Separation method for high-arsenic high-sulfur tin rough concentrate

A separation method and rough concentrate technology, which is applied in the field of separation of high-arsenic and high-sulfur tin rough concentrate, can solve problems such as unsatisfactory recovery indicators, inconvenient popularization and application, and cumbersome operation, so as to reduce the problem of excessive sulfur and arsenic and improve the product structure. Reasonable distribution, preventing cassiterite from being easily crushed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

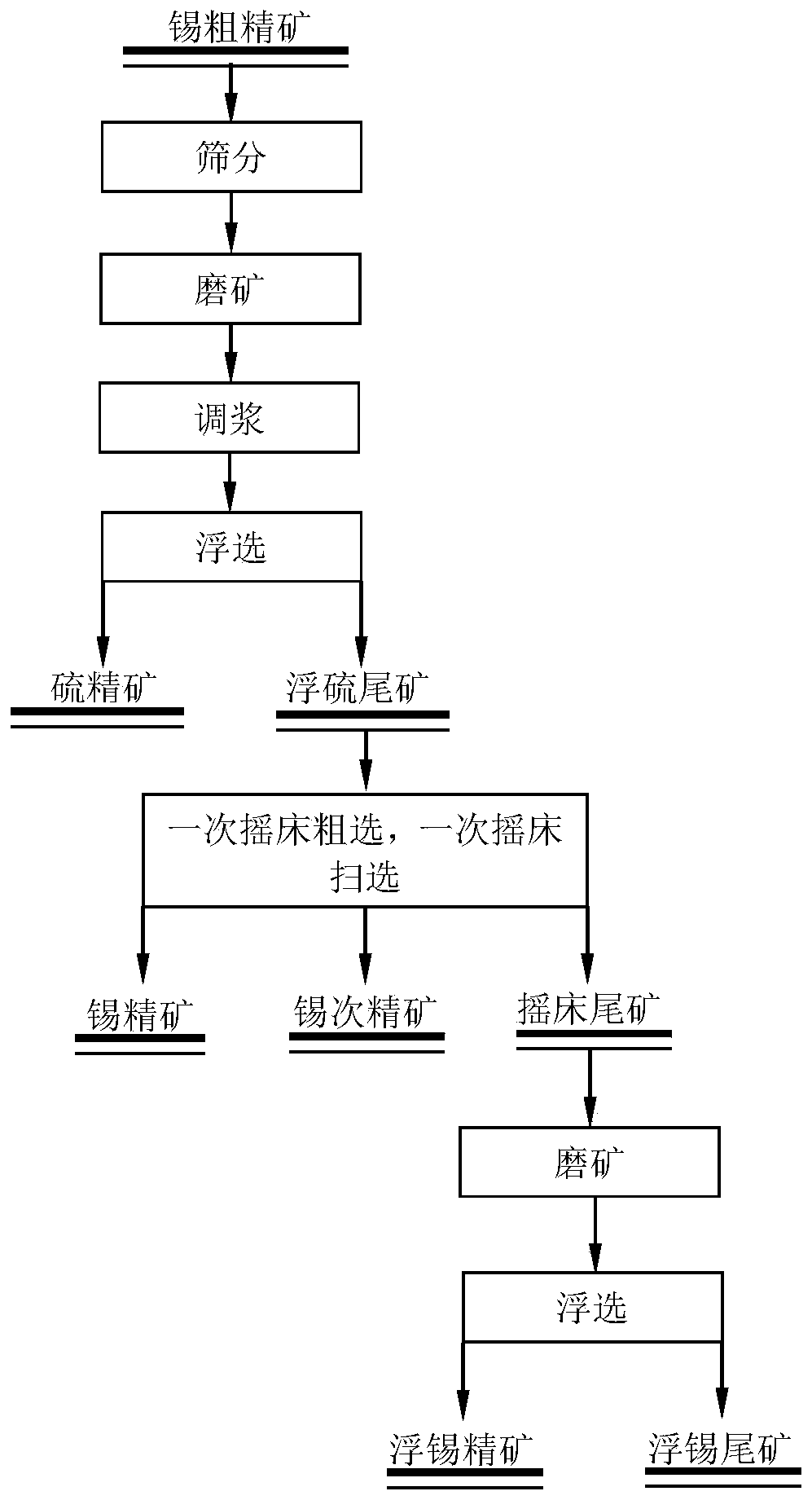

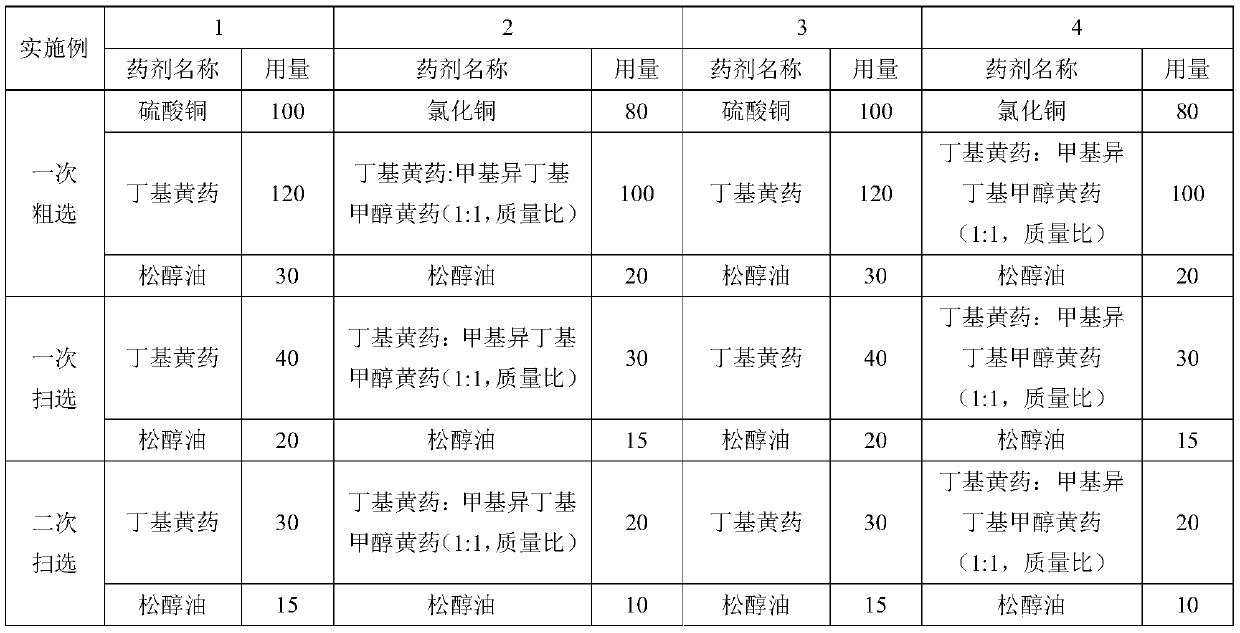

[0038] This embodiment provides a method for separating high-arsenic and high-sulfur tin rough concentrate. Such as figure 1 , the specific steps and the amount of each substance are as follows and Table 1.

[0039] The tin coarse concentrate is pre-screened-closed-circuit grinding (after the tin coarse concentrate is pre-screened, the product on the screen is repeatedly ground-screened), and ground to -0.25mm; adjust the pulp concentration to 30%; add Sulfuric acid is used to adjust the pH of the pulp to 6; operate according to the dosage of chemicals listed in Table 1, and perform flotation (one roughing, one sweeping, two sweeping, roughing foam for three times of blank separation) to obtain sulfur concentrate and floating sulfur tailings ore, after the floating sulfur tailings are passed through the shaking table (shaking table roughing, shaking table sweeping), tin concentrate, tin sub-concentrate and shaking table tailings are obtained; the shaking table tailings are su...

Embodiment 2

[0042] This embodiment provides a method for separating high-arsenic and high-sulfur tin rough concentrate. Such as figure 1 , the specific steps and the amount of each substance are as follows and Table 1.

[0043]The tin coarse concentrate is pre-screened-closed-circuit grinding (after the tin coarse concentrate is pre-screened, the product on the screen is repeatedly ground-screened), and ground to -0.25mm; adjust the pulp concentration to 30%; add Sulfuric acid is used to adjust the pH of the slurry to 5; operate according to the dosage of chemicals listed in Table 1, flotation (one roughing, one sweeping, two sweeping, roughing foam for three times of blank separation) to obtain sulfur concentrate and floating sulfur tailings ore, the floating sulfur tailings are passed through the shaker to obtain tin concentrate, tin sub-concentrate and shaker tailings; the shaker tailings are subjected to flotation separation: the shaker tailings are ground to -0.074mm to account for ...

Embodiment 3

[0046] This embodiment provides a method for separating high-arsenic and high-sulfur tin rough concentrate. Such as figure 1 , the specific steps and the amount of each substance are as follows and Table 1.

[0047] The tin coarse concentrate is pre-screened-closed-circuit grinding (after the tin coarse concentrate is pre-screened, the product on the screen is repeatedly ground-screened), and ground to -0.25mm; adjust the pulp concentration to 30%; add Adjust the pH of the pulp to 6 with oxalic acid; operate according to the amount of chemicals listed in Table 1, and obtain sulfur concentrate and floating sulfur tailings by flotation (one roughing, one sweeping, two sweeping, roughing foam for three times blank selection) ore, the floating sulfur tailings are passed through the shaker to obtain tin concentrate, tin sub-concentrate and shaker tailings; the shaker tailings are subjected to flotation separation: the shaker tailings are ground to -0.074mm to account for 85%, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com