Beam forming device and method

A beam and ring beam technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of low spiral drilling processing efficiency, low energy utilization rate, melting and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention is described in detail below in conjunction with accompanying drawing:

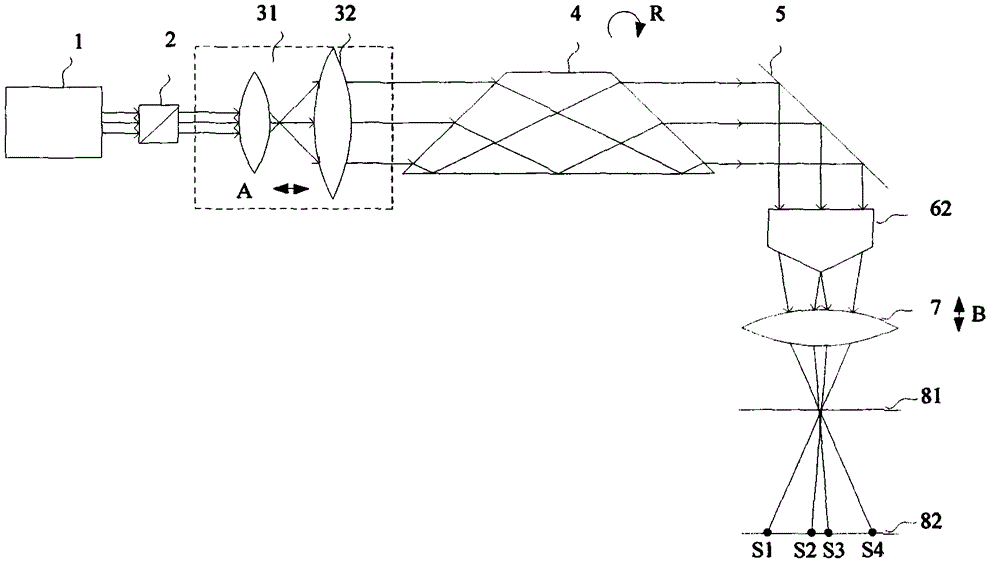

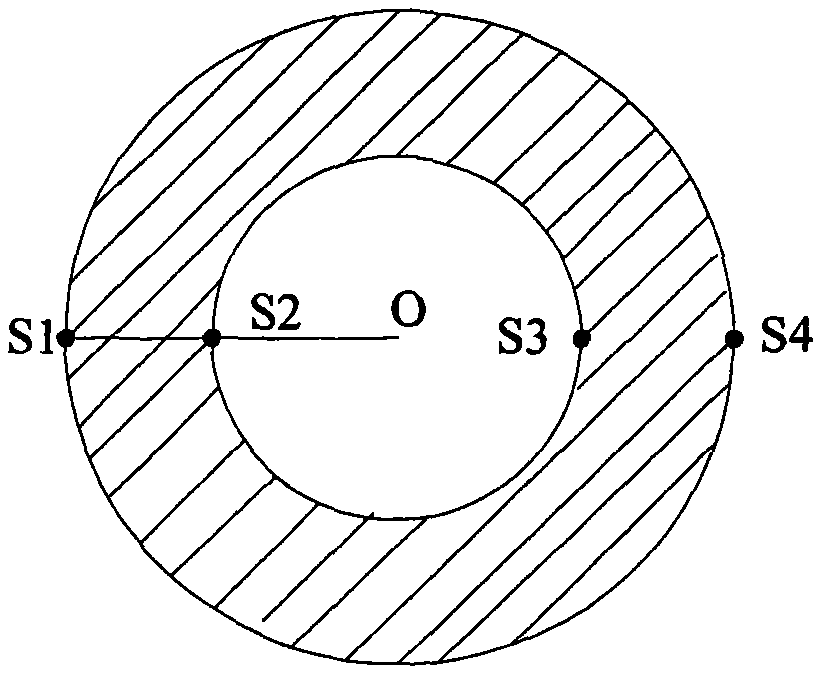

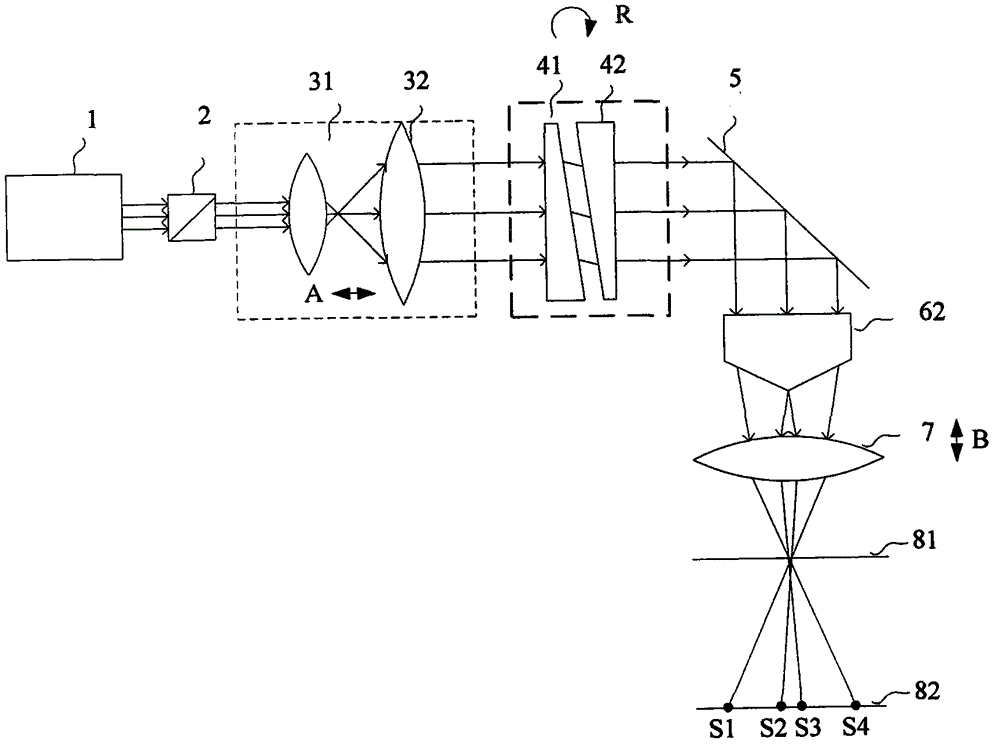

[0035] Such as figure 1 As shown, the light beam emitted by the laser 1 passes through the optical gate 2 to control whether to continue to transmit. The distance between the lens 31 and the lens 32 is relatively adjustable, and is used to adjust the divergence angle and spot size of the laser beam. The Dove prism 4 is installed in the hollow shaft rotating motor, so that the Dove prism rotates R around the optical axis, and the light beam emitted from the Dove prism 4 will also rotate accordingly. The rotating laser beam enters the plane reflector 5, and the propagation direction of the laser is changed to vertical propagation. The vertically propagating laser beam enters the positive axicon 62 and the focusing lens 7, and the outgoing beam is a rotating ring beam, such as figure 2 As shown, the spot radius OS2 of the ring beam and the ring width S1S2 will change with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com