Low-sugar or cane-sugar-free yoghourt and preparation method thereof

A sucrose-free and yogurt-free technology, which is applied to milk preparations, bacteria and dairy products used in food preparation, etc., can solve the problems of low viscosity, poor taste, rough state, etc. Increase the effect of sweetness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

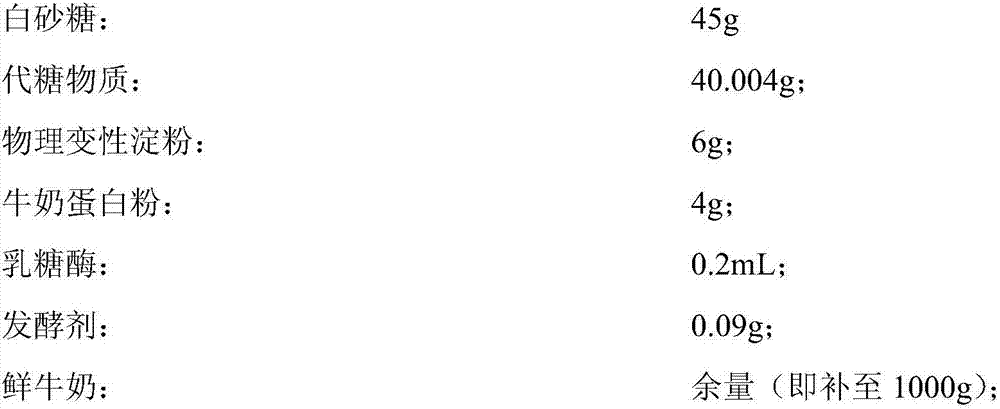

[0027] 1. Raw material formula (measured in 1000g):

[0028]

[0029] Wherein, the sugar substitute substance is erythritol 15g, xylitol 10g and steviol glycoside 0.01g;

[0030] The starter is 0.045g of Lactobacillus bulgaricus and 0.045g of Streptococcus thermophilus.

[0031] 2. Preparation method:

[0032] (1) Standardization: standardize the fresh milk;

[0033] (2) Ingredients: mix and circulate the standardized fresh milk obtained in step (1), sugar substitutes, milk protein powder and white sugar (that is, other raw materials except lactase and starter) at 55-60°C 20~30min, make them mix evenly, get a mixed material;

[0034] (3) Degassing: the mixed material obtained in step (2) is degassed in a degassing tank with a negative pressure of -0.03 to -0.07 MPa at 60 to 70 ° C;

[0035] (4) Homogenization and sterilization: homogenize and sterilize the degassed mixed material obtained in step (3). The time is 95±5℃ / 300s;

[0036] (5) Enzymolysis and fermentation: ...

Embodiment 2

[0039] 1. Raw material formula (measured in 1000g):

[0040]

[0041] Wherein, the sugar substitute substance is 15g of erythritol, 15g of xylitol, 10g of maltitol and 0.004g of steviol glycoside;

[0042] The starter is 0.045g of Lactobacillus bulgaricus and 0.045g of Streptococcus thermophilus.

[0043] 2. Preparation method:

[0044] The preparation method is the same as in Example 1.

Embodiment 3

[0046] 1. Raw material formula (measured in 1000g):

[0047]

[0048] Wherein, the sugar substitute substance is erythritol 30, xylitol 10g, soybean oligosaccharide 15g and steviol glycoside 0.02g;

[0049] The starter is 0.03g of Lactobacillus bulgaricus, 0.06g of Streptococcus thermophilus, 0.005g of Lactobacillus acidophilus and 0.005g of Bifidobacterium lactis.

[0050] 2. Preparation method:

[0051] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com