Patents

Literature

177results about "Cleaning recording heads" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

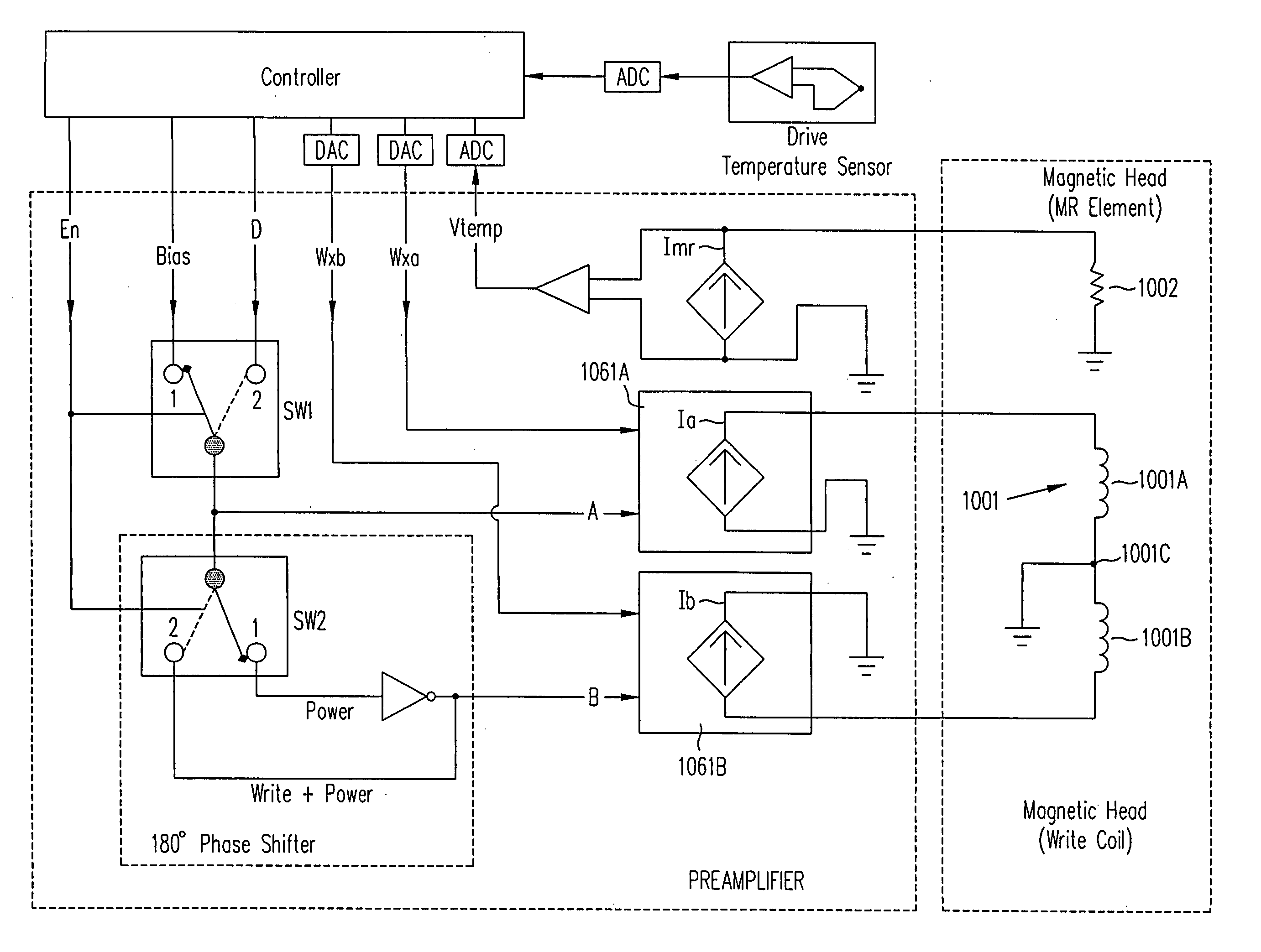

Storage device including a center tapped write transducer

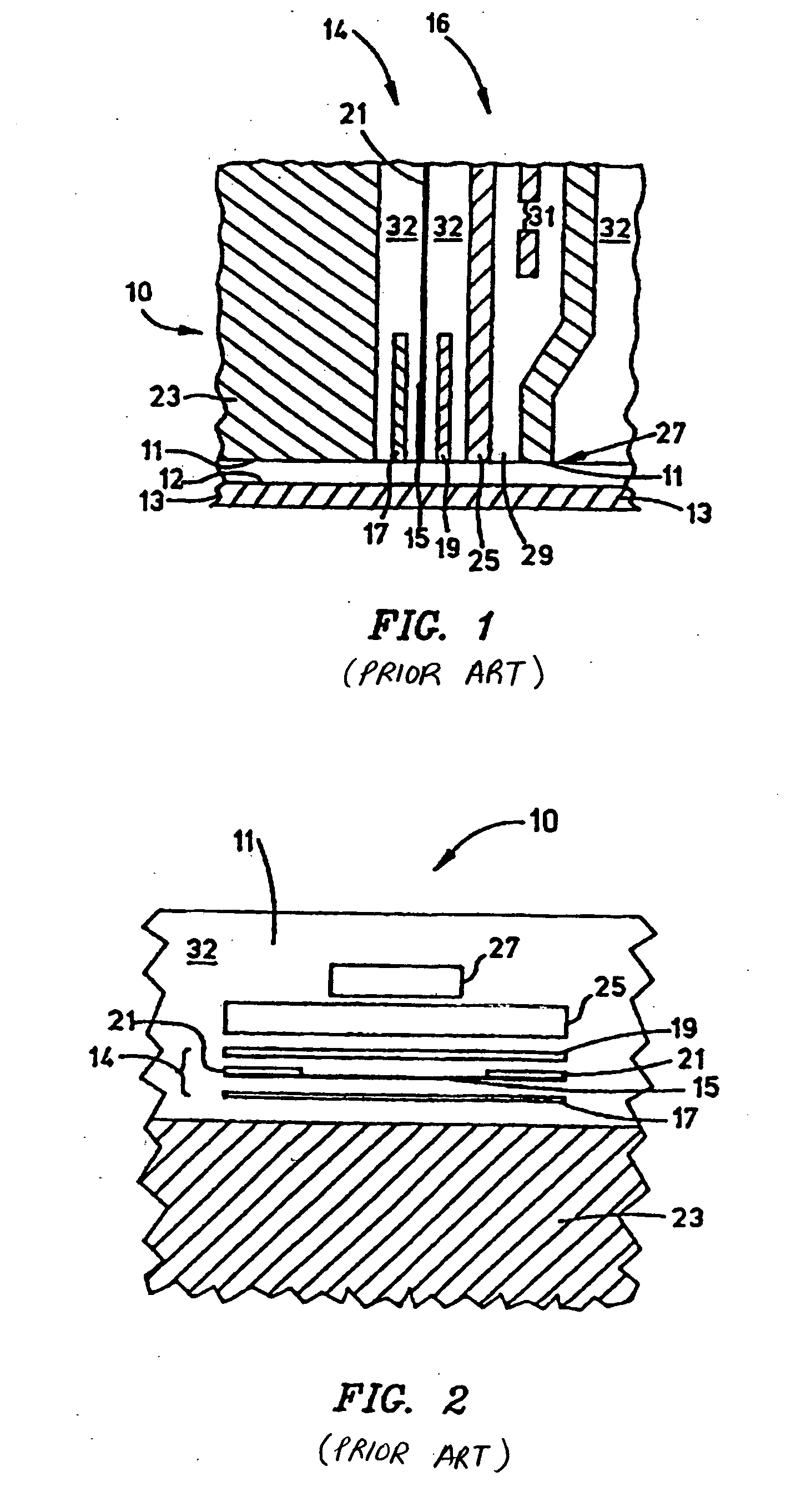

A head for use in a drive includes a heating element capable of generating heat sufficient to cause the head to have a shape that is similar or identical to the shape that the head has when performing an operation (e.g. writing) on a recording medium in the drive. The heating element is activated when the operation is not being performed. Hence, a head generates the same amount (or similar amount) of heat and is therefore at the same temperature (also called “operating temperature”), regardless of whether or not an operation (such as writing) is being performed. Therefore, the head maintains a fixed shape or has a shape that varies minimally, within a predetermined range around the fixed shape, that in turn results in maintaining fly height (distance between the head and the recording medium). The heating element may be implemented to use loss mechanisms inherent in a write transducer, e.g. by providing a center tap to the write transducer. When using a center tapped write transducer, currents in phase with one another are provided to perform a write operation. When not performing the write operation, the same currents are provided, but out of phase.

Owner:WESTERN DIGITAL TECH INC

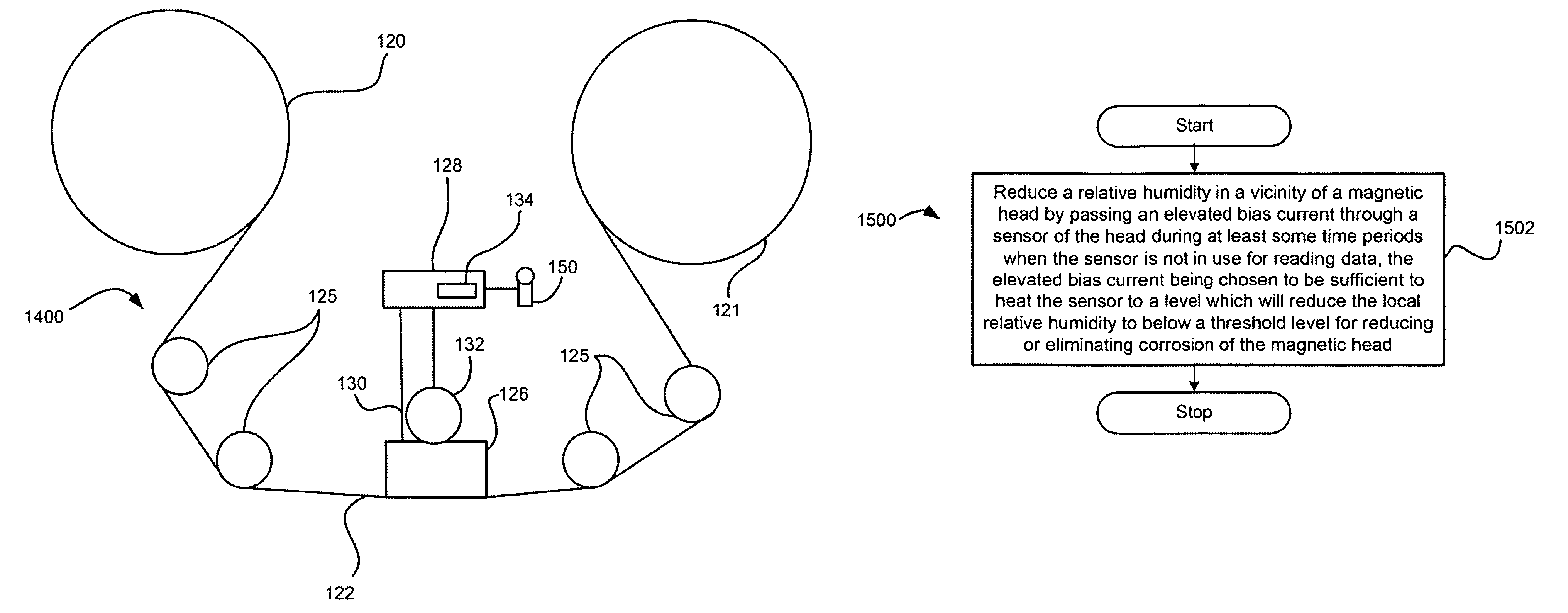

Systems and methods for protecting a sensitive device from corrosion

ActiveUS7656602B2Reduce humidityEliminate corrosionUndesired vibrations/sounds insulation/absorptionRecord information storageTime segmentEngineering

A method for protecting a magnetic head according to one embodiment includes reducing a relative humidity in a vicinity of a magnetic head by passing an elevated bias current through a sensor of the head during at least some time periods when the sensor is not in use for reading data, the elevated bias current being chosen to be sufficient to heat the sensor to a level which will reduce the local relative humidity to below a threshold level for reducing or eliminating corrosion of the sensor. Additional methods are also presented.

Owner:INT BUSINESS MASCH CORP

Systems and methods for protecting a sensitive device from corrosion

InactiveUS8318242B2Reduce exposureManufacture head surfaceRecord information storageMagnetic storageEngineering

A method in one embodiment includes applying an organic coating to a magnetic head for reducing exposure of the head to oxidation promoting materials; and storing the magnetic head. A method in another embodiment includes applying an organic coating to a magnetic head for reducing exposure of the head to oxidation promoting materials, the organic coating being applied to the magnetic head after the head is installed in the magnetic storage system. Another method includes fabricating a tape having an applicator portion for applying an organic coating to a magnetic head for reducing exposure of the head to oxidation promoting materials; applying the organic coating to the applicator portion of the tape; and applying a lubricant to a data portion of the tape. A method in another embodiment includes fabricating a tape having a data portion, and a cleaning portion for removing an organic coating from a magnetic head.

Owner:IBM CORP

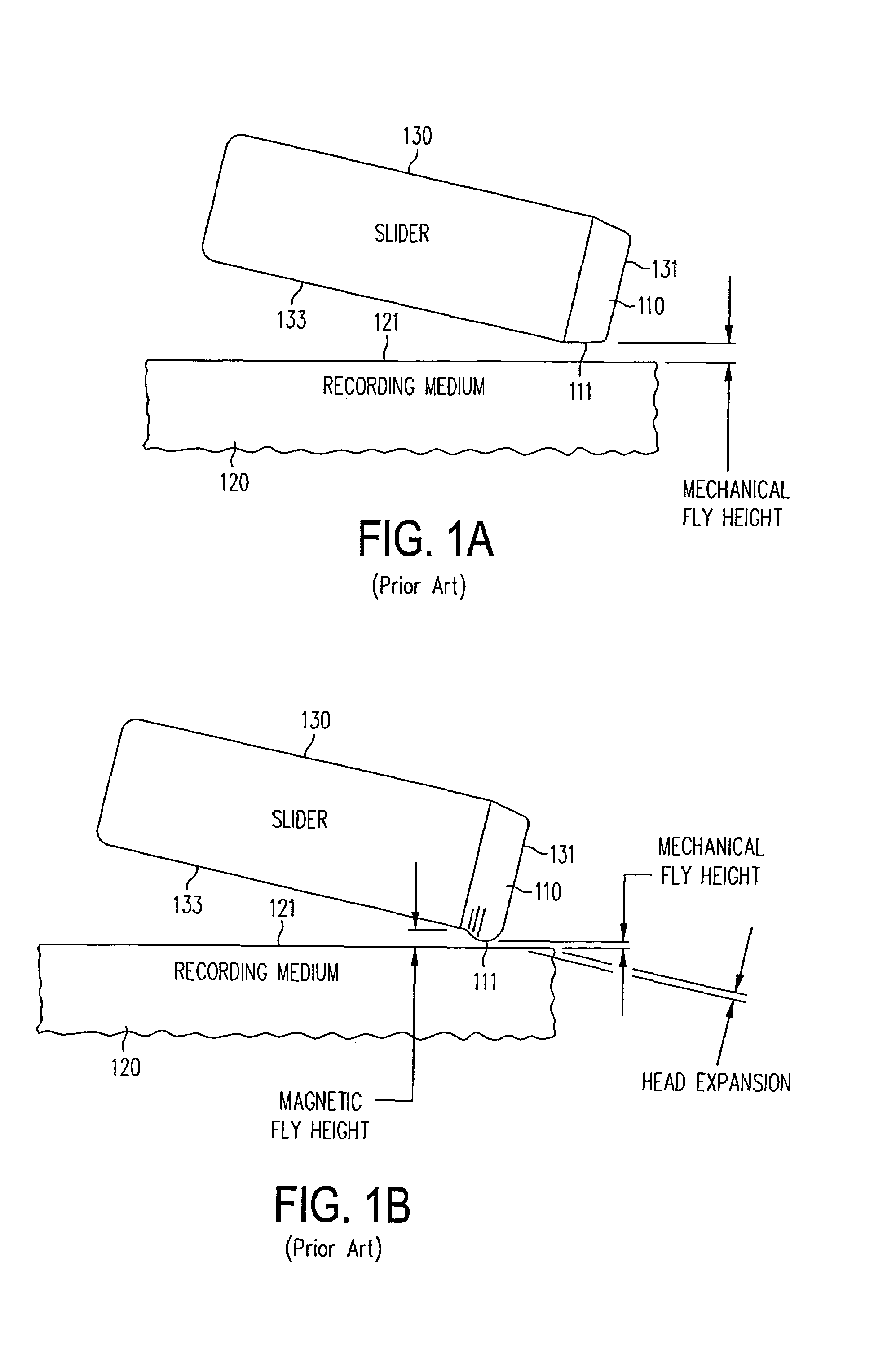

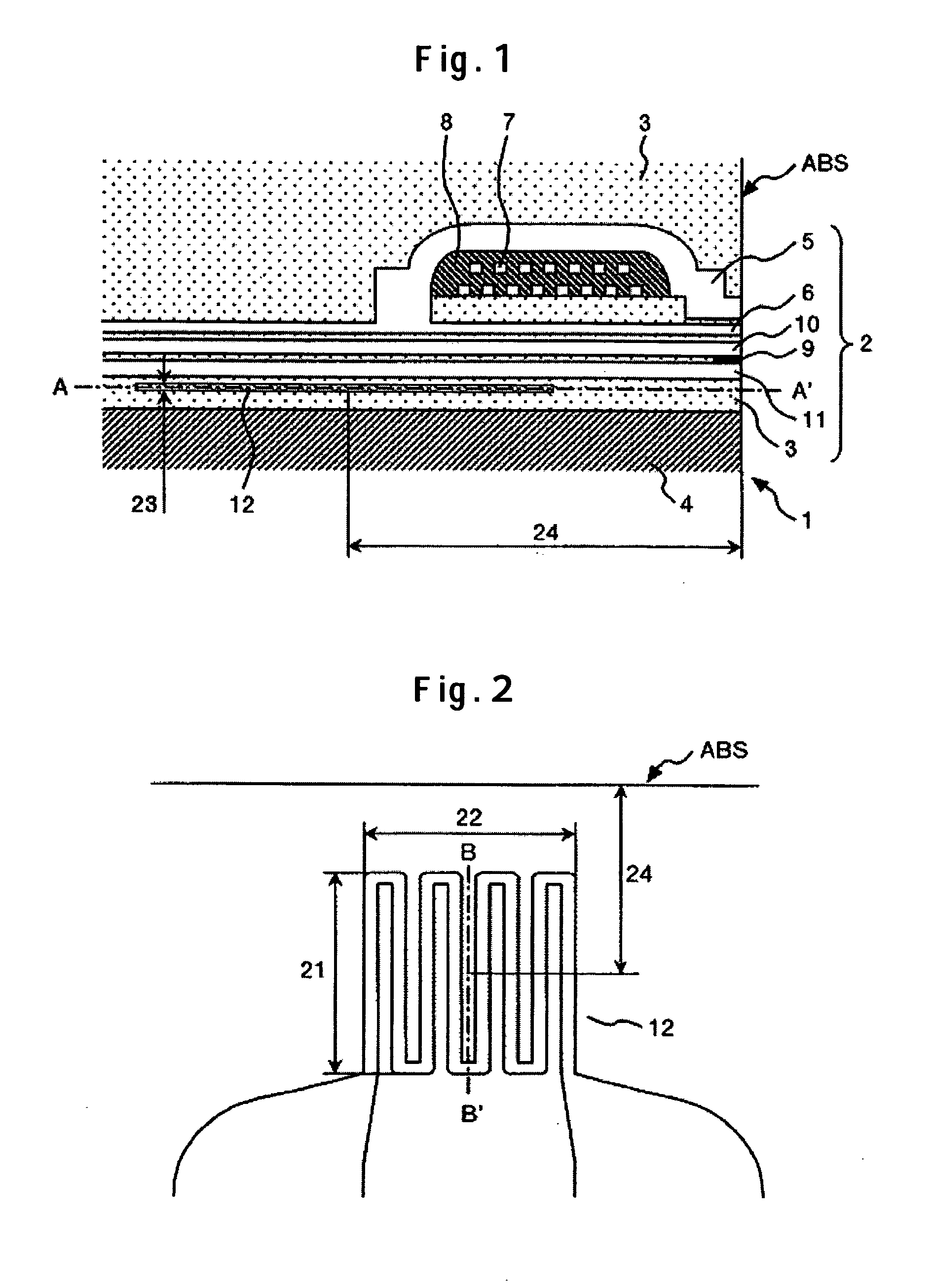

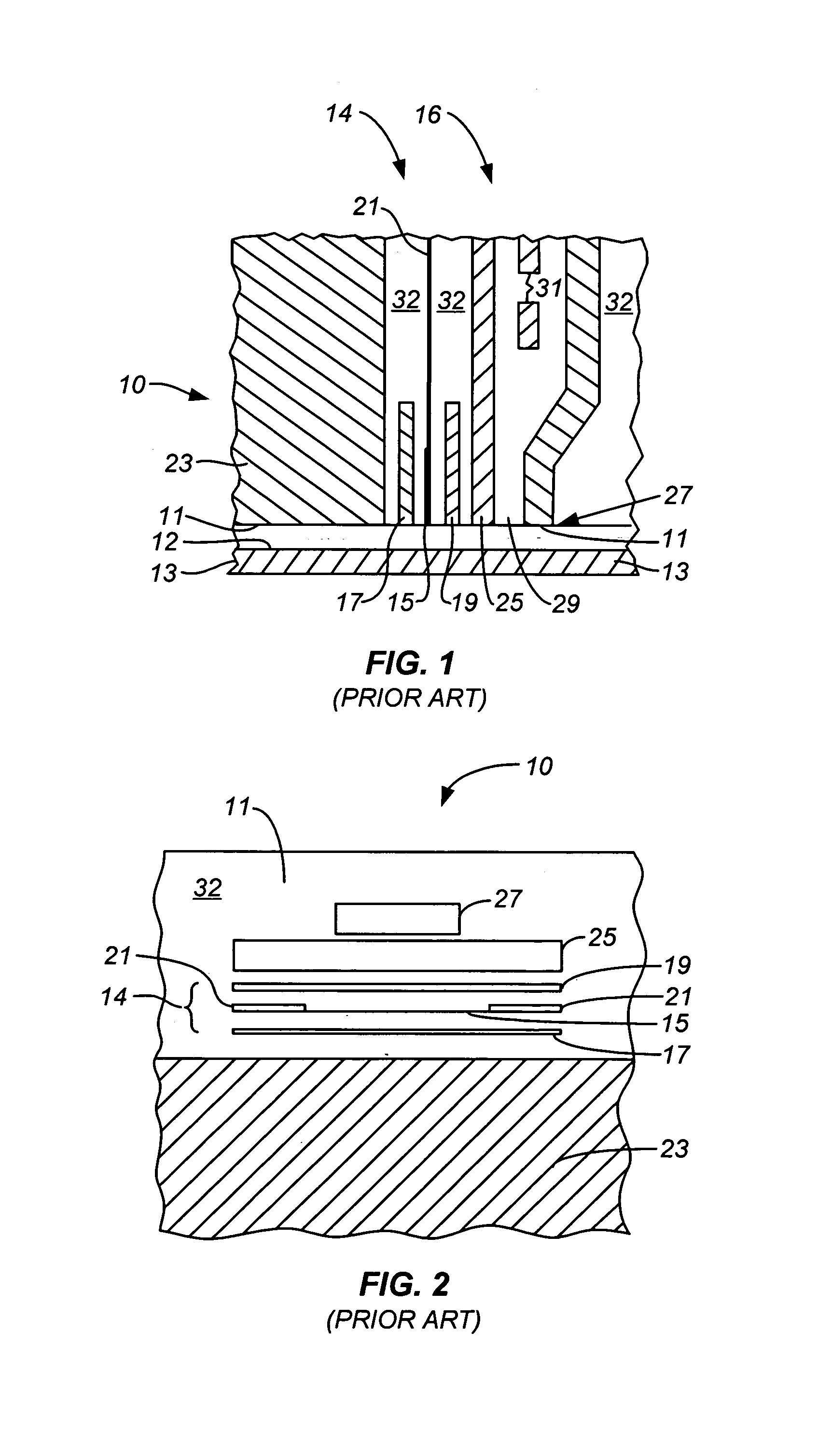

High reliability heater for flying height control

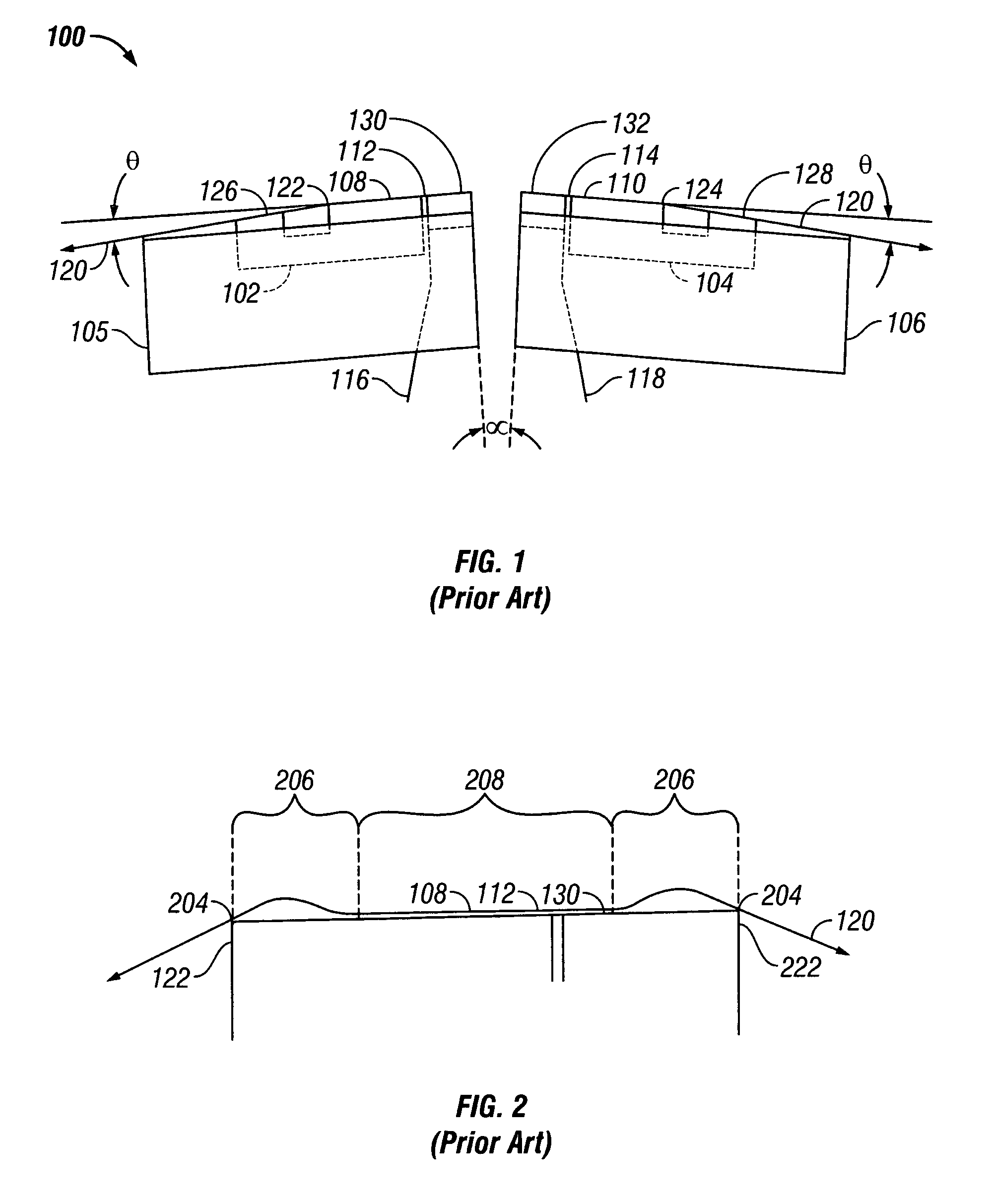

InactiveUS20060034013A1Avoid contactSolution to short lifeRecord information storageFluid-dynamic spacing of headsResistMagnetic poles

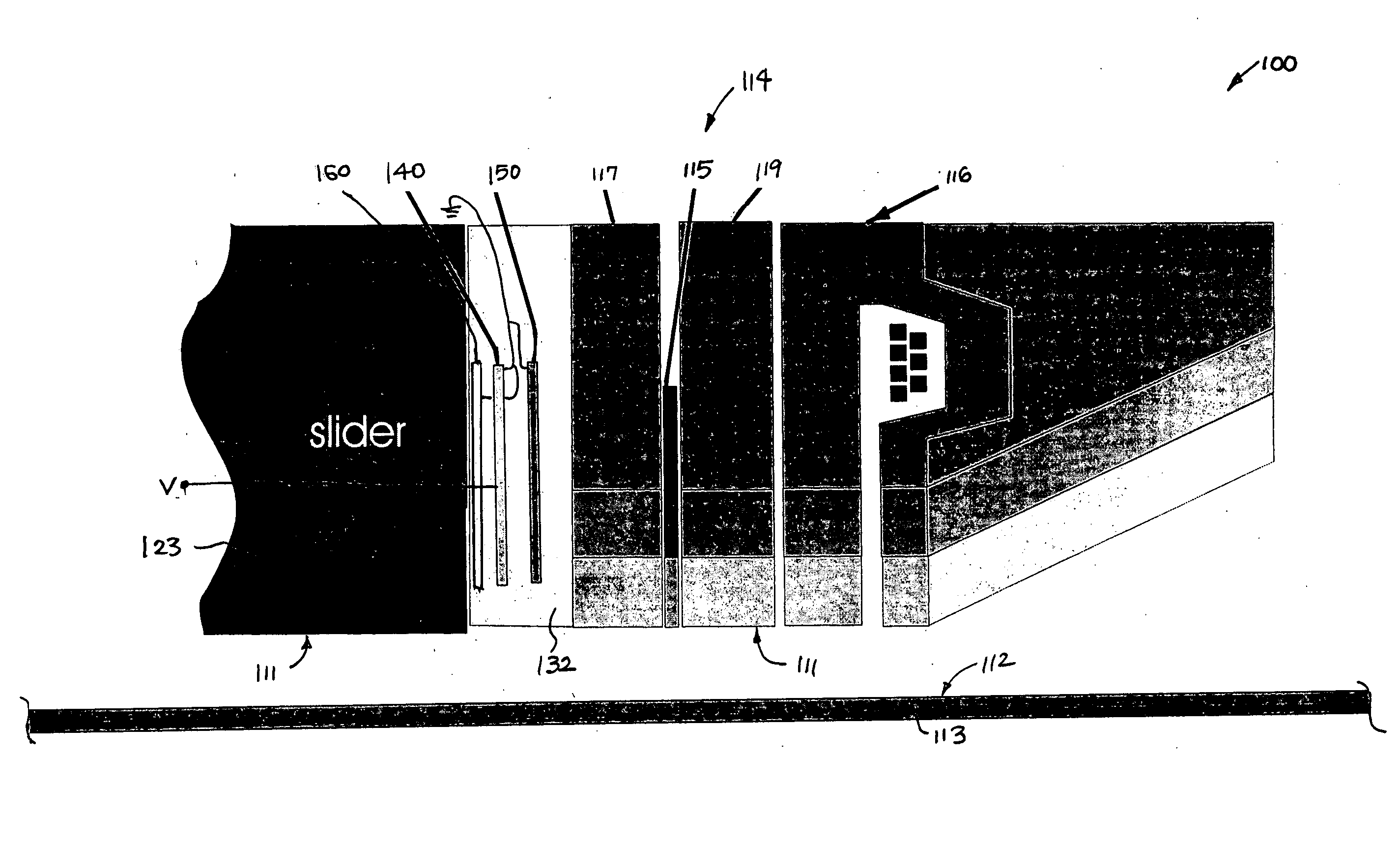

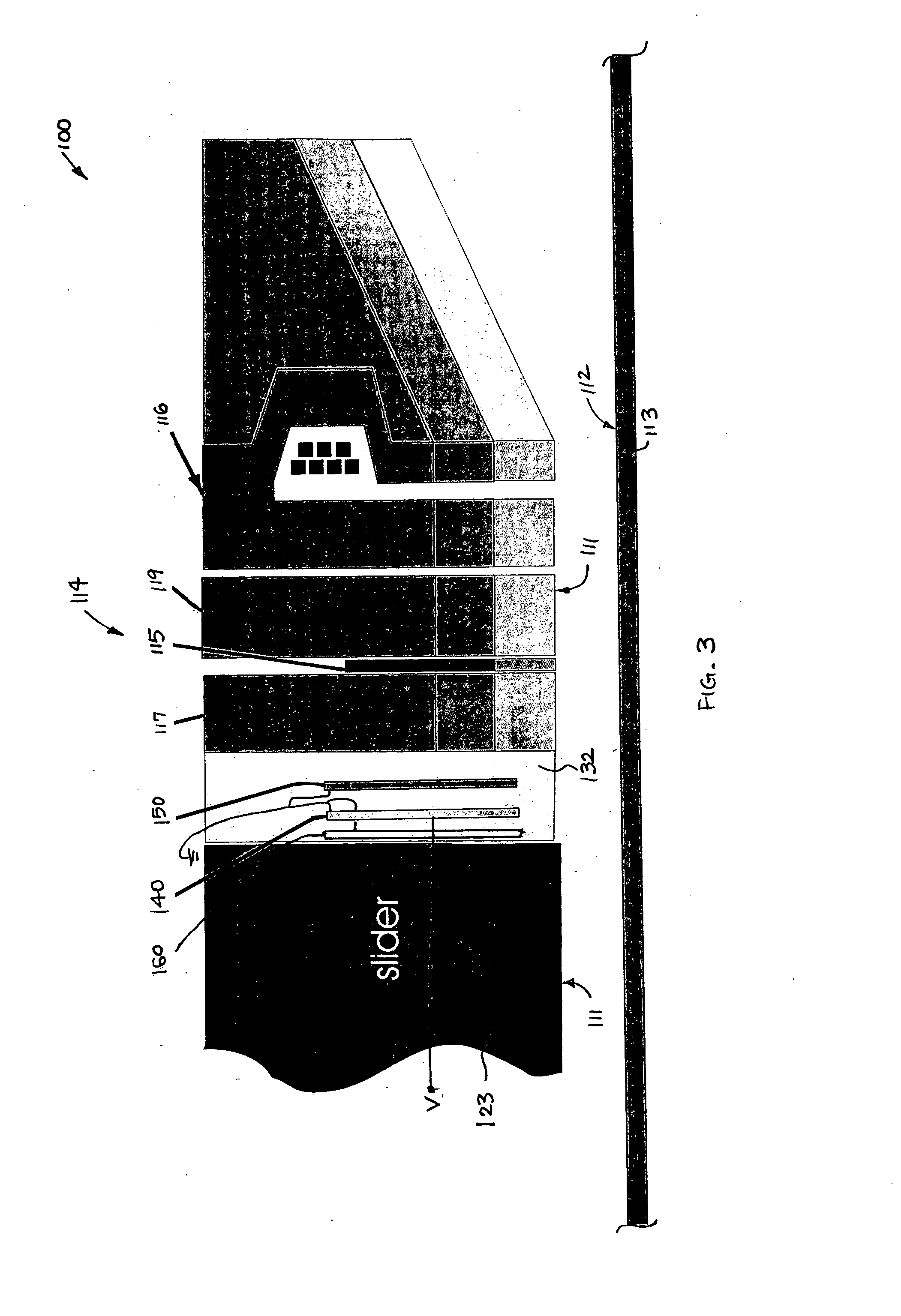

Embodiments of the invention improve the power consumption and response speed of a heater for the gap flying height (hg) adjustment, to minimize an influence that the heater has on a life of a read element, and to provide a heater having resistance lines reduced in breaking and ensuring higher reliability. In one embodiment, a read / write element is formed near an air bearing surface (ABS) on a slider, and the circumference of the read / write element is filled with alumina. The read / write element includes an upper magnetic pole piece, a lower magnetic pole piece, a coil, and a resist filling around the coil, and a read element (MR) for performing reading, and an upper shield and lower shield for protecting the read element from an external magnetic field. A heater for adjusting the flying height is provided between the slider and the read / write element but near the read / write element. A temperature gradient relaxing material having a thermal conductivity higher than that of the heater and that of a material (alumina) filling around the heater is formed near the heater.

Owner:WESTERN DIGITAL TECH INC

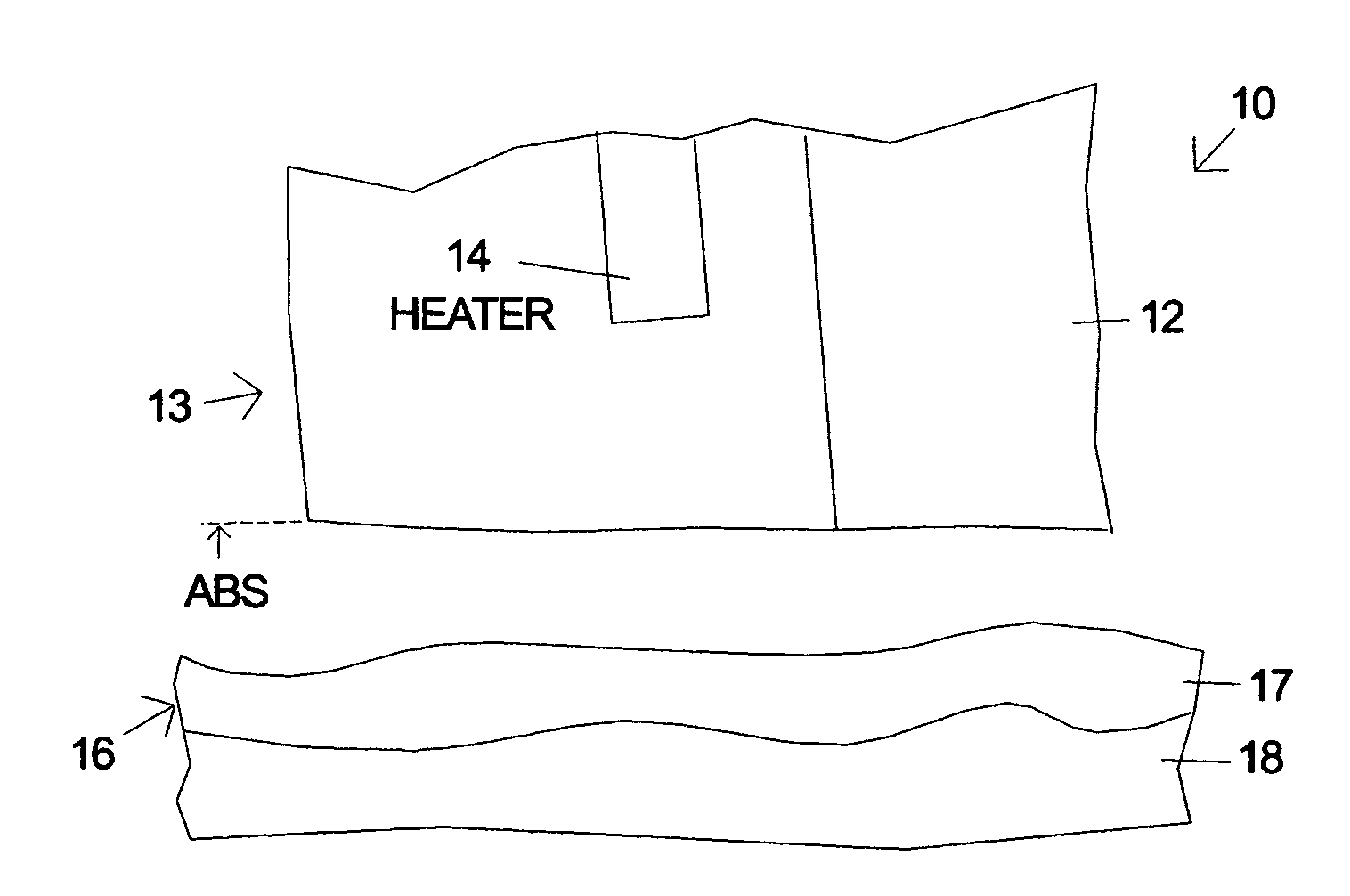

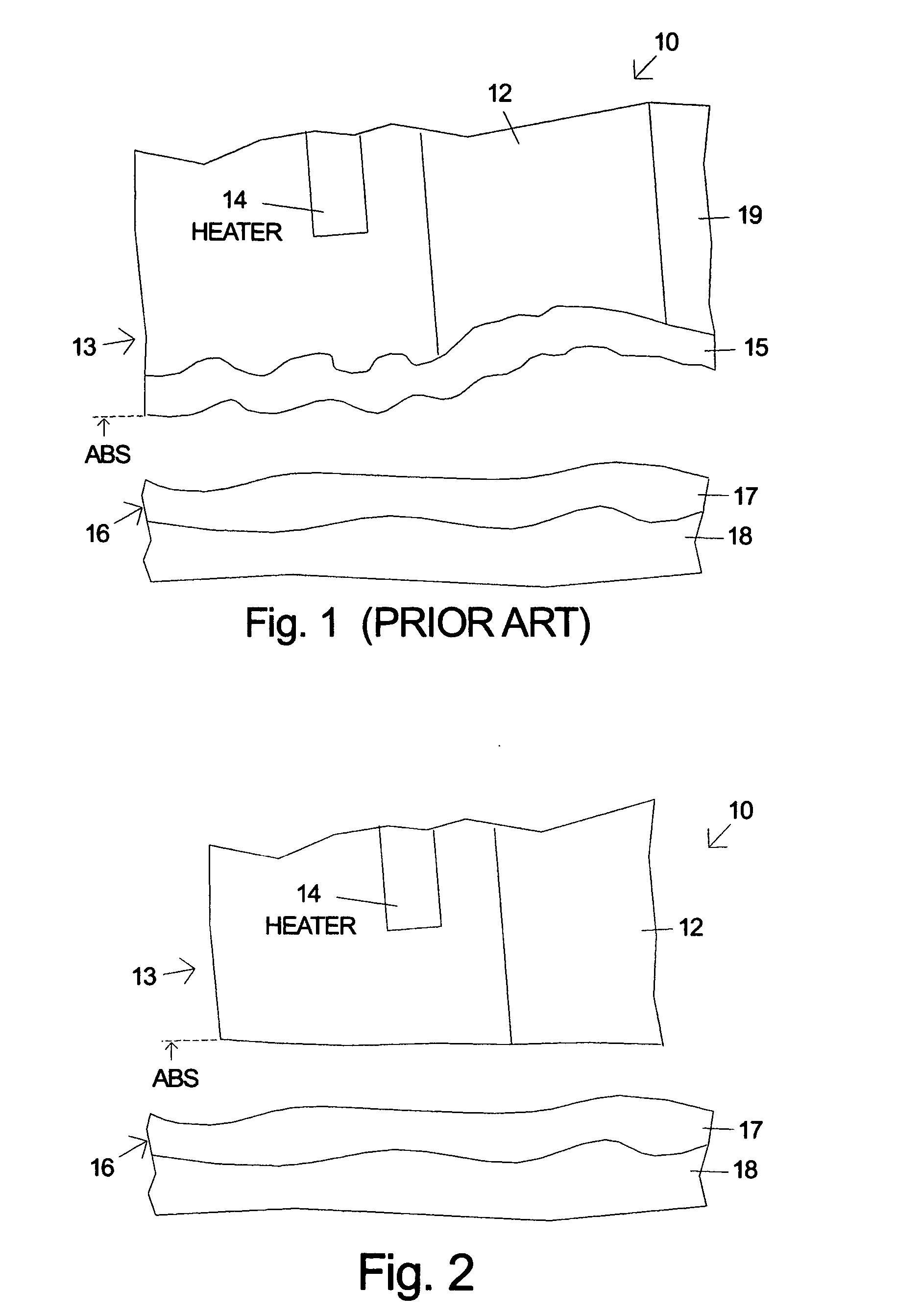

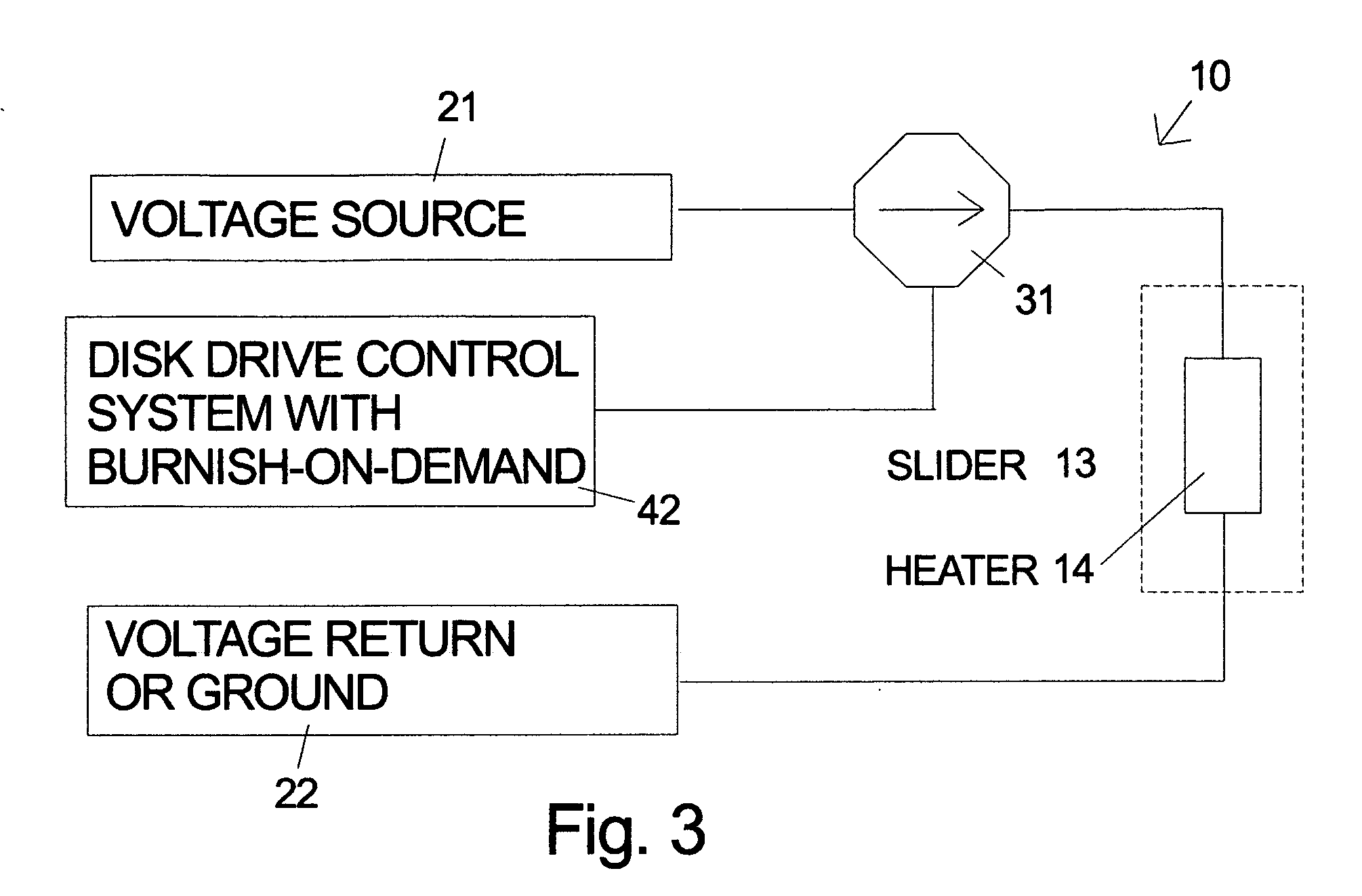

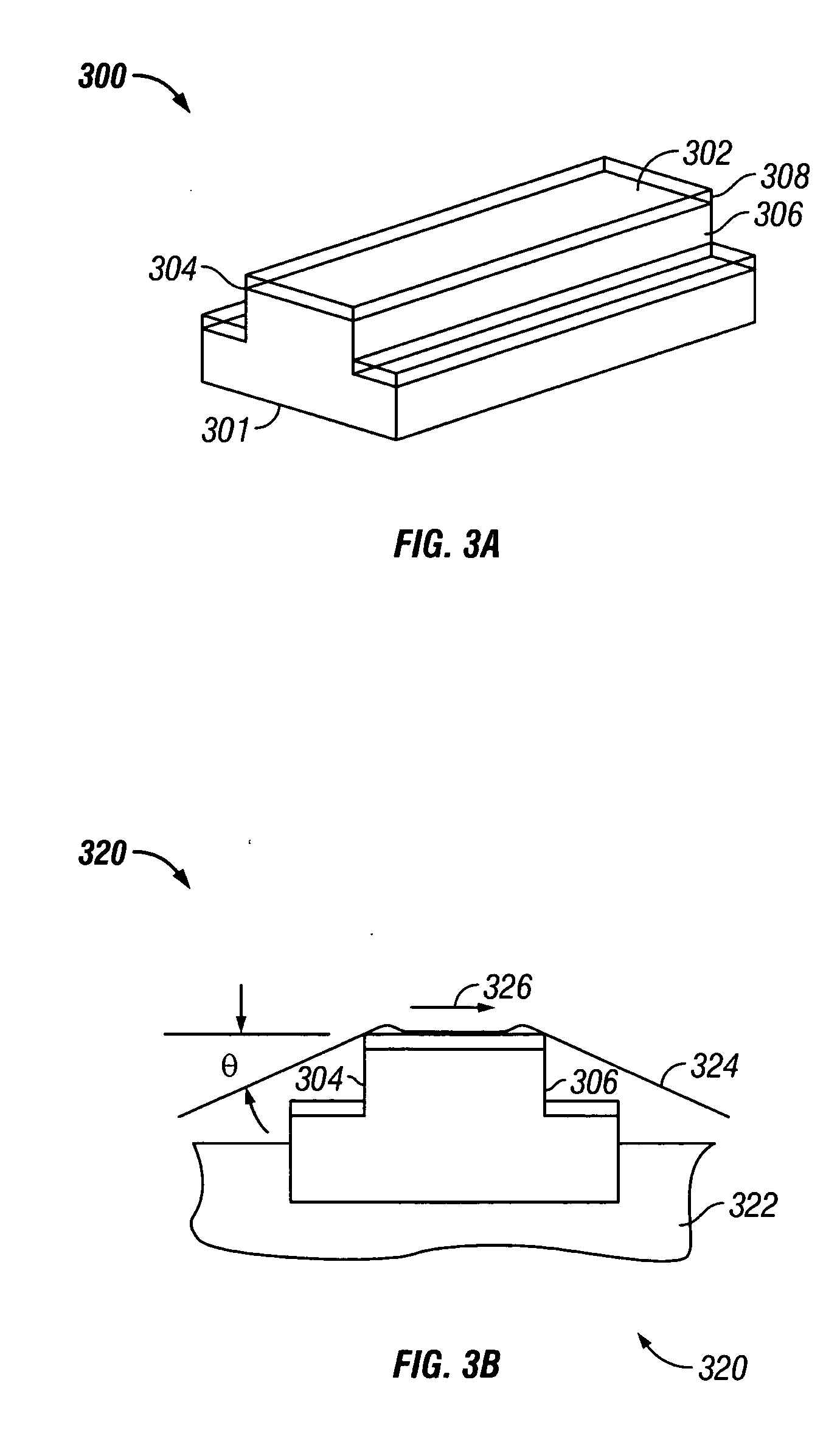

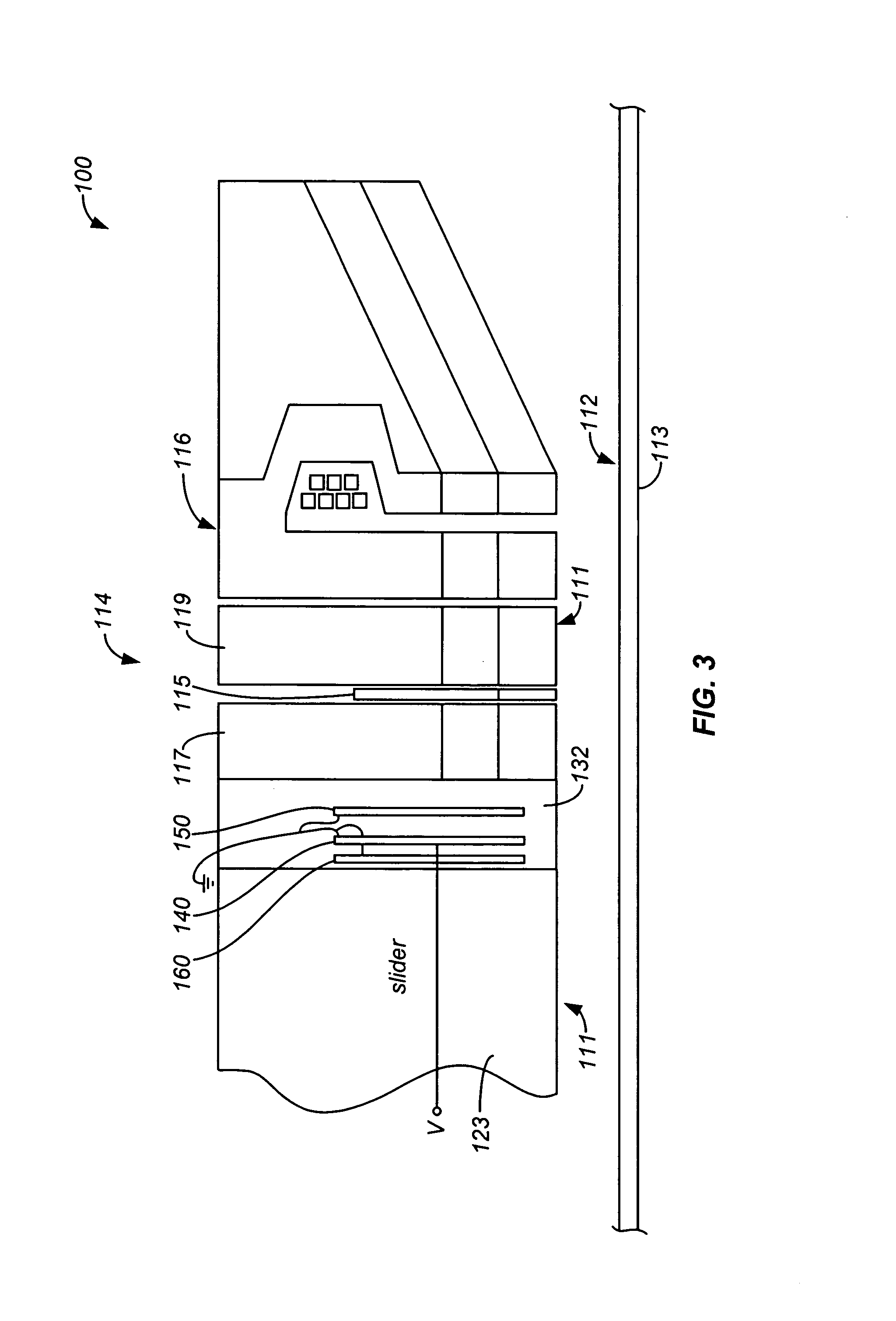

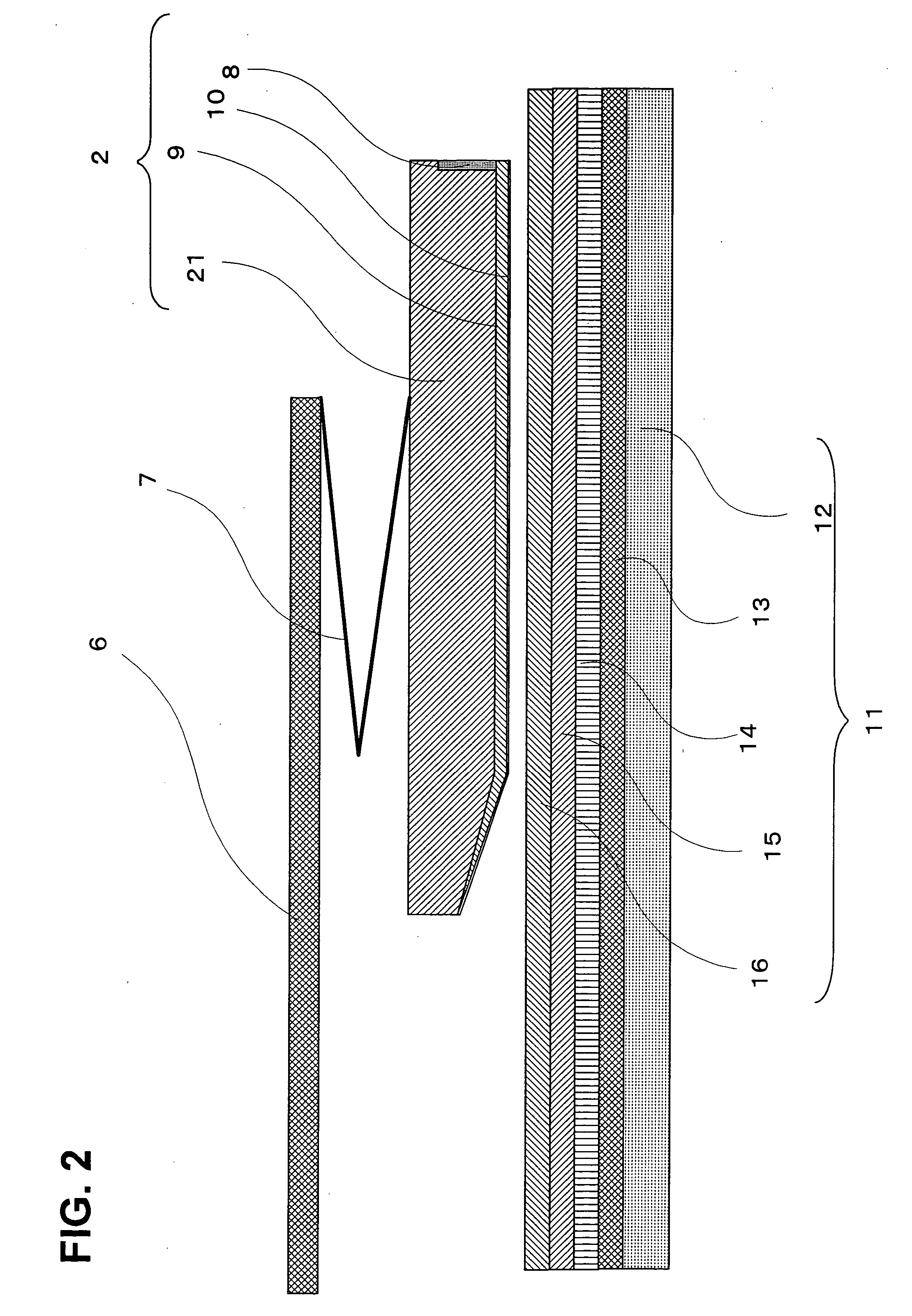

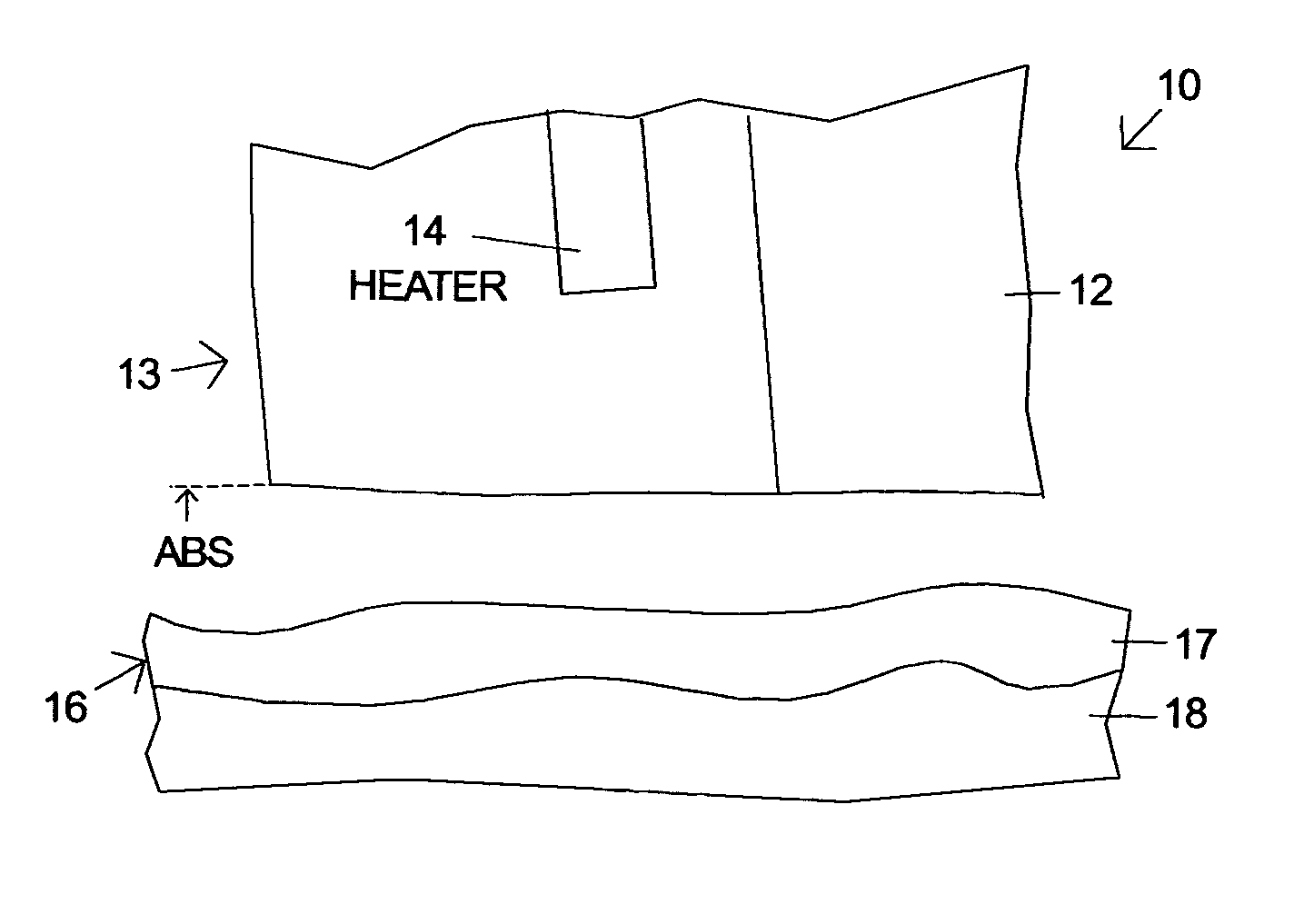

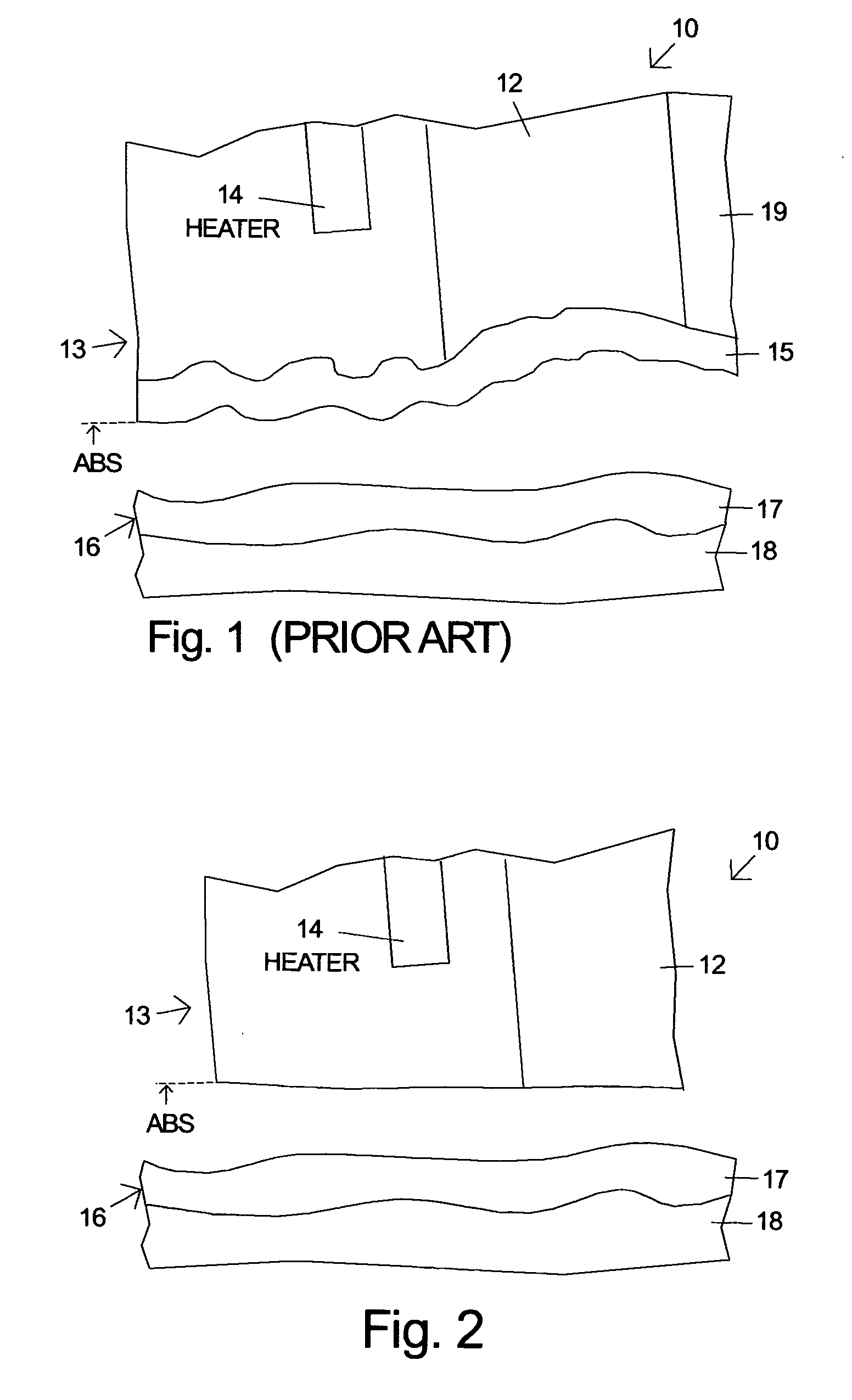

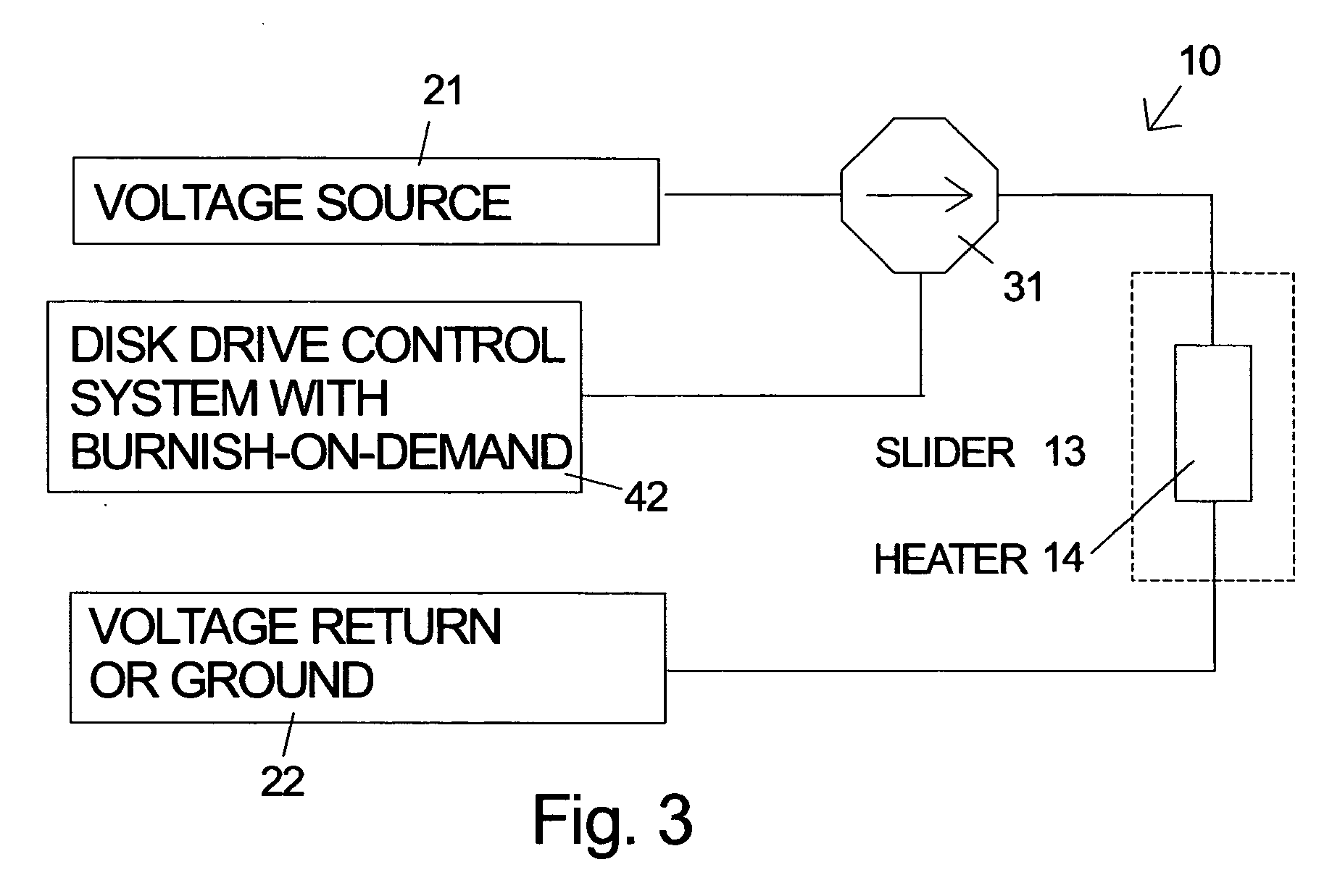

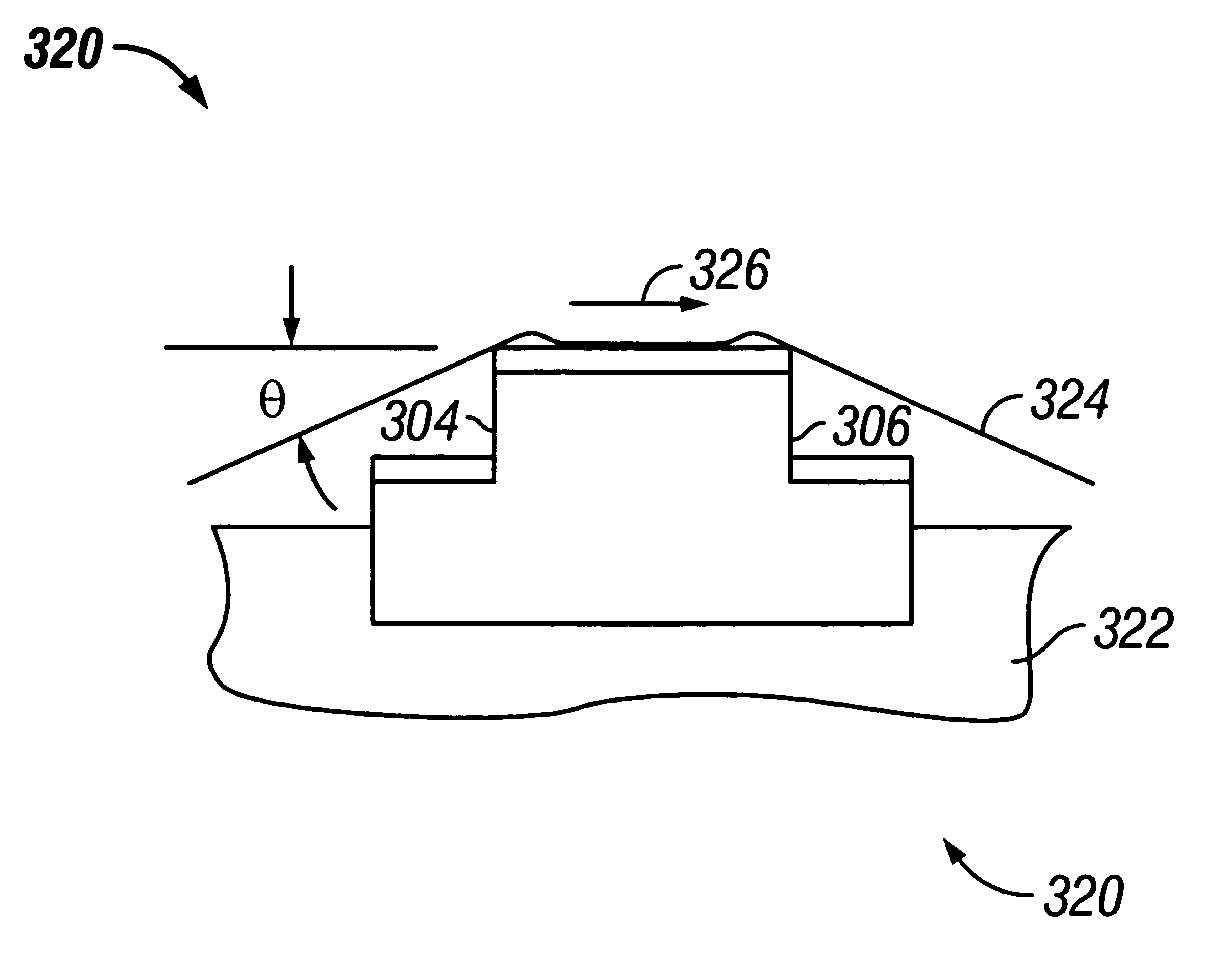

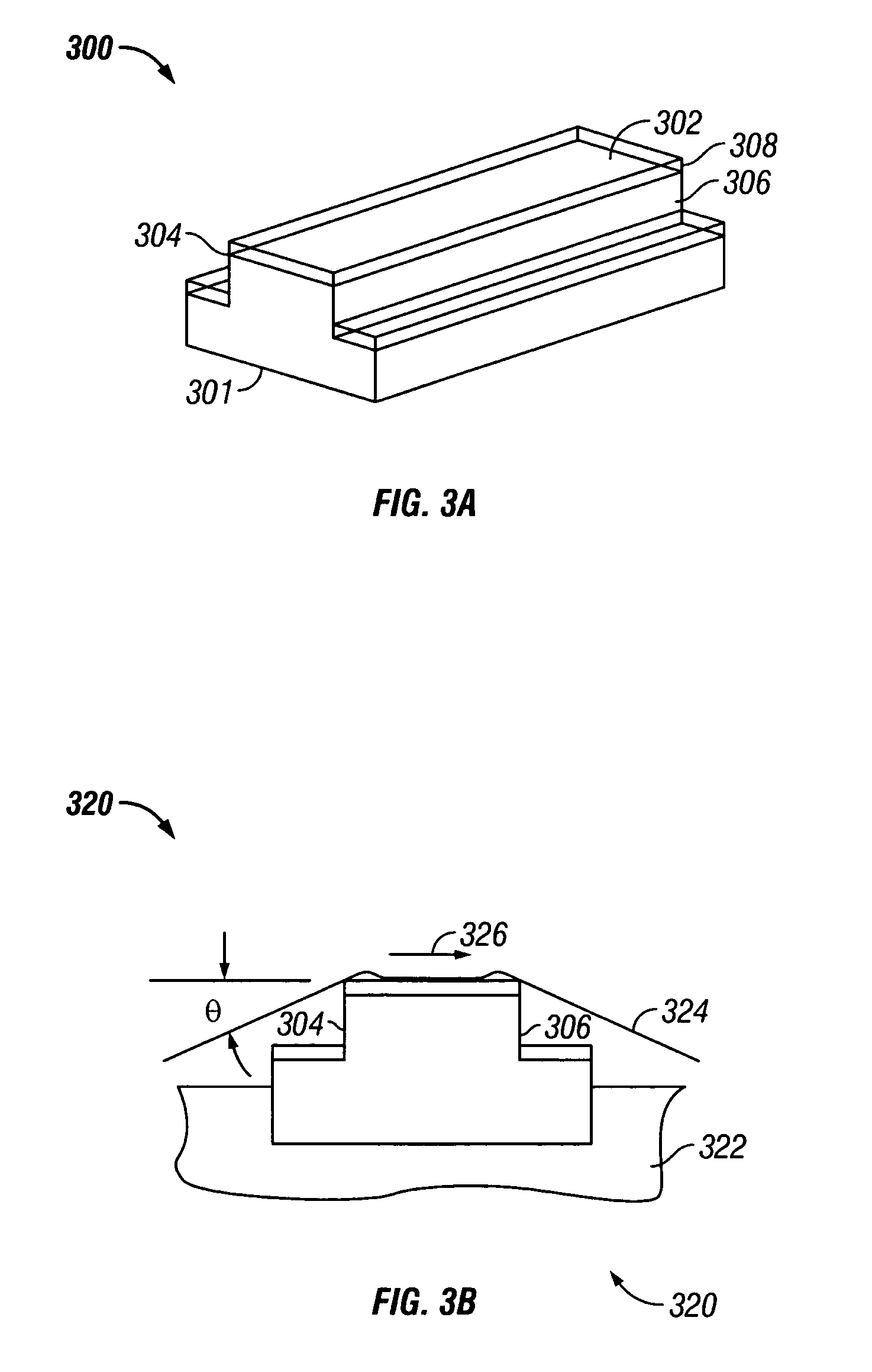

Disk drive slider design for thermal fly-height control and burnishing-on-demand

InactiveUS20060092570A1Reduced risk of corrosionAvoid corrosionElectrical transducersDriving/moving recording headsEngineeringFlying height

Owner:WESTERN DIGITAL TECH INC

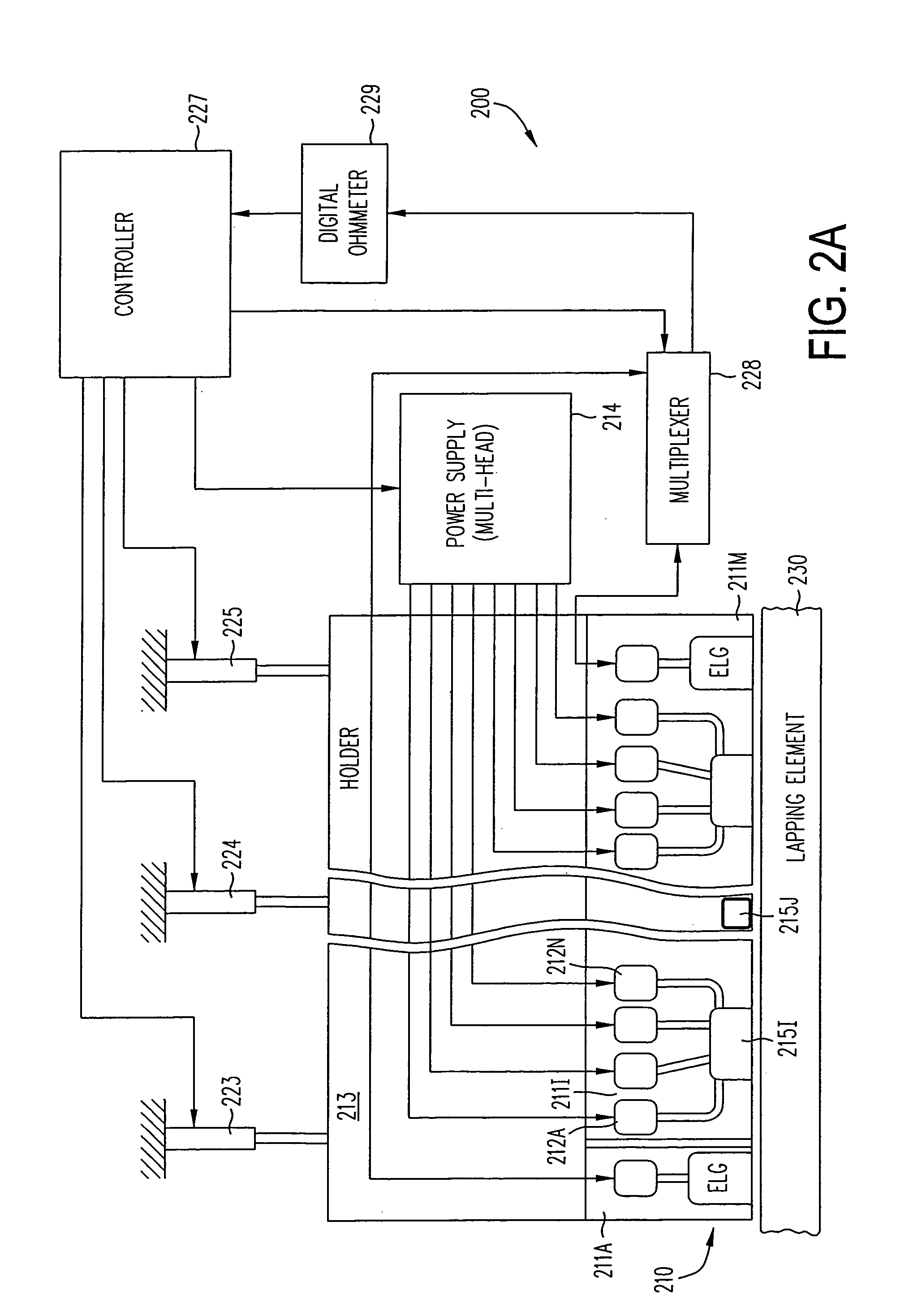

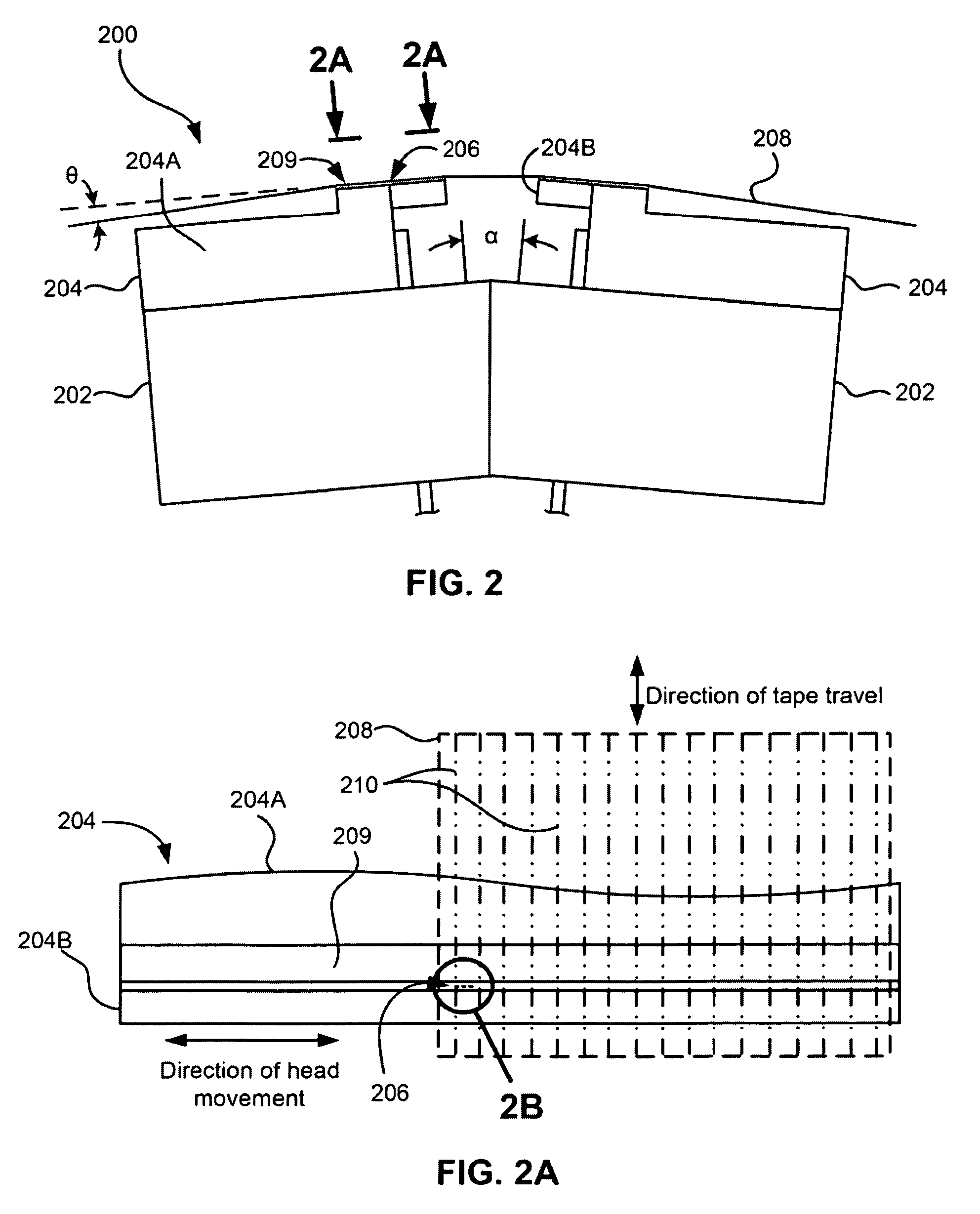

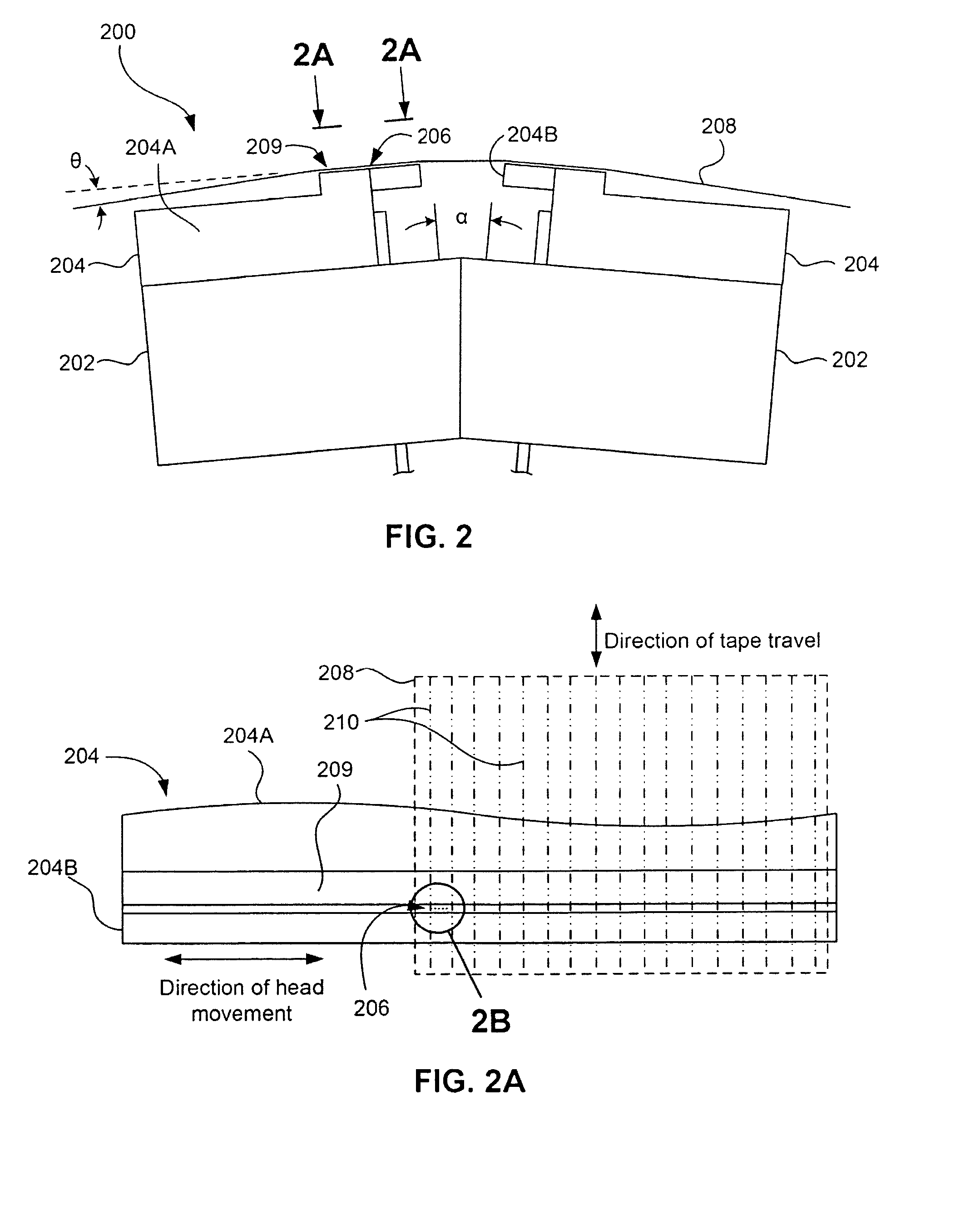

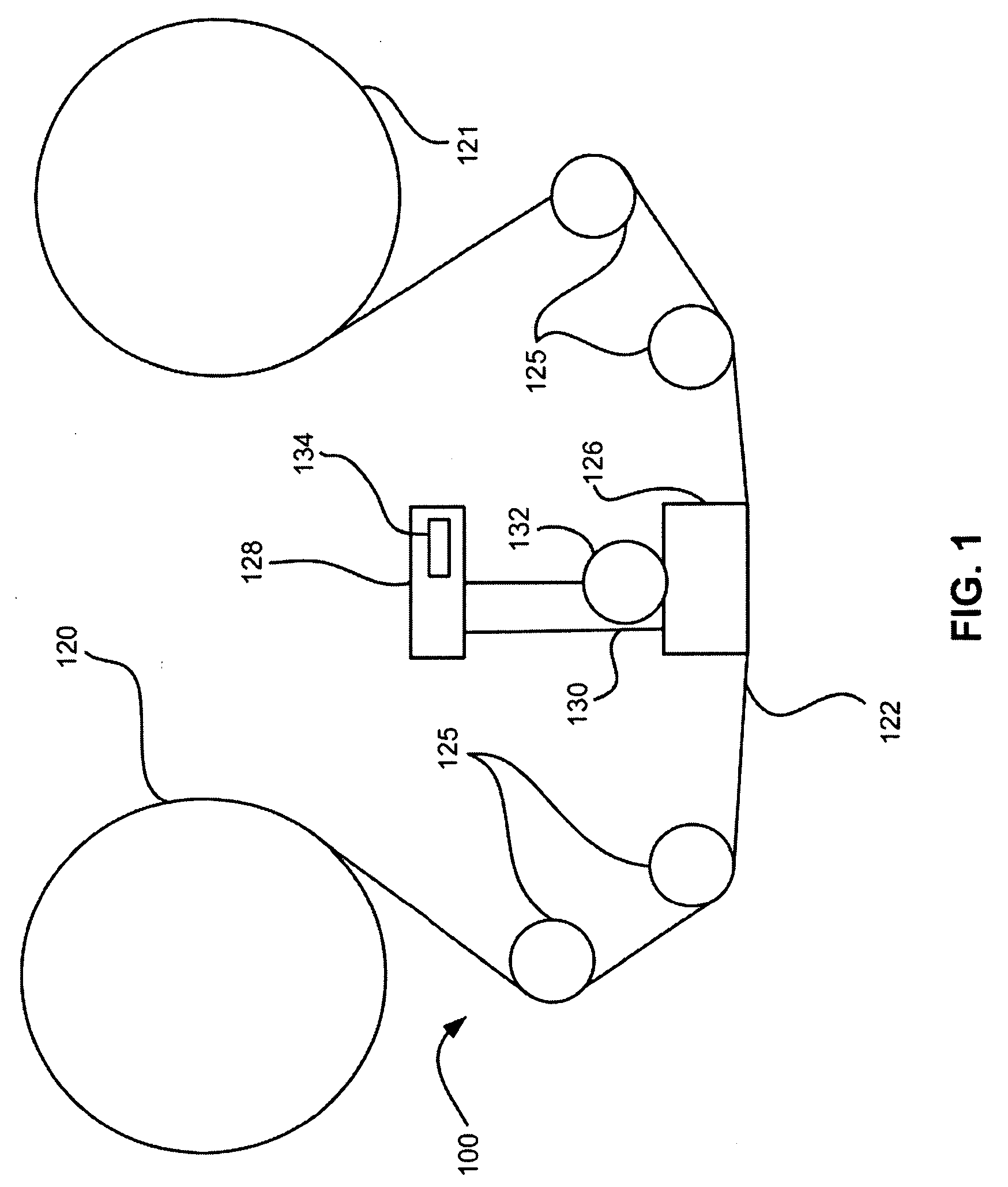

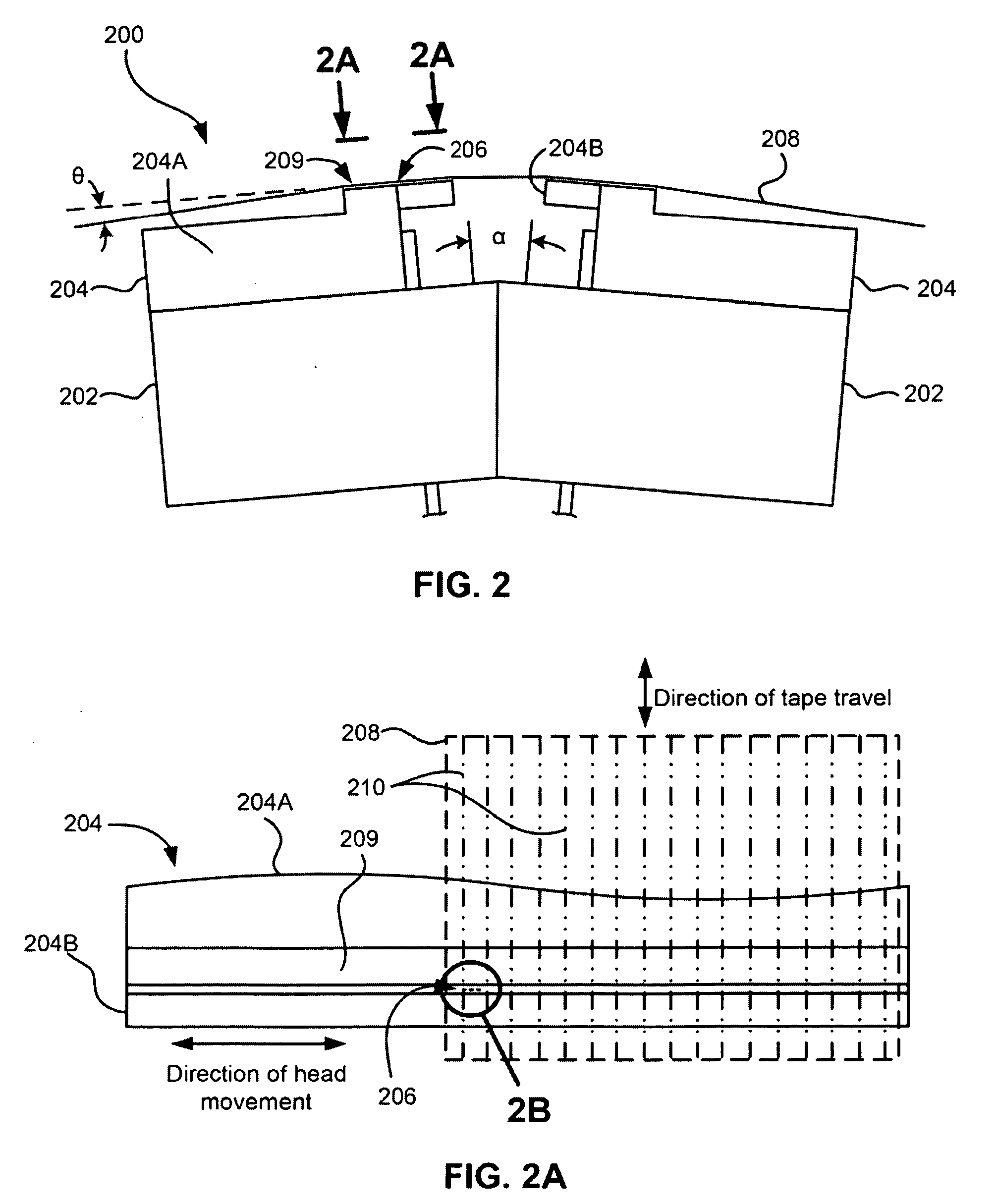

Wear gauge and method of use

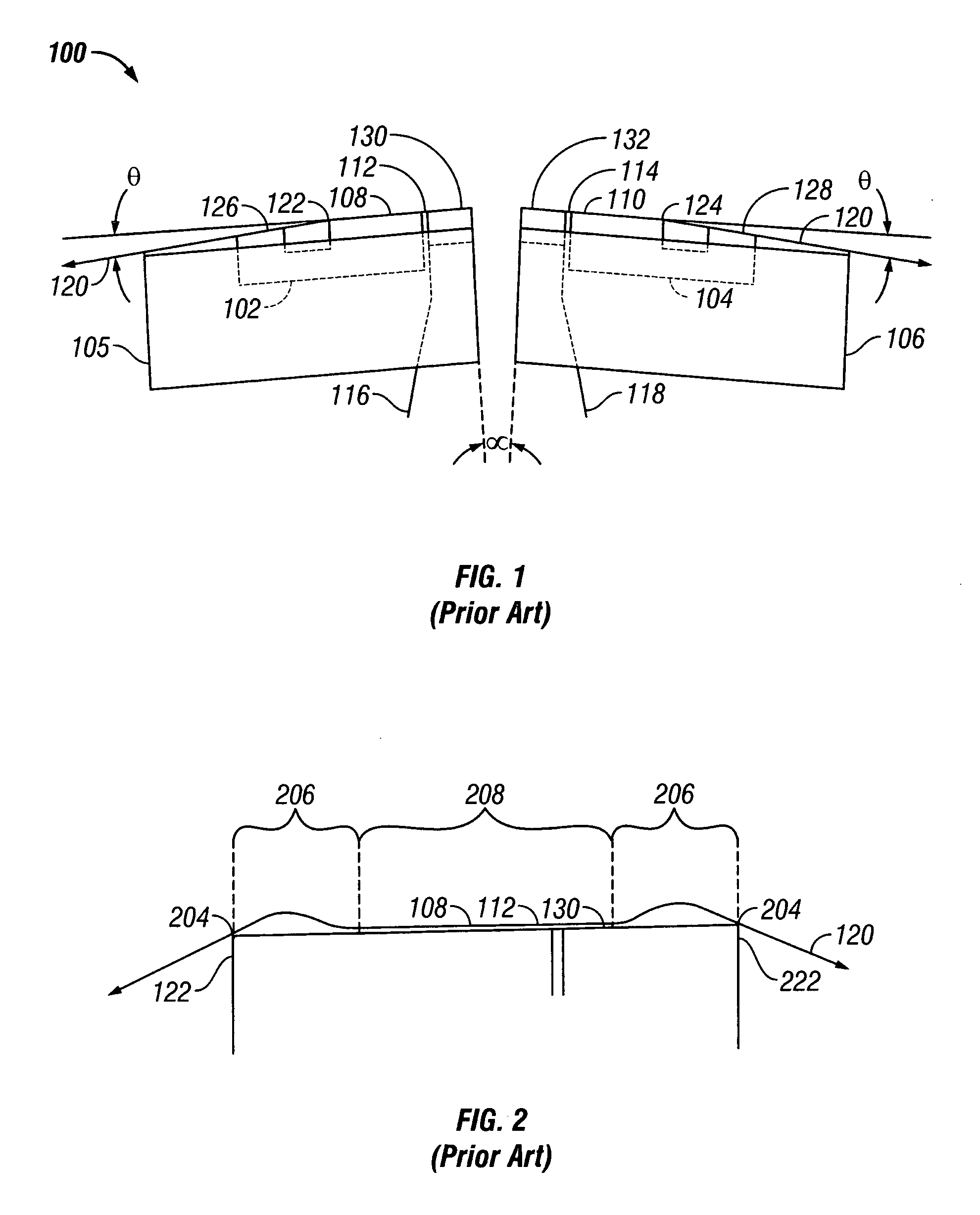

InactiveUS20050284207A1Photometry using reference valueMetal rolling stand detailsMagnetic storageColor changes

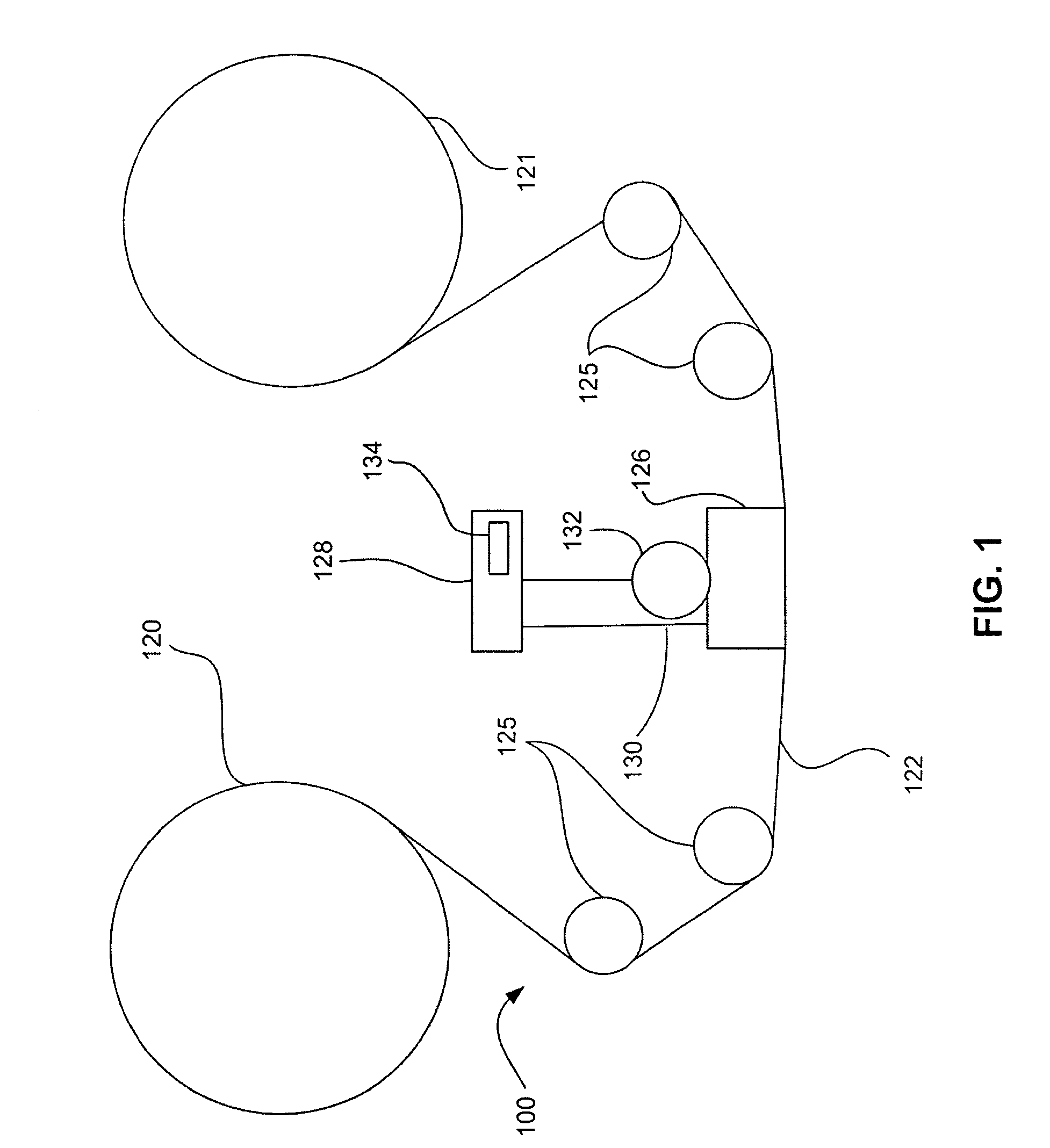

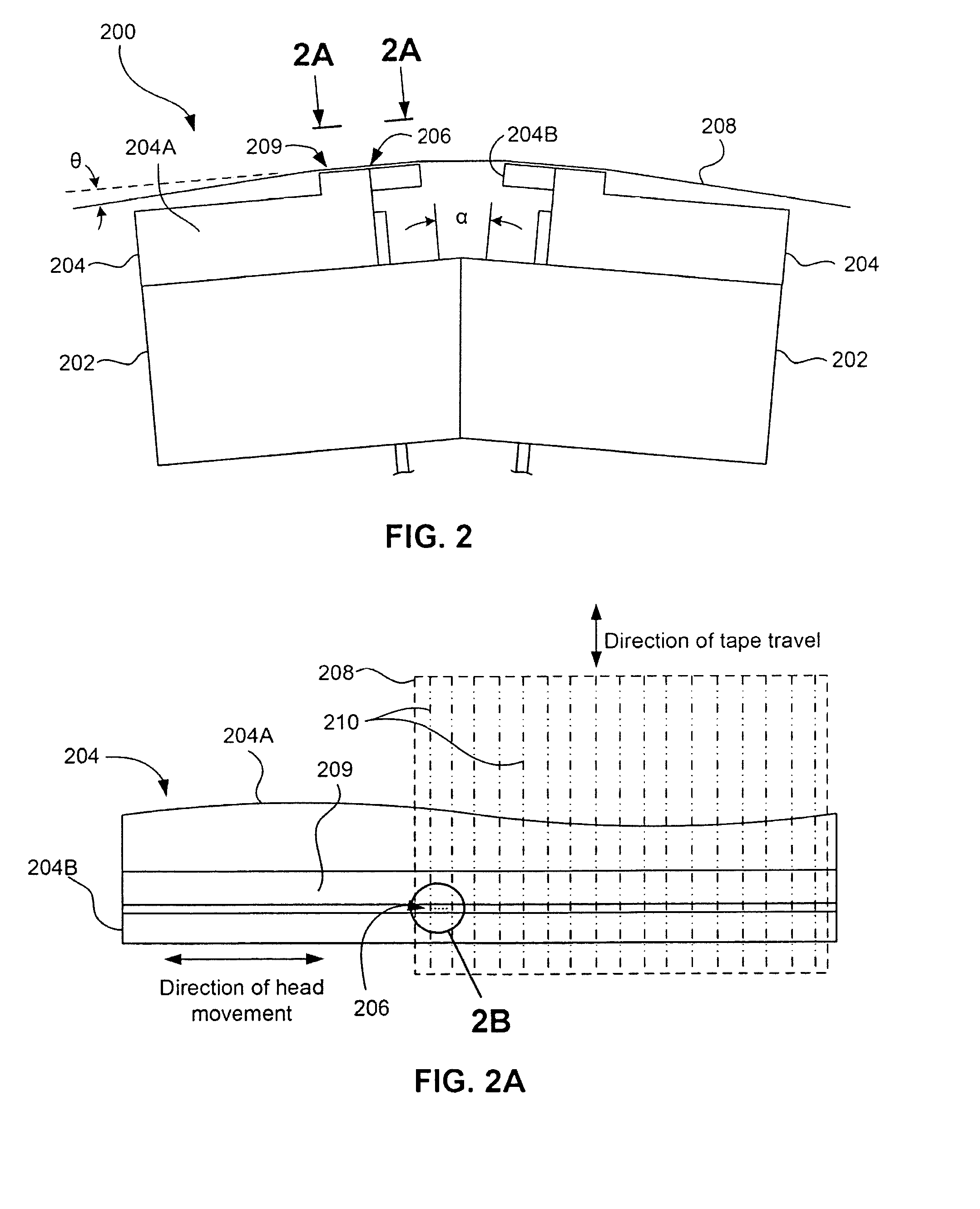

A wear gauge is provided for simulating the wear of a magnetic recording component at its interface with a magnetic storage medium comprising a wear gauge block having a wear surface that substantially approximates the geometrical dimensions and contour of the working surface of the magnetic recording component, wherein the wear surface has a coating of transparent material. A test method comprises mounting the wear gauge in a test fixture, positioning a tape and adjusting the overwrap angle at edges of the wear surface, choosing the desired tape tension, speed and runtime, and running the tape, preferably unidirectionally, in operational contact with the wear surface for the desired runtime. The wear surface is inspected under white light illumination to observe and record locations of interferometric color changes on the wear surface. The color changes are correlated to thickness changes of the transparent coating on the wear surface.

Owner:GLOBALFOUNDRIES INC

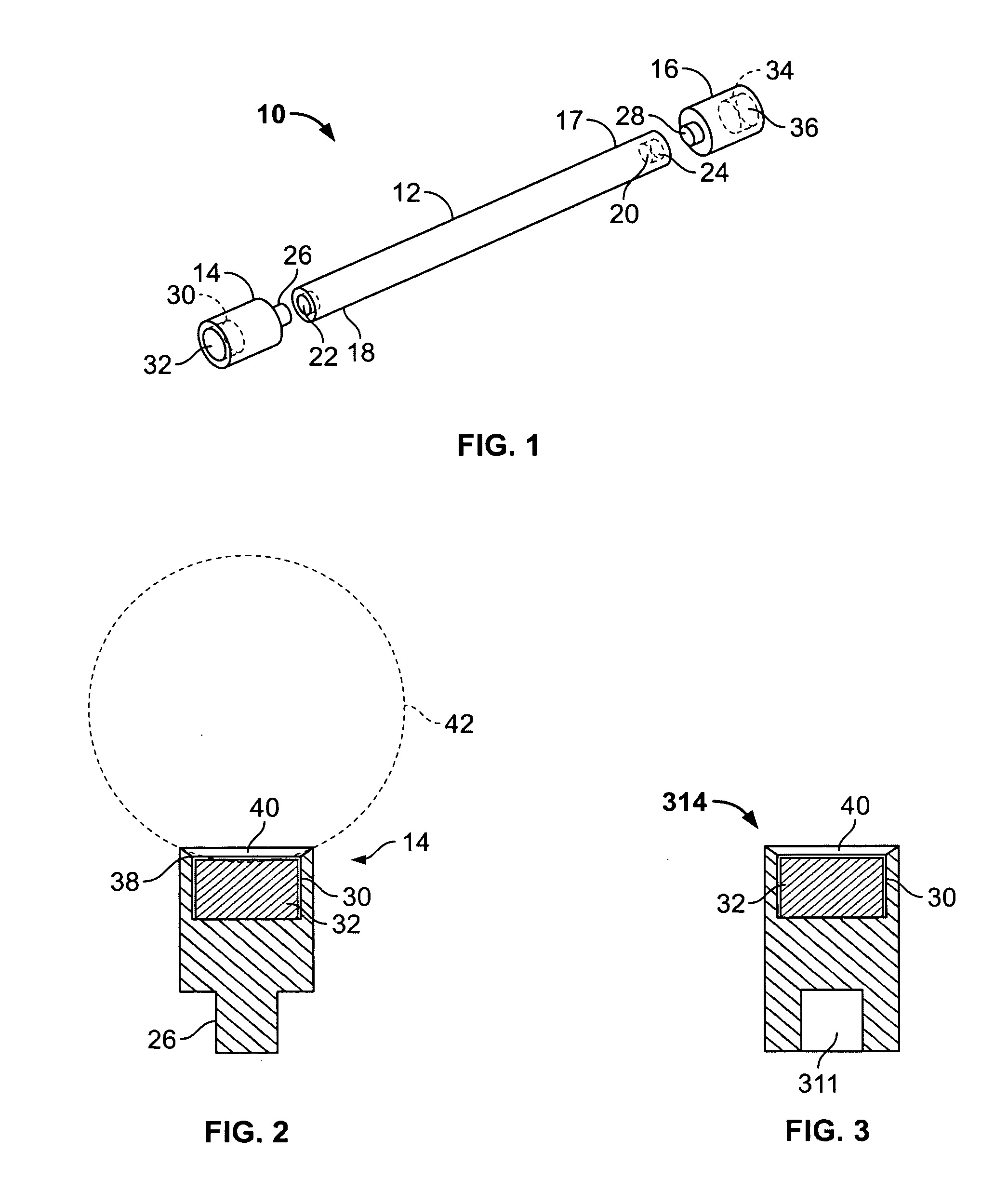

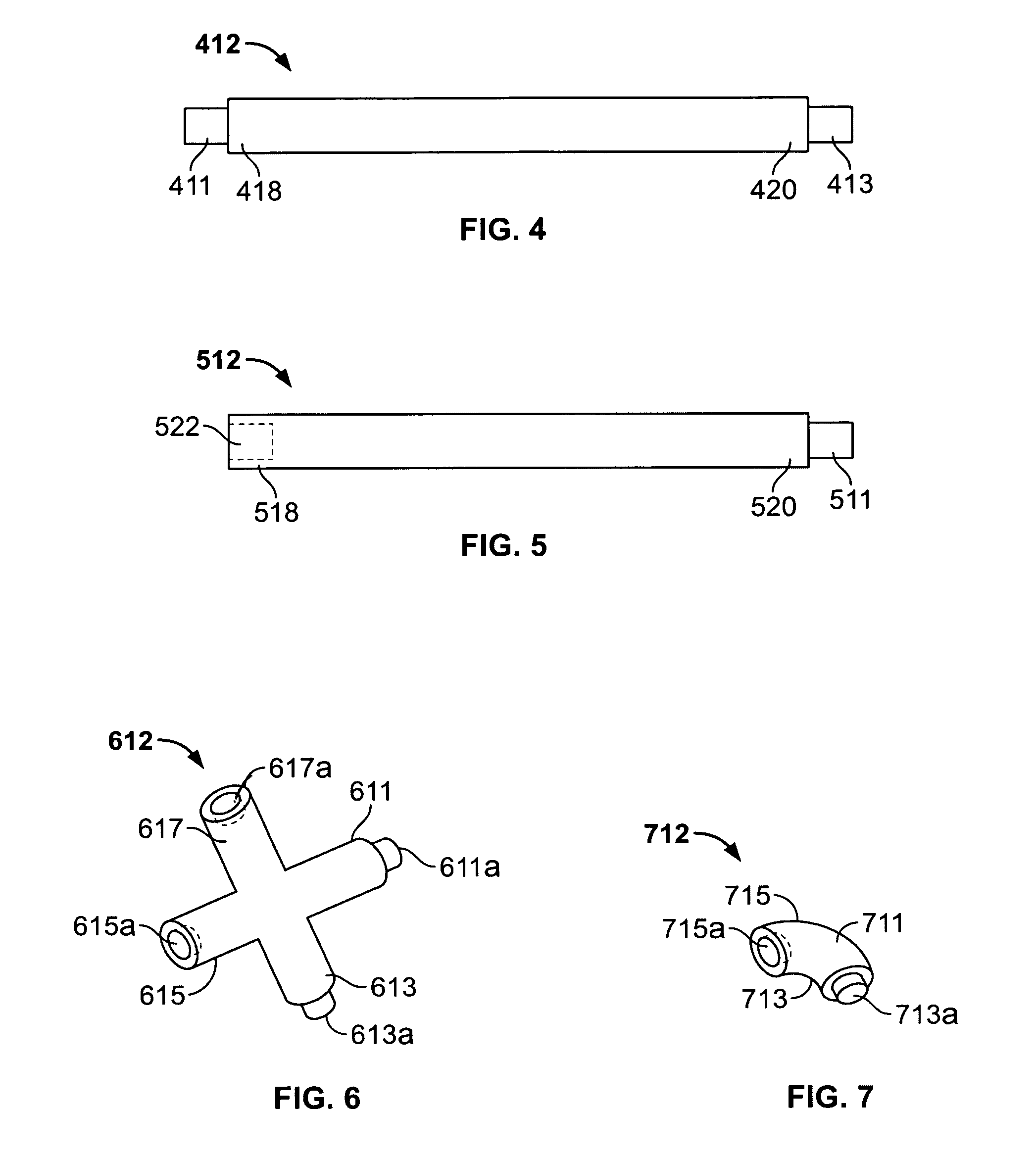

Magnetic construction module with interchangeable magnet holders

InactiveUS20050159076A1Improved structural profileImprove construction flexibilityRecord information storageToysArchitectural engineeringMetal sphere

A magnetic construction module that is suitable for creating a variety of different construction profiles and lengths and that permits the construction of modules where at least some of the members are adapted to be flexible. A rod is attachable to a holder adapted for retaining a magnet. The magnet is retained in a pocket of the holder. The holder can be attached in rods of various lengths, curves, rigidities to conform to the shape desired by the user. An outer surface of the magnet is adapted to provide a magnetic connection to a magnetizeable element such as a metal sphere with which the rod and holder can be operatively associated for a particular construction profile. Moreover, the holder may also be securely, selectively connected to the rod via a male-female connection in order to provide greater construction flexibility.

Owner:ROSE ART INDS +1

Cleaning tape

A cleaning tape for a magnetic head system having a magnetoresistance effect head as a reproducing head, comprising a nonmagnetic support, and a cleaning layer containing a magnetic powder and a binder formed on one surface of said support, wherein said cleaning layer has a specific surface resistivity of 3x103 to 5x108 OMEGA / cm2, does not cause performance failure due to the electrostatic breakdown of the magnetic head or the generation of an electric current, which does not cause performance failure due to electrostatic breakdown of a magnetic head or the generation of an electric current.

Owner:HITACHT MAXELL LTD

Systems and methods for protecting a sensitive device from corrosion

ActiveUS20090273857A1Reduce humidityEliminate corrosionUndesired vibrations/sounds insulation/absorptionRecord information storageEngineeringRelative humidity

A method for protecting a magnetic head according to one embodiment includes reducing a relative humidity in a vicinity of a magnetic head by passing an elevated bias current through a sensor of the head during at least some time periods when the sensor is not in use for reading data, the elevated bias current being chosen to be sufficient to heat the sensor to a level which will reduce the local relative humidity to below a threshold level for reducing or eliminating corrosion of the sensor. Additional methods are also presented.

Owner:IBM CORP

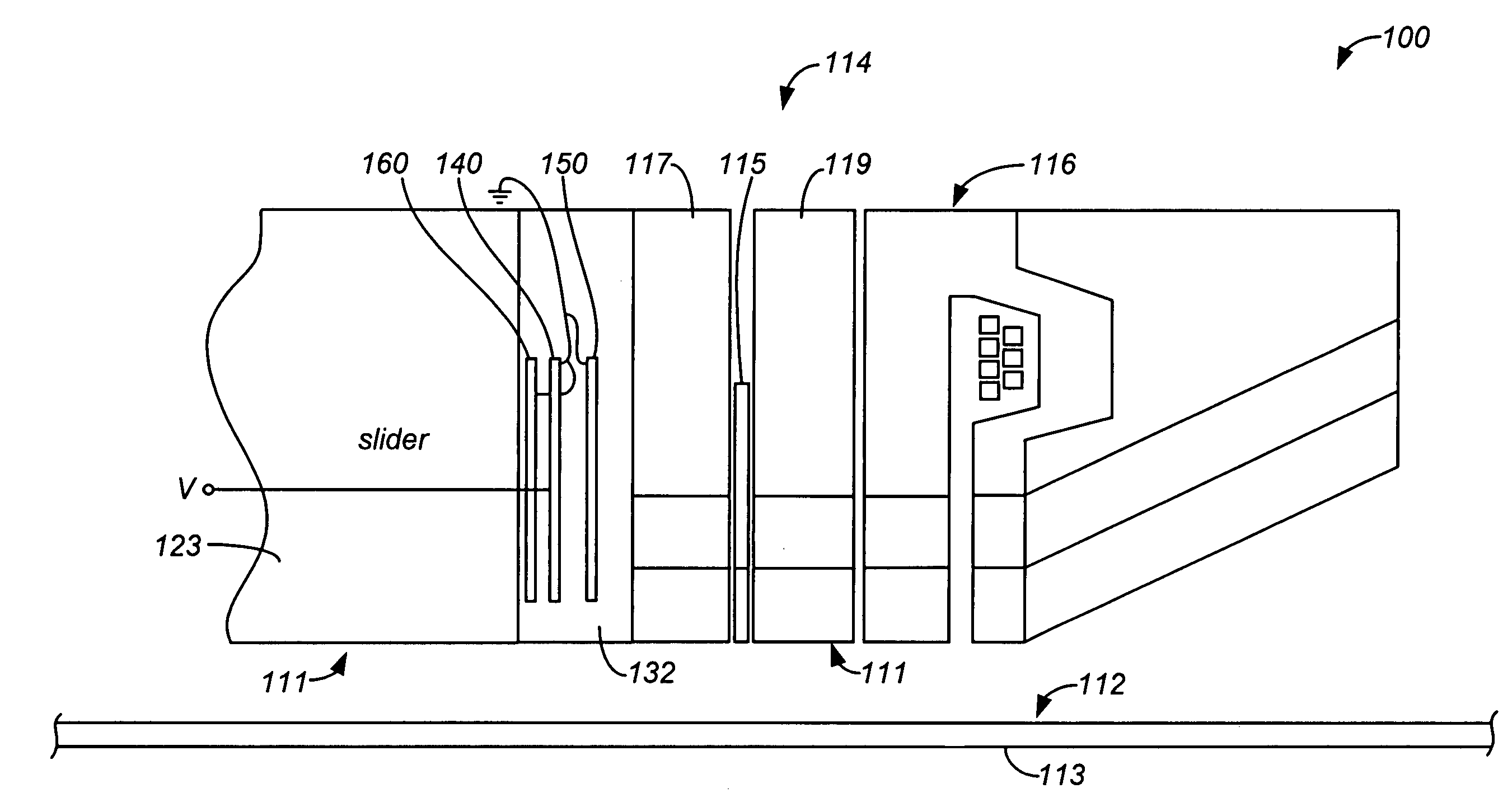

Eliminating ESD exposure for read/write head with heating element

InactiveUS7199982B2Eliminate leaksDisposition/mounting of recording headsRecord information storageEngineeringVoltage

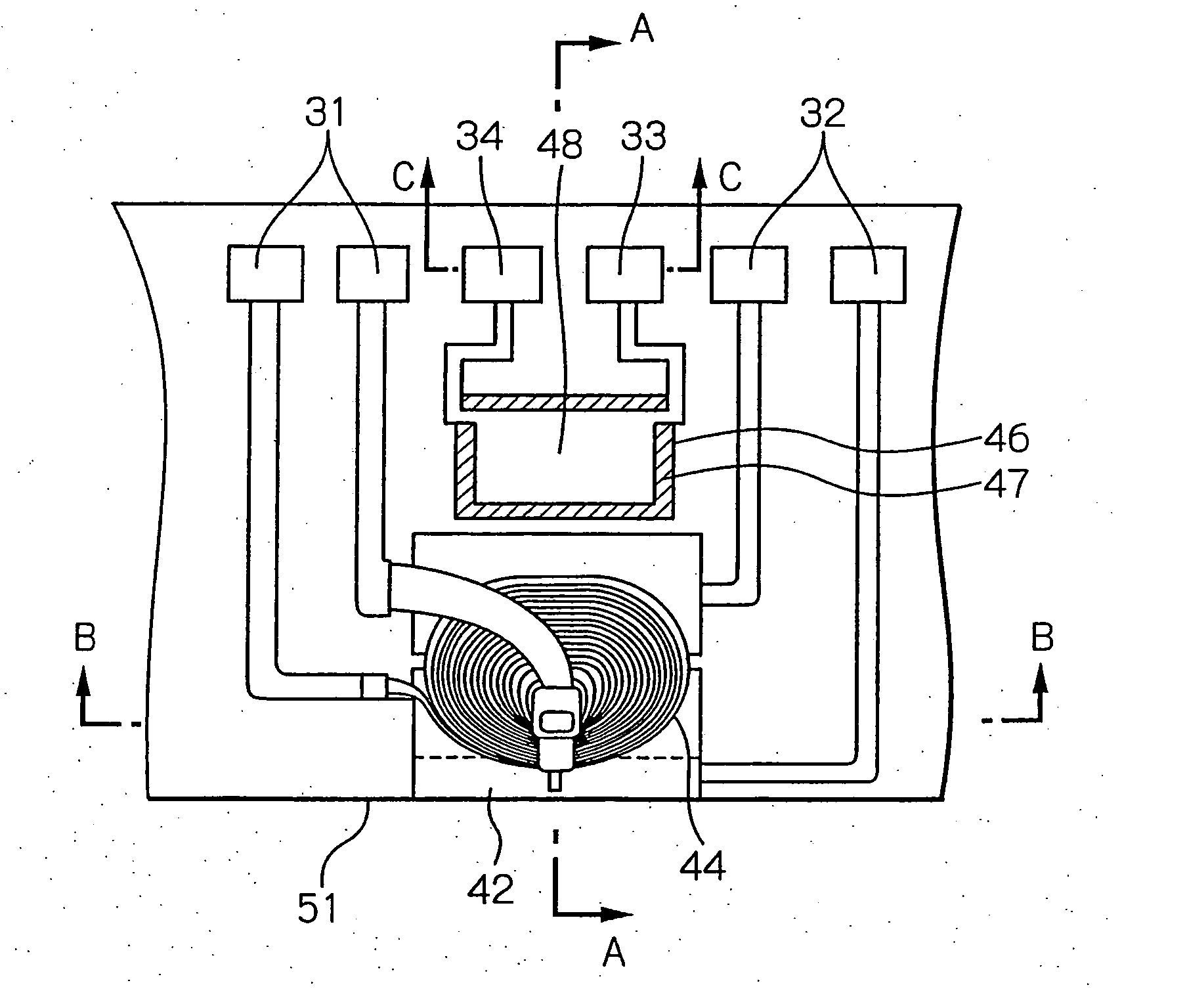

Embodiments of the present invention provide a grounded conductive layer between the heater and the lower magnetoresistive (MR) shield in the read / write head structure. The grounded conductive layer eliminates or at least substantially prevents the accumulation of charges on the lower MR shield as a result of the voltage supplied to the heater. In one embodiment, a magnetic head comprises a plurality of read / write components; a heater disposed near the plurality of read / write components; and a grounded conductive layer disposed between the heater and the plurality of read / write components.

Owner:WESTERN DIGITAL TECH INC

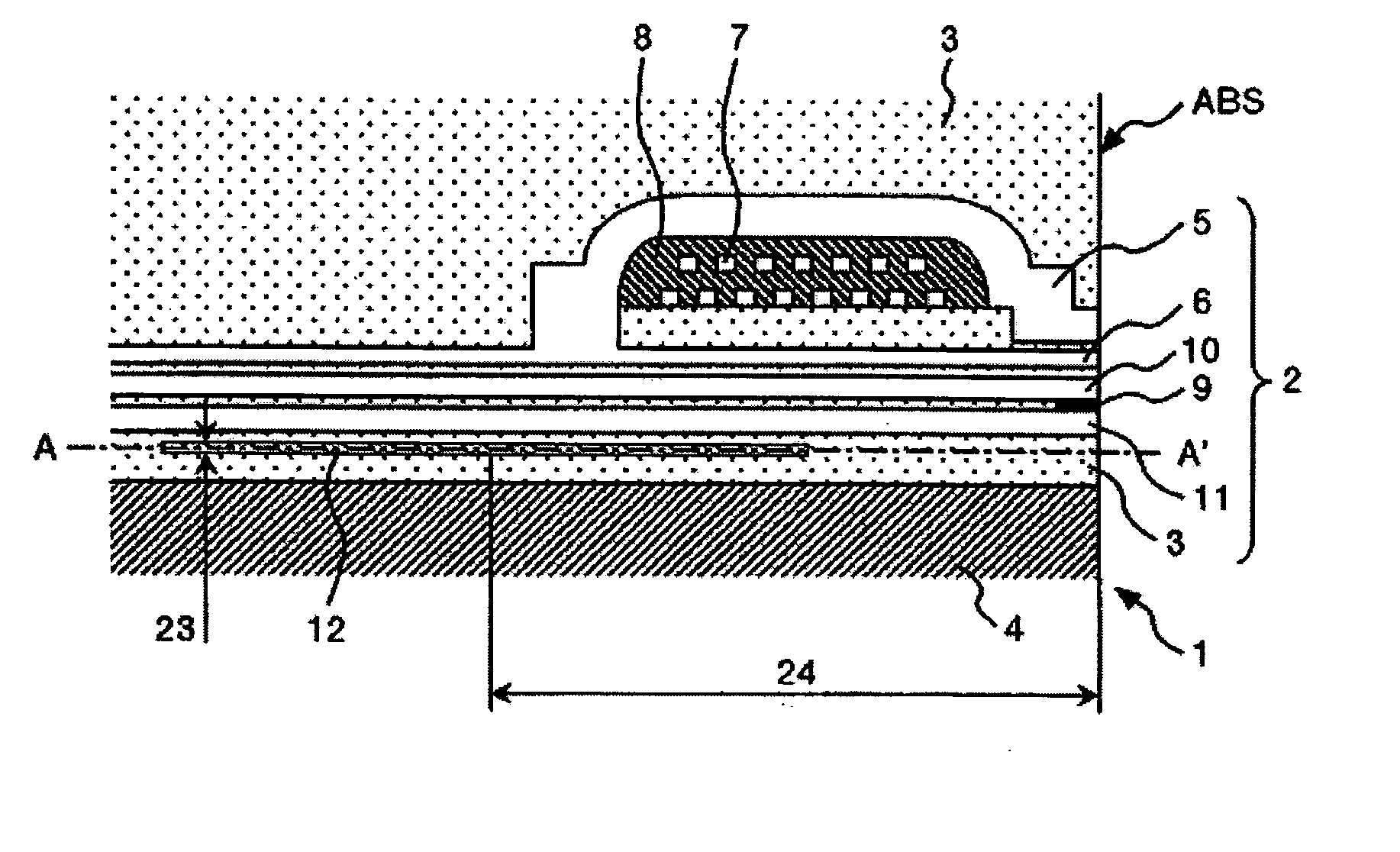

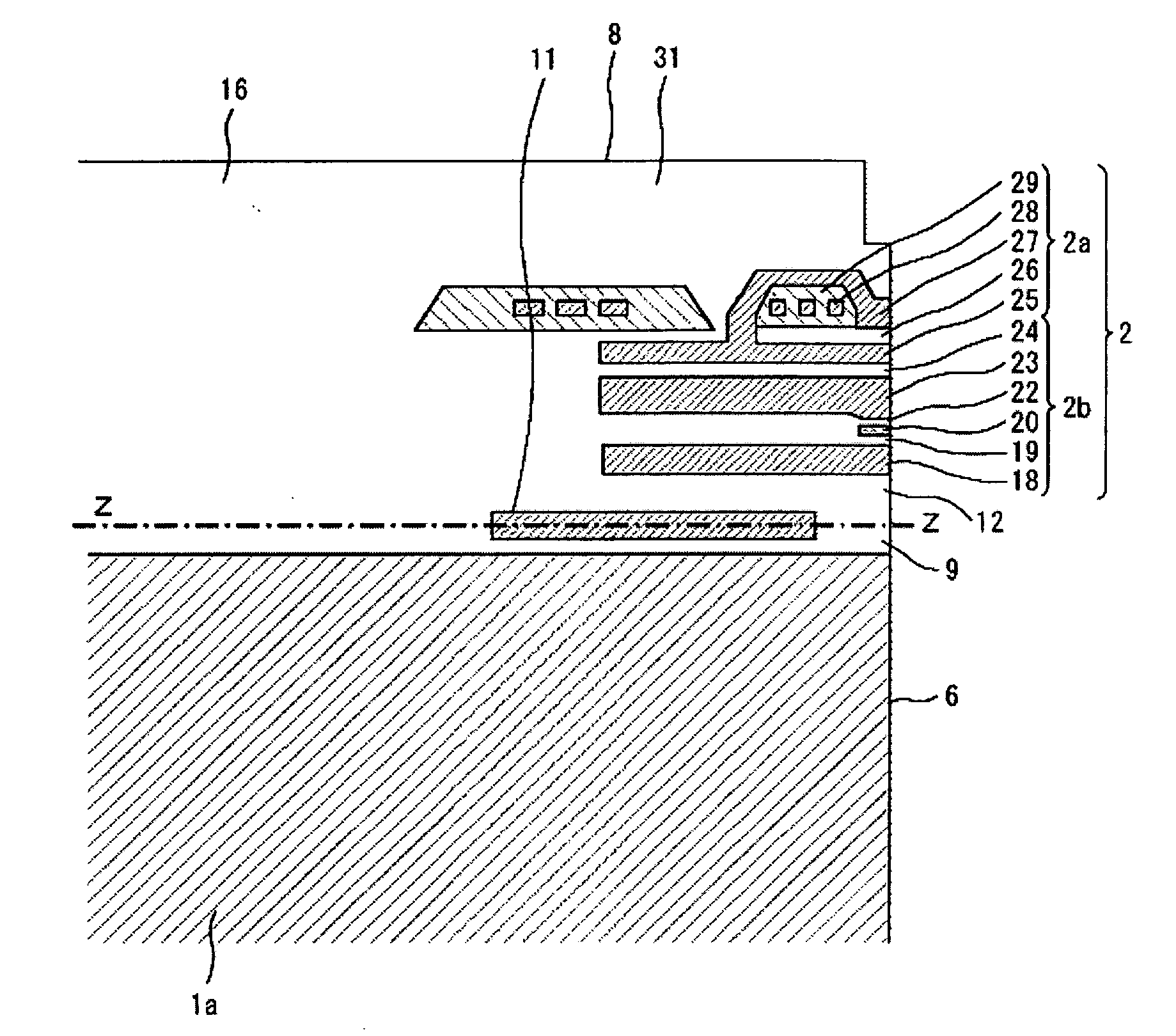

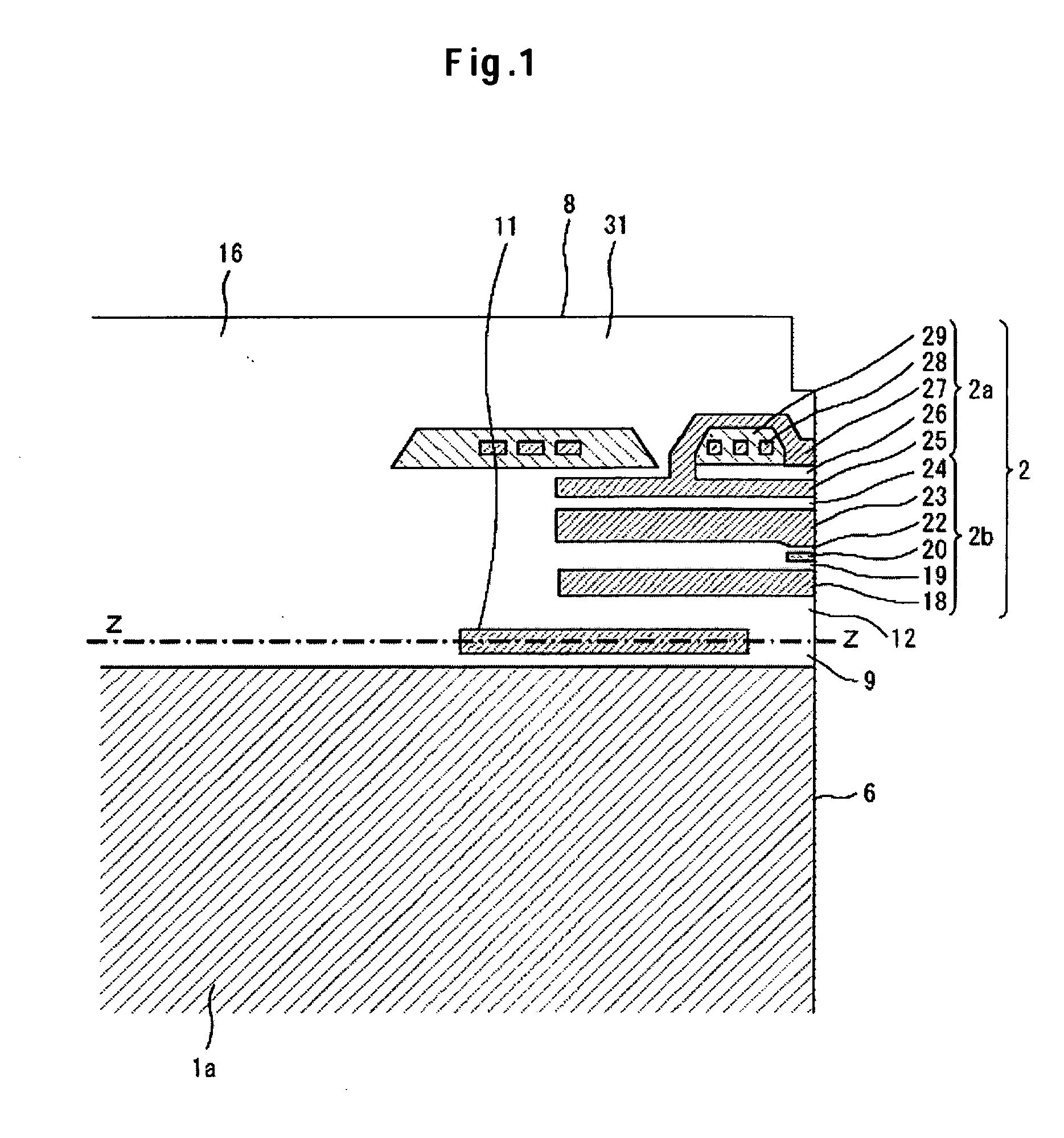

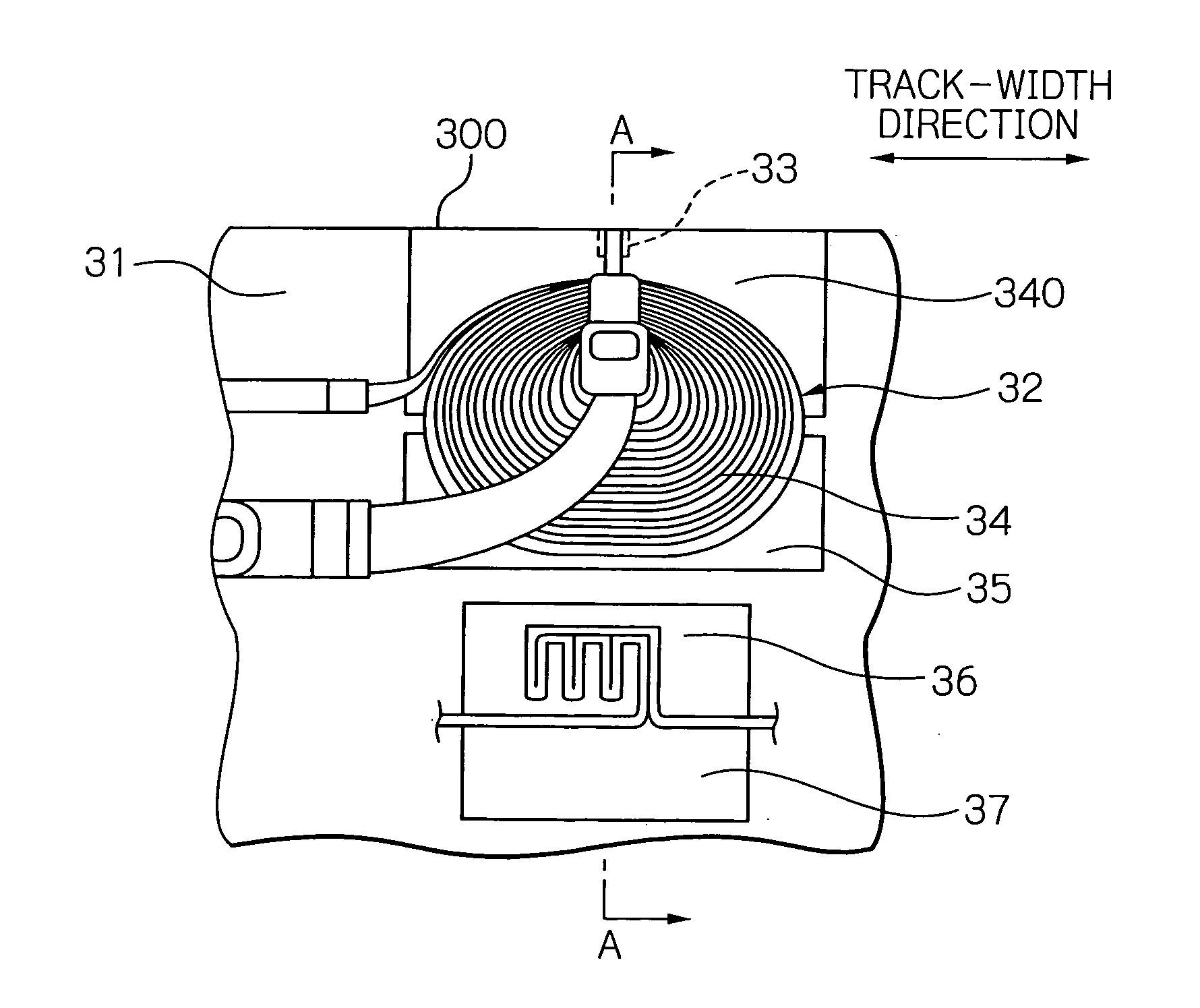

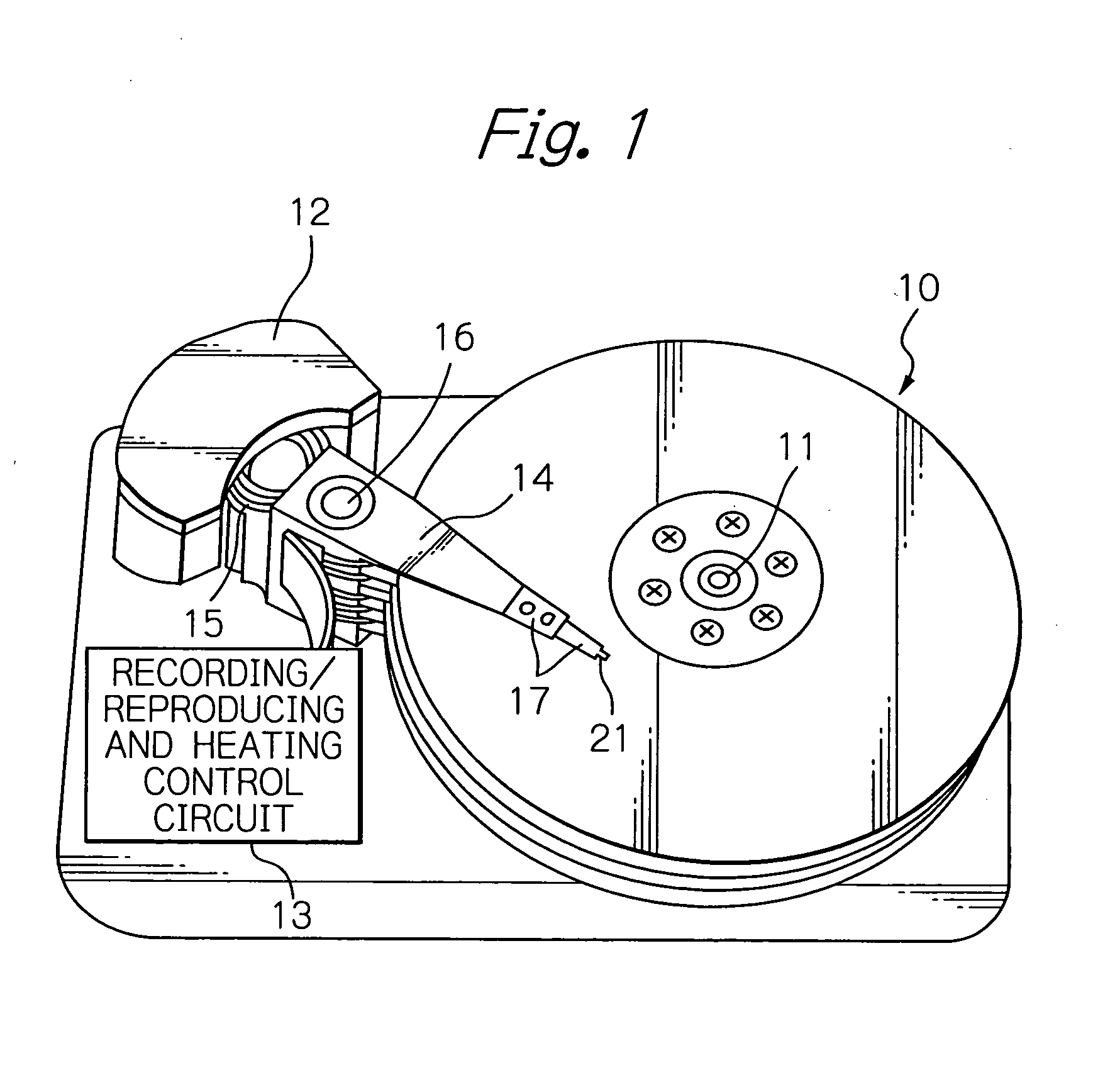

Magnetic head with heater of thermal flying height control

InactiveUS20060034014A1Prevent leakageImprove response speedRecord information storageFluid-dynamic spacing of headsFlying heightResistor

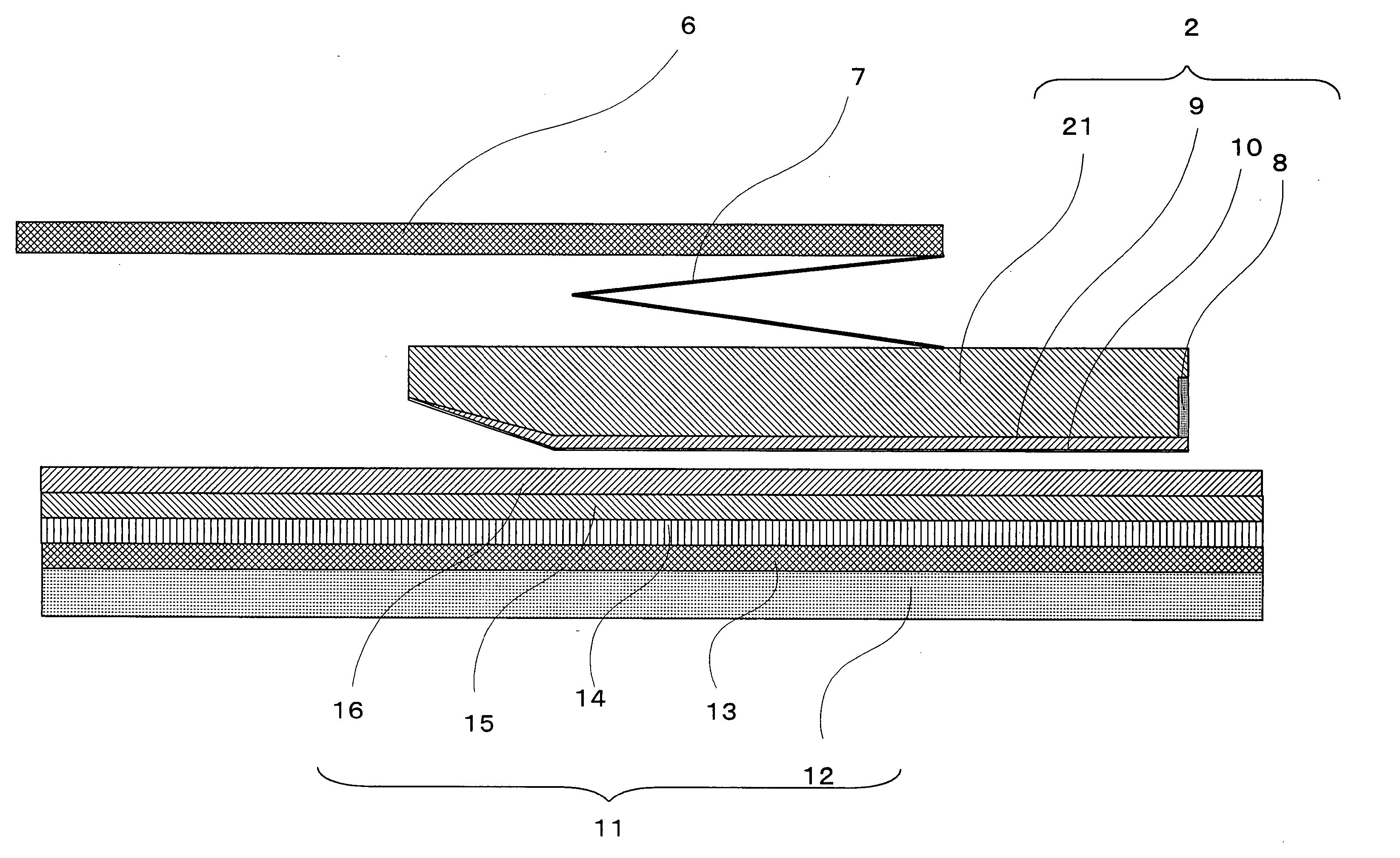

In one embodiment, a magnetic write / read device comprising a magnetic read element and a magnetic write element is formed in a thin film magnetic head portion of a magnetic head slider. A heat generating resistor is formed between a substrate portion and the magnetic reproducing device for heating thereby thermally expanding and protruding a portion of the magnetic head slider to control the flying height. The heat generating resistor is positioned between the substrate portion and the magnetic reproducing device being apart from the magnetic reproducing device for making the response speed for the flying height control of the magnetic head slider as high as possible and decreasing the effect caused by the heat generation of the heat generating resistor on the magnetic reproducing device as little as possible. The thickness of the insulating film is made greater than 10 times or less that of the heat generating resistor for ensuring insulation between the heat generating resistor and the metal film of a lower shield film.

Owner:WESTERN DIGITAL TECH INC

Cleaning medium

ActiveUS20060066998A1Wear minimizationReproducing output decreaseRecord information storageManufacture of flux-sensitive headsAnalytical chemistry

A cleaning medium comprising: a backcoat layer; a nonmagnetic support; and a cleaning layer containing ferromagnetic powder and a binder, in this order, wherein the cleaning layer has projections having a height of 10 nm or higher on a surface of the cleaning layer at a density of from 0.10 to 5.0 / μm2 and a surface microhardness of from 294 to 784 MPa.

Owner:FUJIFILM CORP +1

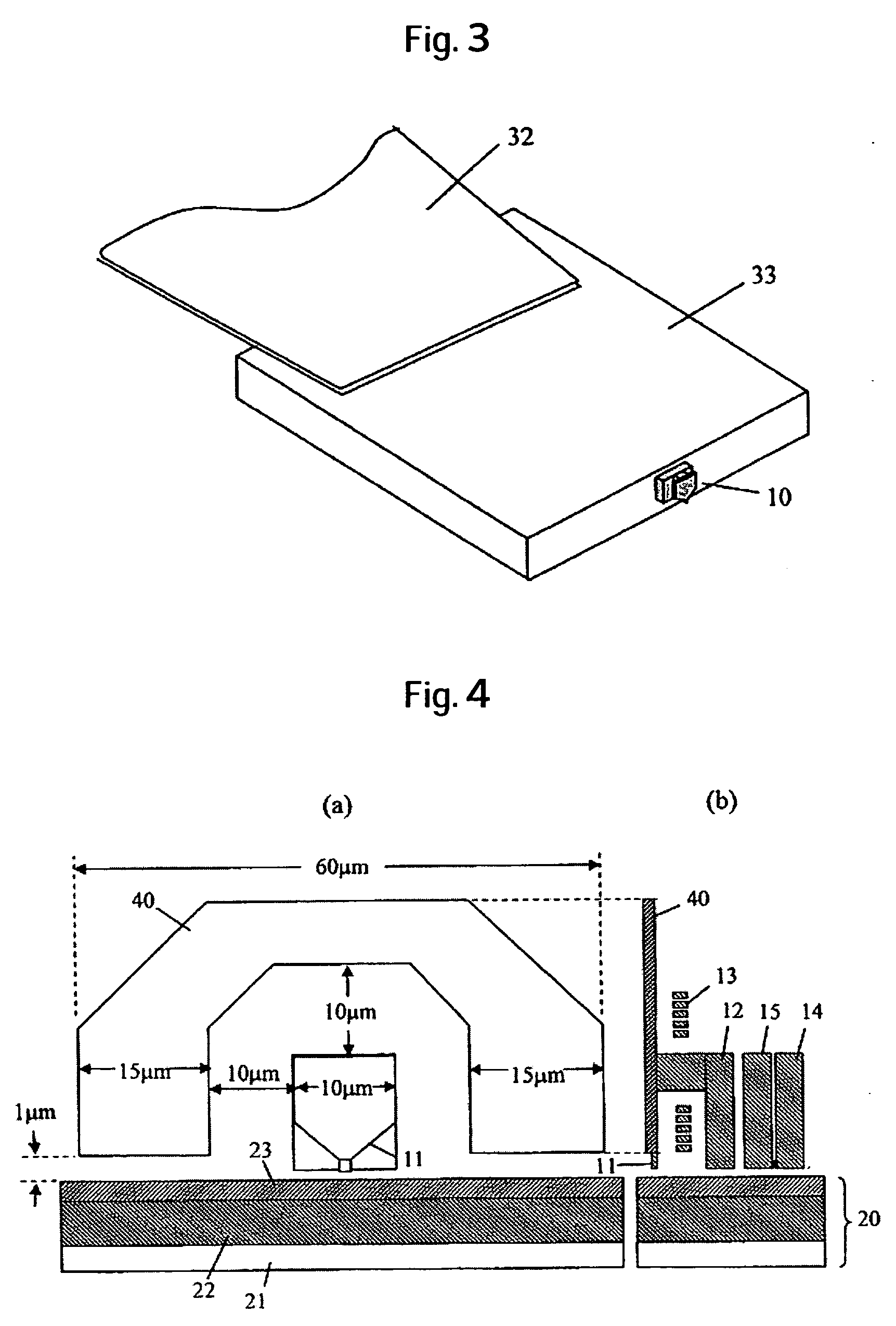

Thin-film magnetic head with heater for adjusting magnetic spacing

ActiveUS20060077591A1Simple designClearly definedRecord information storageCleaning recording headsAir bearing surfaceEngineering

A thin-film magnetic head with a higher protrusion efficiency is provided, which comprises: a substrate with an air bearing surface (ABS); a read head element including a lower and upper shield layers, and a write head element including a magnetic pole layer; a heating element provided in a position opposite to the ABS in relation to the read and write head elements; and a heatsink element including a heatsink layer provided adjacent to an end opposite to an end in the ABS side of at least one layer of the lower and upper shield layers and the magnetic pole layer, the heatsink element having a shape that a pattern width in the track-width direction of an end portion in the ABS side is larger than a pattern width in the track-width direction of an end portion opposite to the end portion in the ABS side.

Owner:TDK CORPARATION

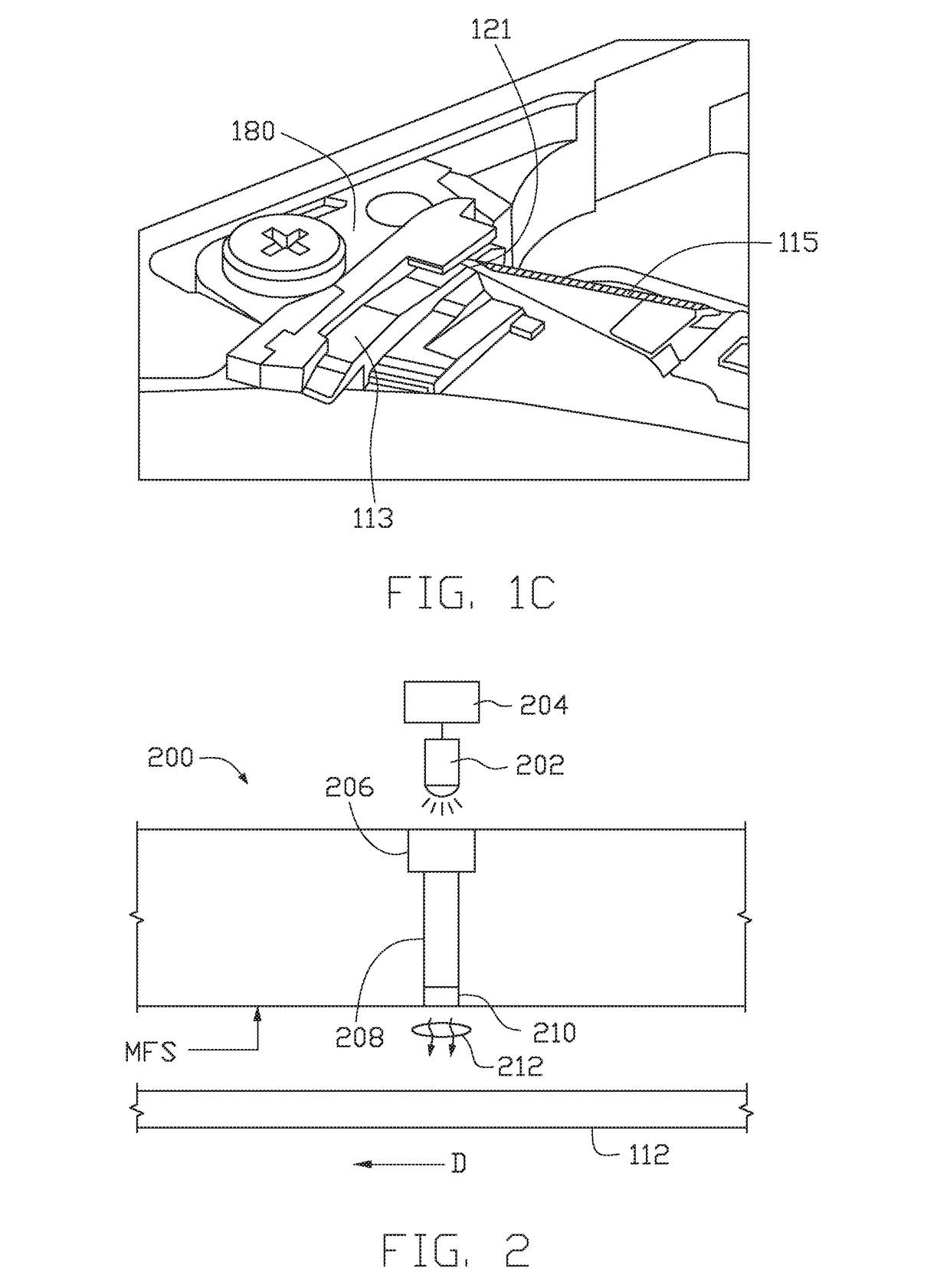

Reducing carbonaceous smear at the NFT area on HAMR head

InactiveUS20170221511A1Combination recordingOptical beam sourcesMagnetic mediaBiomedical engineering

The present disclosure generally relates a method for removing a smear from a write head in a HAMR system. The smear can be removed by sufficiently heating the smear in an oxidative atmosphere to oxidize the smear. The material buildup that forms the smear has carbon, that when oxidized, is a gaseous product that leaves the write head with a reduced and / or eliminated smear. The heating occurs when the head is disposed in the parking location on the ramp remote from the magnetic media. Heating is possible using the same heat source for the HAMR head that is used to write data to the magnetic media.

Owner:WESTERN DIGITAL TECH INC

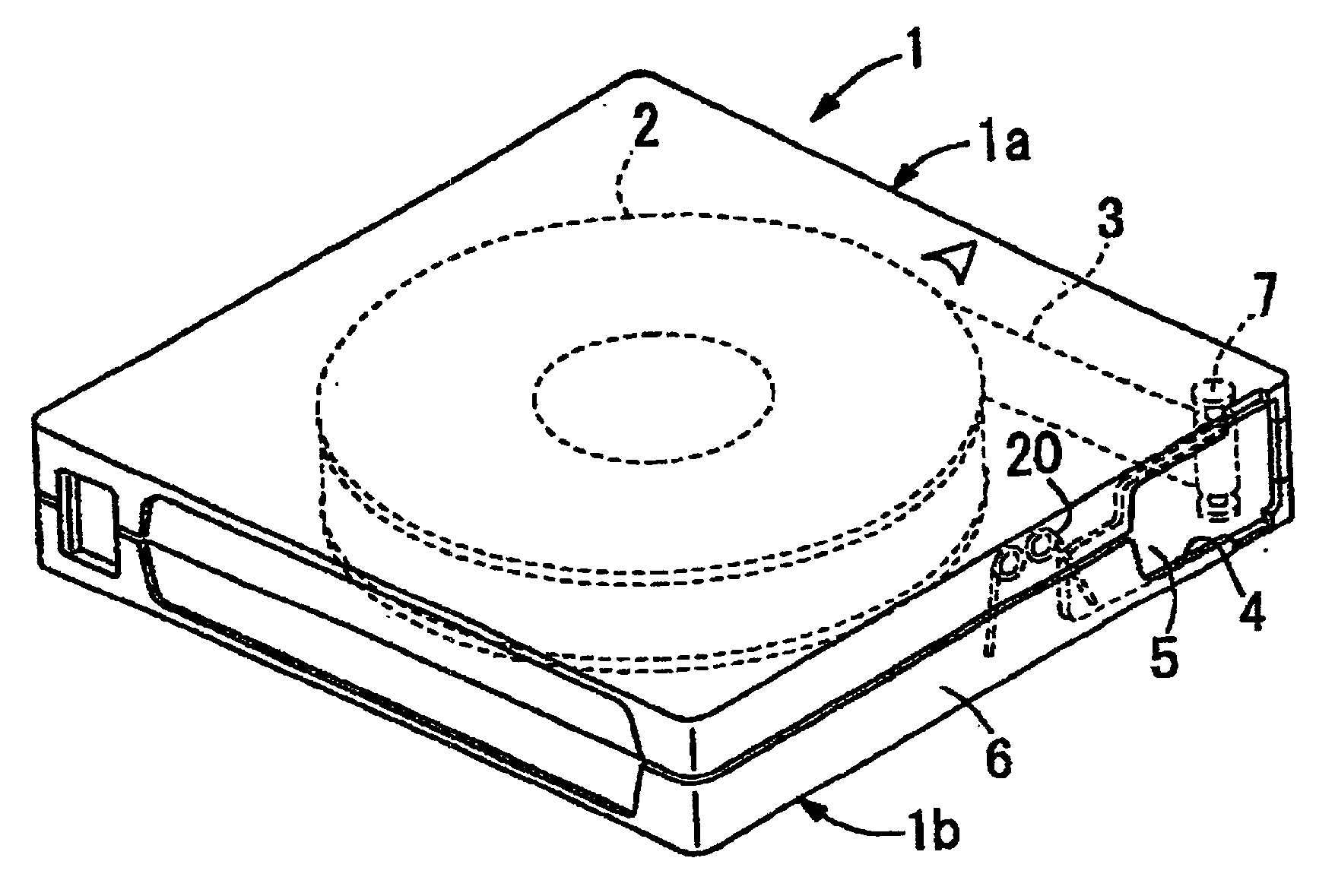

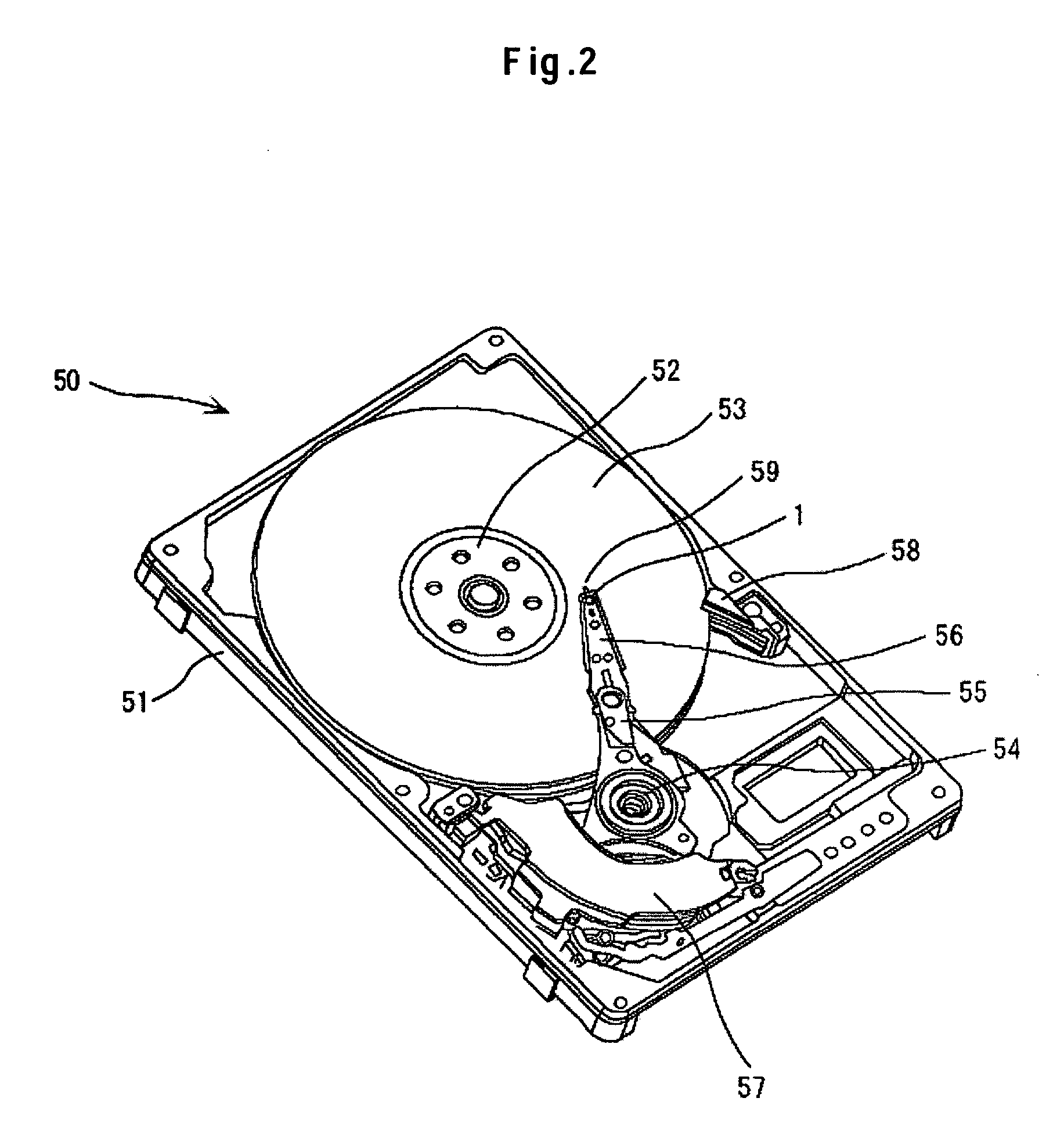

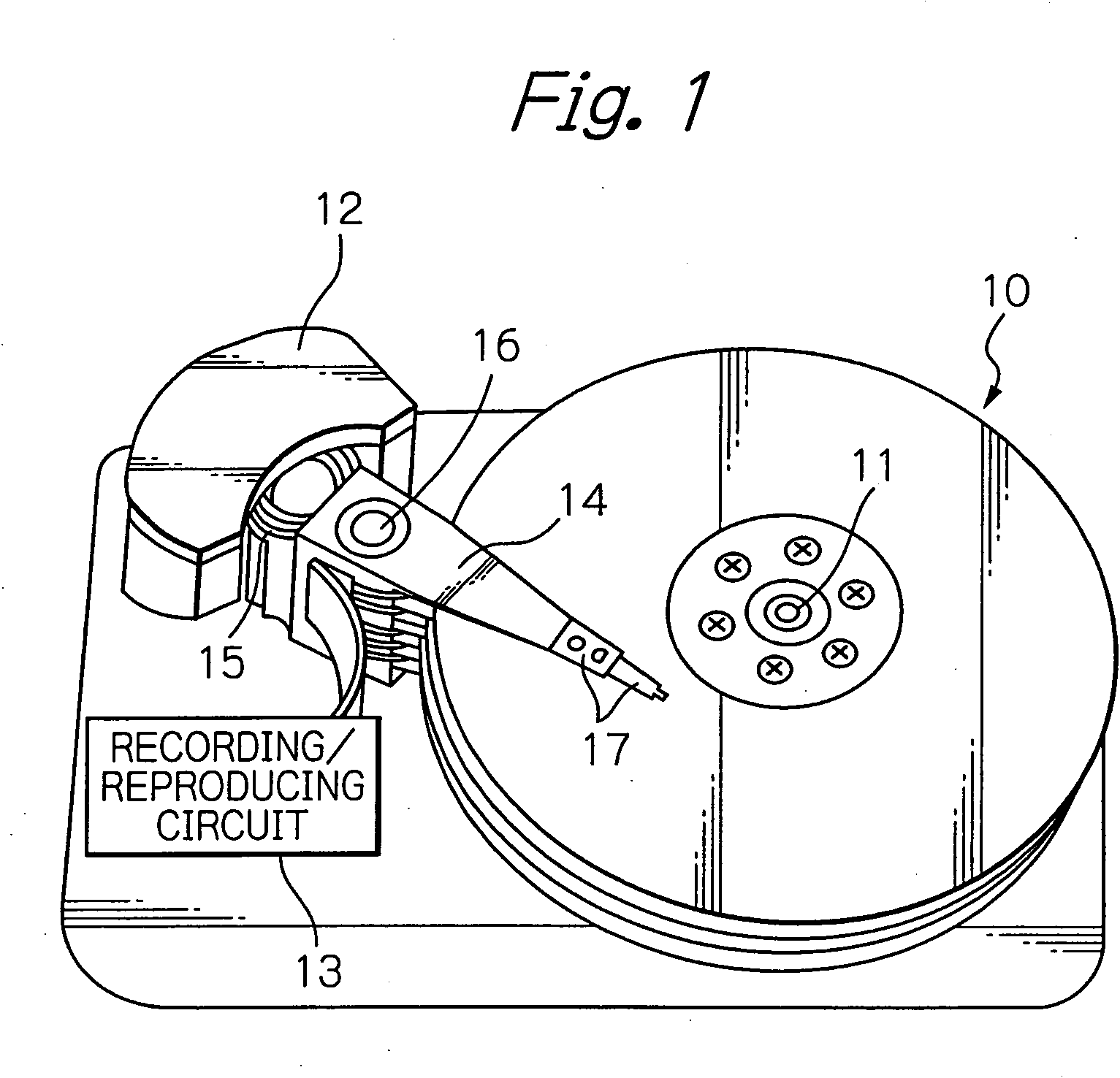

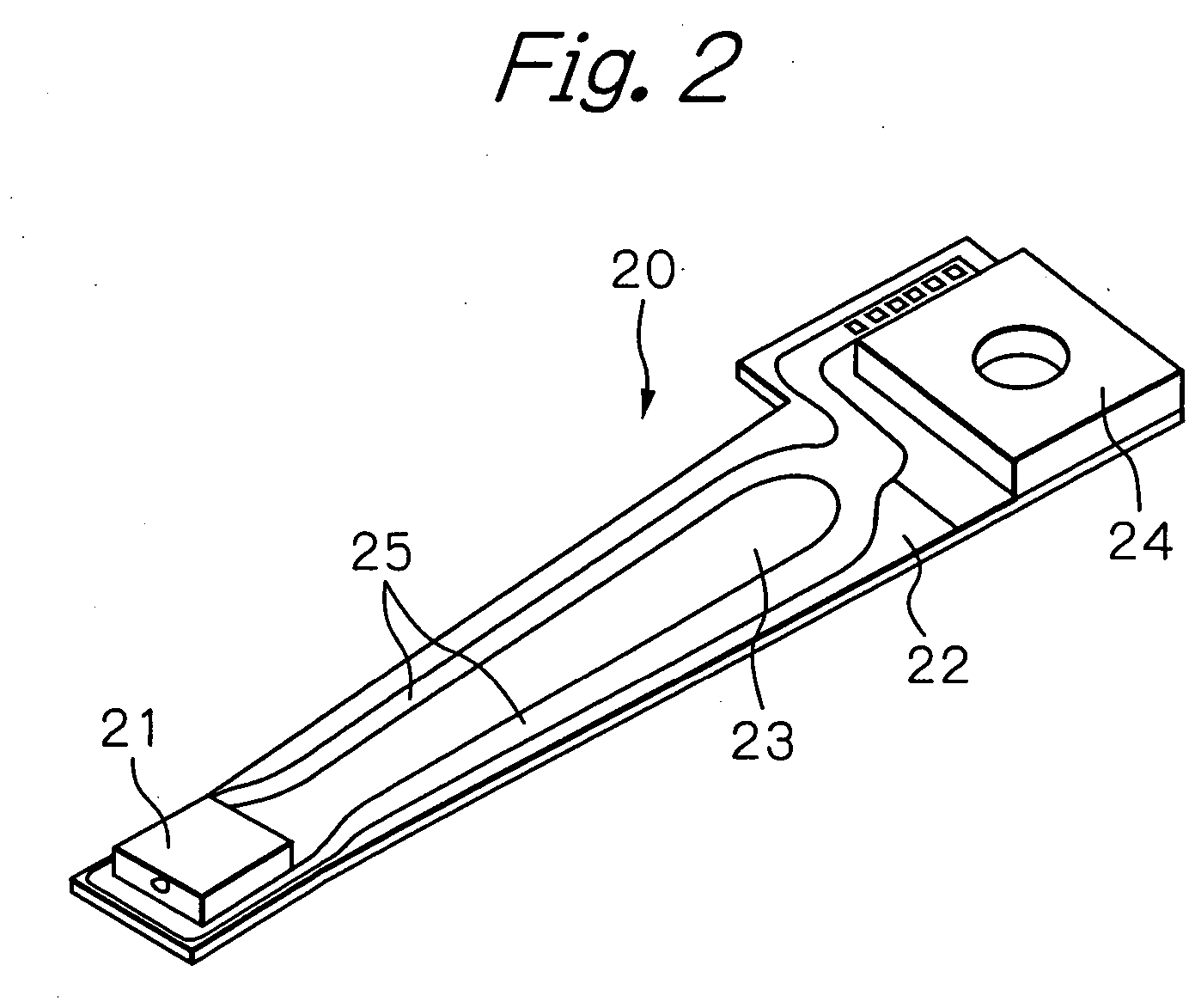

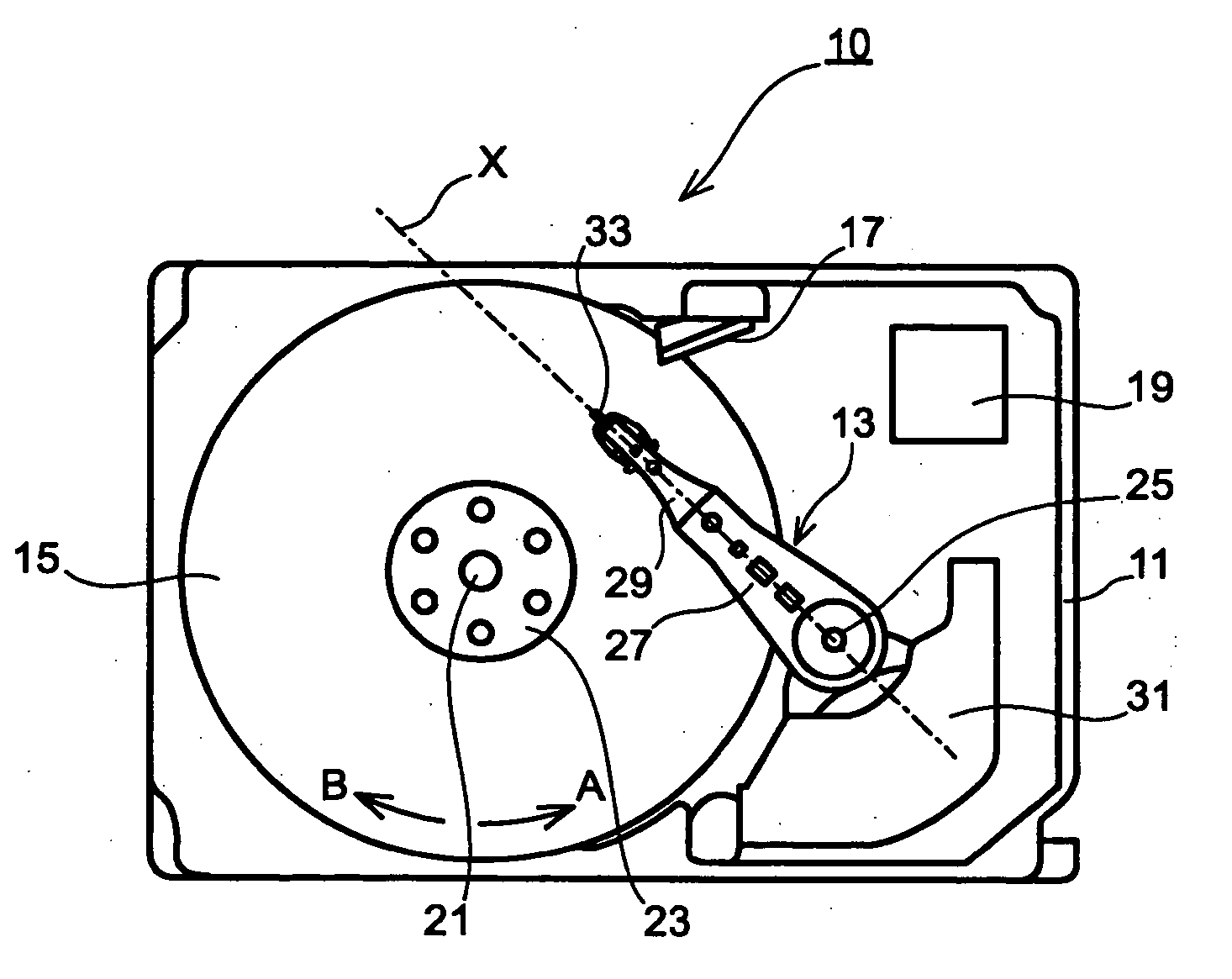

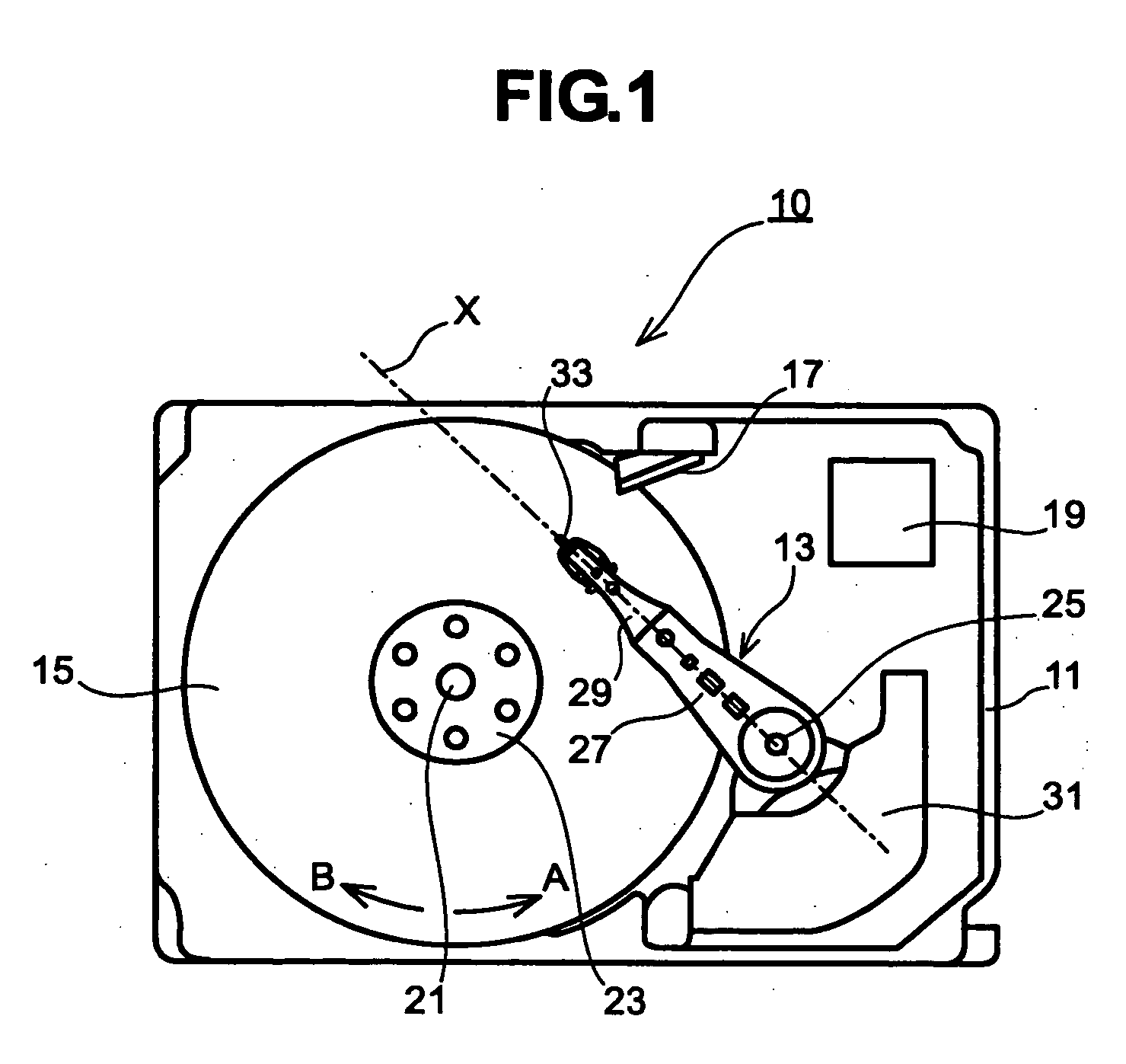

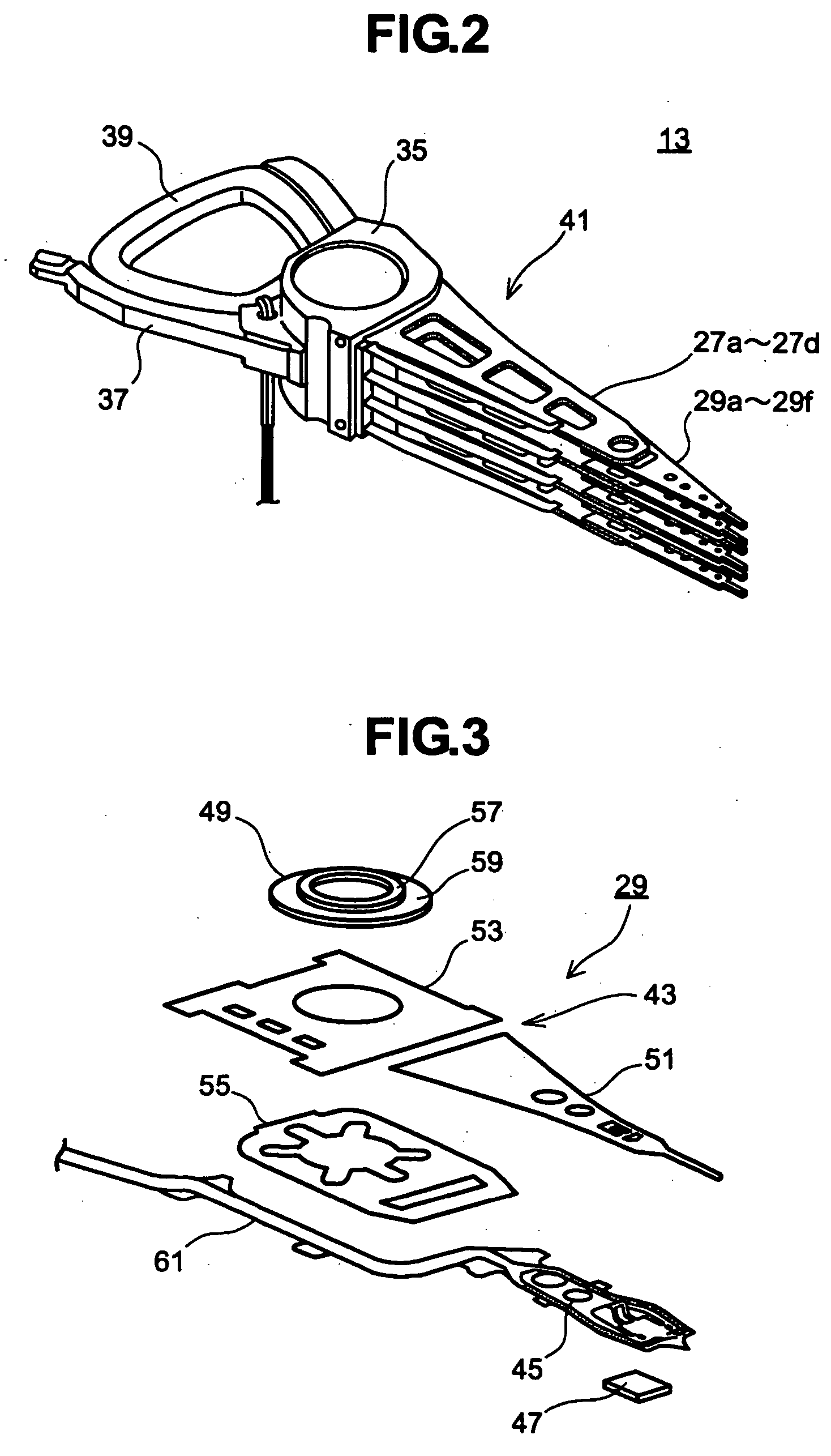

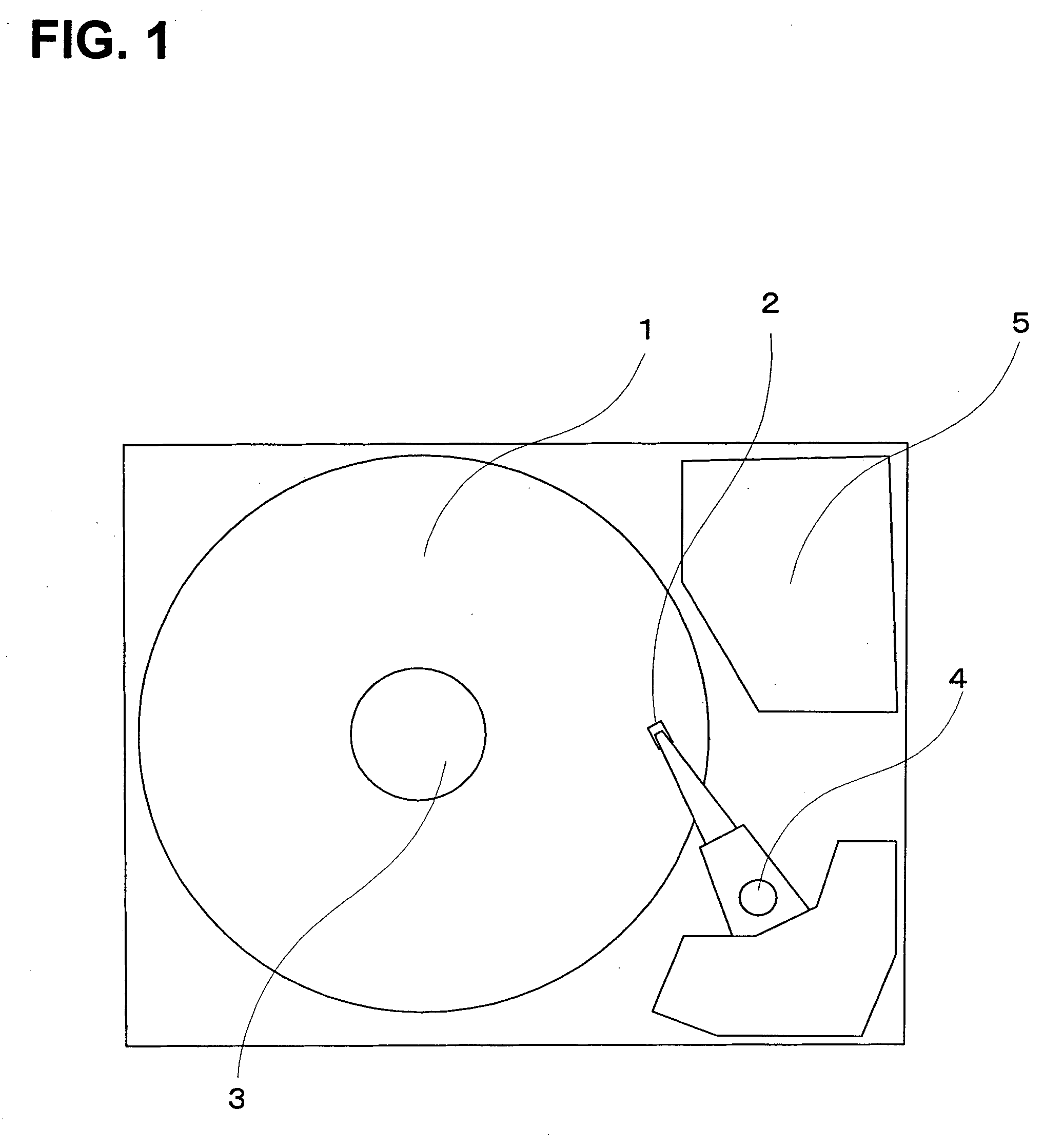

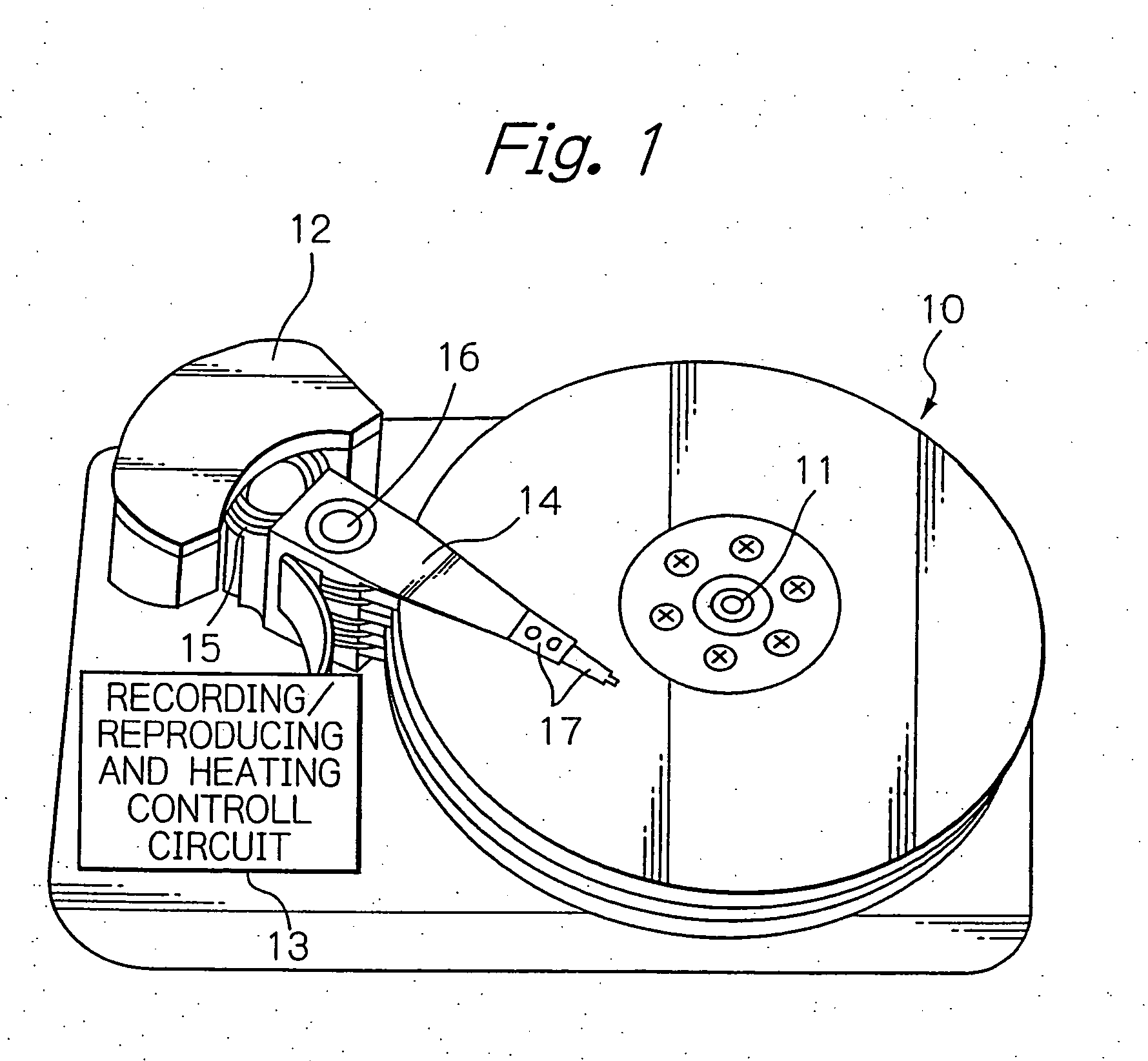

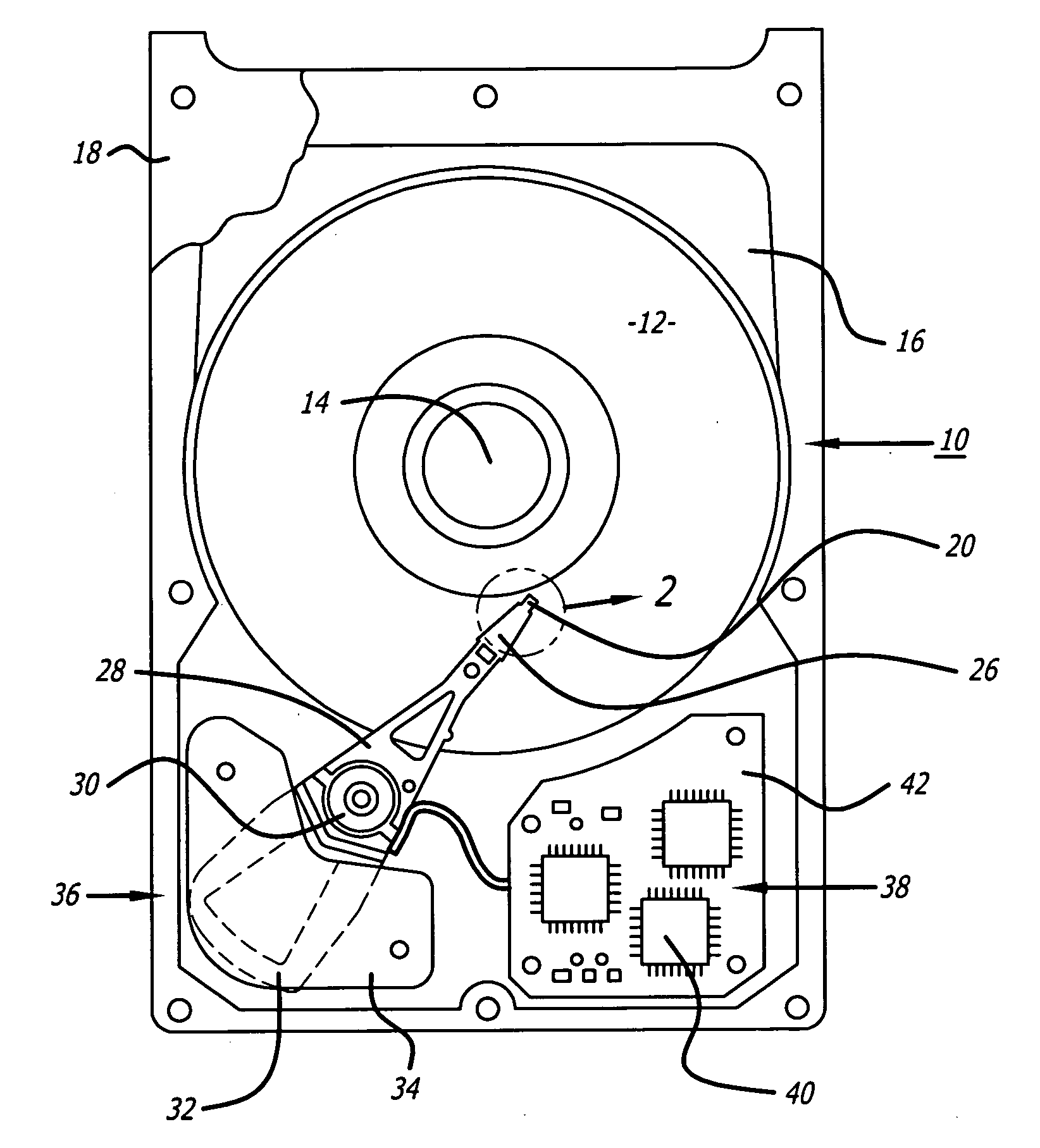

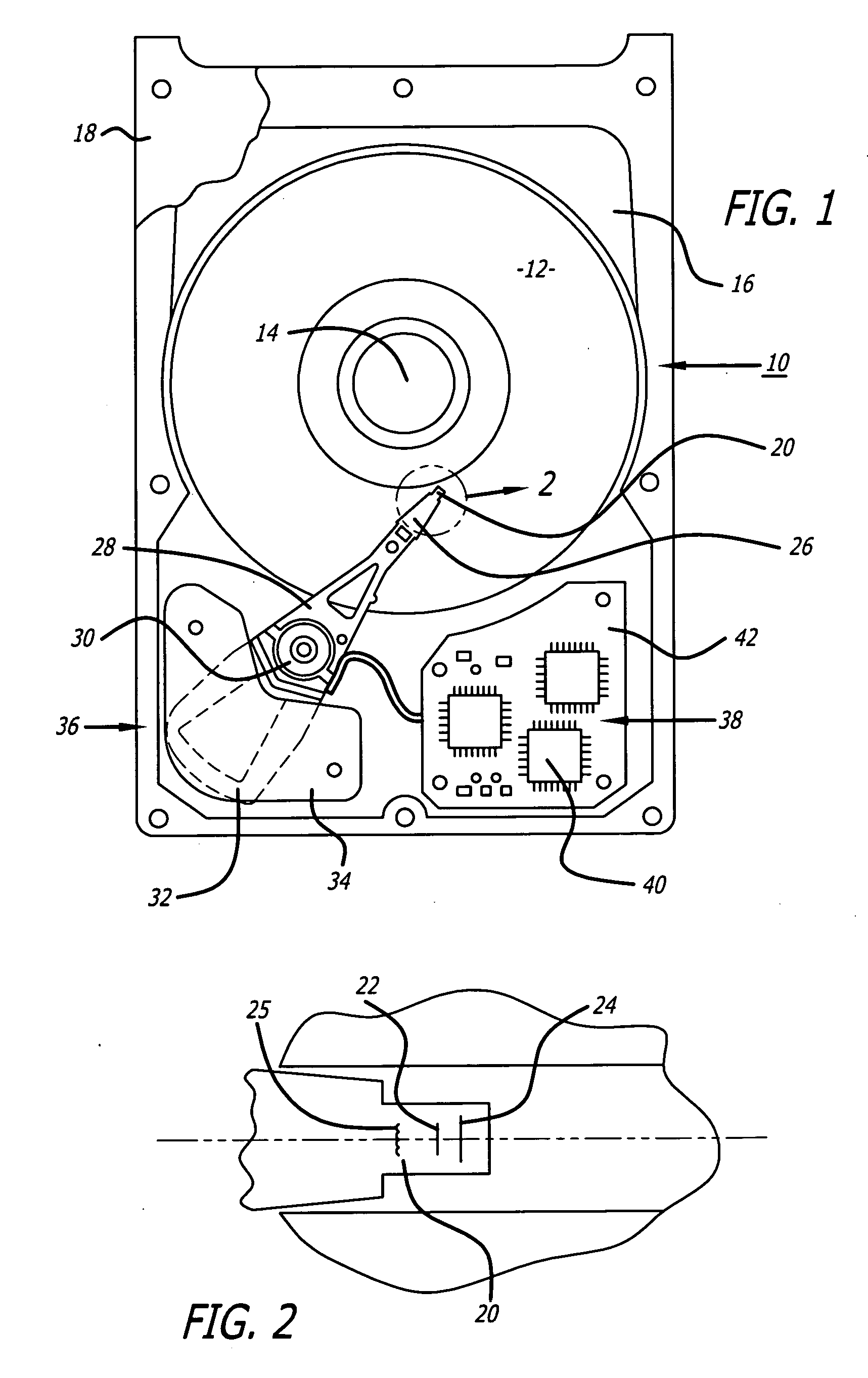

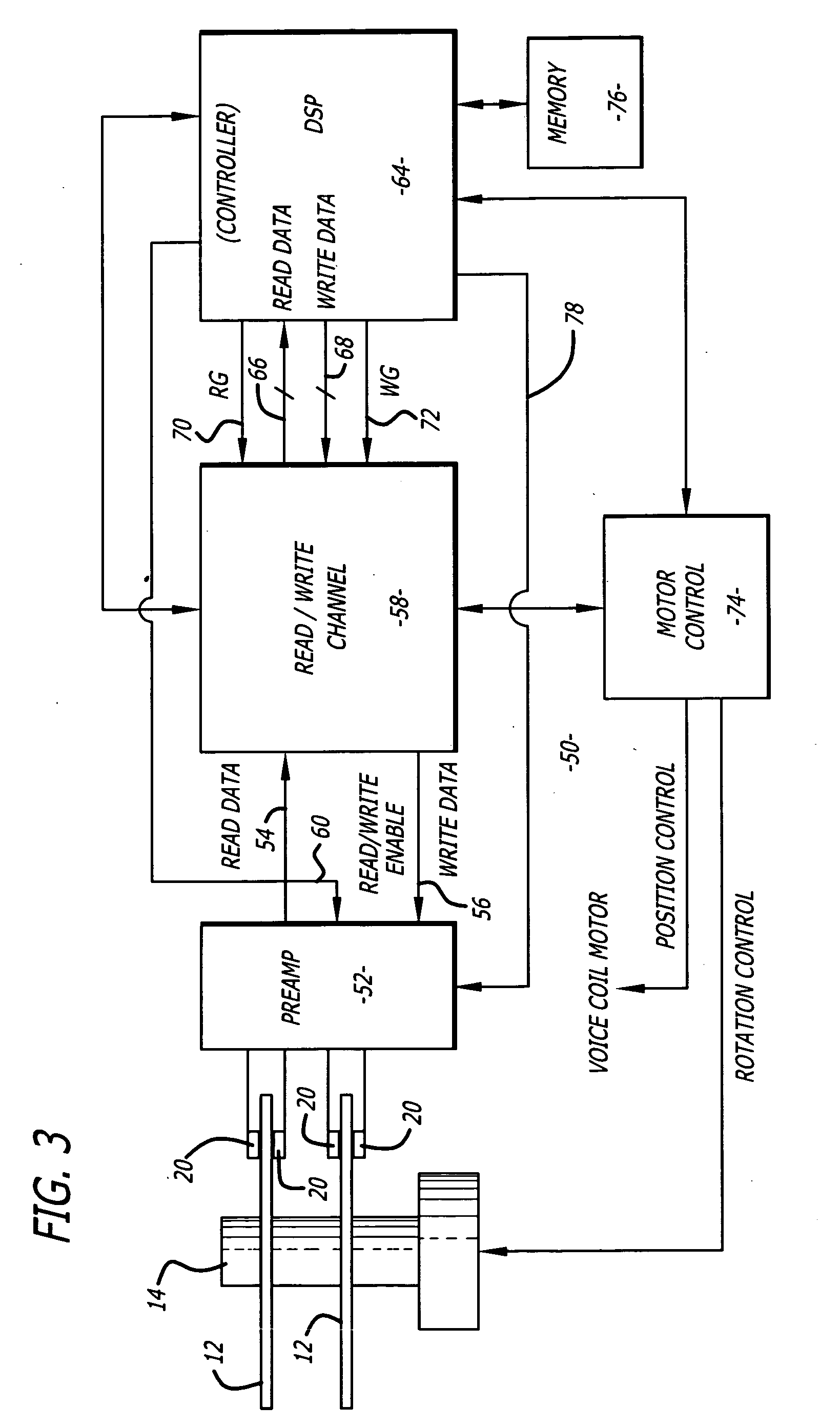

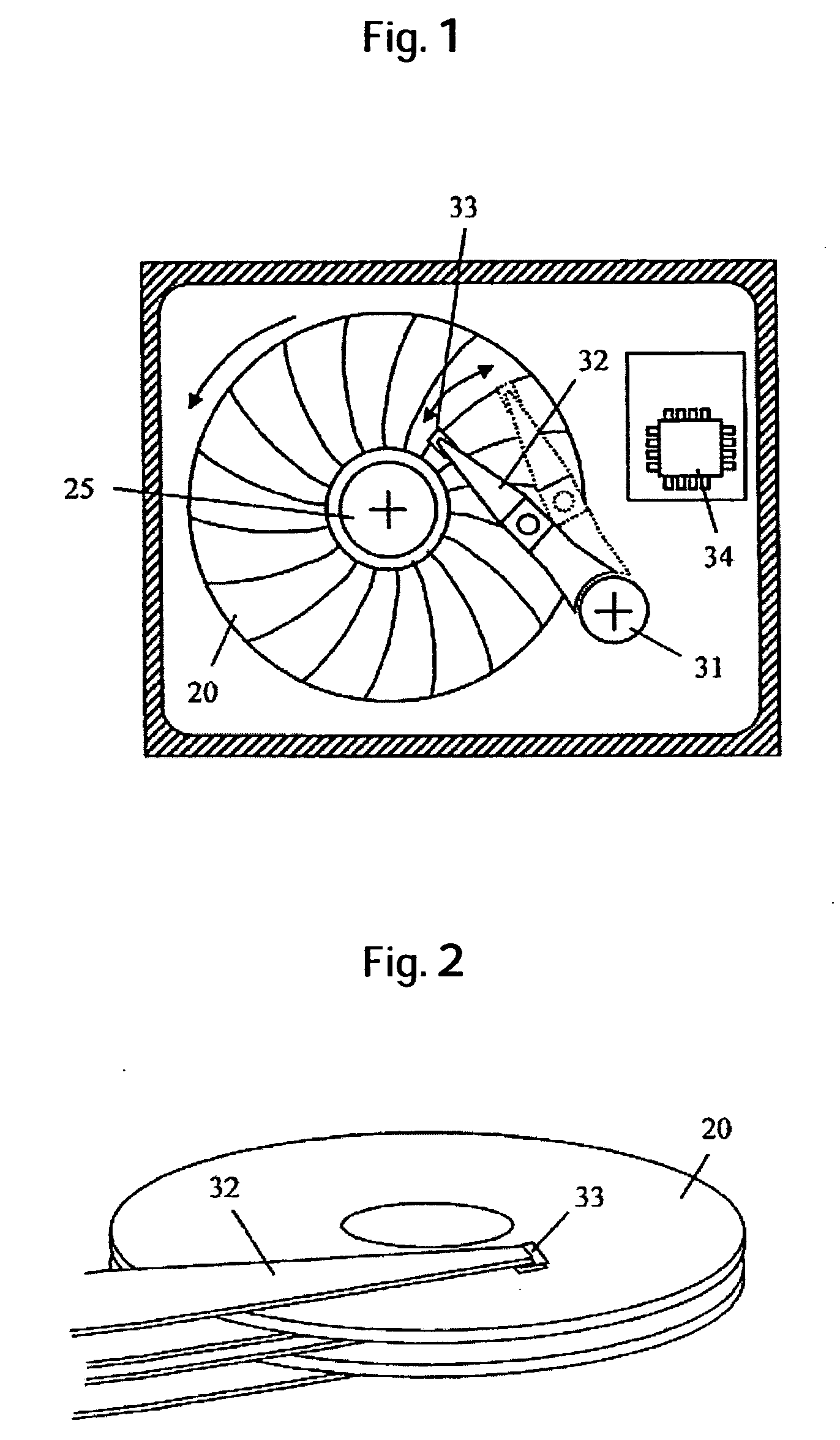

Rotary disk storage device and method

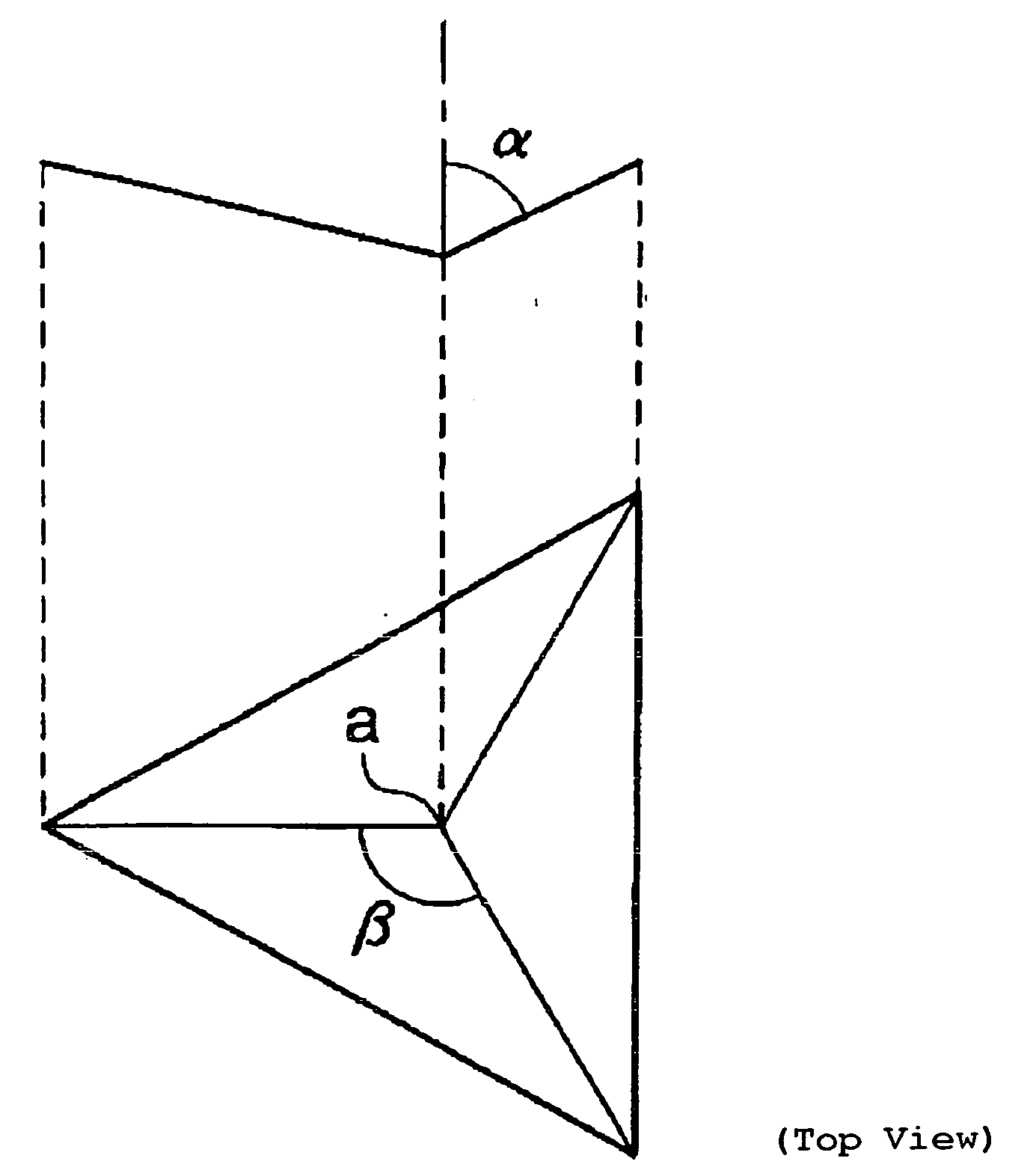

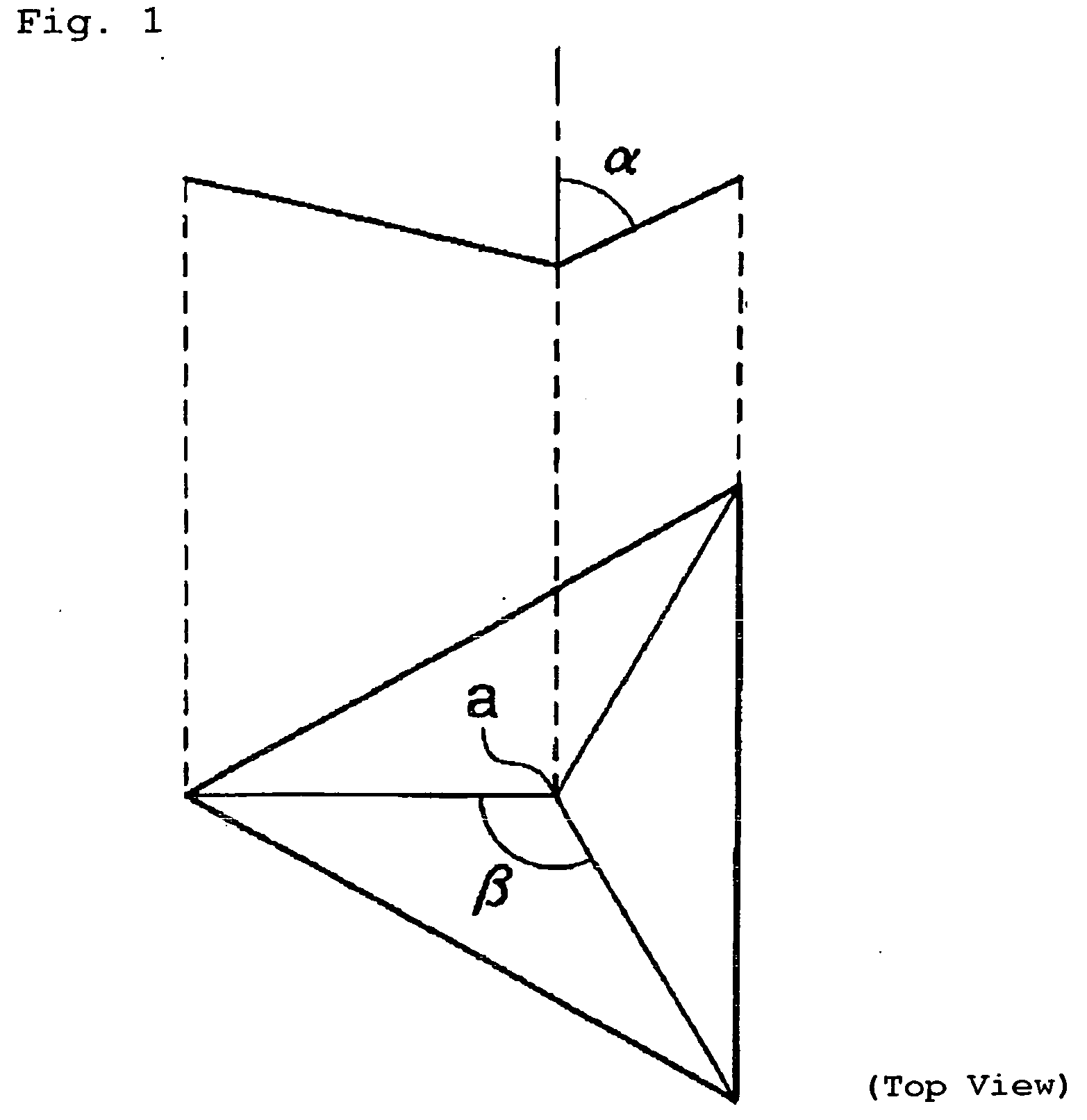

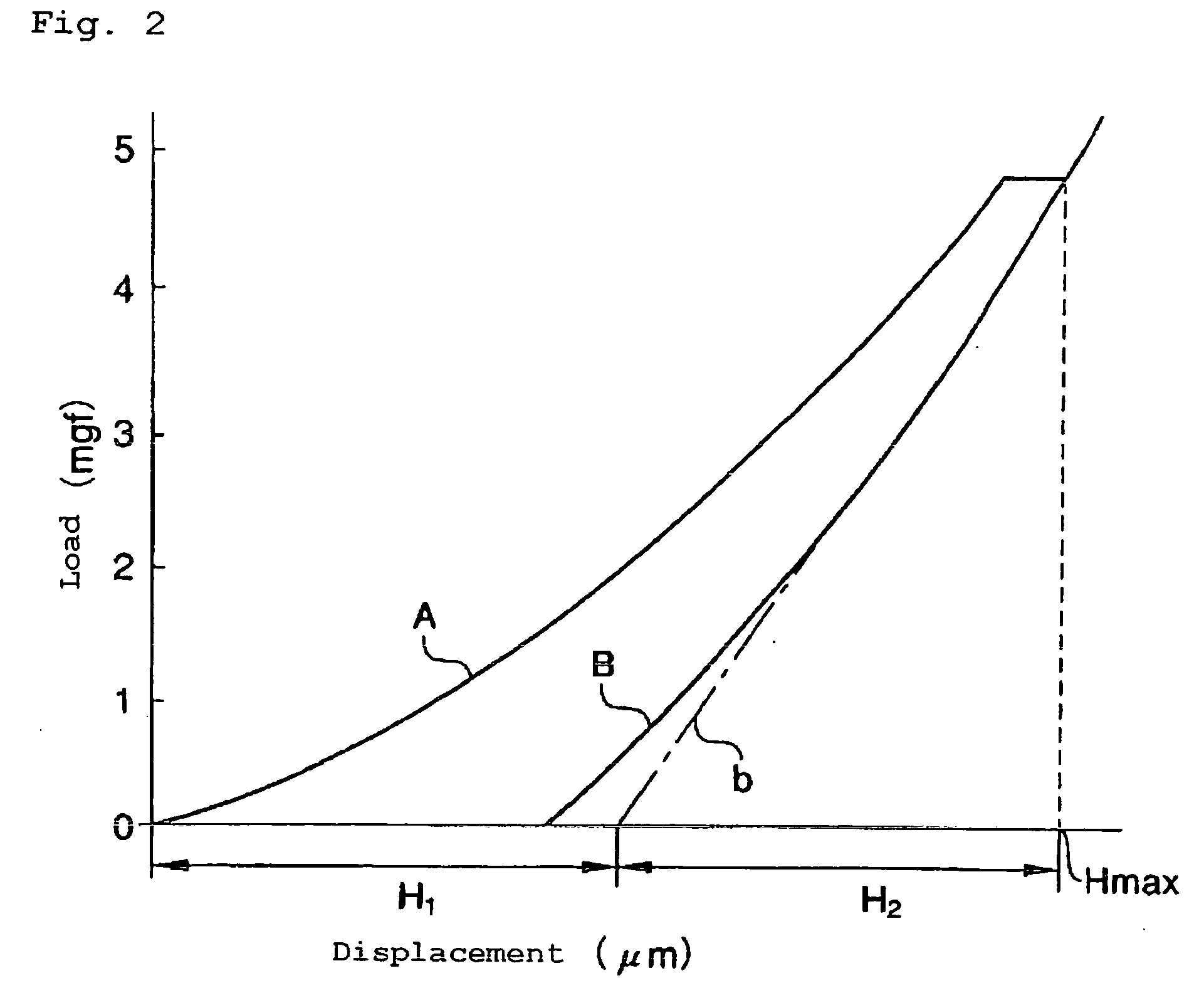

InactiveUS20050036241A1Avoid changeLarge influenceElectrical connection between head and armFluid-dynamic spacing of headsSkew angleActuator

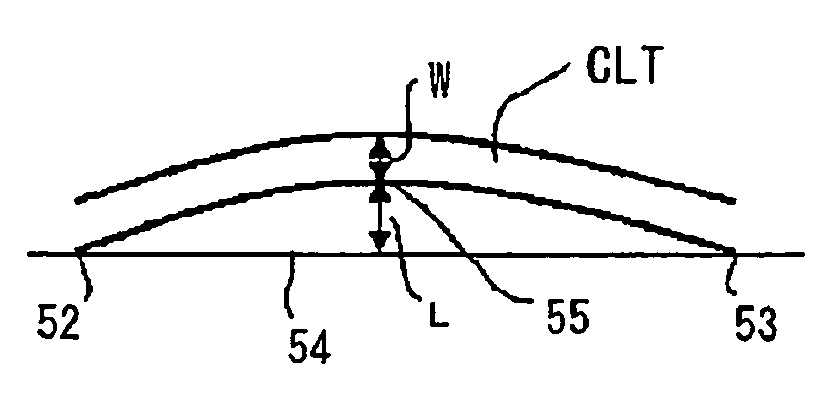

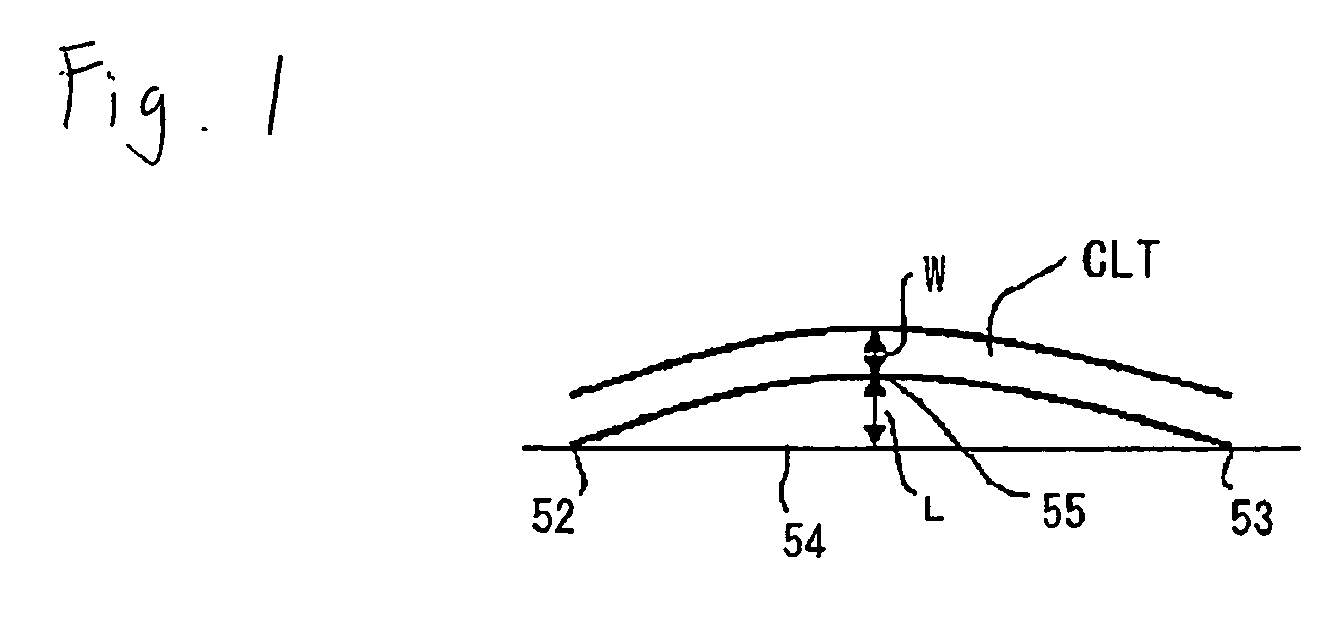

Embodiments of the invention provide a rotary disk storage device in which dust particles are less likely to deposit on the air bearing surface of each head / slider. The actuator head suspension assembly is configured so as to make the skew angle of the head / slider positive at about 80% or more of all the tracks. Specifically, the actuator head suspension assembly is configured in such a manner that the distance L2 between the center of the pivot shaft and the intersection point P of the trailing edge of the head / slider is made longer than a given length or there is an angle β between the reference line Y and the pivot line Z.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

Cleaning tape for magneto-resistive head

InactiveUS20060066999A1Inhibit wearEasy to cleanRecord information storageCleaning recording headsSurface roughnessEngineering

Owner:FUJIFILM CORP +1

Protective layer for magnetic recording device, magnetic head, and magnetic recording device

InactiveUS20050254168A1Reduction of magnetic spacingReduce spacingNanostructure manufactureManufacture head surfaceTransducerFlying height

The present invention enables to substantially decrease the magnetic spacing while maintaining the flying height of the transducer and the structure of the protective layers for a magnetic recording device. A magnetic layer containing first magnetic particles is formed on a substrate of a magnetic recording medium, and a magnetic recording medium protective layer containing second magnetic particles is formed on the magnetic layer. If the magnetic recording transducer has a protective layer, that protective layer may contain magnetic particles.

Owner:SHOWA DENKO KK

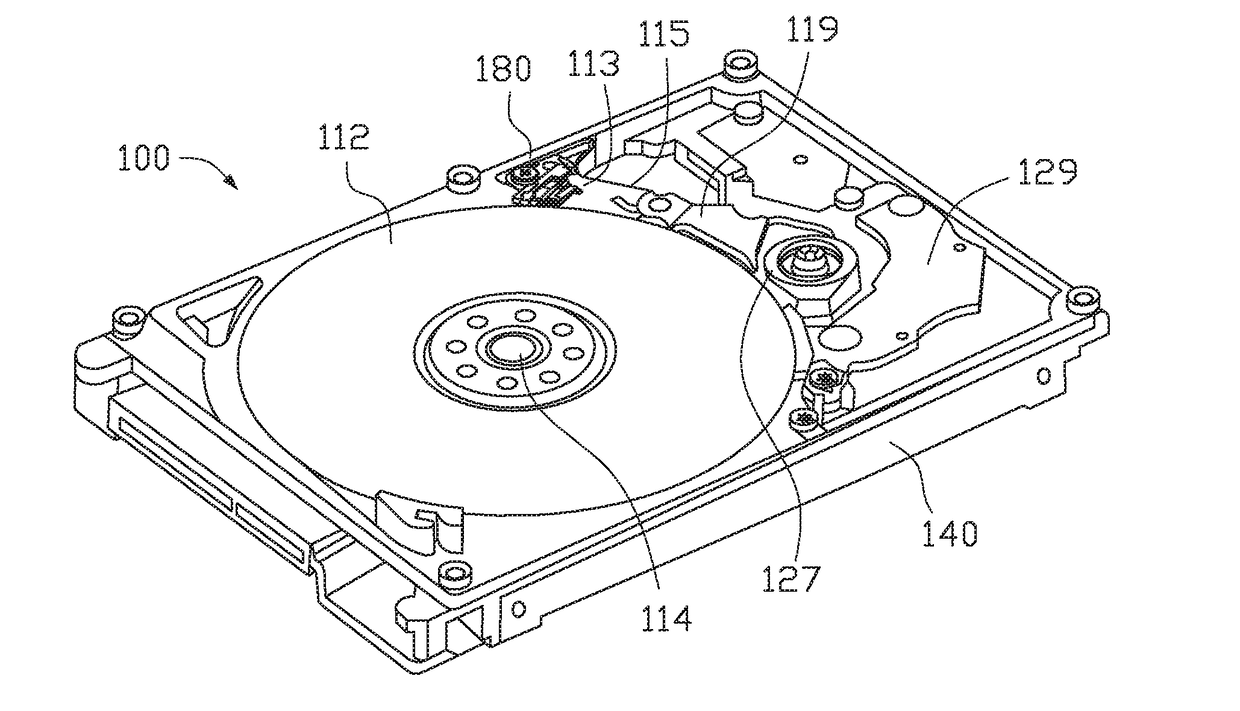

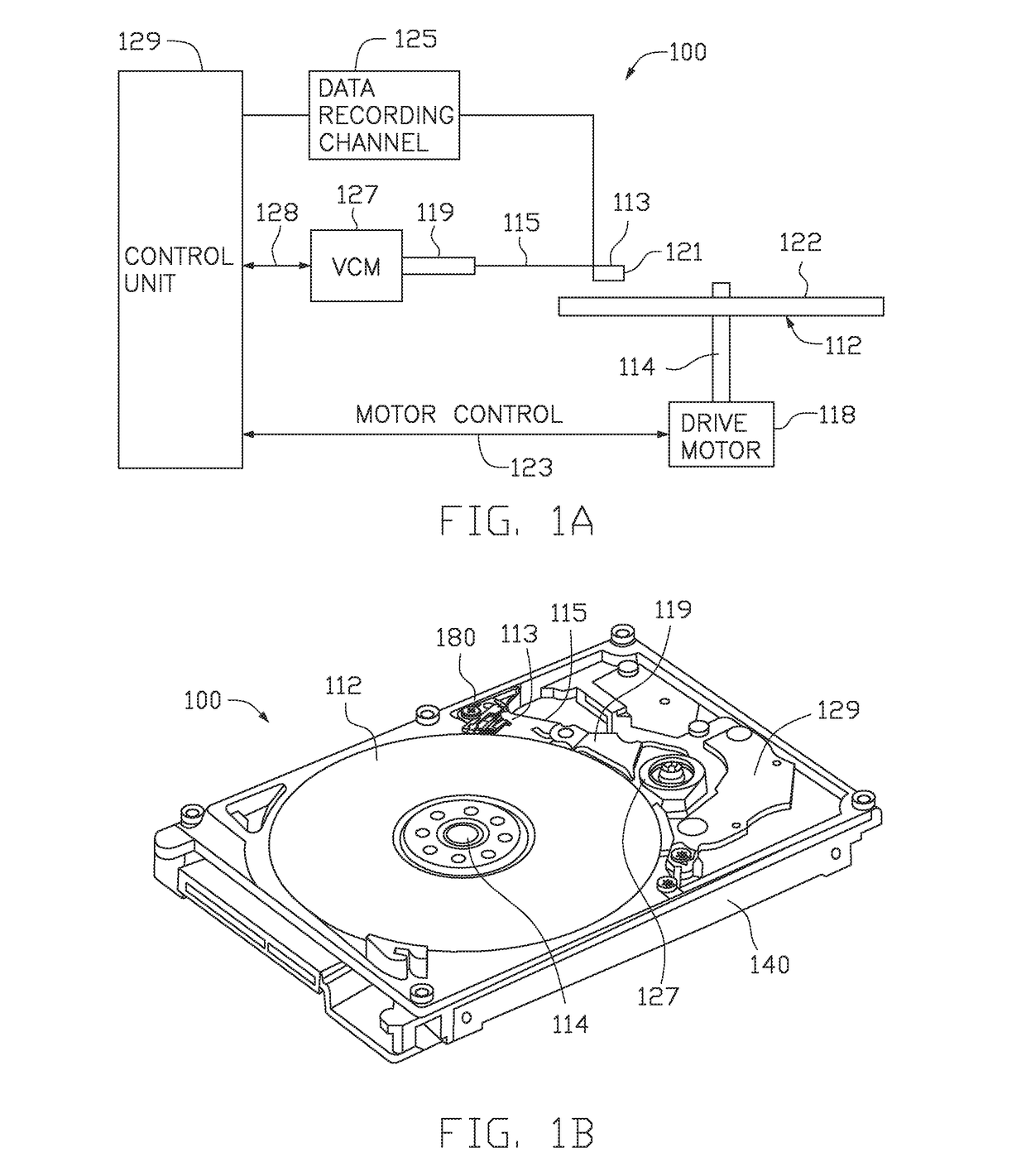

Disk drive with slider burnishing-on-demand

InactiveUS20060023354A1Reduce riskAvoid corrosionDriving/moving recording headsRecord information storageHermetic sealTransducer

A disk drive is described having a capability of burnishing the sliders on demand by using a heater in the slider to thermally protrude the slider. Each slider includes a heating element with a sufficient thermal expansion stroke to bring the area of the slider containing the transducer into contact with the disk surface to burnish the slider. Preferably the heater is used to bring the slider into contact with the disk to burnish the lowest flying part of the slider body after the drive has been assembled, and remove most or all of the overcoat and recession, and exposing the transducers at the ABS. The burnish process is performed in situ in the drive and the drive is preferably hermetically sealed to reduce the risk of corrosion. The slider can be flown and magnetically tested prior to burnishing off the overcoat to avoid corroding the head before the drive is assembled.

Owner:HITACHI GLOBAS STORAGE TECH NETHERLANDS

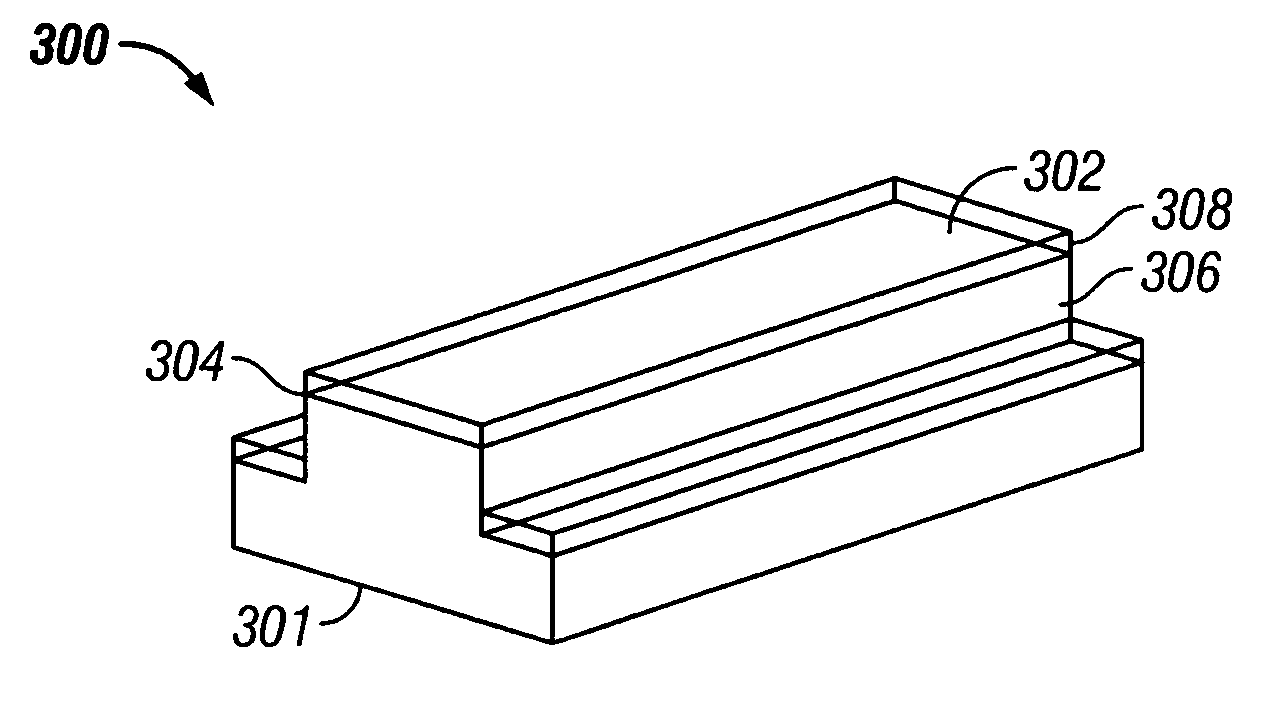

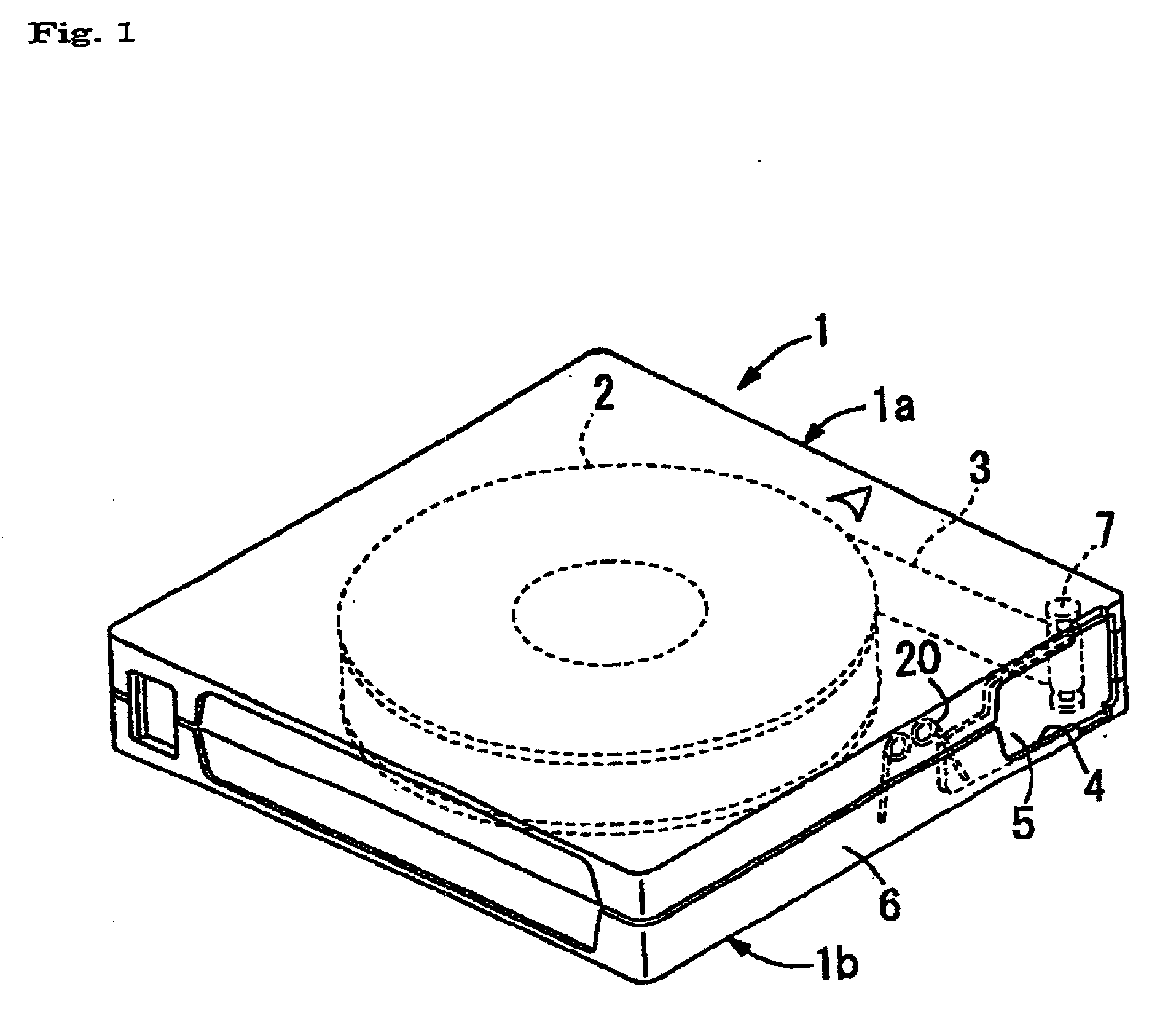

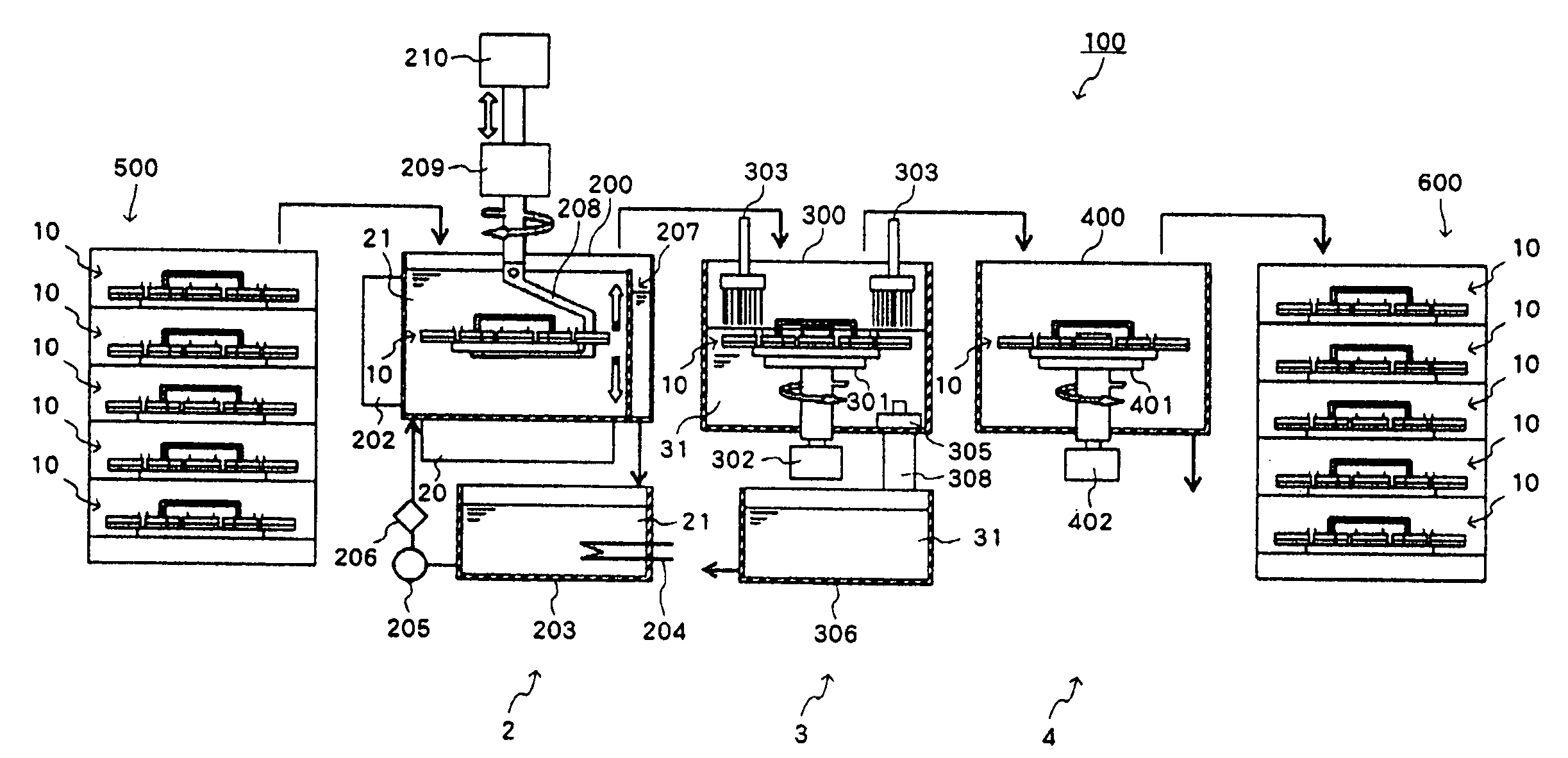

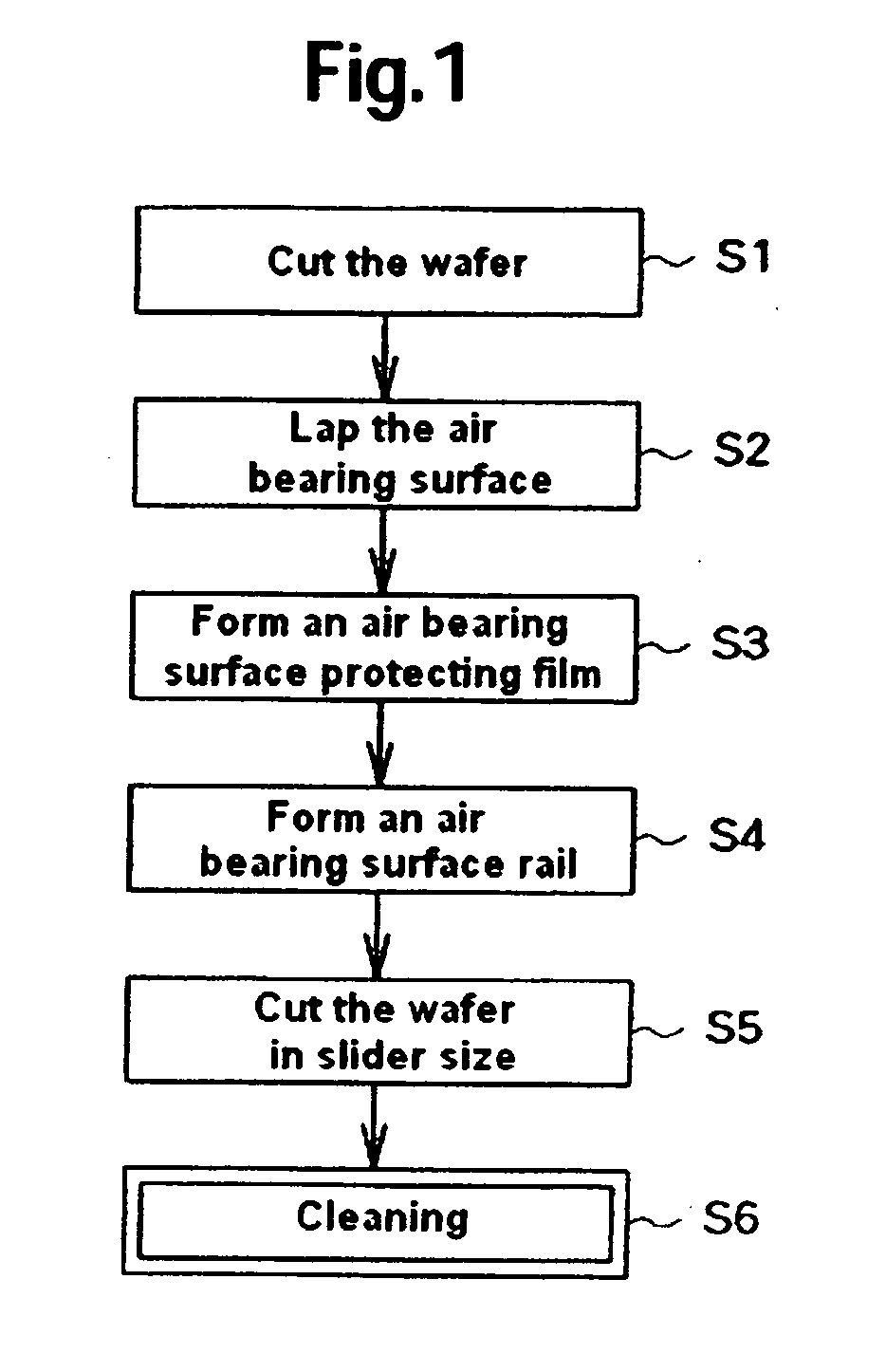

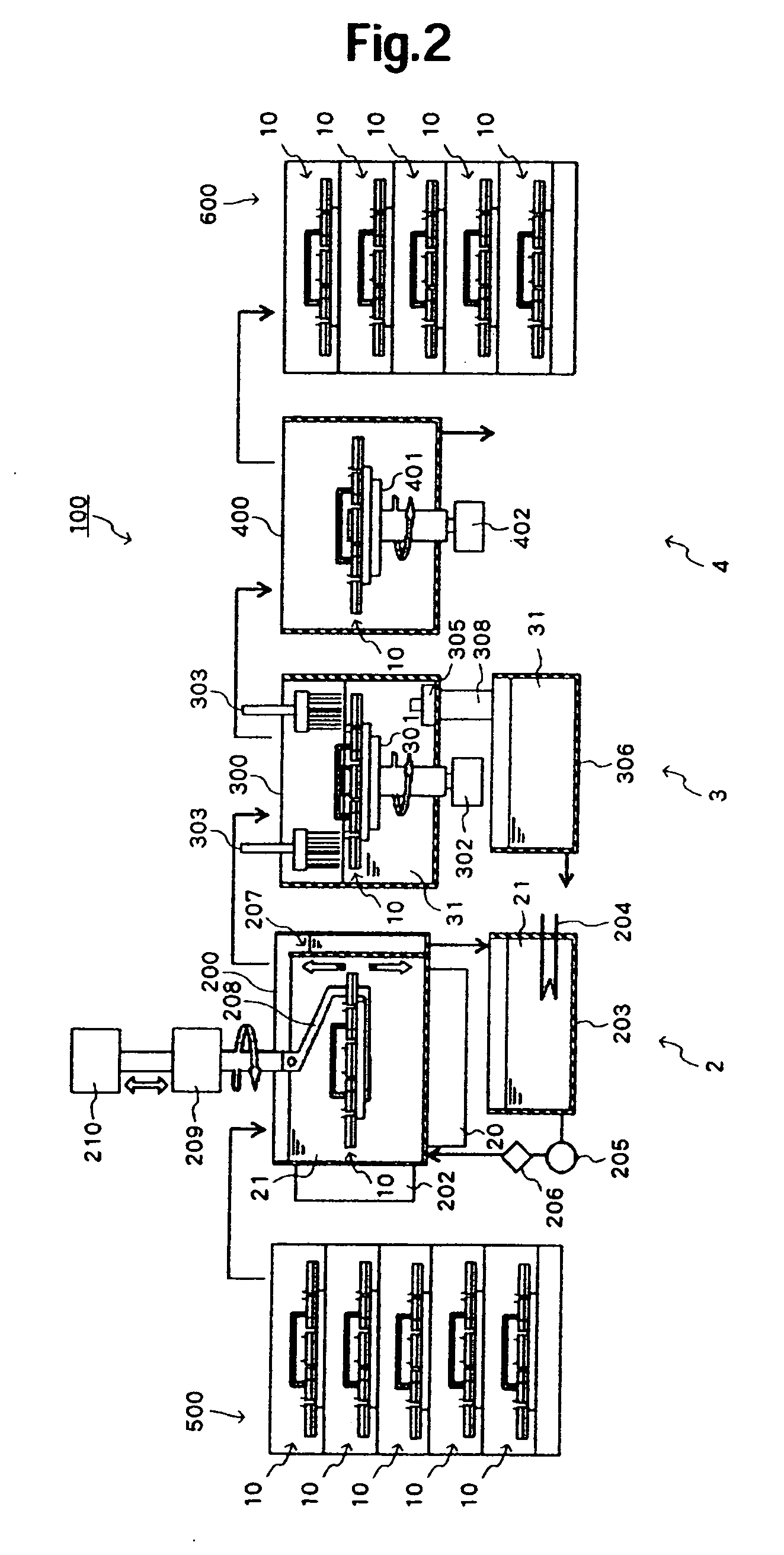

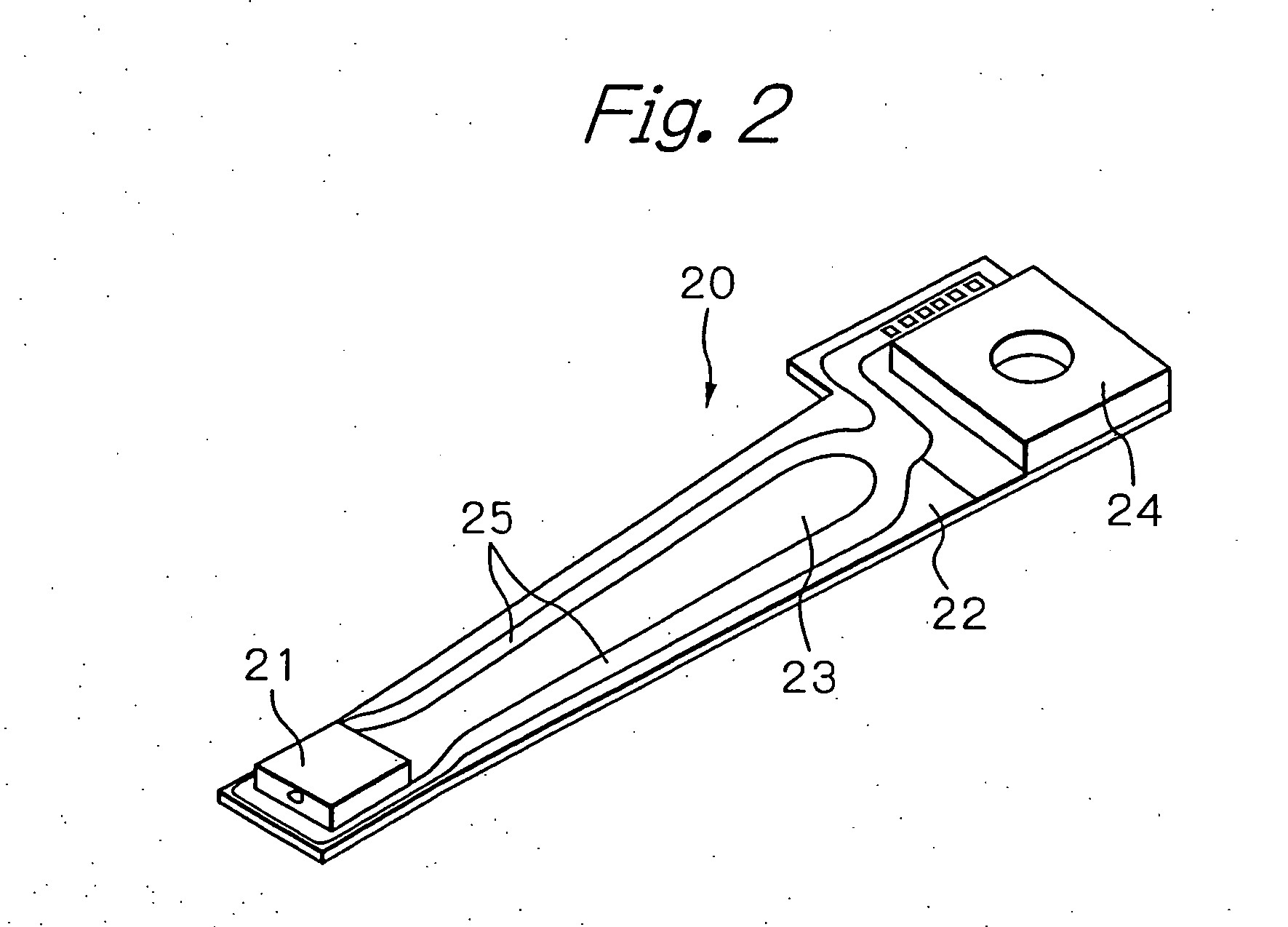

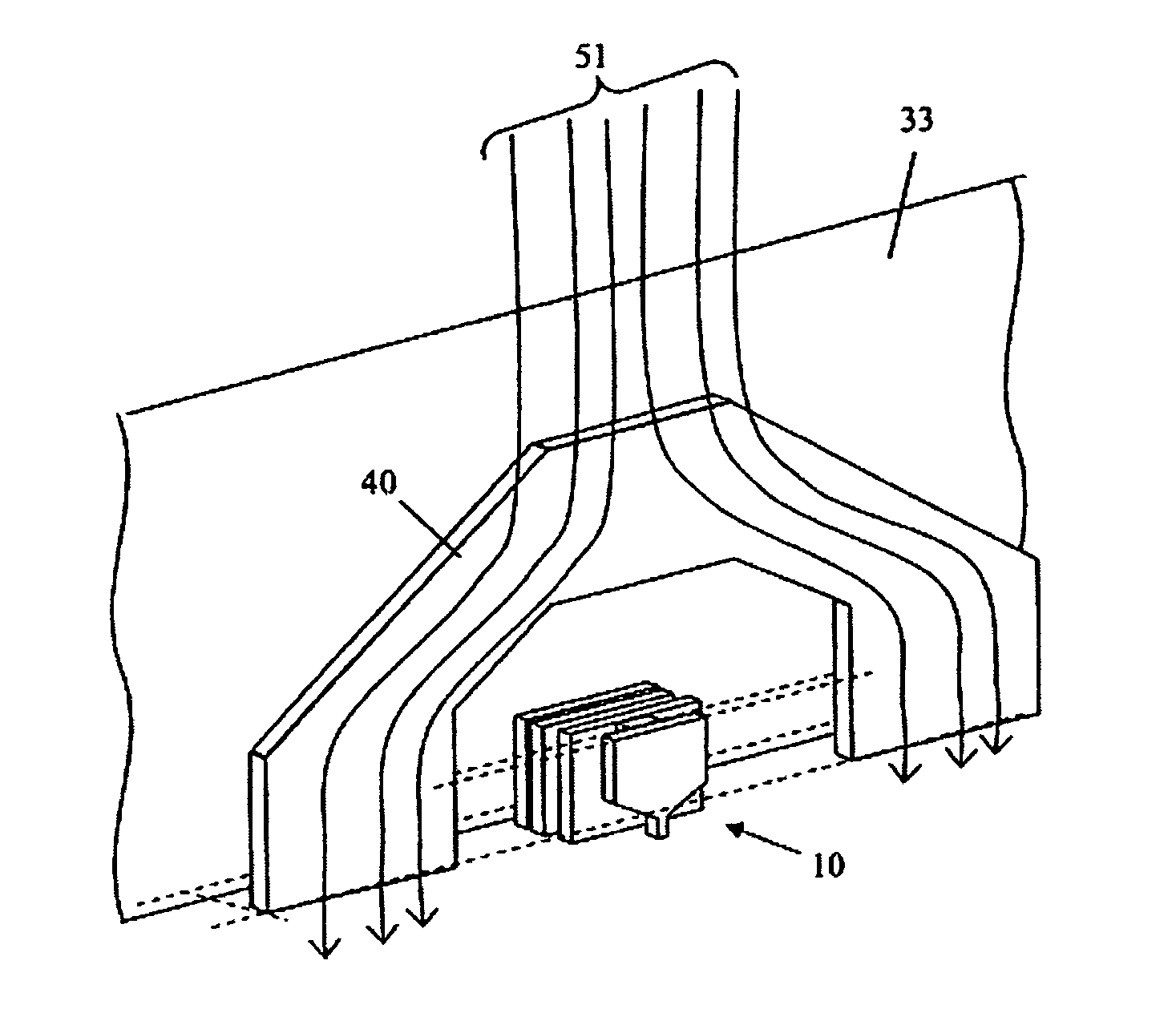

Method and apparatus for cleaning magnetic head slider, and method for manufacturing the same

InactiveUS20080087298A1Improve cleanlinessElectrostatic cleaningCleaning recording headsEngineeringMechanical engineering

Embodiments of the present invention provide a method and an apparatus for cleaning a magnetic head slider, and a method for manufacturing the same, which can achieve a magnetic head slider having high cleanness. According to one embodiment, in a rinsing process, a magnetic head slider is accommodated within a receptacle portion formed in a receptacle tray and the receptacle tray is immersed into rinsing liquid and is moved therein. As a result, the magnetic head slider receives a lifting force from the rinsing liquid which has entered the receptacle portion from through holes, so it flies over and at the same time receives water pressure from the rinsing liquid. Consequently, it is possible to effect rinsing to a satisfactory extent.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

Eliminating ESD exposure for read/write head with heating element

InactiveUS20060023367A1Avoid accumulationEliminate leaksDisposition/mounting of recording headsRecord information storageEngineeringVoltage

Embodiments of the present invention provide a grounded conductive layer between the heater and the lower magnetoresistive (MR) shield in the read / write head structure. The grounded conductive layer eliminates or at least substantially prevents the accumulation of charges on the lower MR shield as a result of the voltage supplied to the heater. In one embodiment, a magnetic head comprises a plurality of read / write components; a heater disposed near the plurality of read / write components; and a grounded conductive layer disposed between the heater and the plurality of read / write components.

Owner:WESTERN DIGITAL TECH INC

Thin-film magnetic head with heating means for adjusting magnetic spacing

ActiveUS20060126224A1Small electric power consumptionSolve the large consumptionRecord information storageCleaning recording headsThermal dilatationThin membrane

A thin-film magnetic head that the protrusion of the head end surface due to heat generated from the heating means becomes large enough to set the magnetic spacing dMS to the smaller value efficiently is provided. The head comprises: a substrate having an element-formed surface on which at least one concave portion is formed and an ABS; at least one magnetic head element formed above or on the element-formed surface; at least one thermal expansion layer embedded in the at least one concave portion; and at least one heating means positioned directly above the at least one thermal expansion layer.

Owner:TDK CORPARATION +1

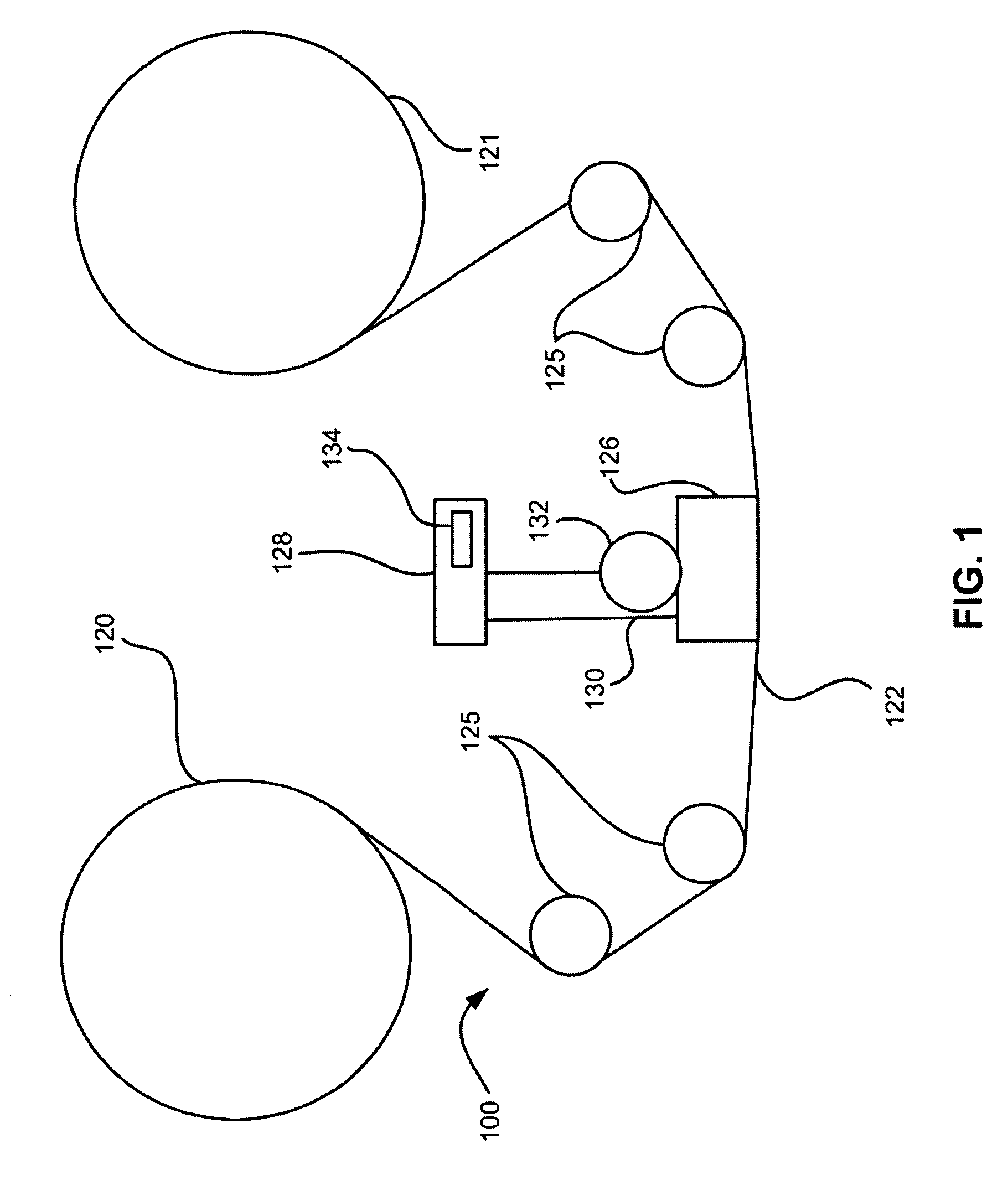

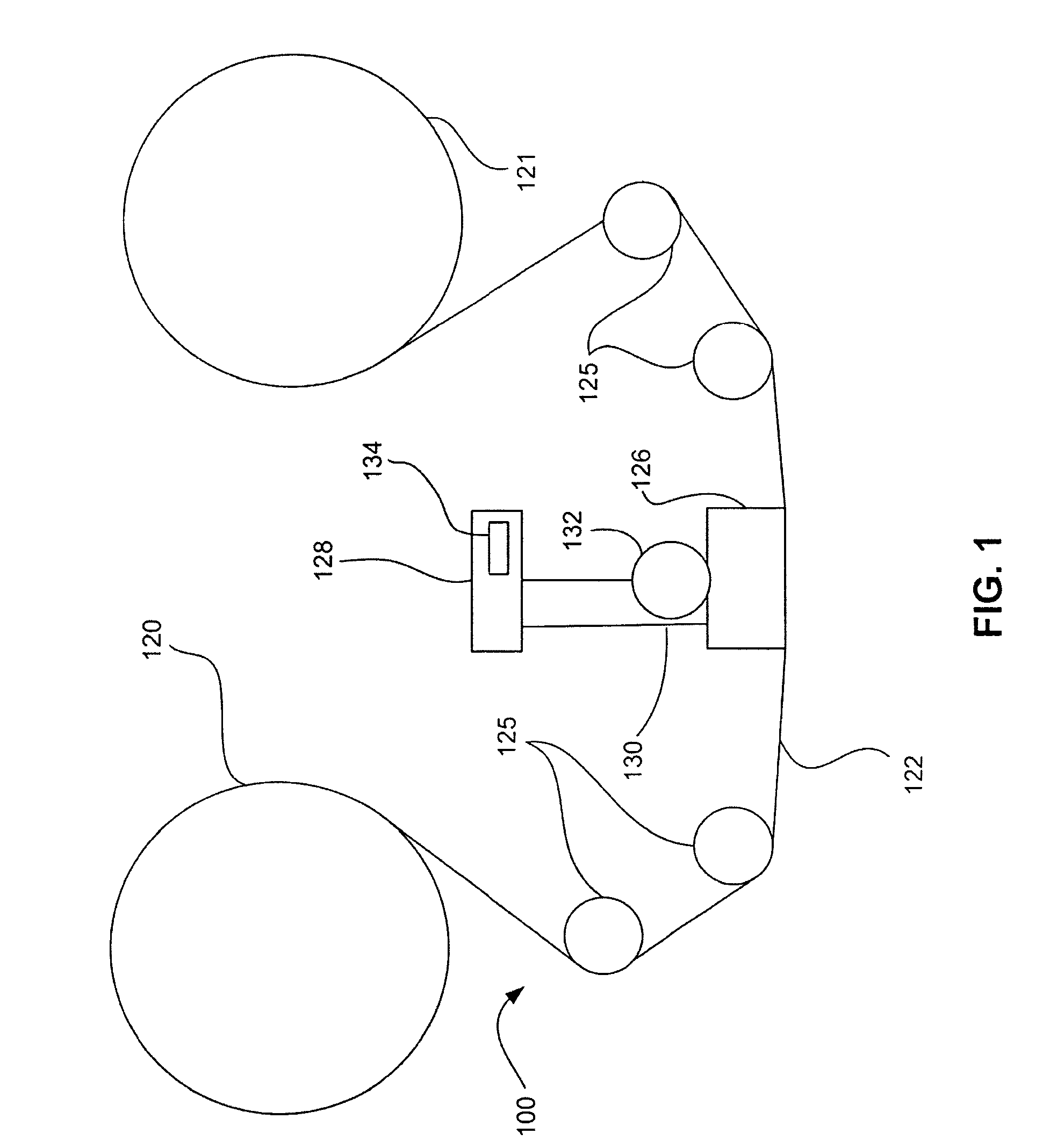

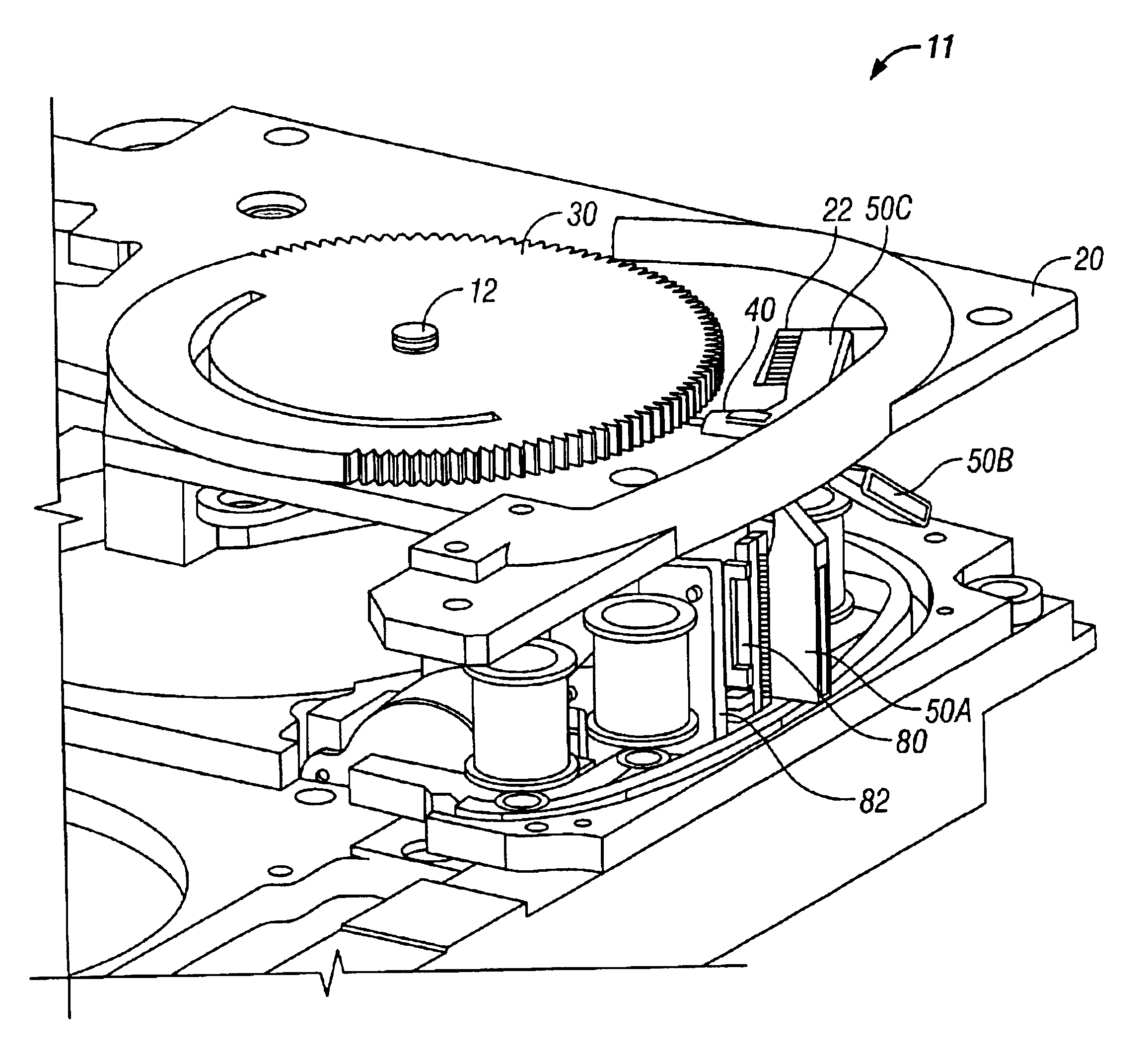

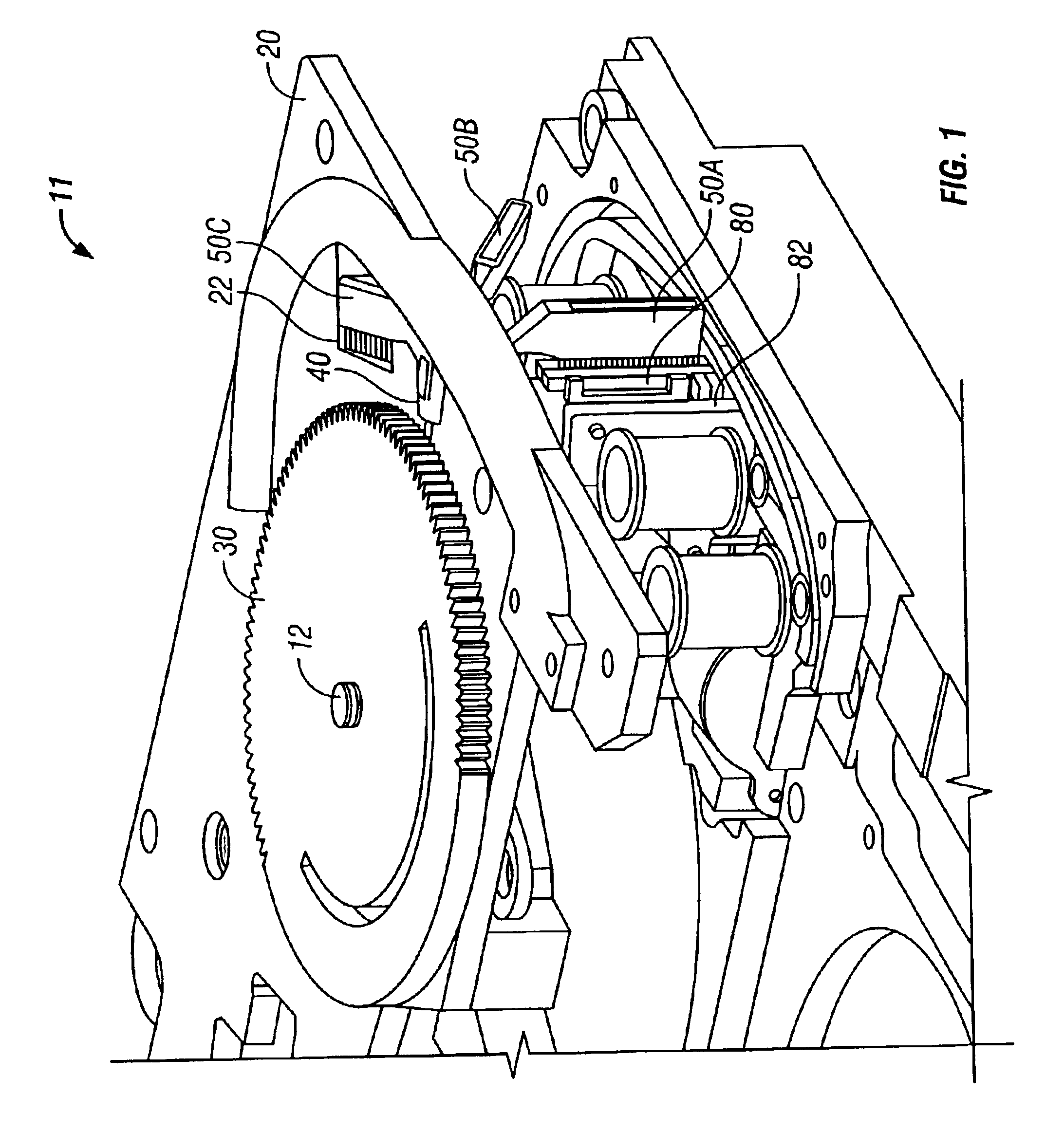

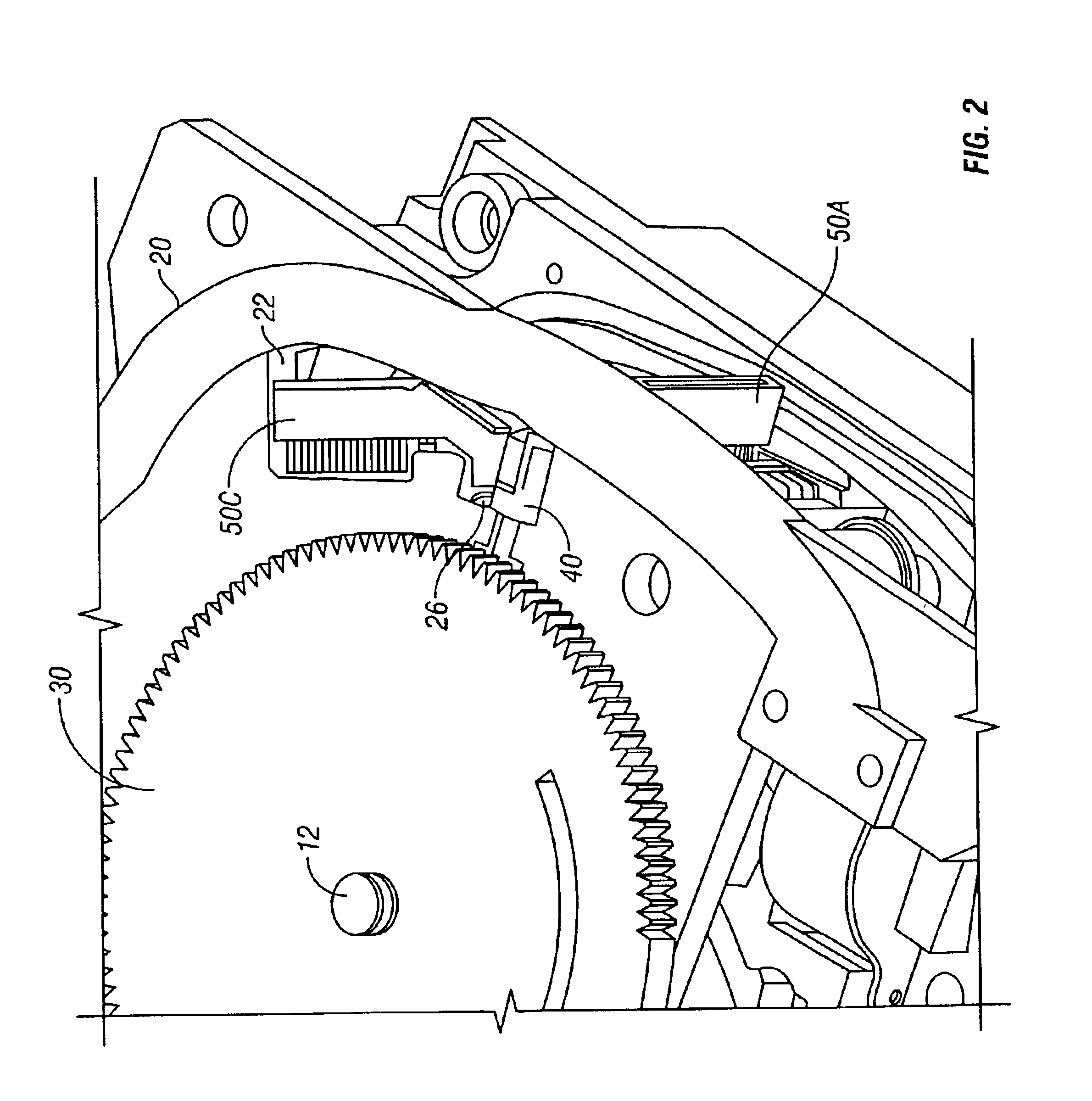

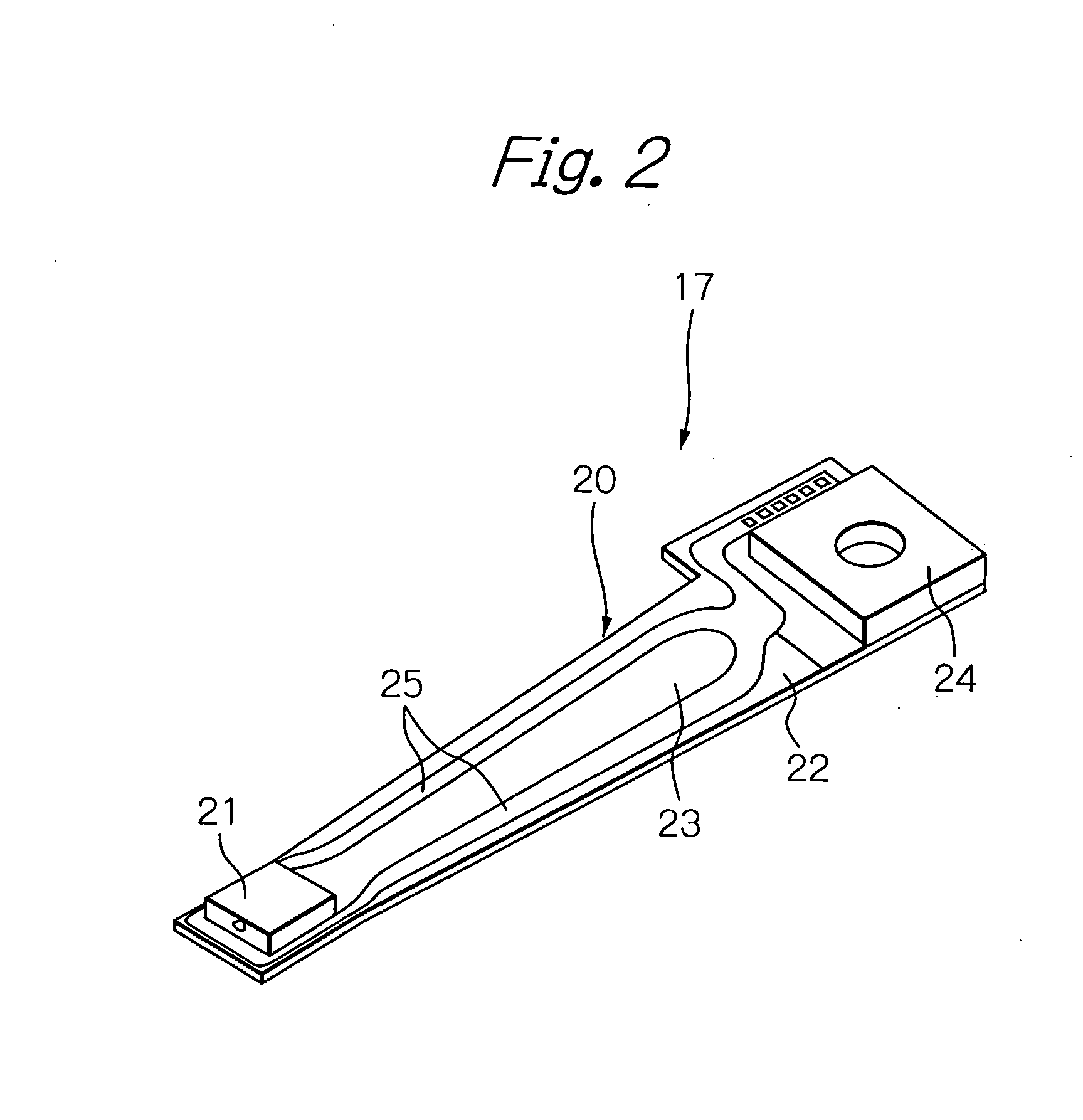

Retractable low profile head brush assembly for cleaning read/write heads in a media tape drive

Owner:INT BUSINESS MASCH CORP

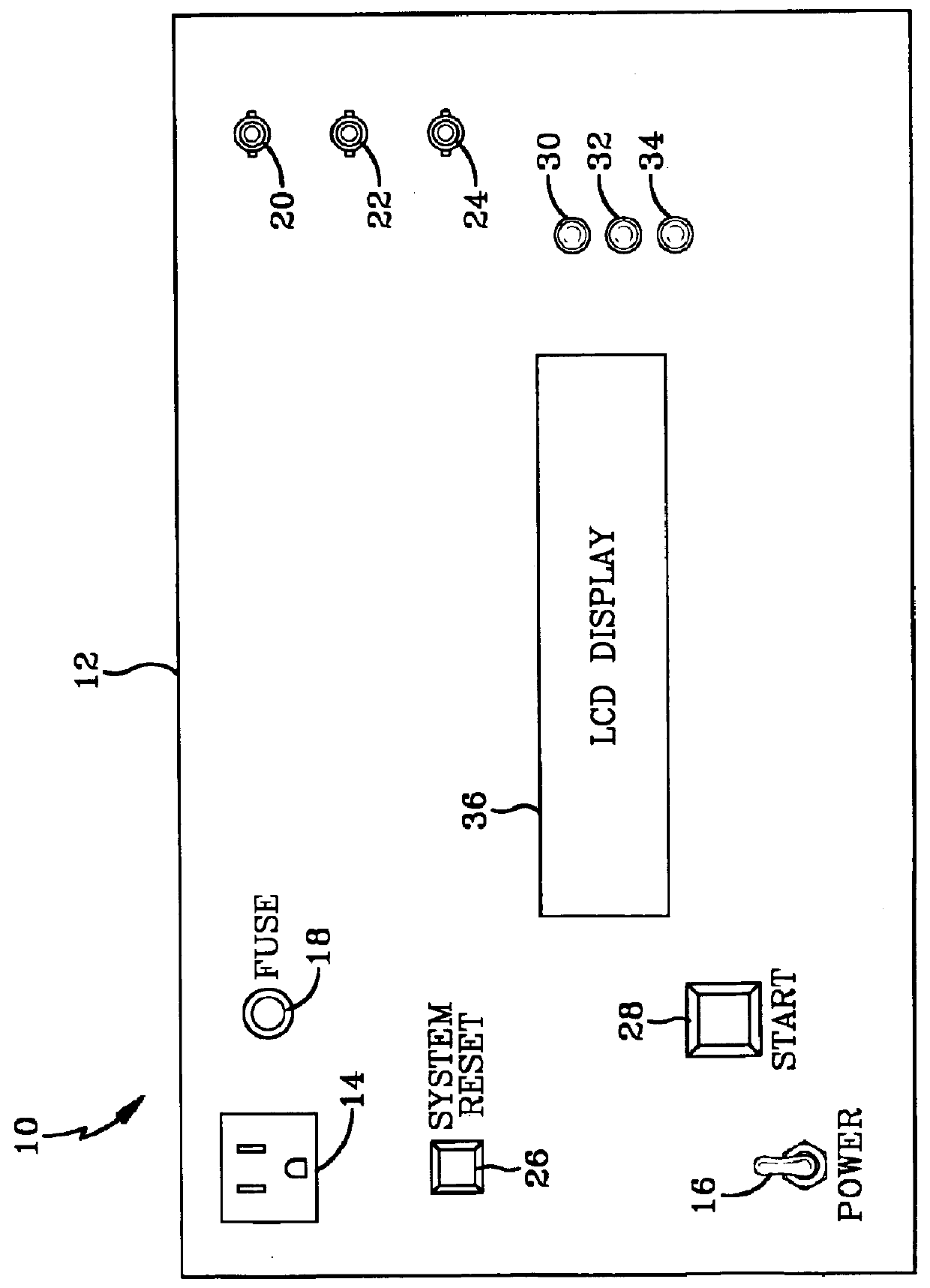

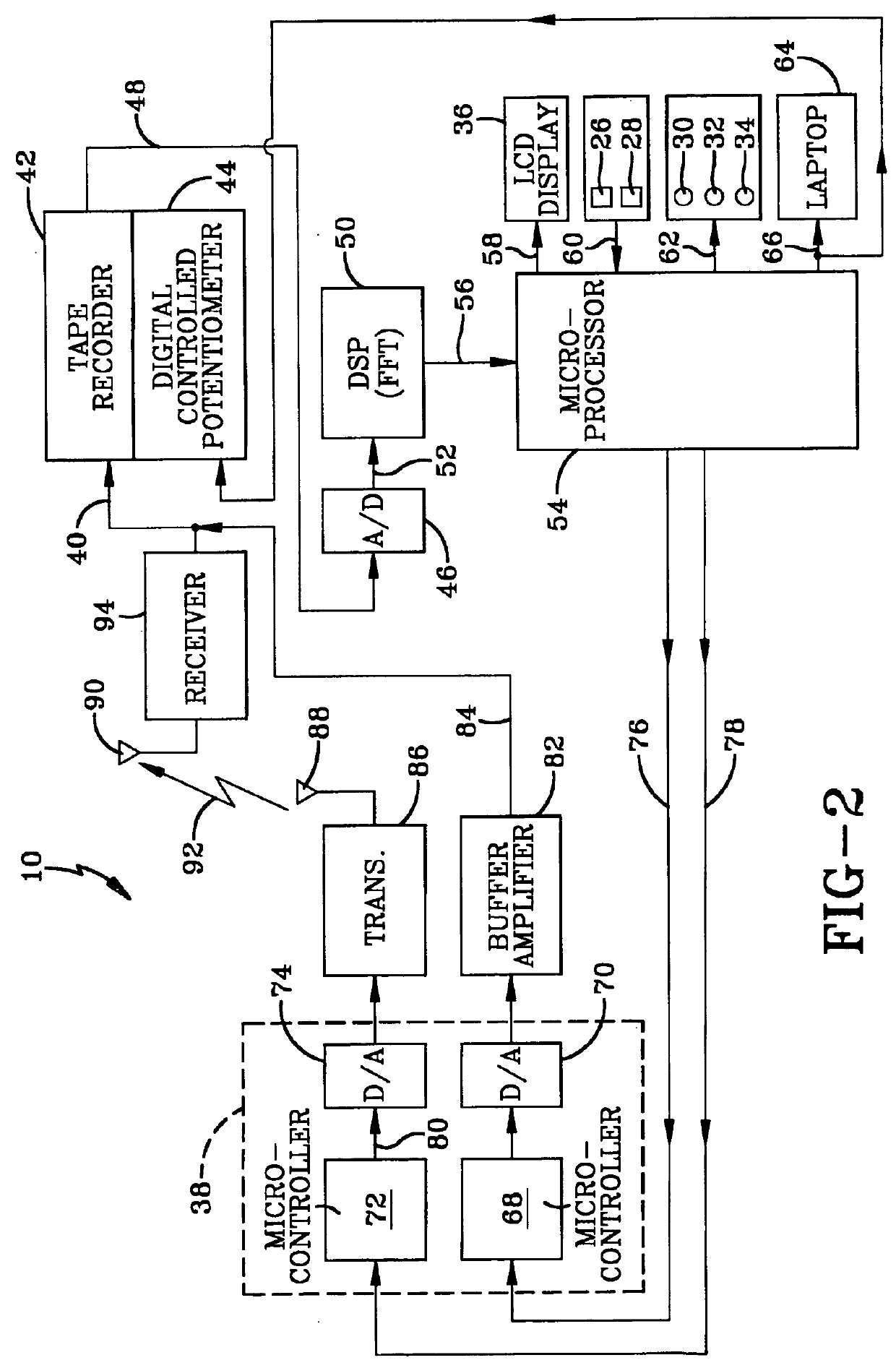

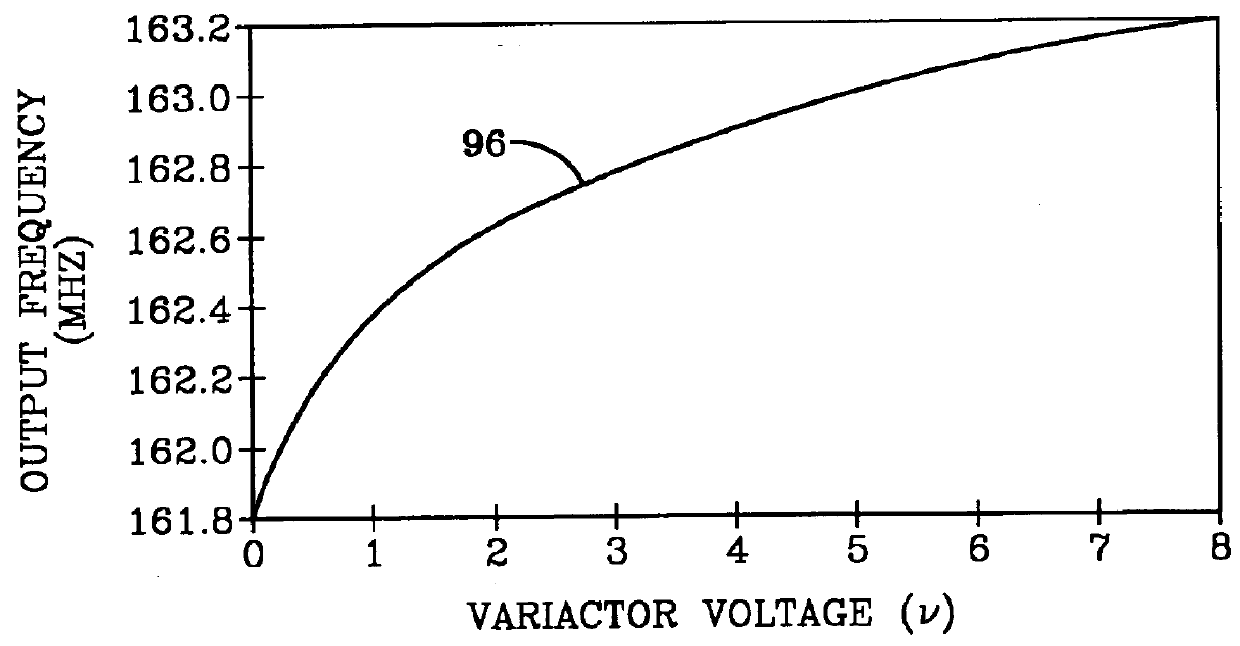

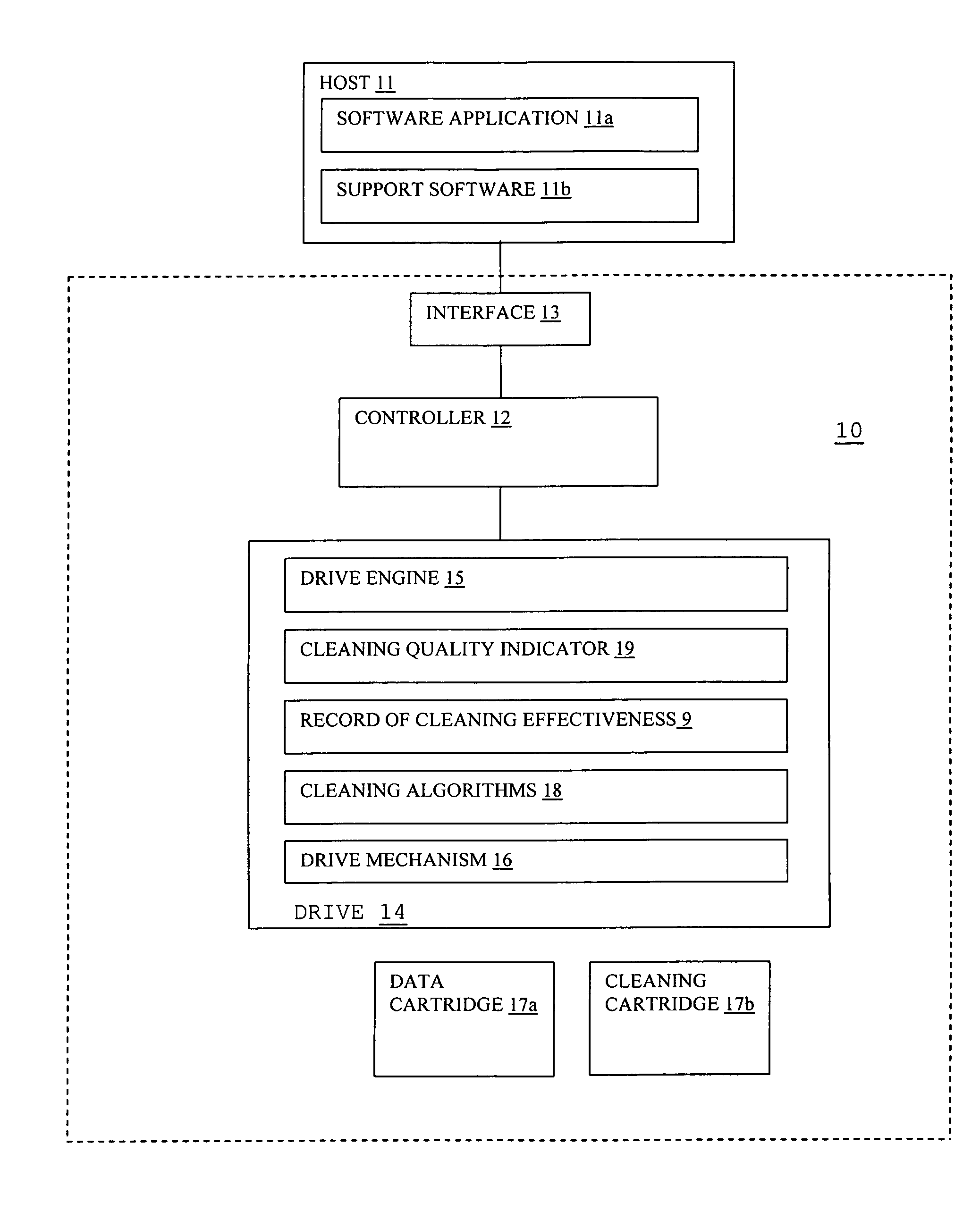

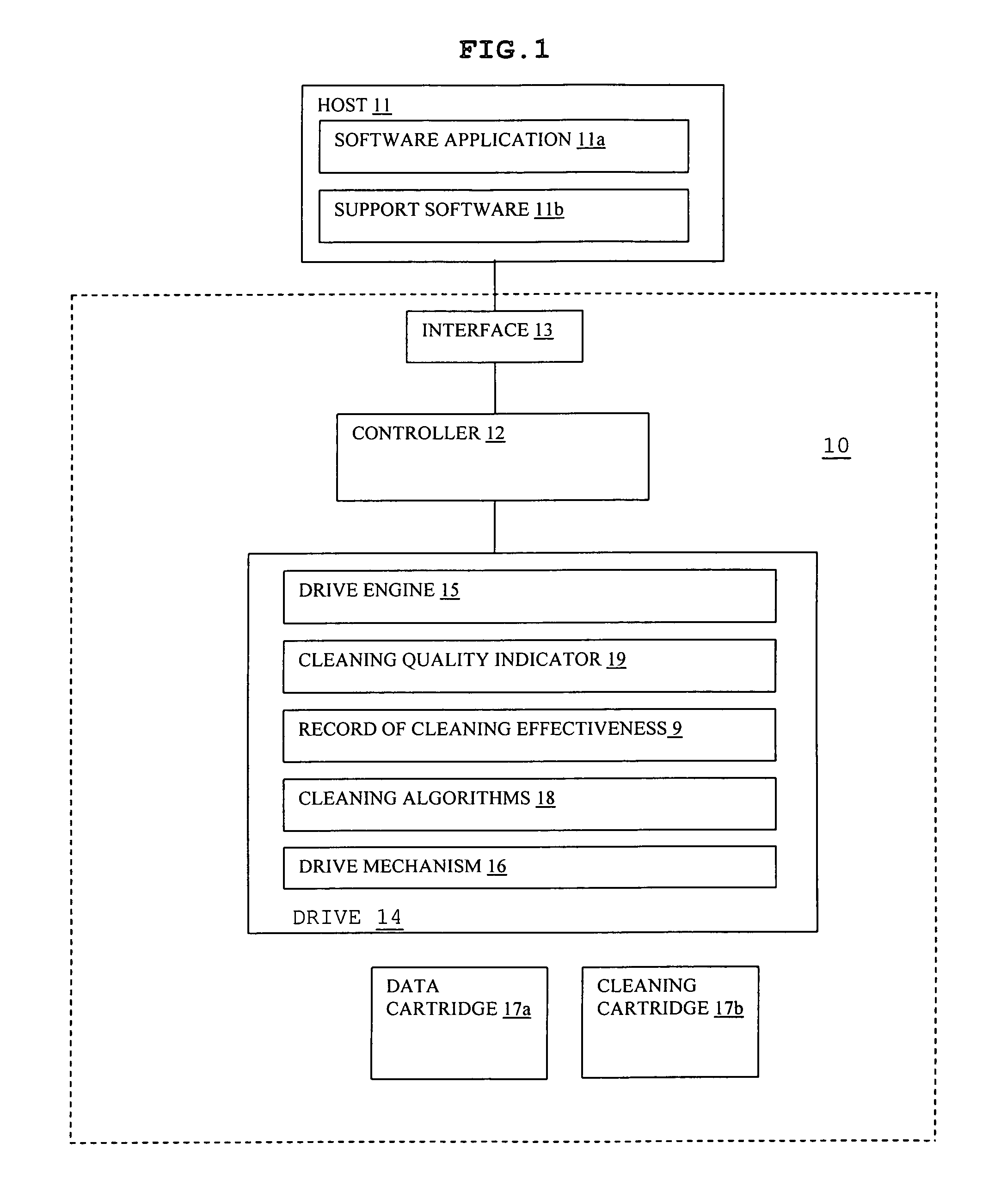

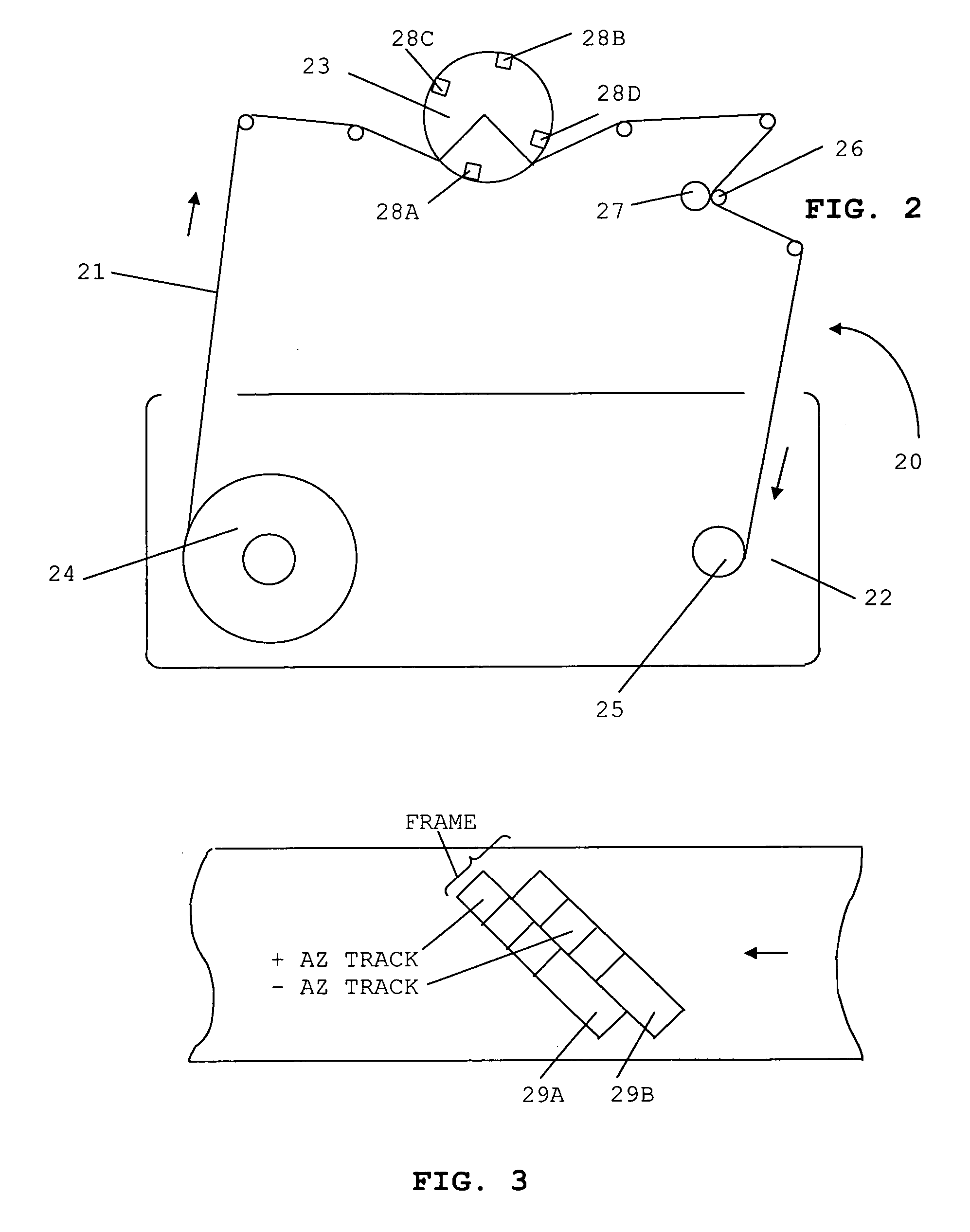

System and a method of operation thereof for analyzing the performance of a tape recorder

InactiveUSH2143H1PerformanceAutomatically performCarrier indicating/warning arrangementsRecord information storageDigital dataData stream

A system, and a method of operation thereof, for analyzing the performance of a tape recorder having a playback head is disclosed. The system allows for the recorded data of the tape recorder to be routed to a analog-to-digital converter whose output is delivered to a digital signal processor preferably having a routine to convert the digital data to an FFT data stream which, in turn, is routed to a microprocessor. The computer analyzes the FFT data and provides digital signals to external display devices that indicate the proper recording of the tape recorder, the need for the recorder's heads to be cleaned, the occurrence of excessive dropout data recording rate, or the need to manually or automatically adjust the bias and equalization levels of the tape recorder.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

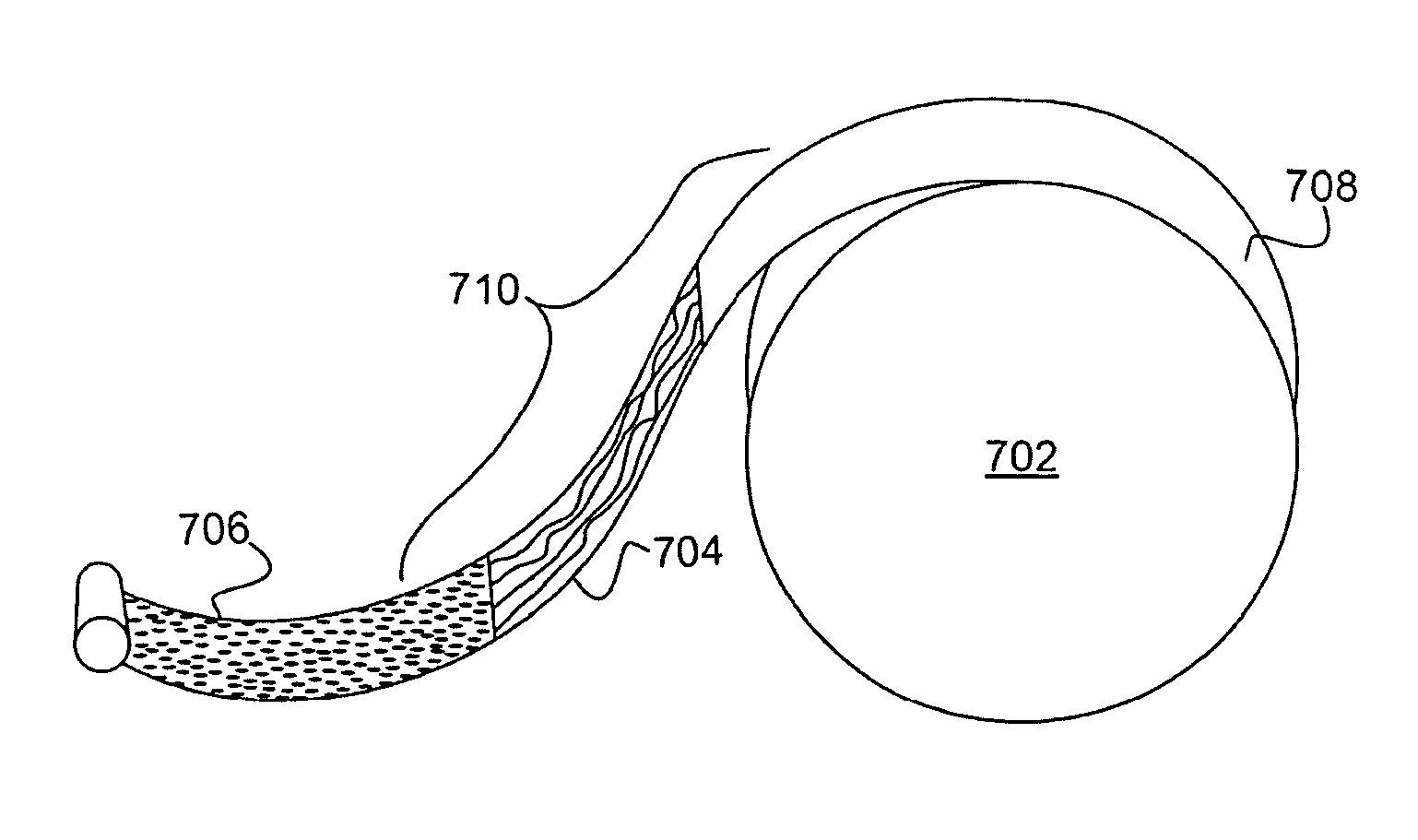

Wear gauge and method of use

InactiveUS7509833B2Material analysis by optical meansCleaning recording headsMagnetic storageColor changes

A wear gauge is provided for simulating the wear of a magnetic recording component at its interface with a magnetic storage medium comprising a wear gauge block having a wear surface that substantially approximates the geometrical dimensions and contour of the working surface of the magnetic recording component, wherein the wear surface has a coating of transparent material. A test method comprises mounting the wear gauge in a test fixture, positioning a tape and adjusting the overwrap angle at edges of the wear surface, choosing the desired tape tension, speed and runtime, and running the tape, preferably unidirectionally, in operational contact with the wear surface for the desired runtime. The wear surface is inspected under white light illumination to observe and record locations of interferometric color changes on the wear surface. The color changes are correlated to thickness changes of the transparent coating on the wear surface.

Owner:GLOBALFOUNDRIES INC

Hard disk drive tunneling magnetoresistive annealing heads with a fly on demand heater

A hard disk drive that includes a head coupled to a disk. The head has a heater element. The drive also includes a controller that causes the heater element to heat the head to a temperature sufficient to anneal material within the head. The head is heated to a temperature sufficient to cause oxidation of any metal, such as aluminum, within the head, and / or oxygen redistribution and homogenization in the barrier. This heating process preferably occurs while the drive is not writing or reading data and the head is off disk.

Owner:SAMSUNG ELECTRONICS CO LTD

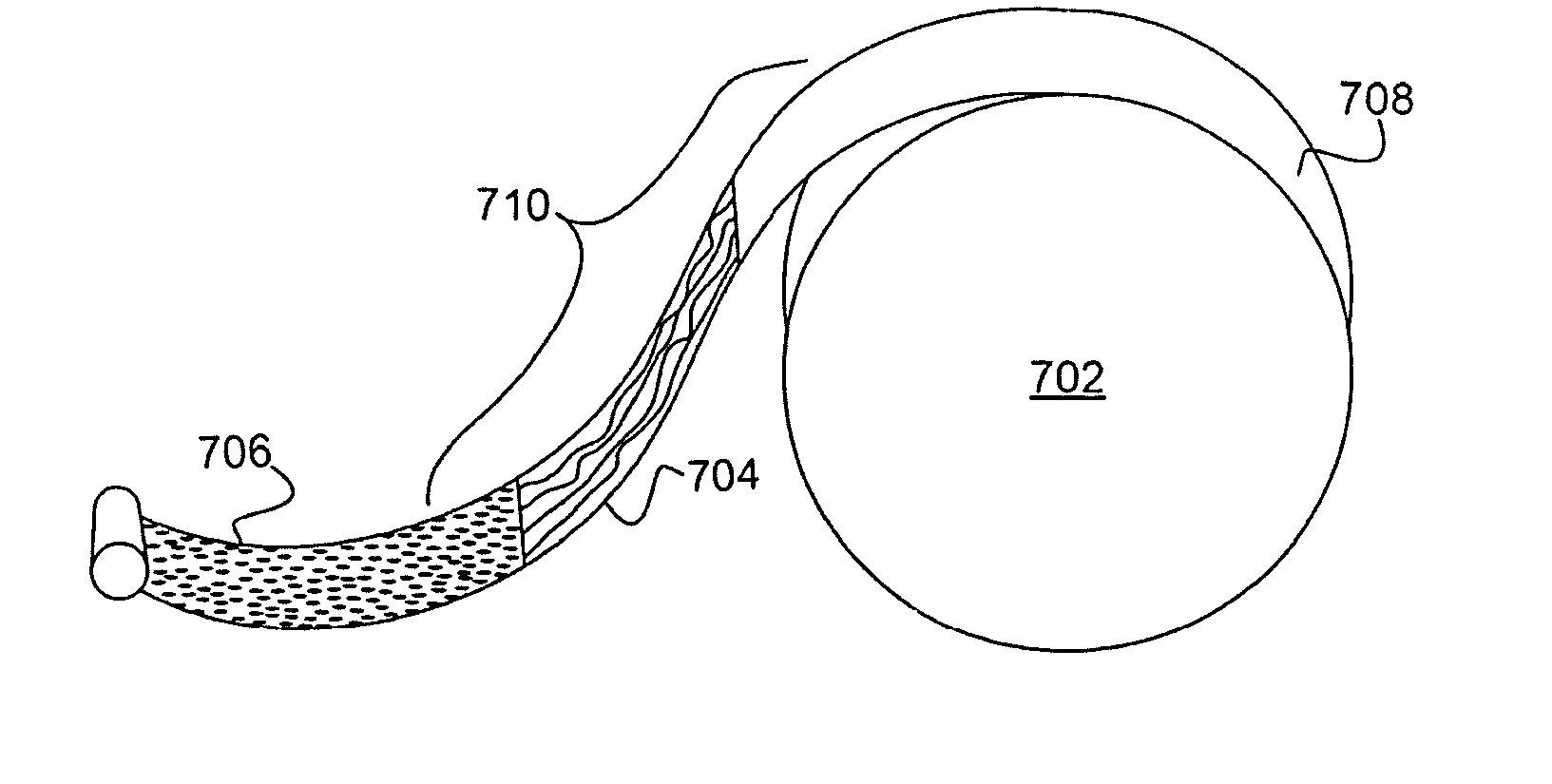

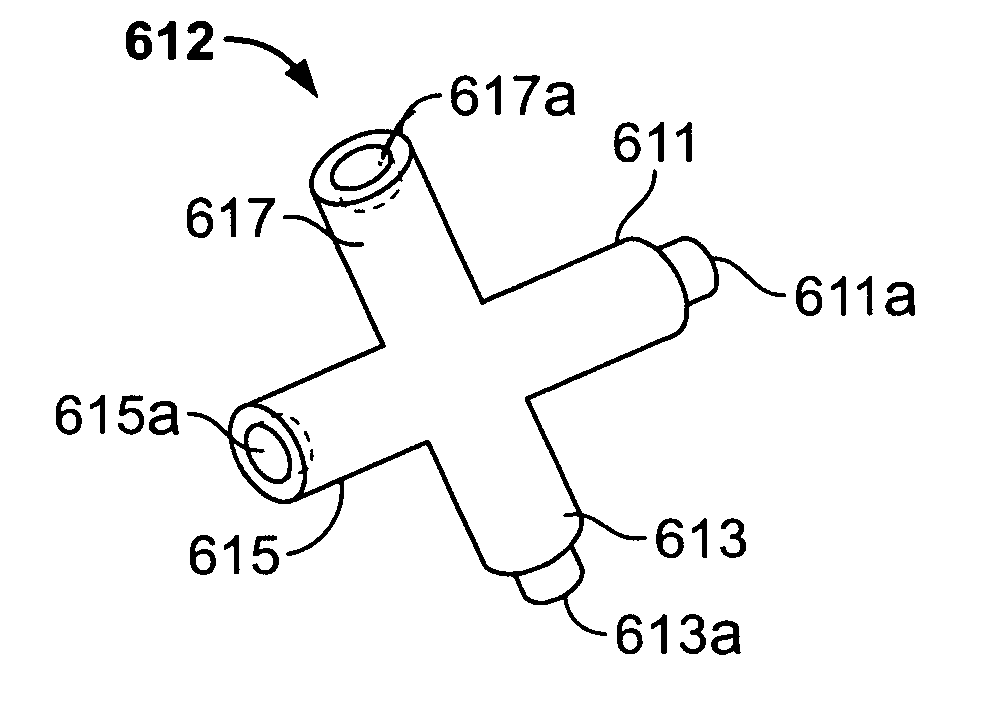

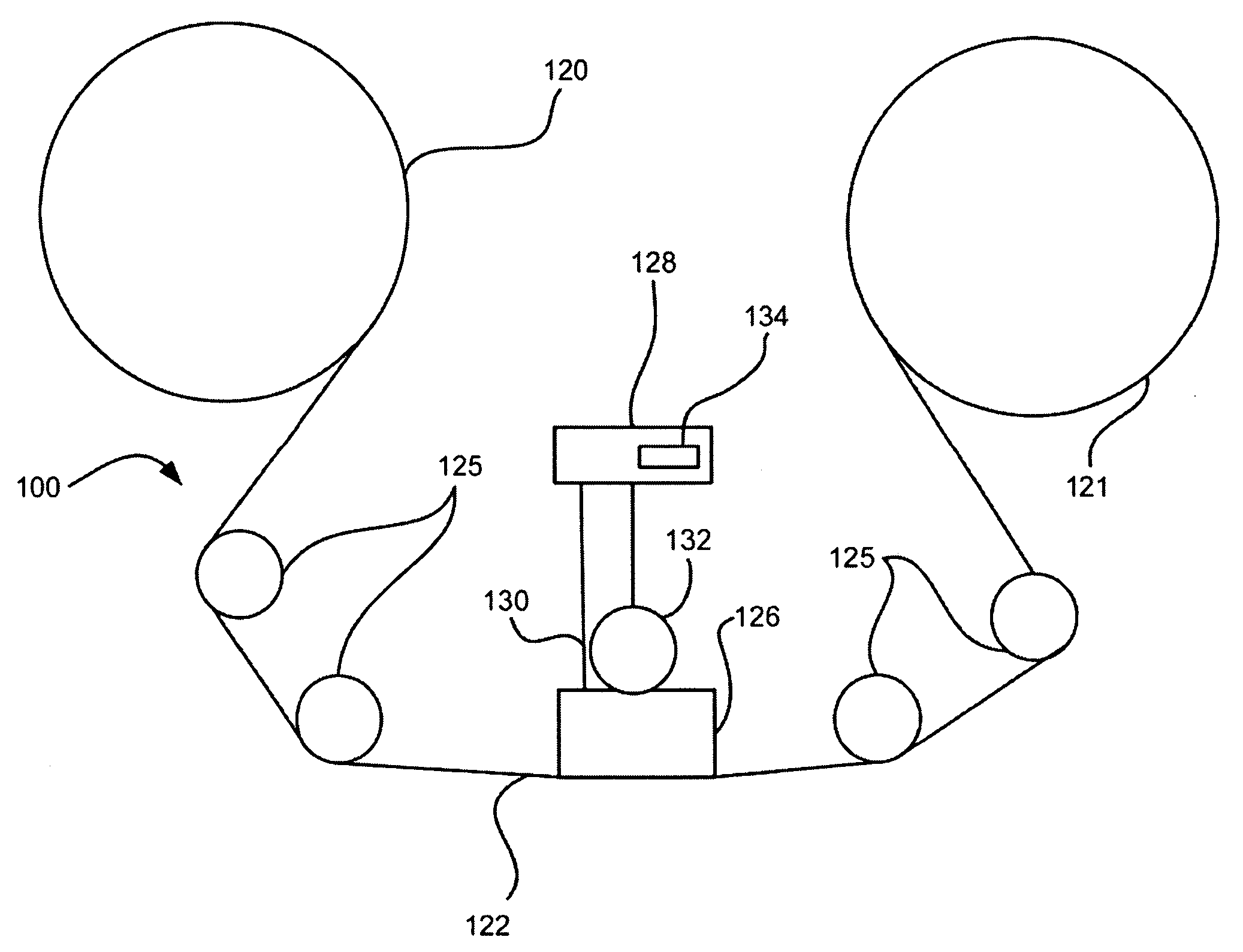

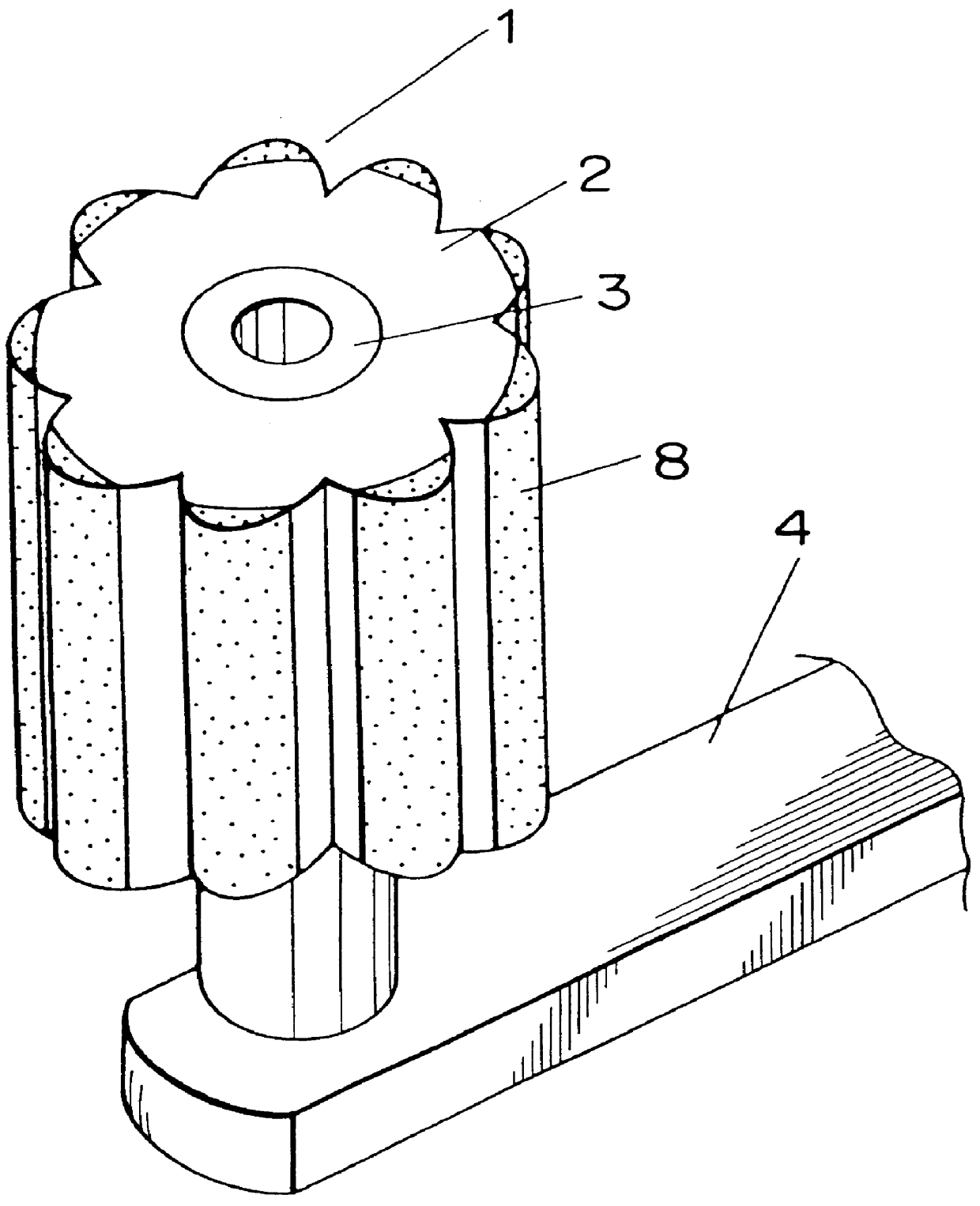

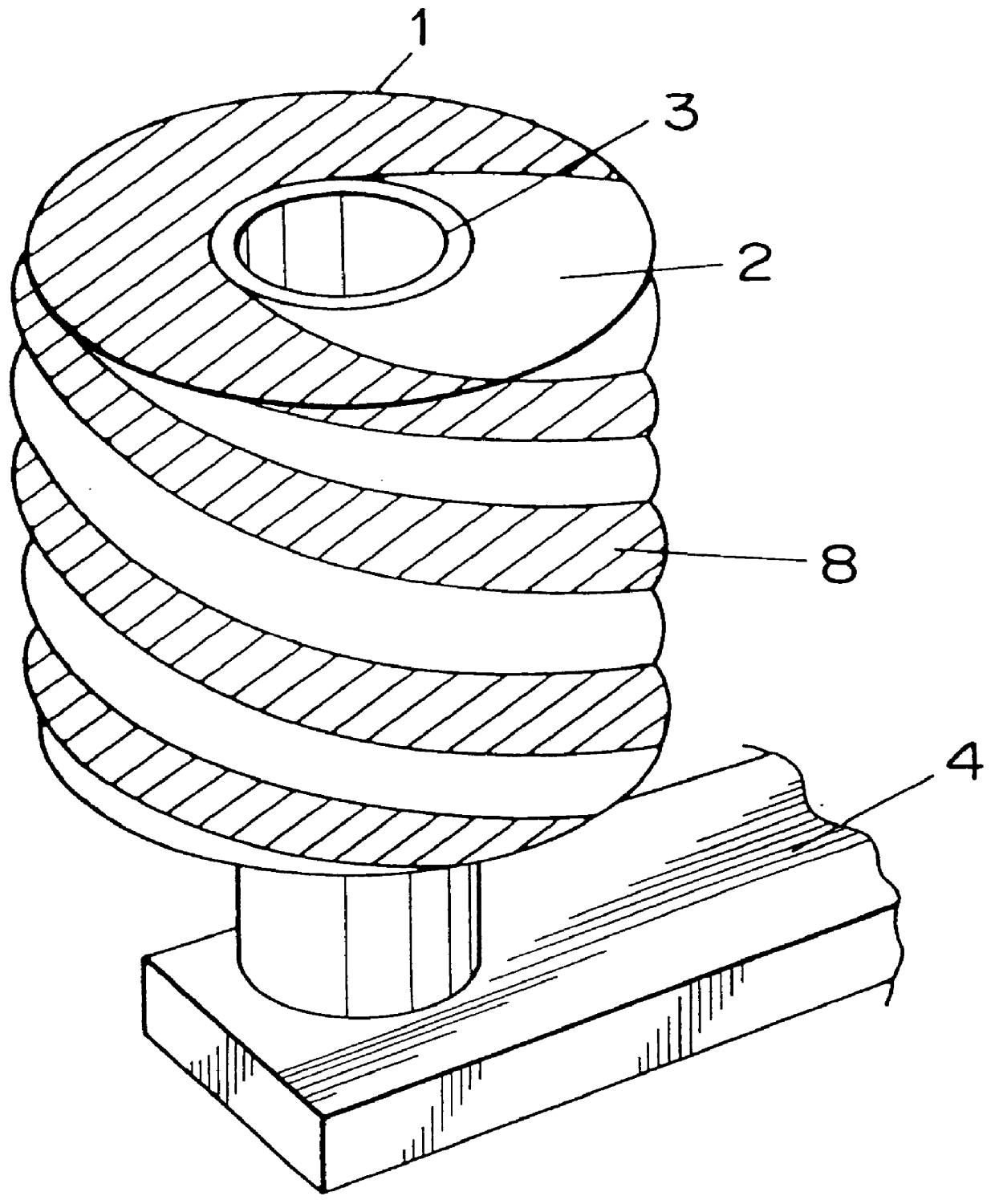

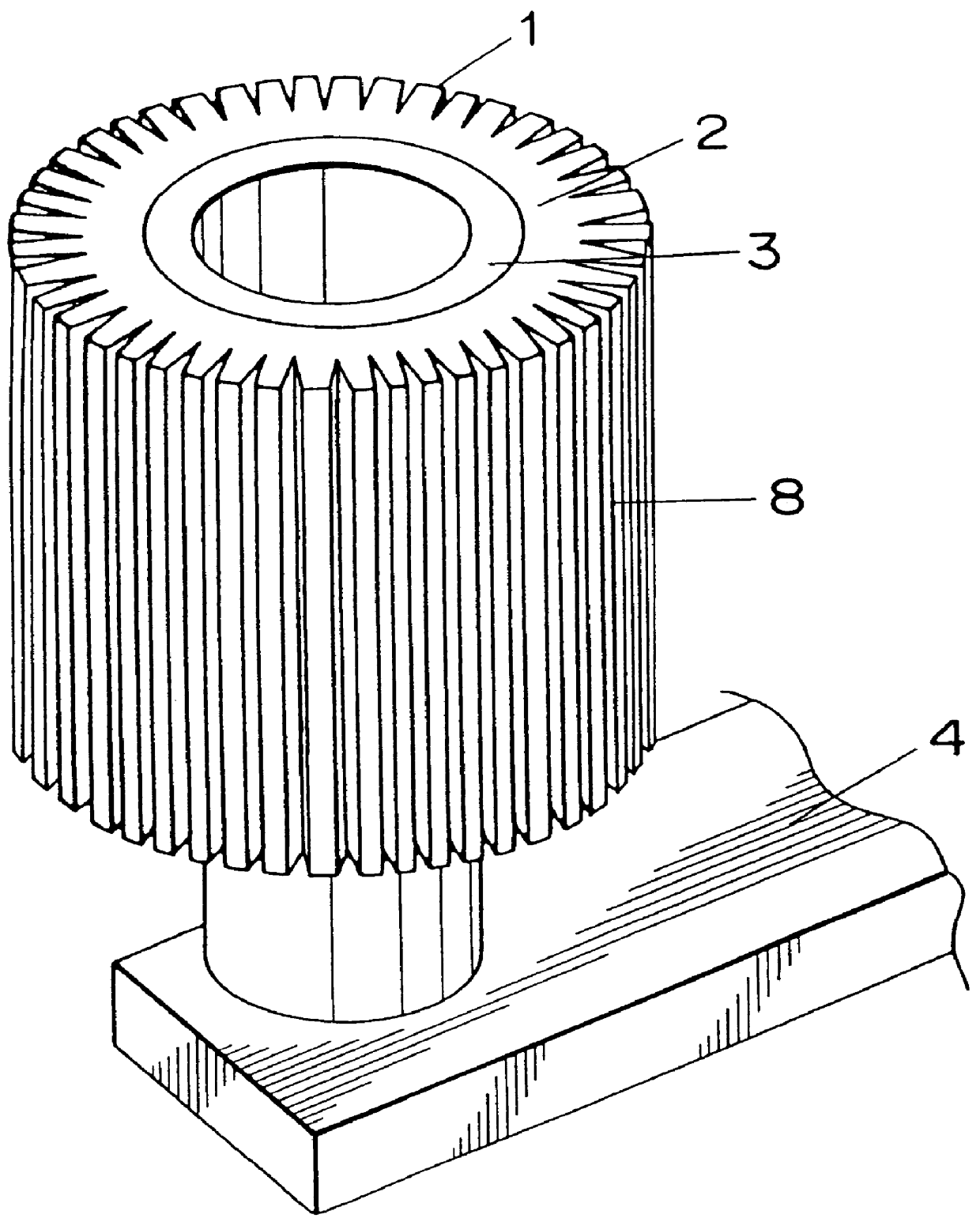

Tubular rotary head cleaner having a non-woven fabric for a magnetic recording and/or reproducing apparatus

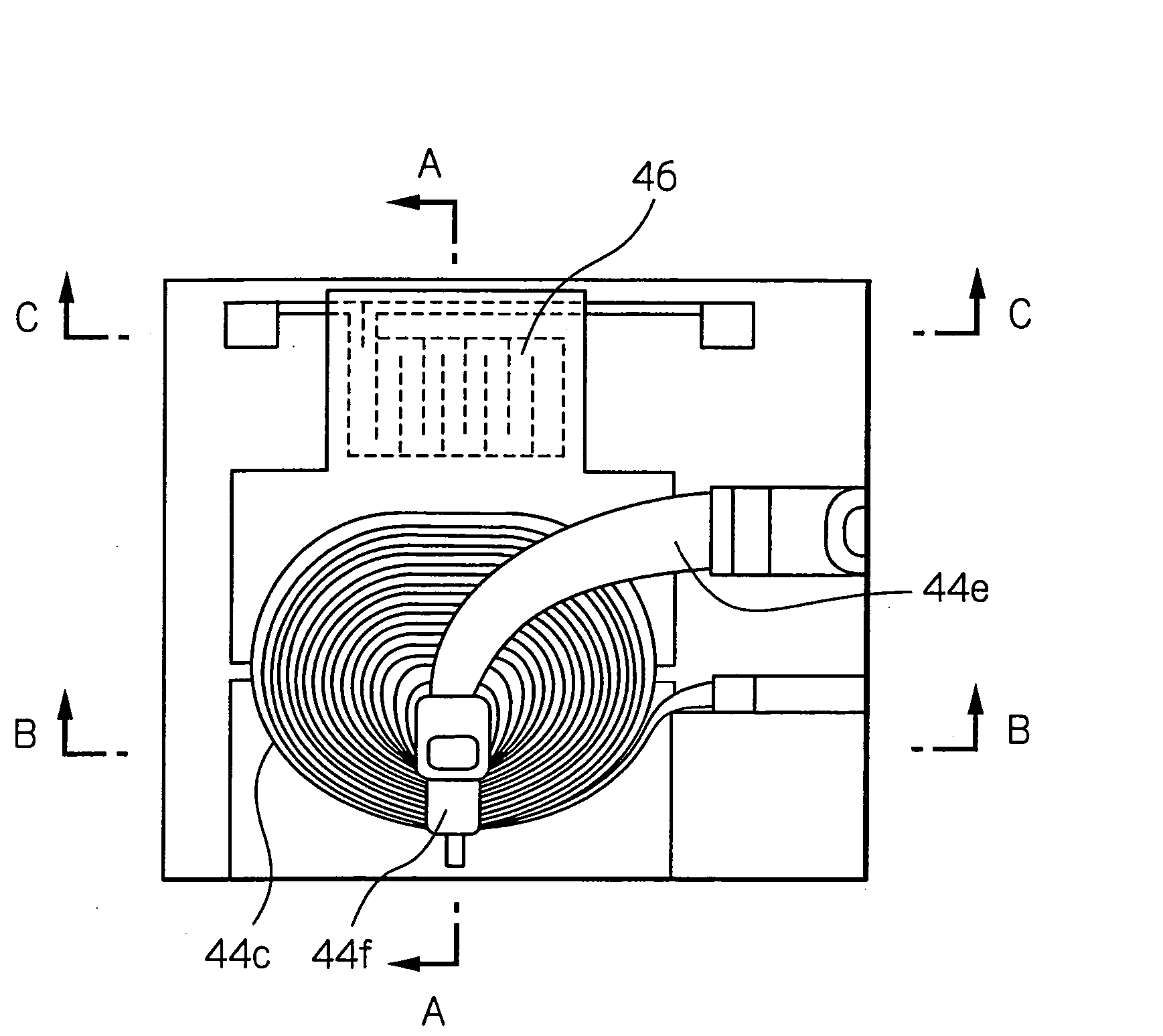

InactiveUS6069776AFilamentary/web record carriersRecord information storageEngineeringMechanical engineering

A head cleaner for a magnetic recording and / or reproducing apparatus for cleaning rotary magnetic heads. The head cleaner includes a rotary spindle rotatably mounted on a support arm movable between an operative position, in which the head cleaner is in position to clean the magnetic heads, and an inoperative position separated from the magnetic heads. The head cleaner also includes a plurality of oblong webs of non-woven fabric with or without an abrasive material coated on one surface thereof. The oblong webs of non-woven fabric are fixedly secured to the rotary spindle so as to extend radially outwardly therefrom while being spaced an equal distance from each other in a direction circumferentially thereof.

Owner:PANASONIC CORP

Magnetic head with soft magnetic shield and magnetic storage

InactiveUS20060119984A1Improve reliabilityImprovement of floating field robustnessRecord information storageCleaning recording headsMagnetic storageEngineering

Embodiments of the invention avoid erasure of recorded data by concentrating stray fields on a magnetic head element. According to one embodiment, in a magnetic storage apparatus using a perpendicular recording medium with a soft magnetic under layer, a soft magnetic shield is provided so as to surround the upper parts and sides of magnetic head elements. A distance between the soft magnetic shield and the medium is shorter than that between the soft magnetic shield and the magnetic head element.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

Systems and methods for protecting a sensitive device from corrosion

InactiveUS20090274836A1Reduce exposureManufacture head surfaceRecord information storageMagnetic storageEngineering

A method in one embodiment includes applying an organic coating to a magnetic head for reducing exposure of the head to oxidation promoting materials; and storing the magnetic head. A method in another embodiment includes applying an organic coating to a magnetic head for reducing exposure of the head to oxidation promoting materials, the organic coating being applied to the magnetic head after the head is installed in the magnetic storage system. Another method includes fabricating a tape having an applicator portion for applying an organic coating to a magnetic head for reducing exposure of the head to oxidation promoting materials; applying the organic coating to the applicator portion of the tape; and applying a lubricant to a data portion of the tape. A method in another embodiment includes fabricating a tape having a data portion, and a cleaning portion for removing an organic coating from a magnetic head.

Owner:IBM CORP

Thin-film magnetic head with heating element and heatsink

ActiveUS20060291098A1Improved protrusion efficiencyStabilizing read outputRecord information storageCleaning recording headsData signalHeat spreader

A thin-film magnetic head that has an improved protrusion efficiency under the condition of not only assuring the reliability of the-heating operation, but also stabilizing the read output is provided. The head comprises: a magnetic head element for writing and / or reading data signals; a heating element for generating heat at least during operations of the magnetic head element; and a first heatsink element provided adjacent to the heating element for receiving a part of the heat generated from the heating element, the first heatsink element being a distance from the magnetic head element.

Owner:TDK CORPARATION +1

Data transfer apparatus head cleaning

InactiveUS20060238911A1Carrier indicating/warning arrangementsFilamentary/web record carriersCombined useData transmission

A data transfer apparatus is described for transferring data between at least one transducer head of the data transfer apparatus and a data medium removably received in the data transfer apparatus. The data transfer apparatus is operable to monitor at least one data transfer performance characteristic, and to use results of the monitoring to set an indicator for access by the data transfer apparatus, for use in connection with a subsequent head-cleaning process using a designated head-cleaning medium, the indicator corresponding to an appropriate quality of head-cleaning process.

Owner:HEWLETT-PACKARD ENTERPRISE DEV LP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com