Steel wire rope for reinforcing belt framework and production equipment and technology thereof

A technology of steel wire rope and steel wire, applied in the field of steel wire rope, can solve the problems of affecting quality, inability to guarantee, waste of glue, etc., and achieve the effect of preventing secondary oxidation pollution, avoiding waste of glue and saving workshop space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

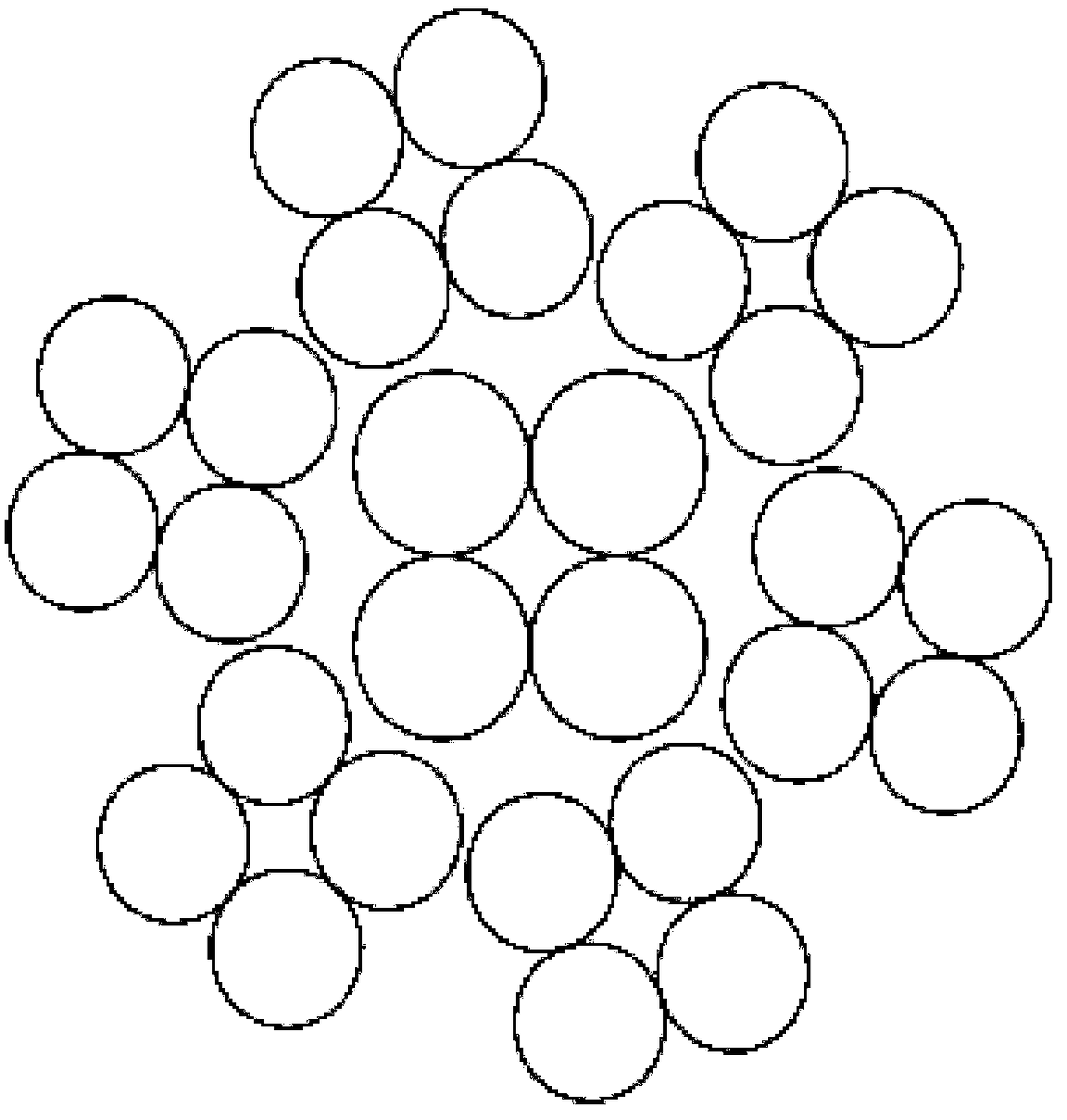

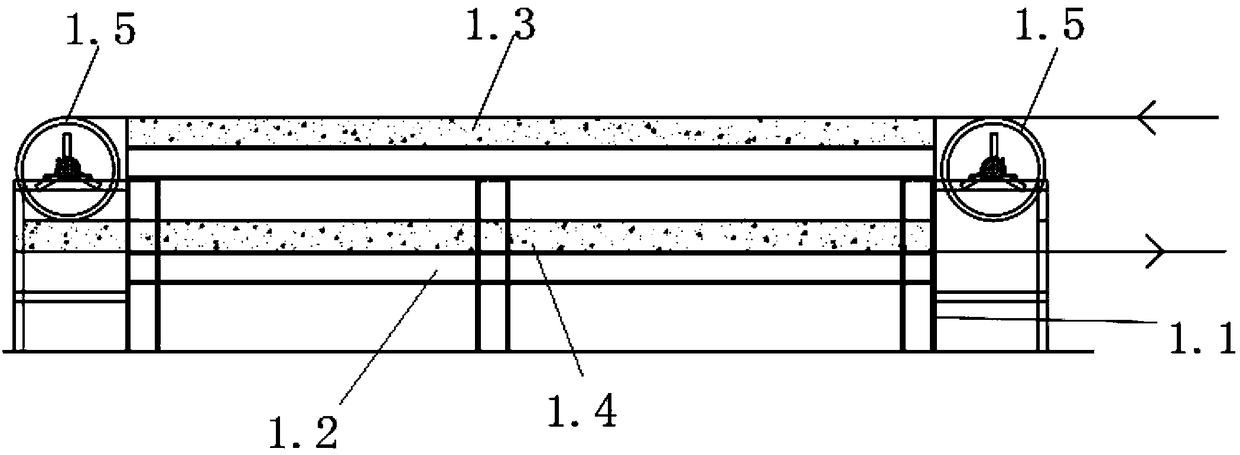

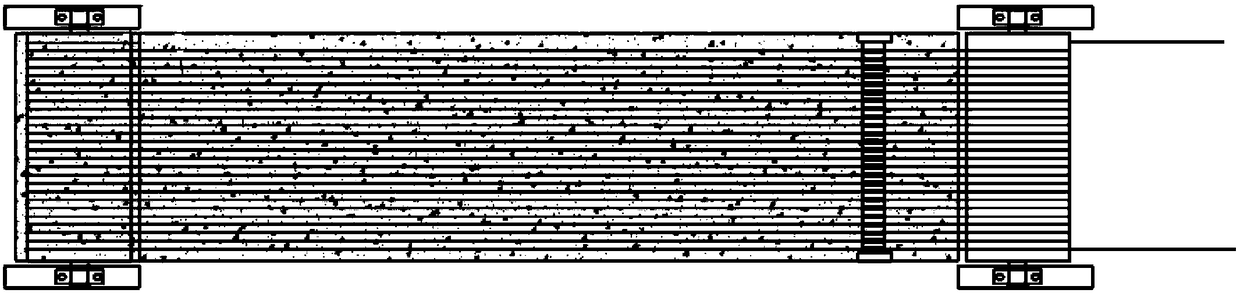

[0069] see figure 1 , the present invention relates to a steel wire rope for belt frame reinforcement and its production equipment and process. The steel wire rope for belt frame reinforcement has a 7*4 structure, and the steel wire rope is twisted from a central strand and six peripheral steel wire strands. , and the size and structure of the central strand and the peripheral steel strand are the same. They are all 1*4 structure steel wire ropes twisted by four steel wires with a diameter of 0.12±0.005mm. The diameter is 0.28±0.01mm. The central strand and six peripheral steel wires After stranding the rope, a 7*4 structure is formed with a diameter of 0.86mm.

[0070] The process of this kind of steel wire rope for belt skeleton reinforcement is as follows:

[0071] 1. Wire rod purchase: Purchase SWRH72A type 5.5mm±0.04mm diameter wire rod.

[0072] 2. Large open blank: Use a straight wire drawing machine to draw the 5.5±0.04mm wire rod to 2.0±0.04mm, the surface is free o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com