A kind of No. 100 unleaded aviation gasoline and preparation method thereof

A technology of unleaded aviation and aviation gasoline, which is applied in the field of aviation gasoline, which can solve the problems of low quality, incomplete combustion of gasoline, and low calorific value of gasoline, and achieve the effects of simple preparation process, good application performance, and high economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

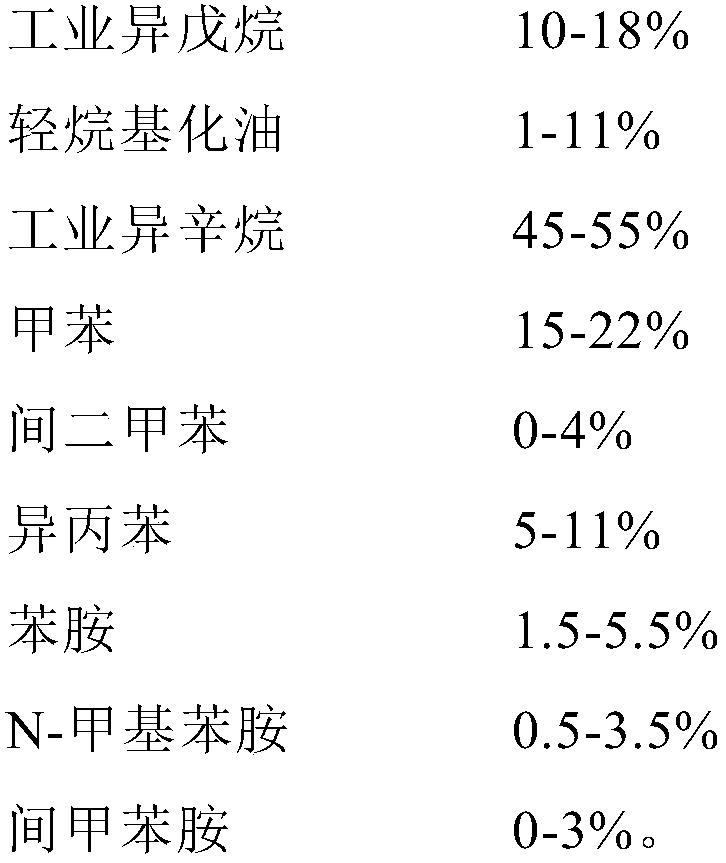

Method used

Image

Examples

Embodiment 1-8

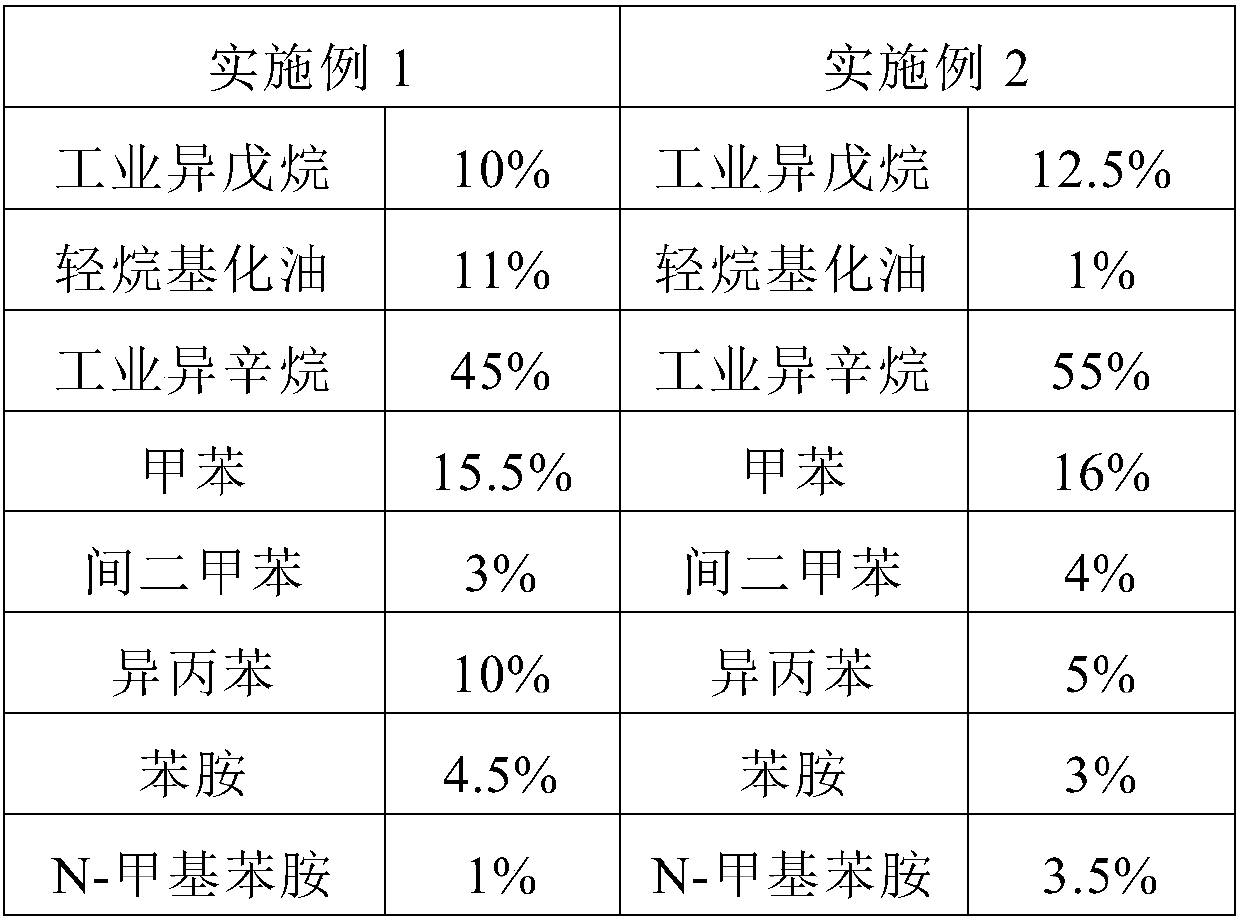

[0039] Table 1 has listed the formula of embodiment 1-2, and table 2 has been the detection result of embodiment 1-2 product, and table 3 has listed the formula of embodiment 3-5, and table 4 is the detection of embodiment 3-5 product Result, table 5 has listed the prescription of embodiment 6-8, and table 6 is the detection result of embodiment 6-8 product.

Embodiment 1-2

[0040] Embodiment 1-2 specifically adopts the following method to prepare:

[0041] The aviation gasoline preparation process adopts the pump to send the formula raw material components into the blending tank. When mixing and stirring, a propeller type agitator is used. The stirring speed is controlled at 70-120rpm, and cumene, m-xylene, toluene are added in sequence. Aniline, N-methylaniline or m-toluidine, isooctane, light alkylated oil, isopentane, mixed and stirred evenly to obtain the finished product.

[0042] Table 1 Embodiment 1-2 formula

[0043]

[0044] The detection result of table 2 embodiment 1-2 product

[0045]

[0046]

[0047] The above examples show that the aviation steam formula of the present invention can meet the national standard, the finished oil is lead-free, MON≥99.5, and other indicators can also meet the use of No. 100 aviation gasoline, but the freezing point of the oil product is higher and close to the index value, and it is not suita...

Embodiment 3-8

[0048] Embodiment 3-8 specifically adopts the following method to prepare:

[0049] Consider adding various types of additives to optimize and modify the quality of oil products. The corresponding aviation gasoline preparation process uses pumping formula raw material components into the blending tank. When mixing and stirring, use a propeller type agitator, and the stirring speed is controlled at 70-120rpm ,Specifically:

[0050] (1) preparing materials by formula, compounding aniline, N-methylaniline and m-toluidine, compounding antioxidant and metal deactivator;

[0051] (2) Add cumene, m-xylene, toluene, compounded aniline, N-methylaniline and m-toluidine, anti-wear agent, anti-icing agent, compounded antioxidant and metal passive agent in order Chemical agent, isooctane, light alkylated carburetor, isopentane, dyeing agent and antistatic agent, mix and stir evenly to obtain the finished product.

[0052] Table 3 embodiment 3-5 aviation gasoline formula

[0053]

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

| freezing point | aaaaa | aaaaa |

| freezing point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com