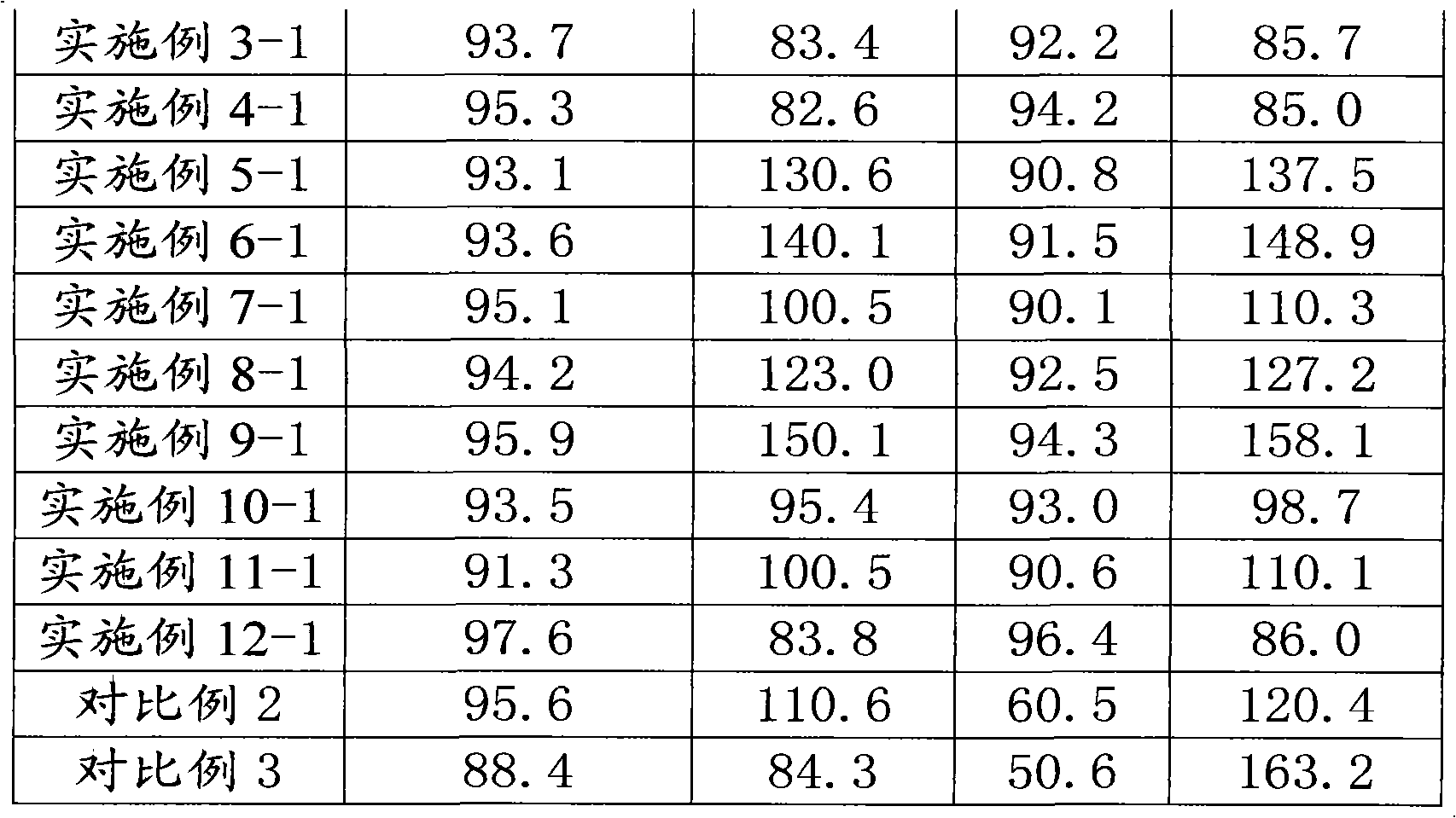

Freeze-dried liposome composition of water-soluble medicament and preparation method thereof

ActiveCN102018672AFreeze-drying achievedStable storageOrganic active ingredientsPharmaceutical product form changeCholesterolPolyethylene glycol

The invention discloses a freeze-dried liposome composition of water-soluble medicament. The composition comprises the following raw materials: water-soluble medicament, phospholipid, polyethylene glycol-phospholipid, cholesterol, carbohydrate freeze-drying protective agent and cyclodextrin or cyclodextrin derivative freeze-drying protective agent. In the invention, the carbohydrate and cyclodextrin or cyclodextrin derivative are used as the freeze-drying protective agent for the liposome dispersion liquid of the water-soluble medicament, and the entrapment rate of the obtained freeze-dried liposome of the water-soluble medicament is not less than 90%, the particle size is between 10 and 500 nm, all indexes conform to the requirements of the quality standard, and the period of validity isnot shorter than 24 months and is more than 4 months longer than that of the liposome of the water-soluble medicament on the market. Meanwhile, the invention also provides a preparation method of thefreeze-dried liposome composition of the water-soluble medicament.

Owner:REGENEX PHARMA LTD

Method for making permeable bricks by using construction wastes

The invention discloses a method for making permeable bricks by using construction wastes. The method comprises the following production steps: taking the construction wastes and calcites, and crushing; adding obtained crushed construction waste particles and sands into a stirring machine, and stirring; adding cement to the stirring machine, and carrying out vibrating mixing to prepare construction wastes mixed particles; and mixing and stirring a sandstone mixture, cement, water and the construction wastes mixed particles to prepare a mixed raw material; taking xanthan gum and water, mixing to form a gum solution, immersing calcite particles in the gum solution, filtering out the gum solution, and air-drying to form calcite micelles; adding the calcite micelles to the mixed raw materials, mixing and stirring, and processing the above obtained stirred mixed material to make green bricks; and immersing the green bricks in water, drying the immersed green bricks, decomposing the calcite, and cooling to normal temperature in order to make the permeable bricks. The permeable bricks made in the invention have the advantages of high strength, strong permeable ability, environmentally-friendly utilization of the construction wastes, and realization of performances according with relevant quality standard requirements.

Owner:潮州市富丽生态环保科技有限公司

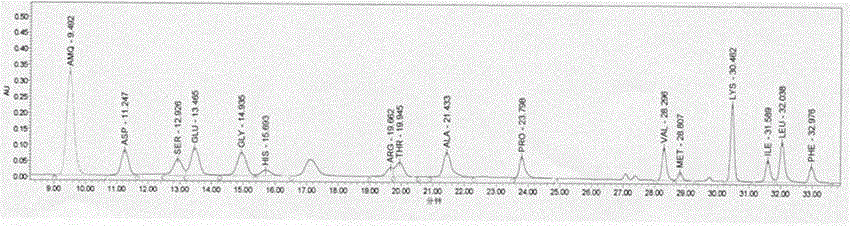

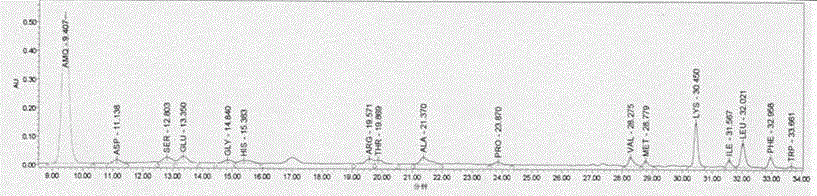

Pure natural cerebroprotein hydrolysate raw material preparation method

ActiveCN104096215AOvercome the defect of insufficient clarityComplete enzymatic hydrolysisNervous disorderHydrolysed protein ingredientsHydrolysateUltrafiltration

The invention discloses a pure natural cerebroprotein hydrolysate raw material preparation method. The method comprises the steps as follows: a, protein purification, to be specific, a cryopreserved fresh pig brain is defrosted, cleaned, homogenized, and subjected to centrifugal separation for obtaining precipitated brain protein; b, pepsin enzymolysis, to be specific, pepsin is added in the precipitated brain protein and stirred, then concentrated hydrochloric acid is added and stirred, and then the centrifugal separation carried out, so that a pepsin enzymatic hydrolysate is obtained; c, acid hydrolysis, to be specific, sulfuric acid is added into the pepsin enzymatic hydrolysate for hydrolyzing, so that an acid hydrolysis liquid is obtained; d, trypsin enzymolysis, to be specific, the pH value is adjusted to 7-9, and pancreatin with the weight 0.1% to 0.4% of that of the pig brain is added for hydrolyzing, and the centrifugal separation is carried out, so that a pancreatin enzymatic hydrolysate is obtained; e, chromatography, to be specific, the pH value is adjusted to 6.5-7.5, and resolving is carried out by using ammonia water, so that a chromatography liquid is obtained; f, concentration, to be specific, the vacuum concentration is carried out, the pH value is adjusted to 6.5-7.5, and then frozen storage is carried out; g, impurity removing, to be specific the condensed frozen liquid is defrosted, and then subjected to centrifugal separation as well as ultrafiltration for obtaining natural cerebroprotein hydrolysate raw material.

Owner:HUNAN LINUO BIOLOGICAL PHARMA

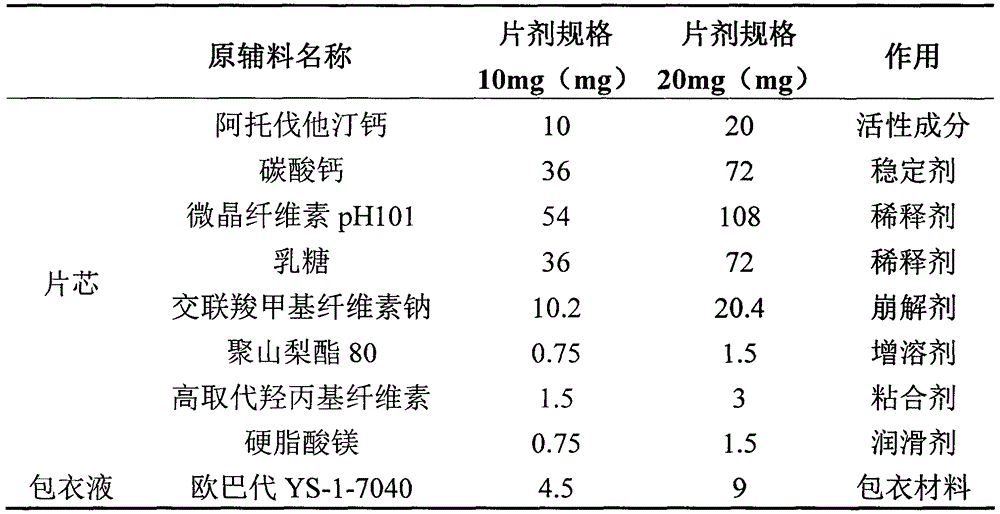

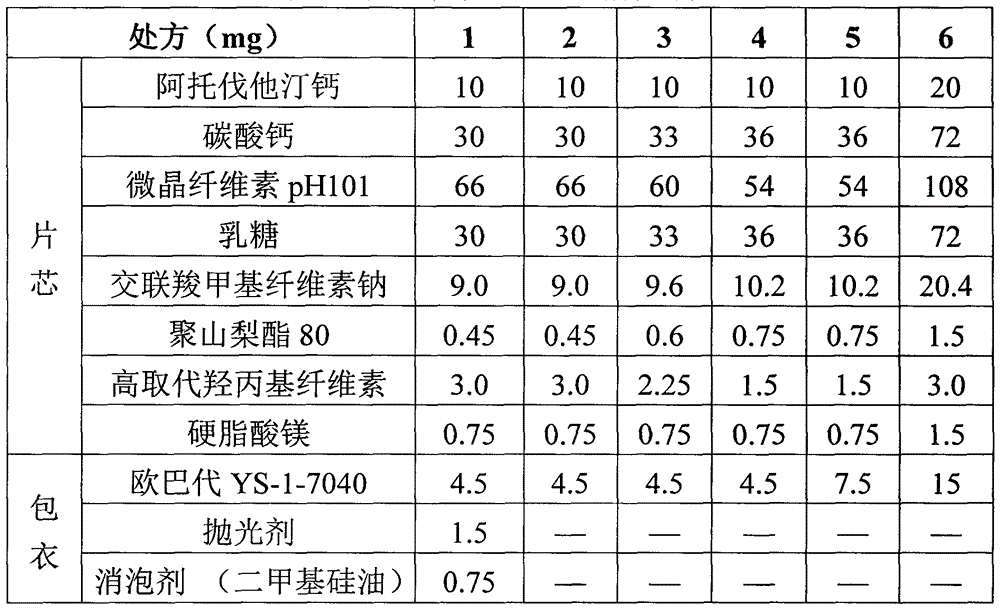

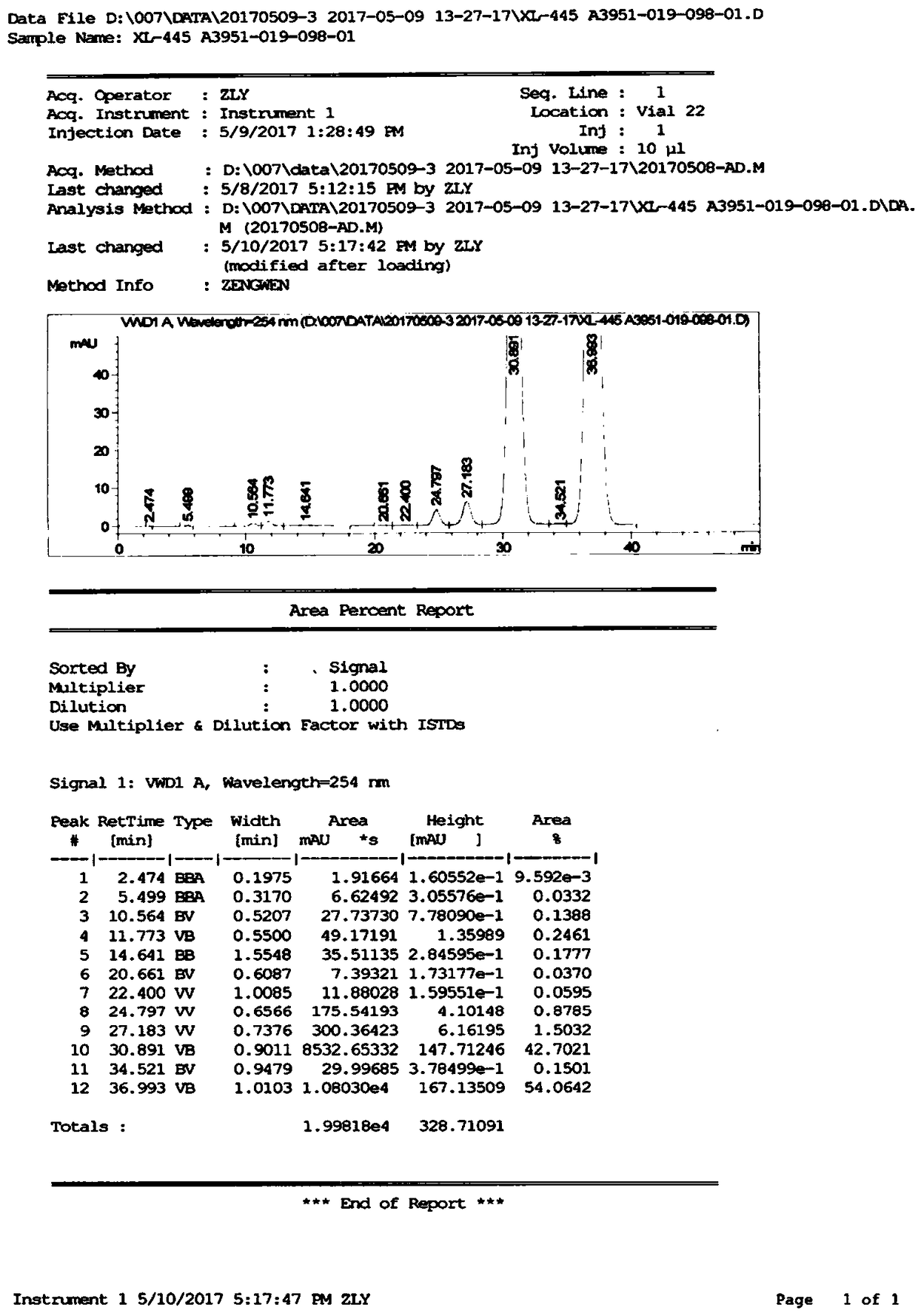

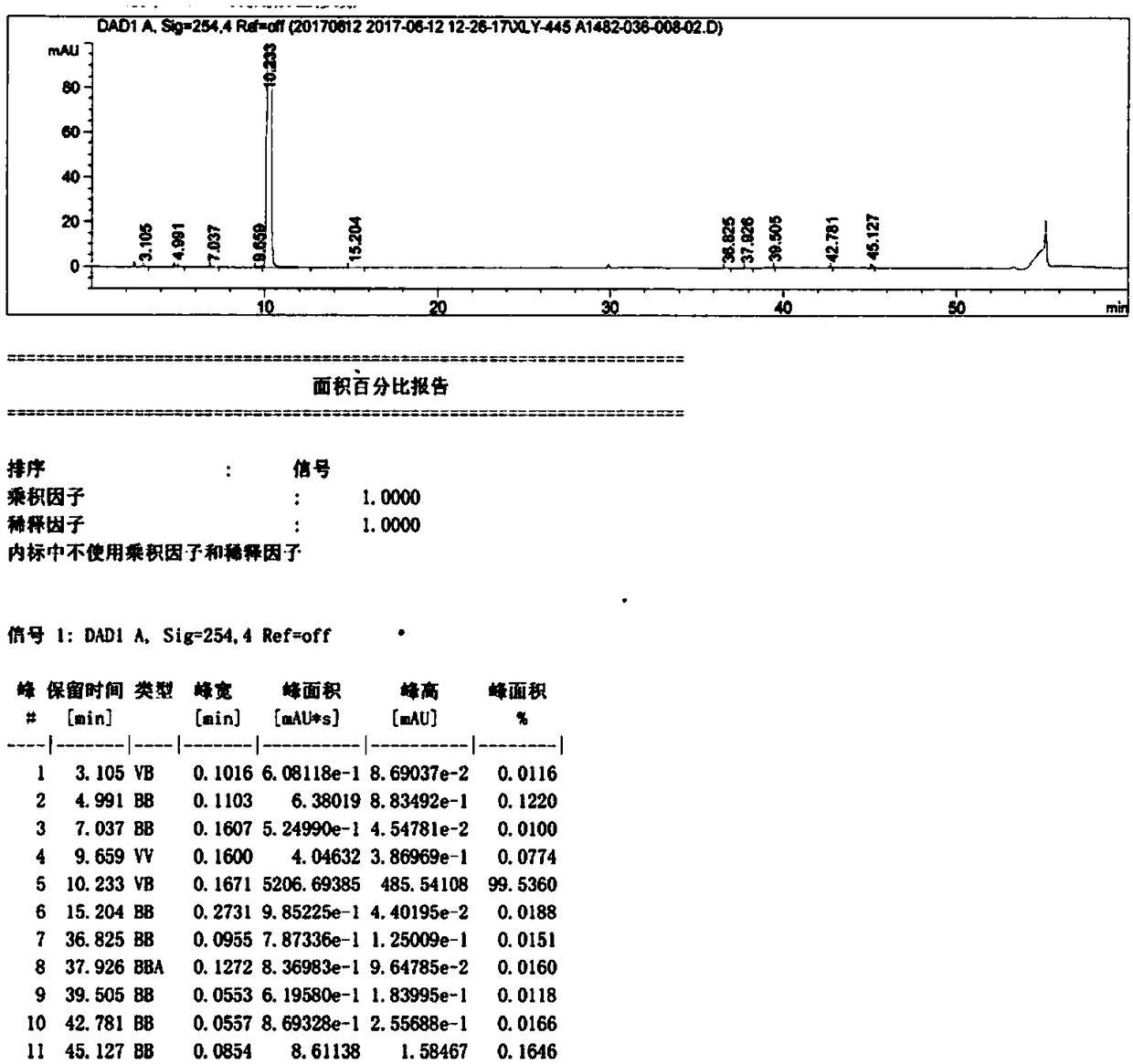

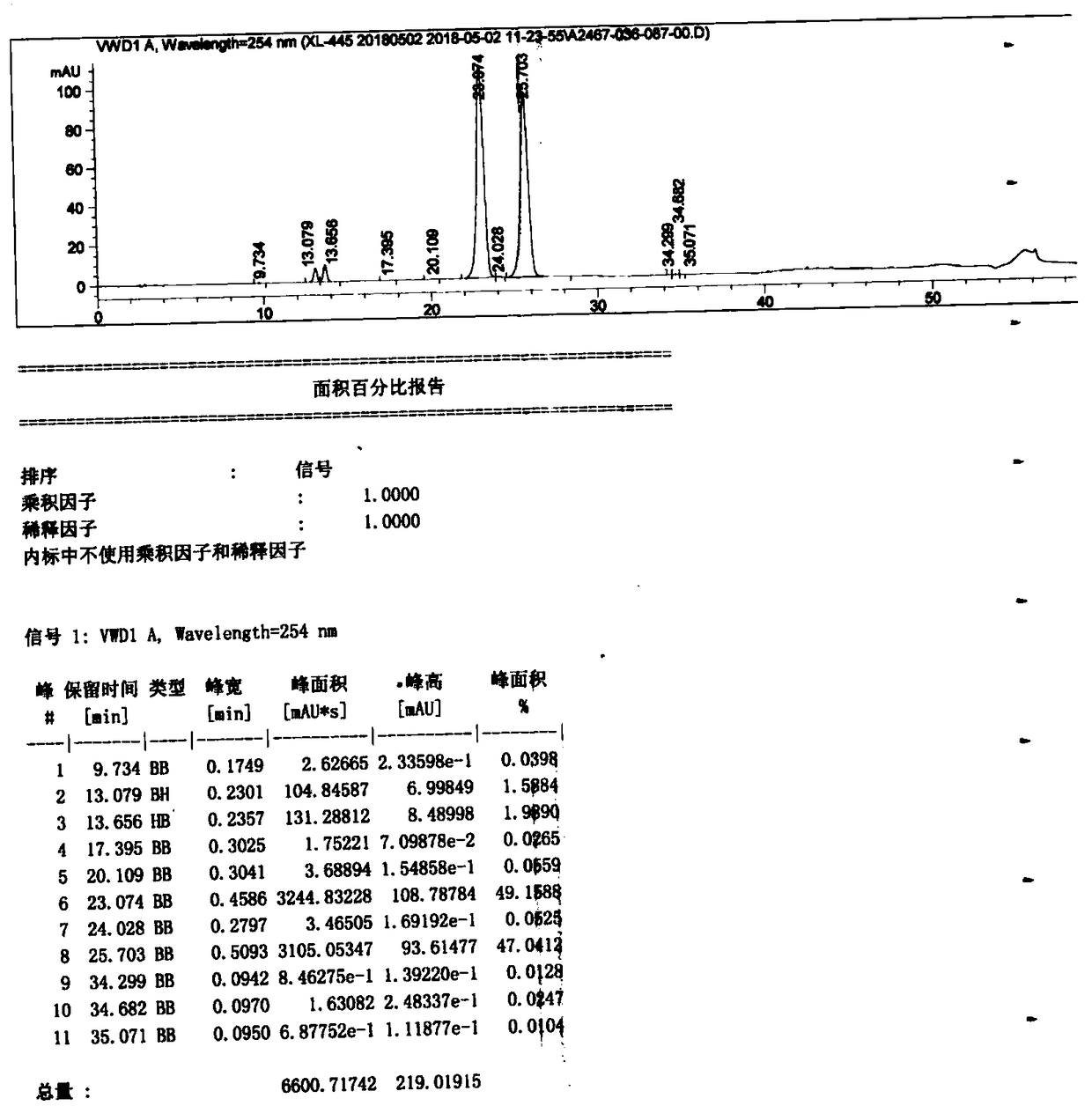

Atorvastatin calcium tablet and preparation method thereof

InactiveCN106176658AQuality improvementGood content uniformityMetabolism disorderPharmaceutical non-active ingredientsCross-linkAdhesive

The invention discloses an atorvastatin calcium tablet, which is prepared from the following raw and auxiliary materials in the weight ratio: 10-20 parts of atorvastatin calcium, 30-72 parts of calcium carbonate, microcrystalline cellulose pH 101 54-108 parts, 30-72 parts of lactose, 9-20.4 parts of croscarmellose sodium, 0.45-1.5 parts of polysorbate 80, 1.5-3 parts of high-substituted hydroxypropyl cellulose, 0.75 parts of magnesium stearate ~1.5 parts, Opadry YS‑1‑70404.5~15 parts. The inventor has fully considered the drug quality of atorvastatin calcium tablets and the simplicity of the production process, using a safe dose of alkaline pH agent calcium carbonate as a stabilizer, high-substituted hydroxypropyl cellulose aqueous solution as a binder, and wet granulation .

Owner:YANGTZE RIVER PHARM GRP SICHUAN HAIRONG PHARM CO LTD

Efficient contrast agent synthesizing method and application thereof

ActiveCN109134289AIn line with the concept of atomic economicsThere is no special requirement for the order of additionOrganic compound preparationCarboxylic acid amide separation/purificationSynthesis methodsIopromide

The invention discloses an efficient contrast agent synthesizing method. The method includes the following steps of firstly, preparing an intermediate mixture of a compound shown in the formula (II) and a compound shown in the formula (I) and / or (III); secondly, conducting separating to obtain the compound shown in the formula (II) and the compound shown in the formula (I) and / or (III); thirdly, taking the compound shown in the formula (II) to prepare a contrast agent (iopromide); fourthly, taking the compound shown in the formula (III) to prepare a contrast agent (iobitridol), and / or taking the compound shown in the formula (I) to prepare a contrast agent (iohexol, ioversol, iopentol or iodixanol). In the method, the iodic contrast agent is prepared by synthesizing and separating intermediates in the formula (II) and the formula (I) and / or the formula (III) and using the intermediates as the raw materials, the problem that diacylation byproducts need to be removed in an existing method is effectively solved, all the intermediates are effectively used, efficiency is high, and the actual application prospects are good. The formulas (I), (II) and (III) can be seen in the description.

Owner:XILING LAB CO LTD

Environment-friendly refining method of theobromine

The invention discloses an environment-friendly refining method of theobromine, and relates to the technical field of synthetic chemistry. The method comprises the following steps: (1) dissolving a crude product to prepare a sodium salt; (2) carrying out decoloration; and (3) carrying out acidification and crystallization. According to the method provided by the invention, the theobromine in a theobromine crude product is converted into a sodium salt by adding a sodium hydroxide solution and insoluble impurities are filtered out; then, the decoloration effect is ensured by use of a decolorant,and pigment impurities are removed; and then, by controlling the pH value during acidification, the residual rate of theobromine in crystallization mother liquor can be reduced and the purity of theobromine in precipitated crystals can be increased. The prepared finished product of theobromine is white or creamy in appearance, and the residual rate of 3-methylxanthine is less than 0.15% or more,and meets requirements of the quality standard of theobromine; and the refining yield reaches 95% or more, thus reducing the loss amount of theobromine in a refining process.

Owner:安徽省百花香料香精有限公司

Soft magnetic alloy smelting production method

InactiveCN1594626ASmelting capacity expansionShorten the production cycleInorganic material magnetismElectric arc furnaceSlag

A magnetically-soft alloy smelt production method is provided, which characterizes as (1) melting in arc furnace, carbon content of material and auxiliary materials being not restricted, operating using return oxygen blast method, element control : Cr,Ni at lower limit or more, Si<=0.35%,slag free tapping, (2)refining steel liquid using AOD furnace, blasting temperature>=1540 DEG C, blasting in whole course, liming according to Si content, blasting in1100m#+[3] / h, O#-[2] / Ar=4 mixed gas, decarbonizing and heating-up, Cr, Ni reclamation calculating according to 97%, 100%, C=0.10%, adjusting O#-[2] / Ar=1; C=0.01%, blasting argon instead of oxygen, flux 480m#+[3] / h, prereduction 7 min, sampling for analyzing slag, adding reduced slag, blasting Ar for melting slag for 5 min, blasting Ar 4min before tapping, tapping with slag, bag suspending temperature :liquid line+55 DEG C, (3)casting ingot of steel liquid under the protection of Ar. The invention has a simple smelt process, little restriction to auxiliary material, low cost, low carbon content. Magnetically-soft alloy ingot smelt in the invention has precise chemical element, high steel liquid metallurgy quality, fit for the quality standard.

Owner:SHANGHAI IRON & STEEL CO LTD NO 5 BAOSHAN IRON & STEEL GRP

Compound betamethasone suspension injection and preparation method thereof

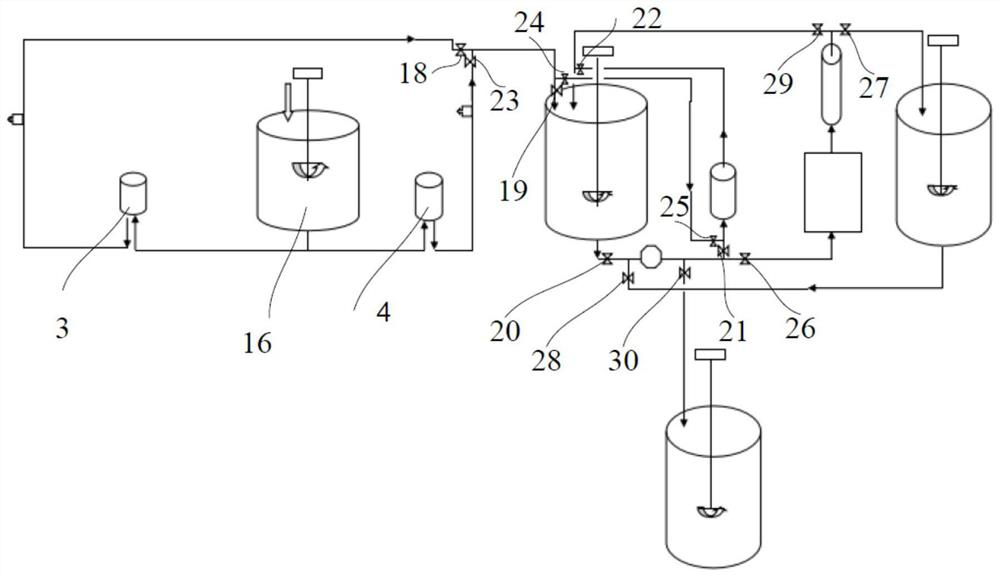

ActiveCN102526078AGood flocculation effectInvention effect is goodOrganic active ingredientsSolution deliveryBetamethasoneInjection solution

The invention finds applications of nipagin and phenylcarbinol for serving as flocculating agents in a compound betamethasone suspension injection, and screens an appropriate flocculating agent using amount. By adding the flocculating agents, the particle size, uniformity and precipitating speed of suspension fine particles can be controlled effectively, and the suspension fine particles can be vibrated and dispersed uniformly without being agglomerated after the injection is kept for a long time. The invention further provides a sterile process for producing the suspension injection by adapting to an industrial way. Due to the adoption of the process, the problems of degradation of a main medicament and agglomeration of fine particles existing in a terminal high-temperature sterilizing method are solved, and a sterile product with stable quality is finally obtained.

Owner:CHONGQING HUAPONT PHARMA

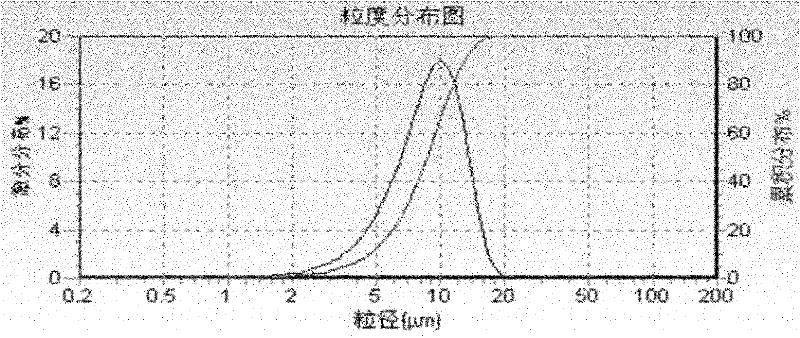

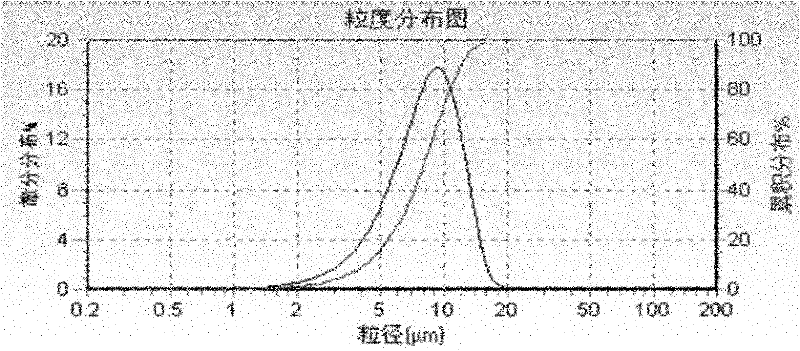

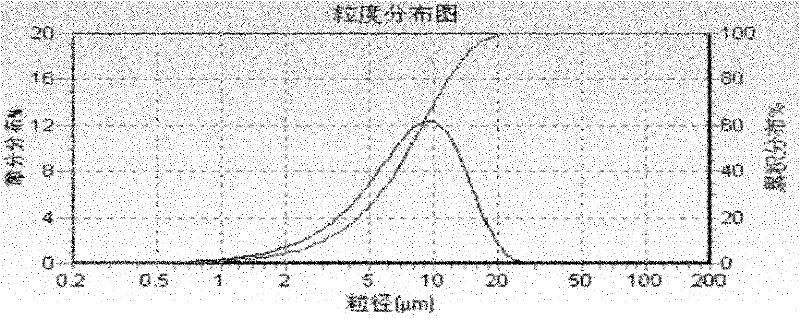

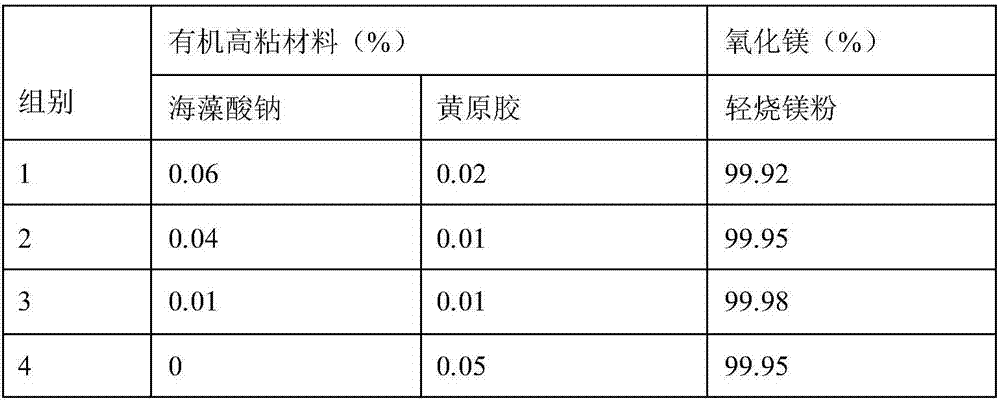

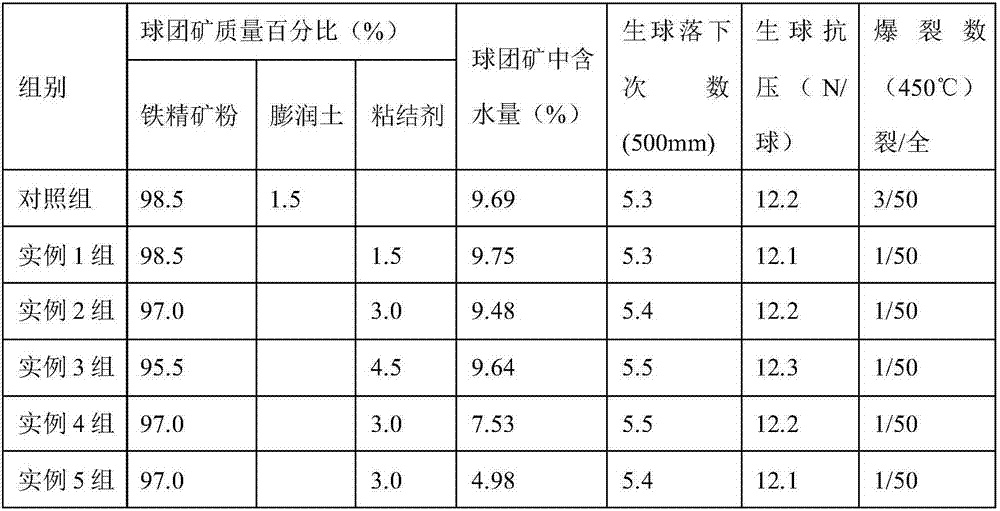

Magnesium-based pellet ore organic binding agent and preparation and using method thereof

The purpose of the present invention is to solve the defects of the pellet binder in the prior art and the problem that the sinter is affected by MgO, and provide a magnesium-based pellet organic binder and its preparation and use methods, which belong to the metallurgical Technical field of binder for sintering. The binder is composed of 0.02%-0.08% of organic high-viscosity material and 99.92-99.98% of magnesium oxide powder. The organic high-viscosity material is one or both of sodium alginate and xanthan gum, and the magnesium oxide powder is lightly burned magnesium Powder, the particle size is less than 0.044mm. The present invention uses magnesium material instead of bentonite, which can improve the quality of pellets, increase the strength and bursting temperature of green pellets, and improve the compressive strength of finished balls and the grade of total iron; at the same time, by adding MgO to pellets, it can not only improve the quality of pellets Excellent metallurgical properties, and can also reduce the MgO content in sinter, so that the quality of sinter and pellets can be improved together.

Owner:ANSTEEL GRP MINING CO LTD

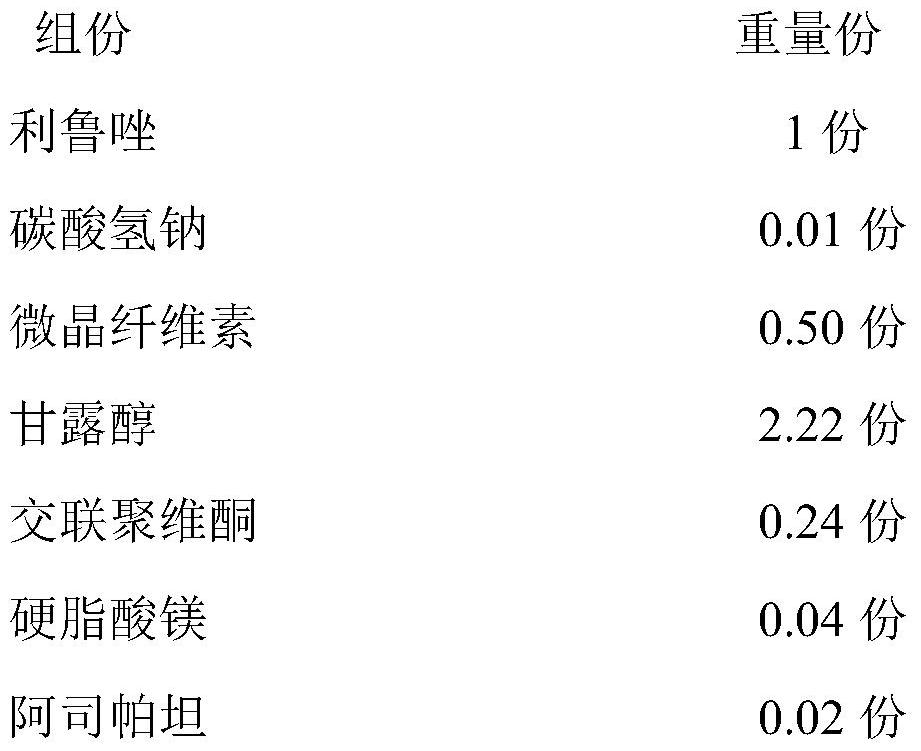

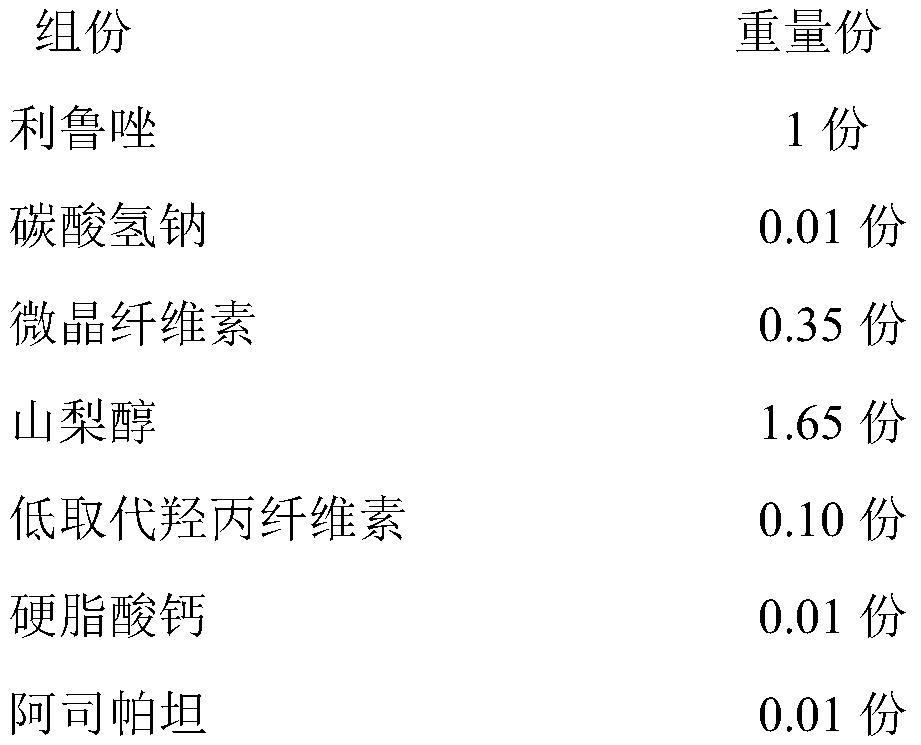

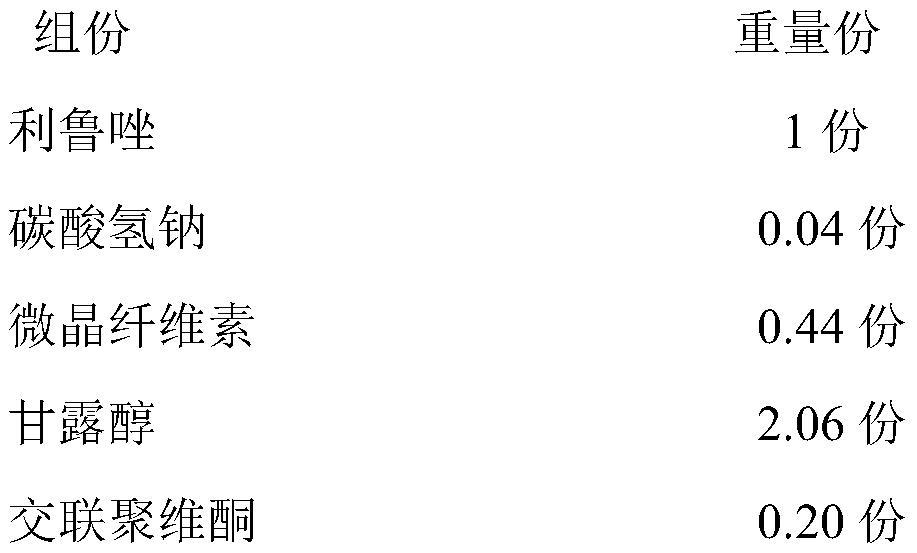

Riluzole orally disintegrating tablet and preparation method thereof

ActiveCN111821289AMeet the quality standard requirementsImprove quality stabilityOrganic active ingredientsAntineoplastic agentsSodium bicarbonateOrally disintegrating tablet

The invention relates to a riluzole orally disintegrating tablet and a preparation method thereof, and belongs to the field of preparations. The tablet is prepared from riluzole, sodium bicarbonate, afilling agent, a disintegrating agent, a lubricating agent and a flavoring agent. The preparation method comprises the following steps of (1) weighing riluzole, sodium bicarbonate and filler according to prescription amounts, and uniformly mixing the riluzole, the sodium bicarbonate and the filler with 50% of the disintegrating agent according to prescription amounts for later use; 2) adding themixture obtained in the step 1) into an ethanol water solution, granulating, drying, and sieving to obtain dry granules for later use; and 3) adding 50% of a prescription amount of the disintegratingagent and a prescription amount of the flavoring agent into the dry particles obtained in the step 2, uniformly mixing, adding a prescription amount of the lubricant, uniformly mixing, and pressing toobtain the riluzole orally disintegrating tablet. The orally disintegrating tablet prepared by the invention has the advantages of short disintegration time limit, high dissolution rate and no gravelfeeling, meets the quality standard requirement of the orally disintegrating tablet, and is suitable for industrial scale-up production.

Owner:LUNAN PHARMA GROUP CORPORATION

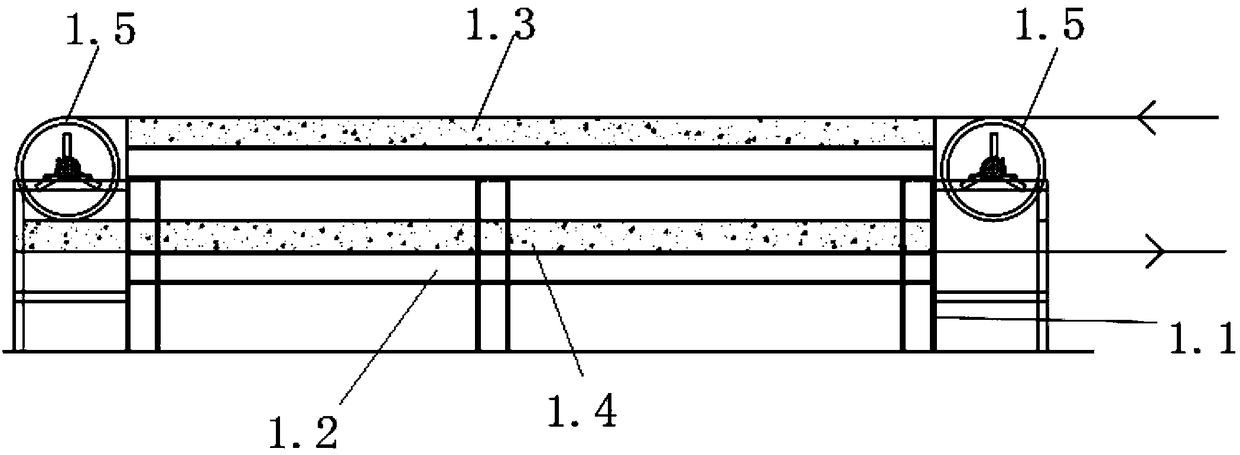

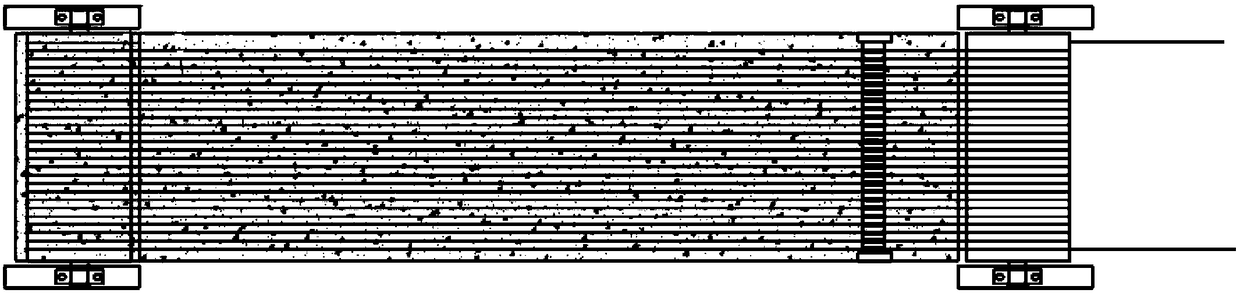

Steel wire rope for reinforcing belt framework and production equipment and technology thereof

InactiveCN108560296AHigh strengthHigh precisionSucessive textile treatmentsLiquid/gas/vapor removalZincUltimate tensile strength

The invention relates to a steel wire rope for reinforcing a belt framework and production equipment and technology thereof. The steel wire rope has ultrahigh strength and high accuracy; the steel wire rope has good integrity and good combination with polyurethane belts and cannot be layered; the steel wire rope can prevent a zinc layer from contacting water and can prevent secondary oxidation pollution; steel wire rebound stress can be eliminated, so that quality of steel wires is improved; furthermore, the length of the steel wire rope is super long, and tensile strength at the connector position can meet a steel wire rope quality standard requirement; the steel wires cannot deviate when being drawn by a deformation cone of a wire drawing mold, and stress is prevented from being generated; thus, accuracy of the steel wires is improved, and quality is improved; when the steel wires are combined into a rope, internal stress twisting to the center is generated in advance, so that the steel wire rope is not prone to loosening, and the rope diameter can be more accurate; a wire release assembly can adjust a wire releasing speed by self elasticity of a spring, so that wire releasing tension can be stabilized, and the steel wires can be evenly stressed in a wire releasing process; as the single wire is evenly stressed, drawn in a high compression mode and tight twisting are realized, the manufactured steel wire rope has the advantages of low elongation and higher quality.

Owner:JIANGYIN WEIYU METAL PROD

Method for manufacturing brick from waste ceramic

ActiveCN102501294AImprove vibrationIncrease intensitySolid waste managementCeramic shaping apparatusMicrowaveBrick

The invention discloses a method for manufacturing a brick from waste ceramic, which comprises the following production steps of: (1) smashing the waste ceramic powder until the particle diameter is 3-12mm; (2) adding the waste ceramic particles and sand of which the particle diameter is 0.2-1.5mm into a stirrer at the mass ratio of 1: (0.2-0.5) to be stirred; (3) keeping the moisture in the stirrer to be 80%, adding cement which accounts for 0.05-0.1wt% of the waste ceramic particles into the stirrer, and vibrating and mixing under the microwave for 20-40 minutes; (4) taking the weight of the waste ceramic particles in the step (2) as a reference, mixing and stirring 0.25-1 part by weight of sand and stone mixture, 0.1-0.5 part by weight of cement, 0.03-0.1 part by weight of water and the waste ceramic particles for 10-30 minutes, wherein sand in the sand and stone mixture accounts for 10-40% of the total weight, and the particle diameter of the stone is 0.5-2cm; and (5) sending the stirred mixed material into a brick manufacturing machine to be shaped. The brick manufactured with the method has the advantages of good compactness and high intensity, and the product performance conforms to the relevant quality standard requirement.

Owner:潮州市富丽生态环保科技有限公司

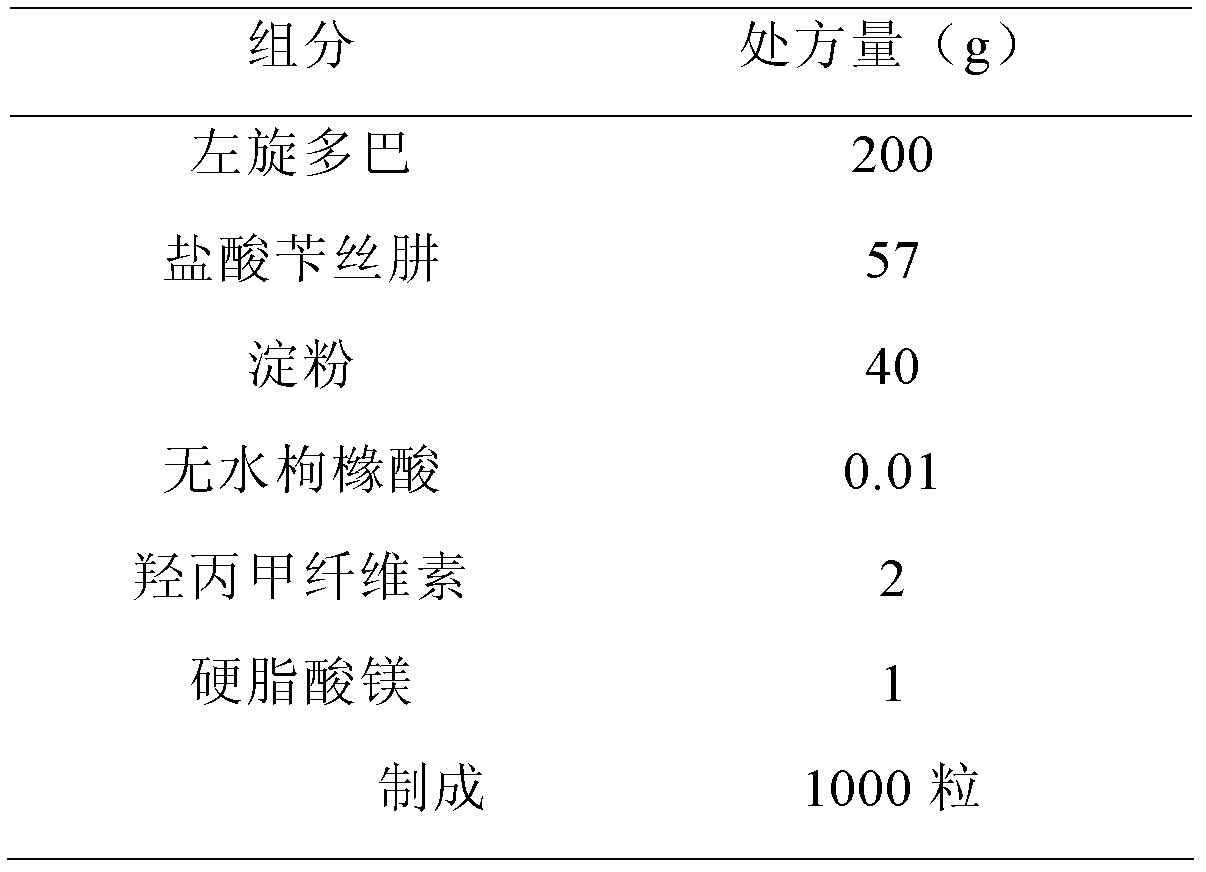

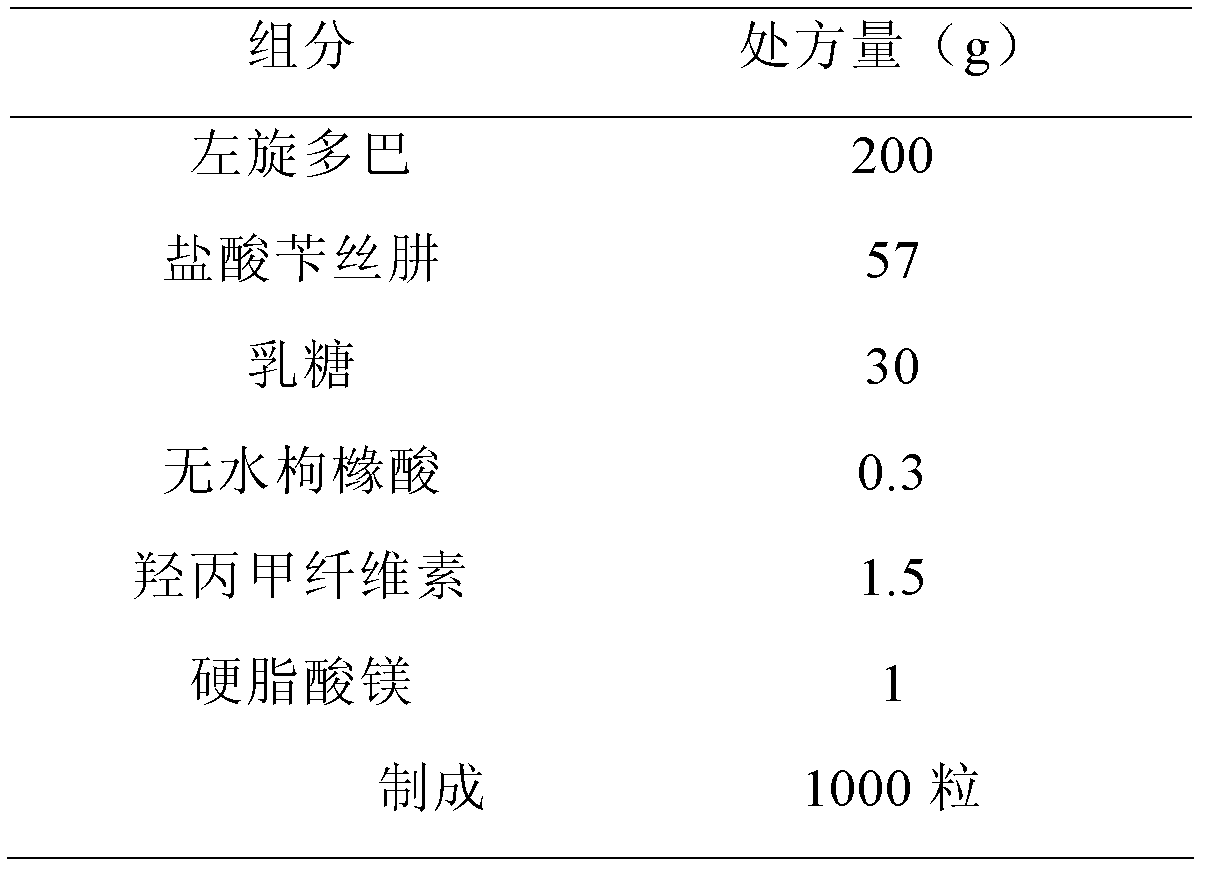

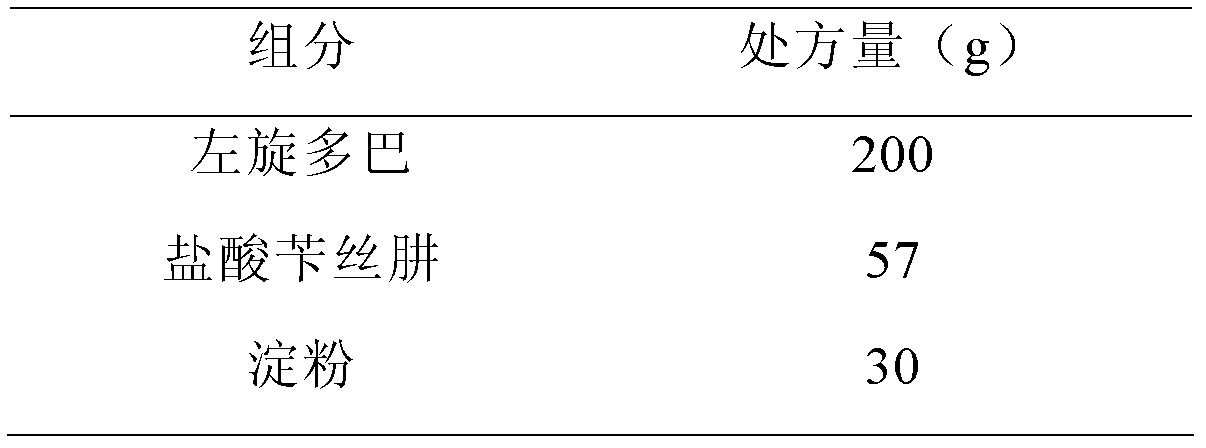

Dopamine prodrug composition and preparation method thereof

ActiveCN102885804AGood stabilitySimple recipeOrganic active ingredientsNervous disorderQuality standardAdhesive

The invention relates to a dopamine prodrug composition and a preparation method of the dopamine prodrug composition. The invention provides a pharmaceutical composition of dopamine prodrug, and the composition comprises the dopamine prodrug, benserazide hydrochloride, an adhesive, a stabilizer and a pharmaceutically acceptable carrier. The pharmaceutical composition containing the dopamine prodrug provided by the invention has excellent stability and does not occur color change, and is capable of effectively guaranteeing that the product quality meets a quality standard requirement within a storage period. The pharmaceutical composition containing the dopamine prodrug provided by the invention has a simple prescription, and auxiliary materials are cheap and available with a small amount; the preparation process provided by the invention is simple and easy to control, used devices are the most conventional workshop production devices, the cost is low, and the preparation process is suitable for industrial production.

Owner:SHANGHAI SINE PHARMA LAB

A kind of No. 100 unleaded aviation gasoline and preparation method thereof

ActiveCN106398783BMeet the quality standard requirementsTackling lead pollutionLiquid carbonaceous fuelsAviationGasoline

Owner:EAST CHINA UNIV OF SCI & TECH

Traditional Chinese medicine for treating cold and preparation method thereof

ActiveCN104474236AMeet the requirements of drug quality standardsMeet the quality standard requirementsGranular deliveryRespiratory disorderSide effectOnosma paniculatum

The invention provides a traditional Chinese medicine for treating cold and a preparation method thereof. The traditional Chinese medicine is a medicament which is prepared from the following raw materials in parts by weight: 416 parts of fructus forsythia, 416 parts of dried rehmannia root, 416 parts of bupleurum candollei, 208 parts of radix scrophulariae, 208 parts of folium mori, 208 parts of thunberg fritillary bulbs, 416 parts of South Isatis Root, 208 parts of dandelion, 208 parts of onosma paniculatum, 416 parts of platycodon grandiflorum, 416 parts of semen raphani and 208 parts of liquorice. The traditional Chinese medicine provided by the invention is exact in curative effect, few in side effect and feasible in preparation method.

Owner:JIANMIN GROUP YEKAITAI SINOPHARM (SUIZHOU) CO LTD

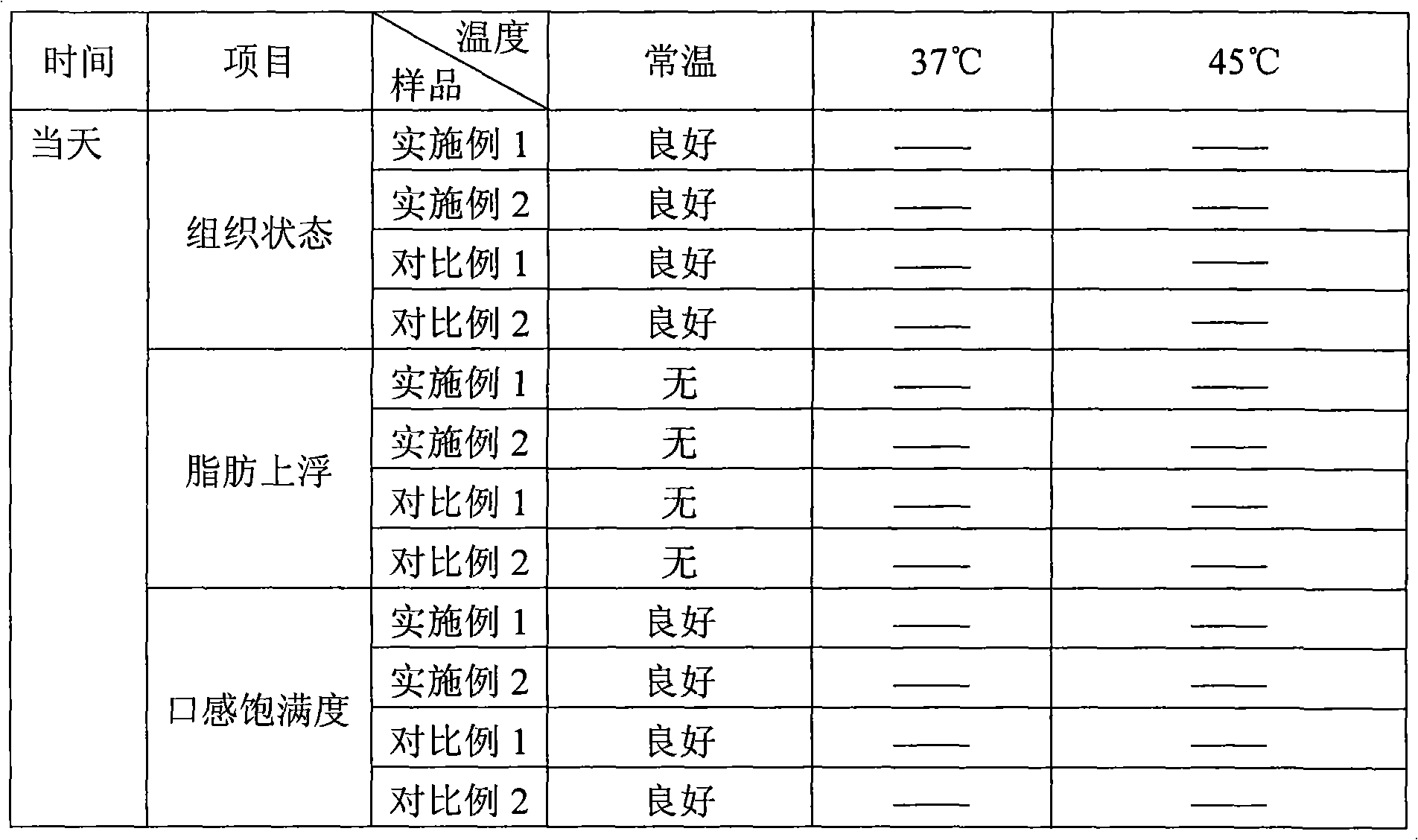

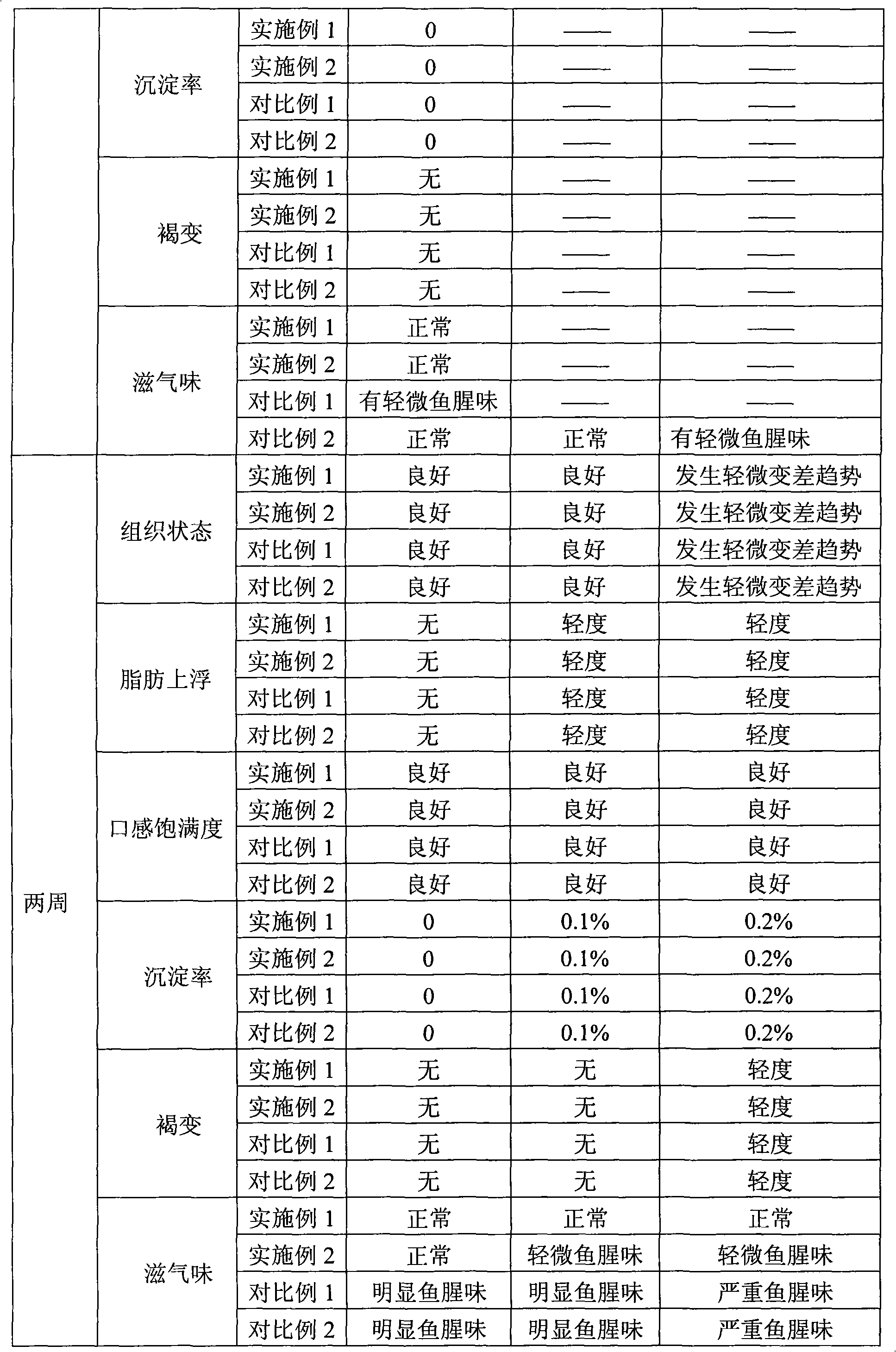

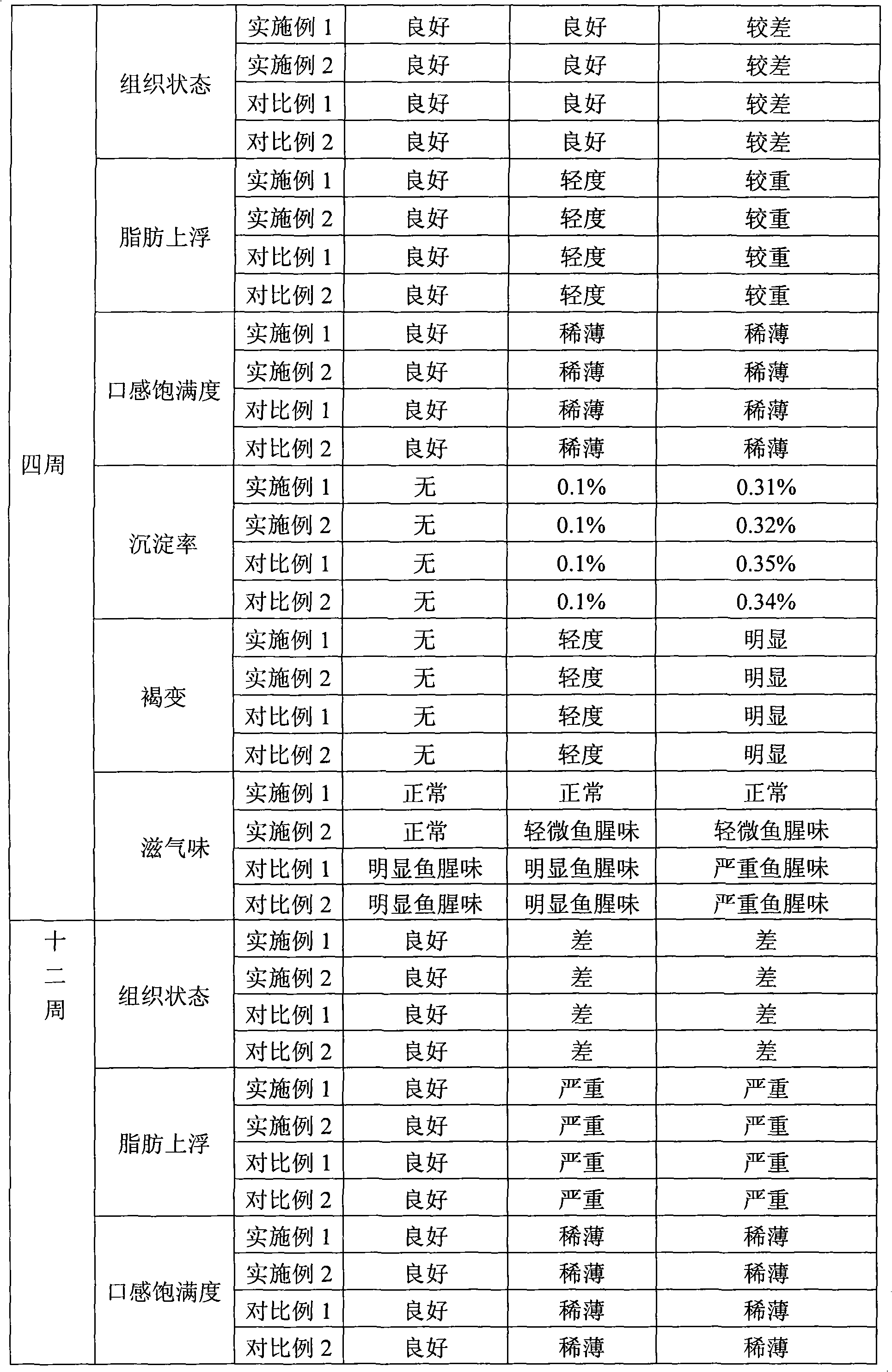

Method for producing liquid state dairy product containing fish oil and products thereof

ActiveCN101406219AEvenly distributedSlow down or prevent fishy smellMilk preparationFood preparationFlavorAdditive ingredient

The invention provides a method for producing a liquid dairy product containing fish oil and a product thereof, in particular to the method for producing the liquid dairy product containing the fish oil through adding the fish oil into the liquid dairy product, and the liquid dairy product containing the fish oil which is produced and obtained according to the method. In the method, the fish oil is added into ingredient milk, is stirred and homogenized at a specific temperature to undergo pre-emulsification treatment, and is added into the liquid dairy product. Through the process design, the method can effectively reduce or eliminate poor flavor influence on the liquid dairy product brought by the addition of the fish oil and provide guarantee for realizing good stability, flavor and mouthfeel of the product in shelf life.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

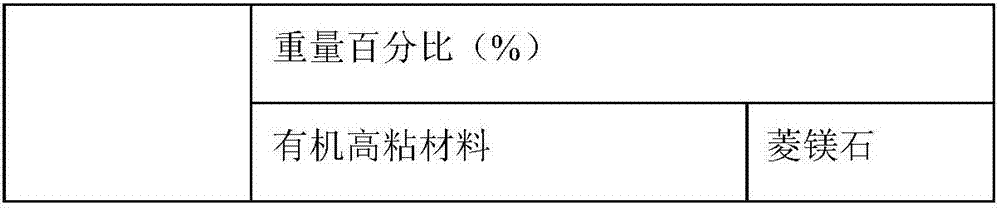

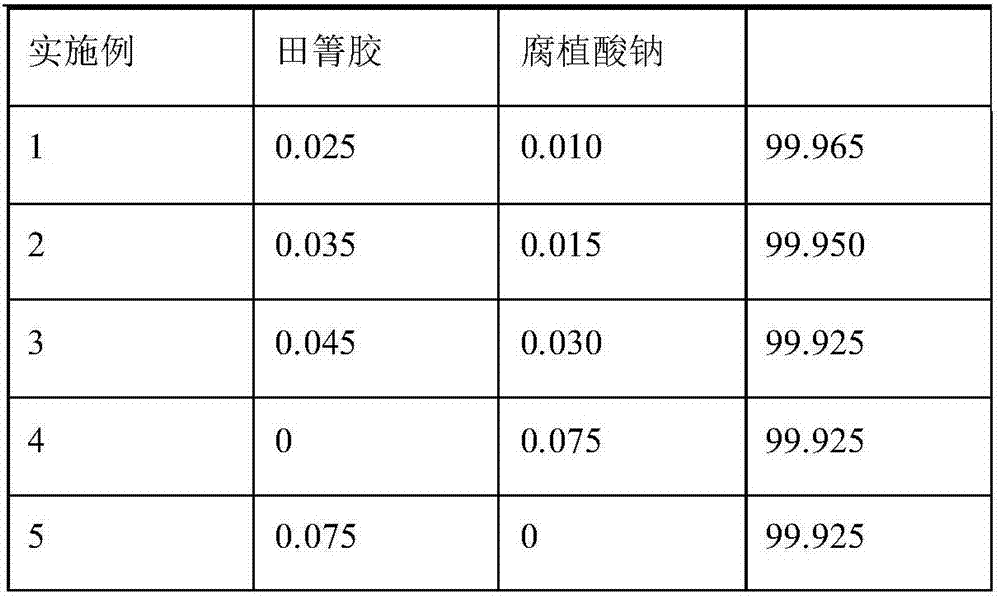

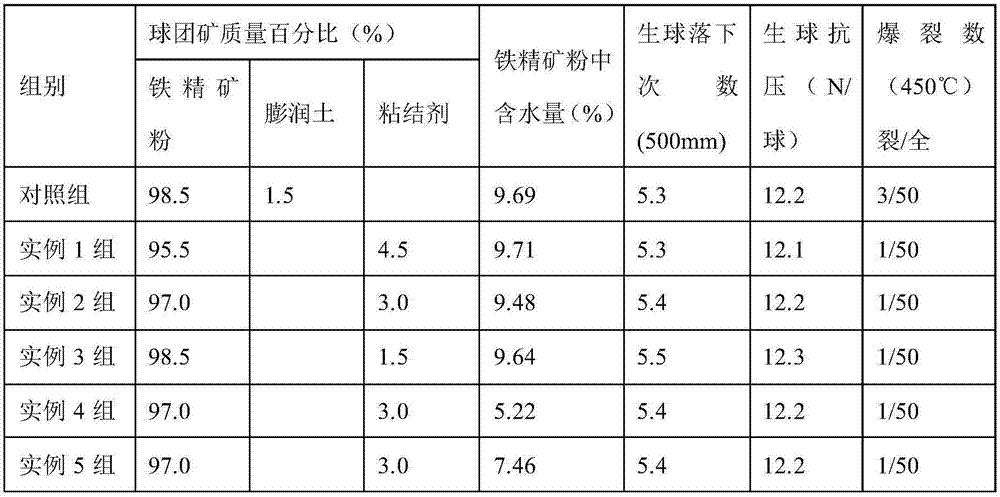

Pellet ore binding agent containing magnesium oxide and preparation and using method of pellet ore binding agent

InactiveCN107345272AMeet the quality standard requirementsImproved metallurgical propertiesCompressive strengthUltimate tensile strength

The object of the present invention is to provide a pellet binder containing magnesium oxide and its preparation and use method in order to solve the defect of the pellet binder in the prior art and the problem that the sinter is affected by MgO. It is composed of 0.035%-0.075% of organic high-viscosity materials and 99.925%-99.965% of magnesium raw materials. The organic high-viscosity materials are one or two of Tianqing gum and sodium humate, and the magnesium raw materials are those with magnesium oxide content ≥ 45%. Magnesite, the particle size is less than 0.044mm, and the mass percentage of magnesite is more than 95%. In this invention, magnesium raw material is used to replace bentonite, which can improve the quality of pellets, increase the strength and bursting temperature of green pellets, and improve the compressive strength and total iron content of finished pellets. At the same time, adding MgO to the pellets can not only improve the metallurgical properties of the pellets, but also reduce the MgO content in the sinter, so that the quality of the sinter and the pellets can be improved together.

Owner:ANSTEEL GRP MINING CO LTD

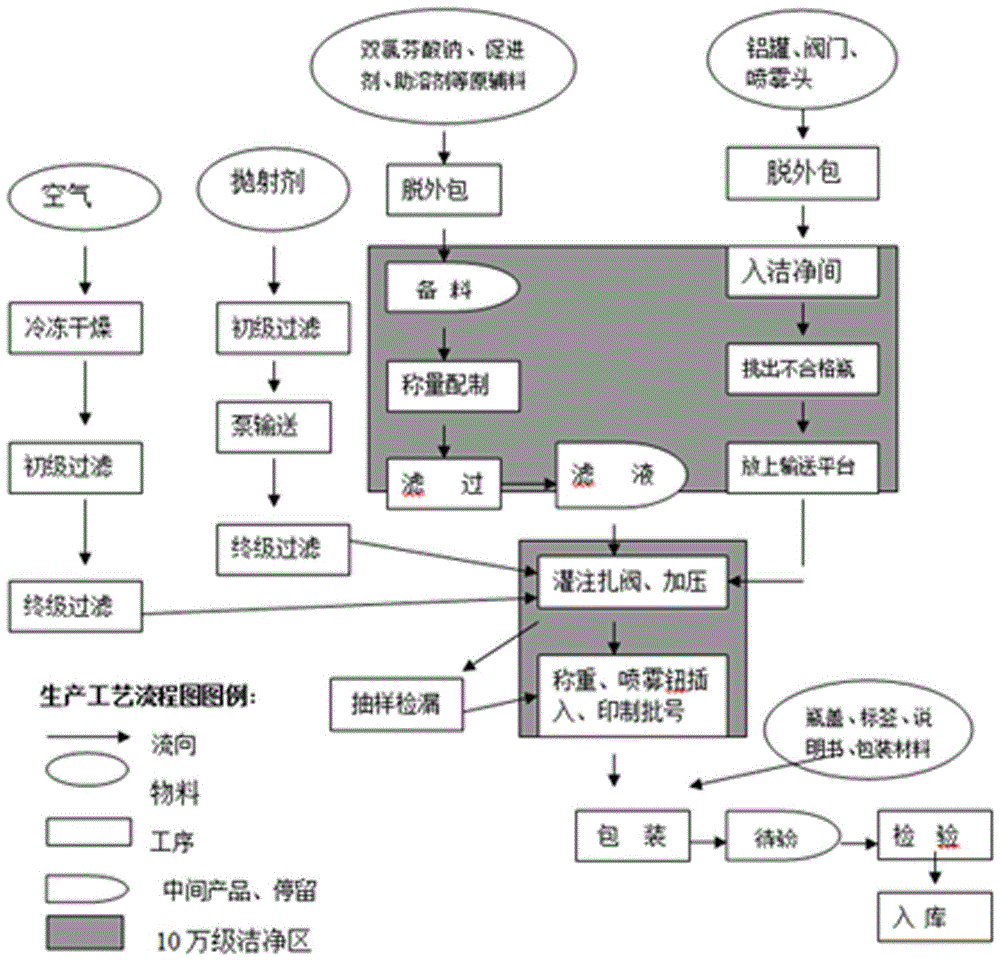

Aerosol with efficacies of diminishing inflammation and easing pain and preparation method of aerosol

InactiveCN106562928AQuick effectPromote absorptionOrganic active ingredientsAntipyreticGas phaseDiclofenac Sodium

The invention relates to an aerosol with the efficacies of diminishing inflammation and easing pain and a preparation method of the aerosol. The aerosol is composed of a gas phase and a liquid phase, wherein the gas phase is a propellant; the liquid phase is prepared from the following raw materials in parts by weight: 10-20 parts of diclofenac sodium, 5-10 parts of laurocapram, 20-50 parts of propylene glycol, 30-40 parts of alcohol, and 10-20 parts of polyethylene glycol; the weight ratio of the gas phase to the liquid phase is 1: (2-6); the propellant is one or more of dimethylmethane and butane mixture, iso-butane, tetrafluoroethane, heptafluoropropane and dimethyl ether. The aerosol with the efficacies of diminishing inflammation and easing pain provided by the invention has the efficacies of diminishing inflammation and relieving swelling, resolving heat and easing pain, and the like; the test of many clinical research institutions proves that the aerosol provided by the invention has very good treatment effects for sport injuries or the acute attack of acute arthritis such as gout and degenerative arthritis.

Owner:广东同德药业有限公司

Technique for refining L-tryptophan

The invention pertains to the technical field of biological engineering and particularly discloses a technique for refining L-tryptophan. The mixed solvent of water and propanol is taken as a dissolvent for dissolving L-tryptophan crude product; after the L-tryptophan crude product is dissolved completely, a reaction is conducted on the solution at the temperature of 50-80 DEG C for 100-120min and a transparent and clean solution containing the product is obtained by filtration, wet L-tryptophan is obtained by removing water from the solution, and then fine L-tryptophan product is obtained by drying the wet L-tryptophan. The technique is simple. In the fine L-tryptophan product obtained by the refining technique, the mass percentage of the L-tryptophan is over 98.5 percent, transmittance is higher or equal to 90 percent (a relative value), optical rotation is -30.0 degrees to -32.5 degrees, all meet requirements for quality standard, and product yield is higher than 85 percent.

Owner:河南孟成生物药业股份有限公司

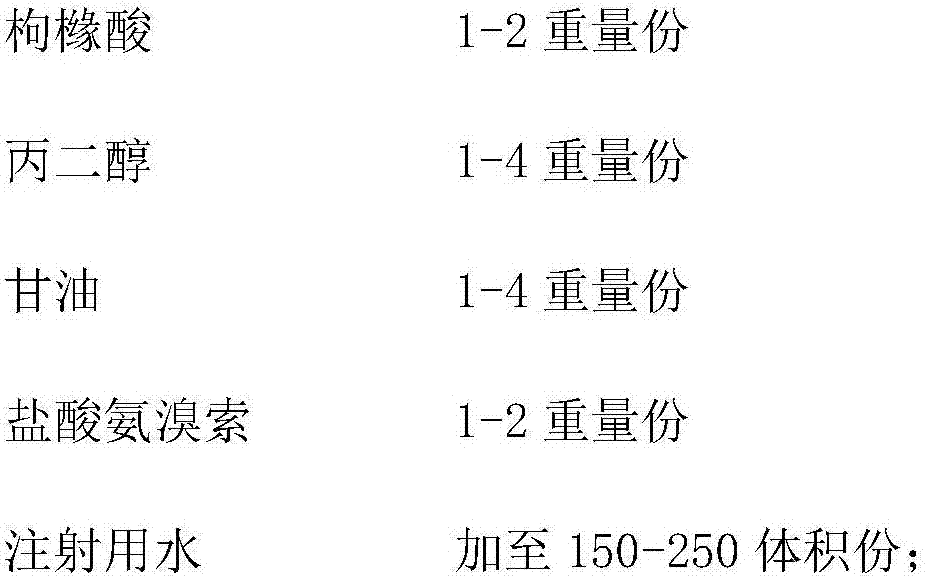

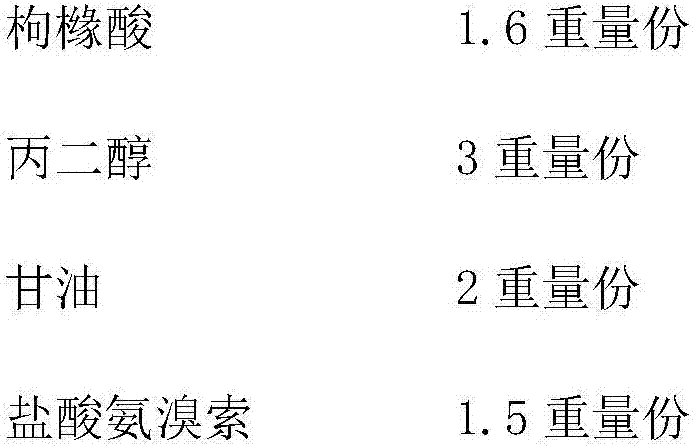

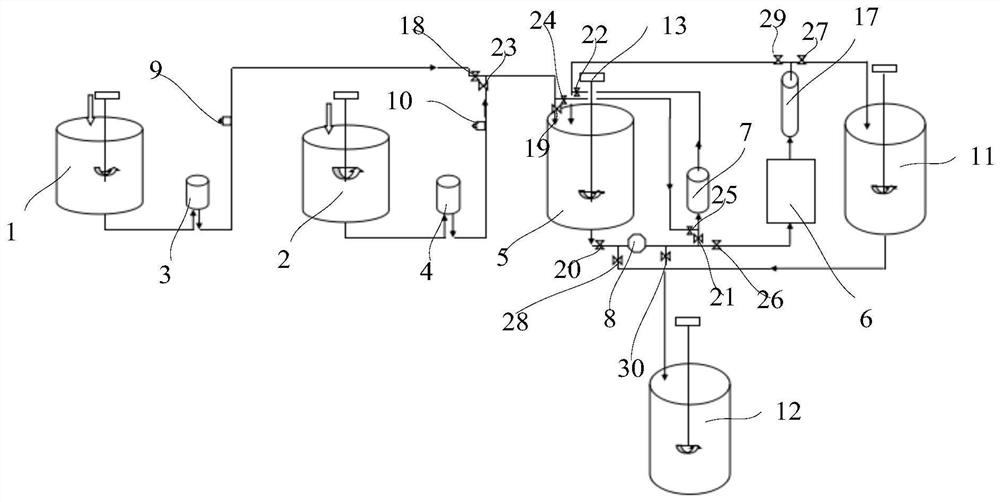

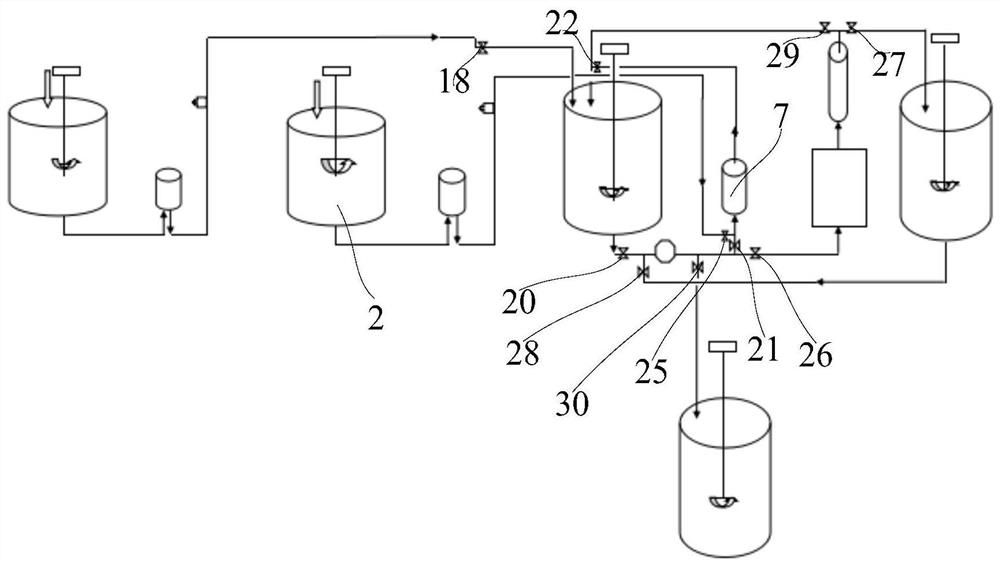

Ambroxol hydrochloride injection composition filled in plastic ampoule and preparation method of same

InactiveCN107496349AMeet the quality standard requirementsAvoid easy openingOrganic active ingredientsPharmaceutical containersGlycerolPropylene glycol

The invention discloses an ambroxol hydrochloride injection composition filled in a plastic ampoule and a preparation method of same. The injection composition is prepared from, by weight, 1-2 parts of citric acid, 1-4 parts of propylene glycol, 1-4 parts of glycerol and 1-2 parts of ambroxol hydrochloride, water for injection added to 150-250 parts by volume. The ambroxol hydrochloride injection composition has reliable quality, satisfies quality standard demand of ambroxol hydrochloride injection and is suitable for industrial production.

Owner:HAINAN XIANTONG PHARMA CO LTD

Preparation method of emulsion containing oleum fructus bruceae

ActiveCN112972374ASmall particle sizeDecreased centrifugal stability constantPharmaceutical non-active ingredientsEmulsion deliveryOil phaseCreaming

The invention provides a preparation method of an emulsion containing oleum fructus bruceae. The preparation method of the emulsion containing the oleum fructus bruceae comprises the following steps: firstly, performing circular emulsifying and shearing on a water-phase material and an oil-phase material to form a primary emulsion; and then, performing circular homogenizing on the primary emulsion to obtain a uniform emulsion which can be filtered by a sterilization filter. More specifically, the step of performing circular emulsifying and shearing means to perform circular shearing on the materials in an emulsifying and shearing tank and a pipeline shearing device. The emulsion containing the oleum fructus bruceae prepared by the preparation method has obviously reduced particle size, so that the emulsion can be filtered through a sterilization-grade filter so as to meet sterile test requirement; and moreover, the emulsion also has greatly improved stability.

Owner:沈阳药大雷允上药业有限责任公司

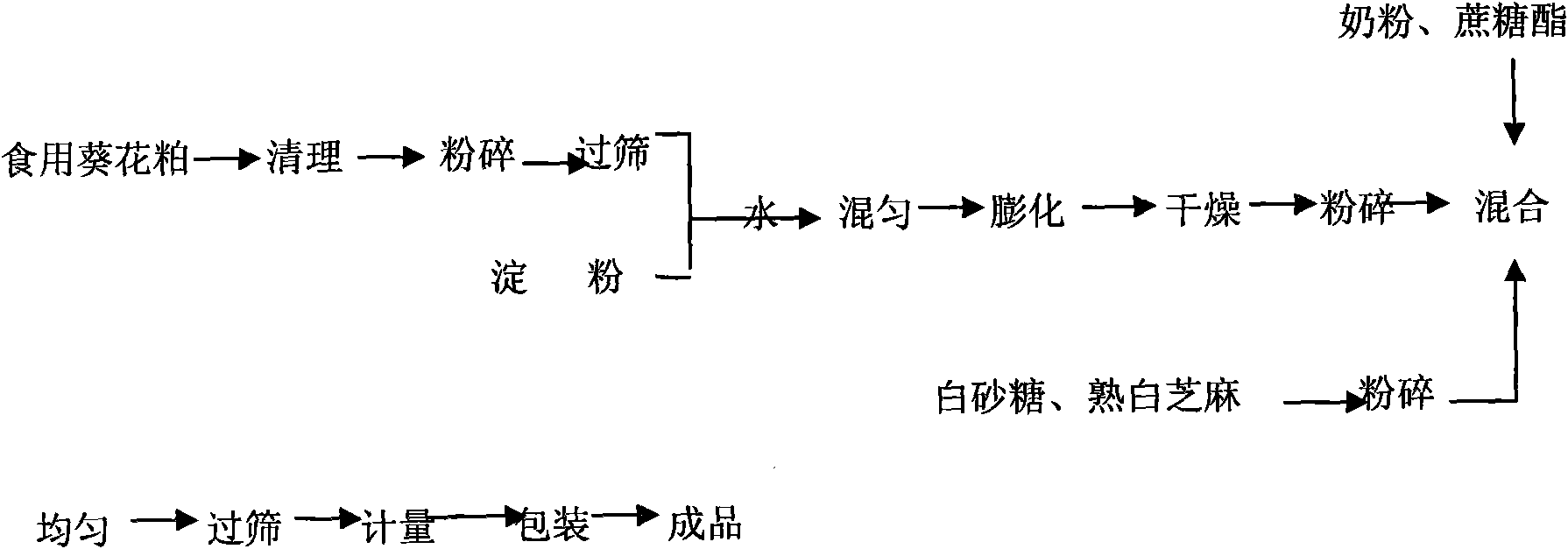

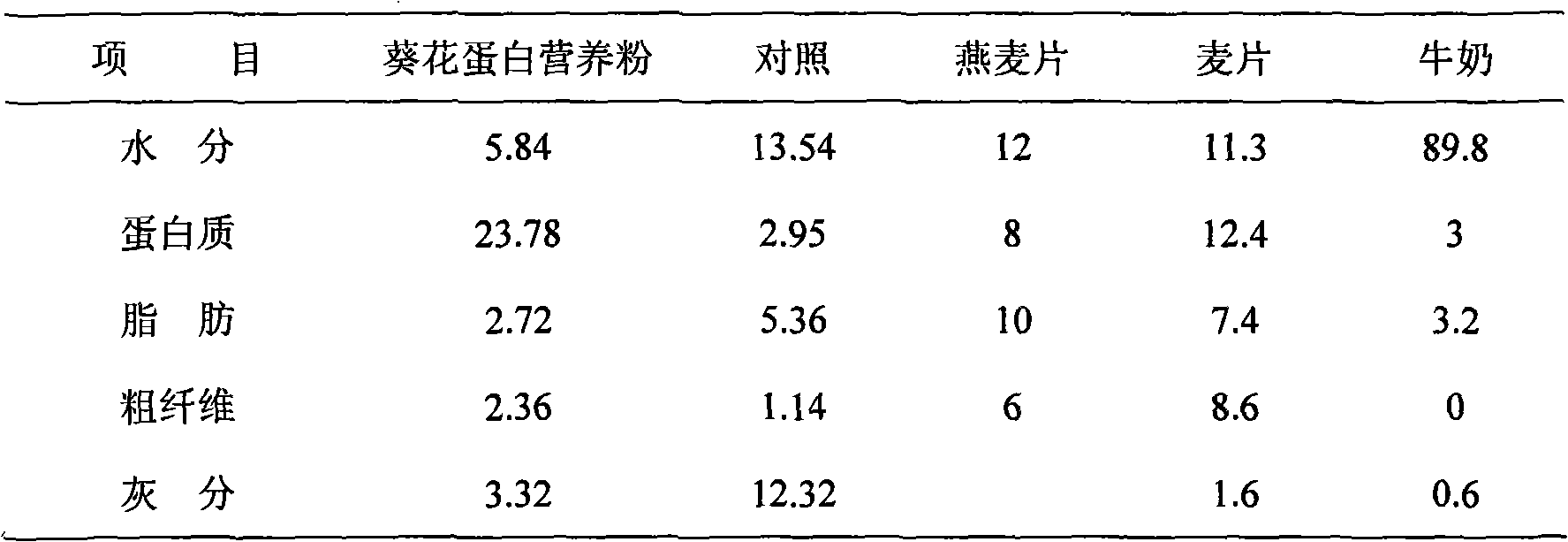

Sunflower protein nutritious powder and method for preparing same

InactiveCN101642266AIncrease added valueMeet the quality standard requirementsFood shapingFood preparationFiberFood flavor

The invention aims to provide a sunflower protein nutritious powder and a method for preparing the same. In the method, edible sunflower meal serving as a main material is mixed with starch in a certain ratio and then added with auxiliary materials such as white granulated sugar, black sesame, powdered milk, maltodextrin and emulsifier, and the mixture undergoes the processes of grinding, screening, conditioned roasting and the like to form the sunflower protein nutritious powder. Compared with the conventional nutritious powder, the main material and auxiliary materials are strictly requiredon grinding degree, so that the contents of protein and coarse fiber are improved, the sunflower protein nutritious powder has good rapid dissolving property and taste, the addition of cream essence has obvious effect on improving flavor of the nutritious powder, and simultaneously the material utilization ratio and the nutritious utilization ratio of the sunflower cake meal are also improved.

Owner:甘肃敬业农业科技有限公司

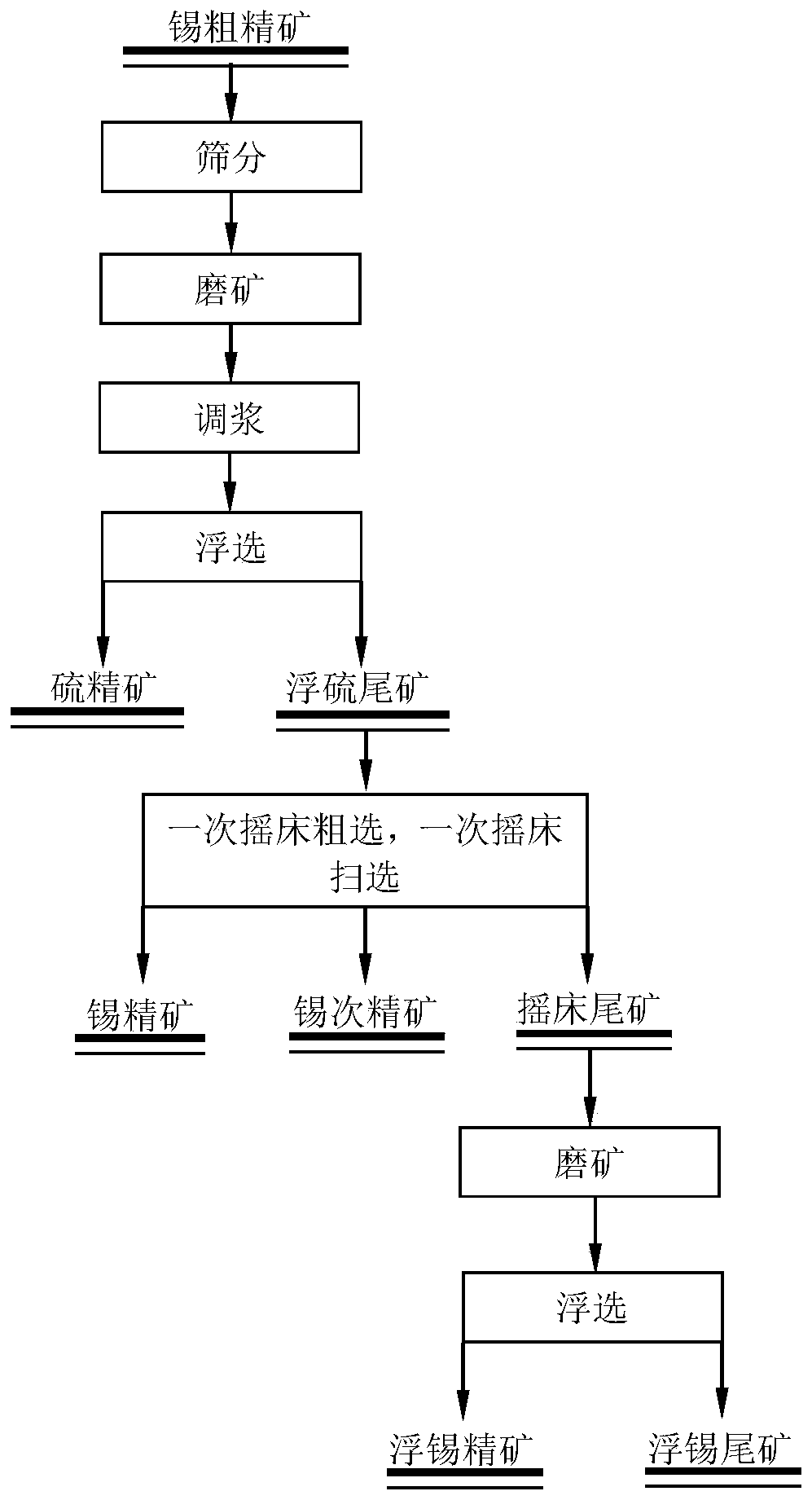

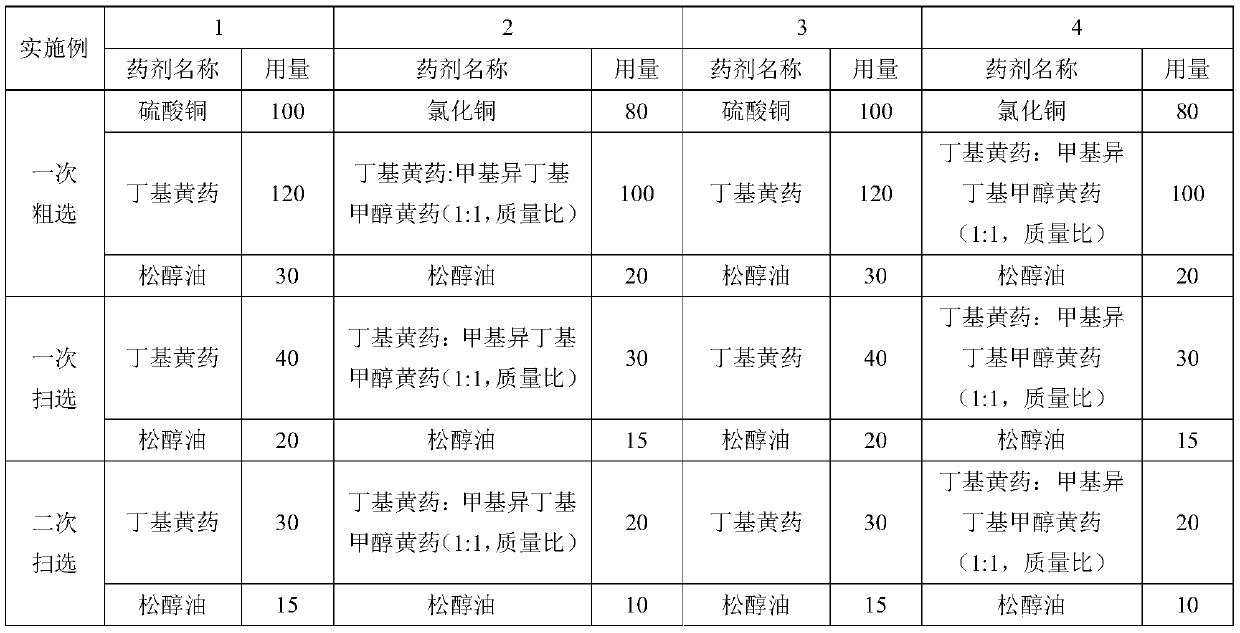

Separation method for high-arsenic high-sulfur tin rough concentrate

InactiveCN110142131APrevent easy crushingGuaranteed flotation to remove the selected particle sizeFlotationWet separationMineral flotationSlurry

The invention relates to a separation method for high-arsenic high-sulfur tin rough concentrate. The separation method comprises the following steps of 1, conducting screening and ore grinding in advance; 2, conducting slurry mixing; 3, conducting flotation separation; 4, conducting gravity separation; and 5, conducting flotation separation. According to the separation method, the mode of prescreening and closed circuit grinding is adopted, the problem that tinstone is likely to be over-crushed is effectively prevented, and in addition, it is guaranteed that the flotation removal selection particle size of arsenic-sulfur ore is guaranteed; the floatability difference generated among pyrite, arsenopyrite and the tinstone is utilized, and in an acid environment, the arsenic-sulfur ore is activated through an activating agent; the arsenic-sulfur ore is removed through flotation, and the problem that sulfur and arsenic of tin concentrate are out of standard is effectively reduced; screening is conducted through a multi-segment table and floatation of the tinstone, the product structures of the tin concentrate and tin sub-concentrate can be distributed more reasonably. The tin grade ofthe tin concentrate obtained through the beneficiation method is greater than 45%, and the recovery rate of tin is greater than 85%; the tin grade of the tin sub-concentrate is greater than 4%, and the recovery rate of tin is greater than 11%; and according to the technical indicators, the quality of the sulfur and the arsenic of the tin concentrate meets the standard requirement.

Owner:广东省资源综合利用研究所

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com