Cleaning method for polyacrylonitrile precursor spinning spinneret

A polyacrylonitrile and spinneret technology, which is applied in spinneret assemblies, textiles and papermaking, etc., can solve the problems of difficult to achieve cleaning effect and long cleaning time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] After spinning, remove the spinneret, fix it on a polytetrafluoroethylene holder, and put them together in a beaker.

[0069] Add analytically pure dimethyl sulfoxide (DMSO) solvent into the beaker to completely submerge the spinneret, then put it into an ultrasonic cleaner to start cleaning. The temperature and power of the ultrasonic cleaner were set at 80°C and 100W, respectively. After washing for 2 hours, replace the dimethyl sulfoxide (DMSO) solvent, and wash again according to the above conditions. Repeat this 3 times.

[0070] The dimethyl sulfoxide (DMSO) solvent was replaced with about 67% concentrated nitric acid, and 1 wt% of ultrafine silica particles with a particle size of 5 μm were added for ultrasonic cleaning. The temperature and power of the ultrasonic cleaner were set at 60°C and 100W, respectively. After cleaning for 2 hours, replace the concentrated nitric acid and ultrafine silica particles, and clean again according to the above conditions. R...

Embodiment 2-5

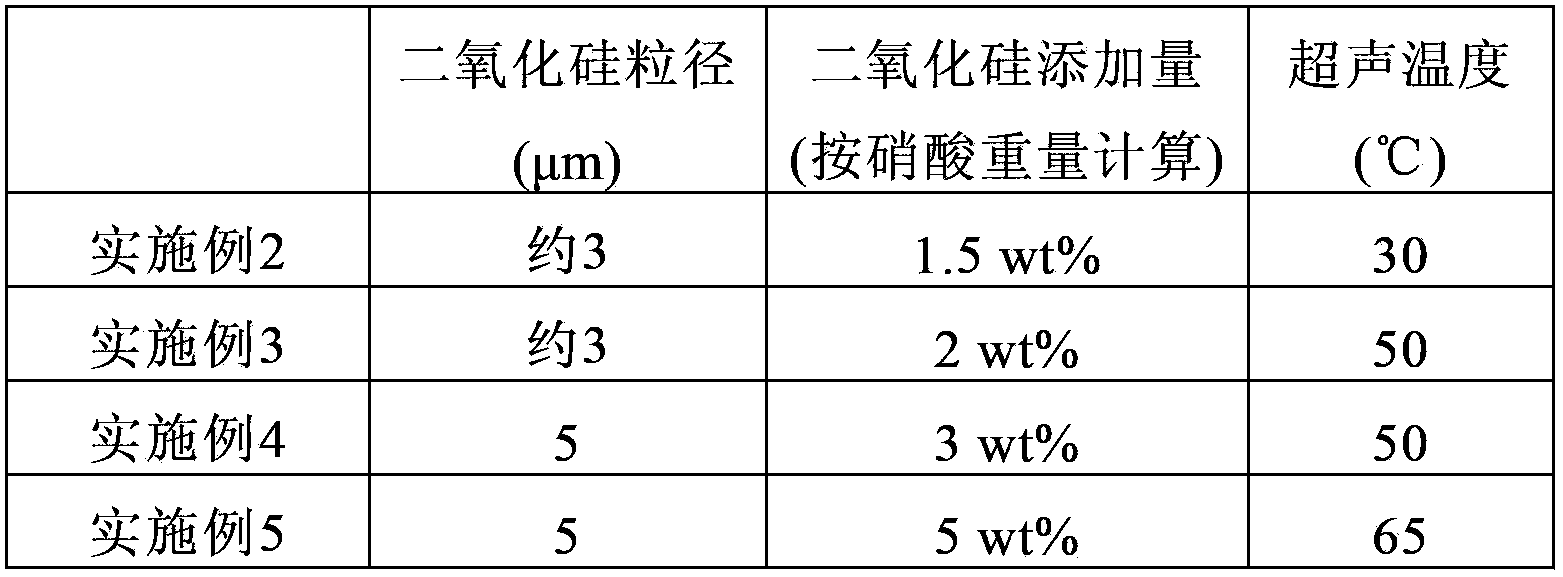

[0076] The same cleaning steps as in Example 1 were adopted, the only change being the conditions shown in Table 1 during the nitric acid ultrasonic cleaning process.

[0077] Table 1

[0078]

[0079] The cleaning effects of Examples 2 to 5 show that the spinneret after cleaning is also detected by an optical microscope, and no clogged spinneret holes are found, which can be used for spinning.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com