Light-weight and high-strength roof panel and production method thereof

A roof panel, high-strength technology, used in roofs, layered products, building components, etc., can solve the problems of overall weight, high strength, low strength of roof panels, etc., and achieve smooth hole walls, uniform distribution of holes, and the same hole diameter. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

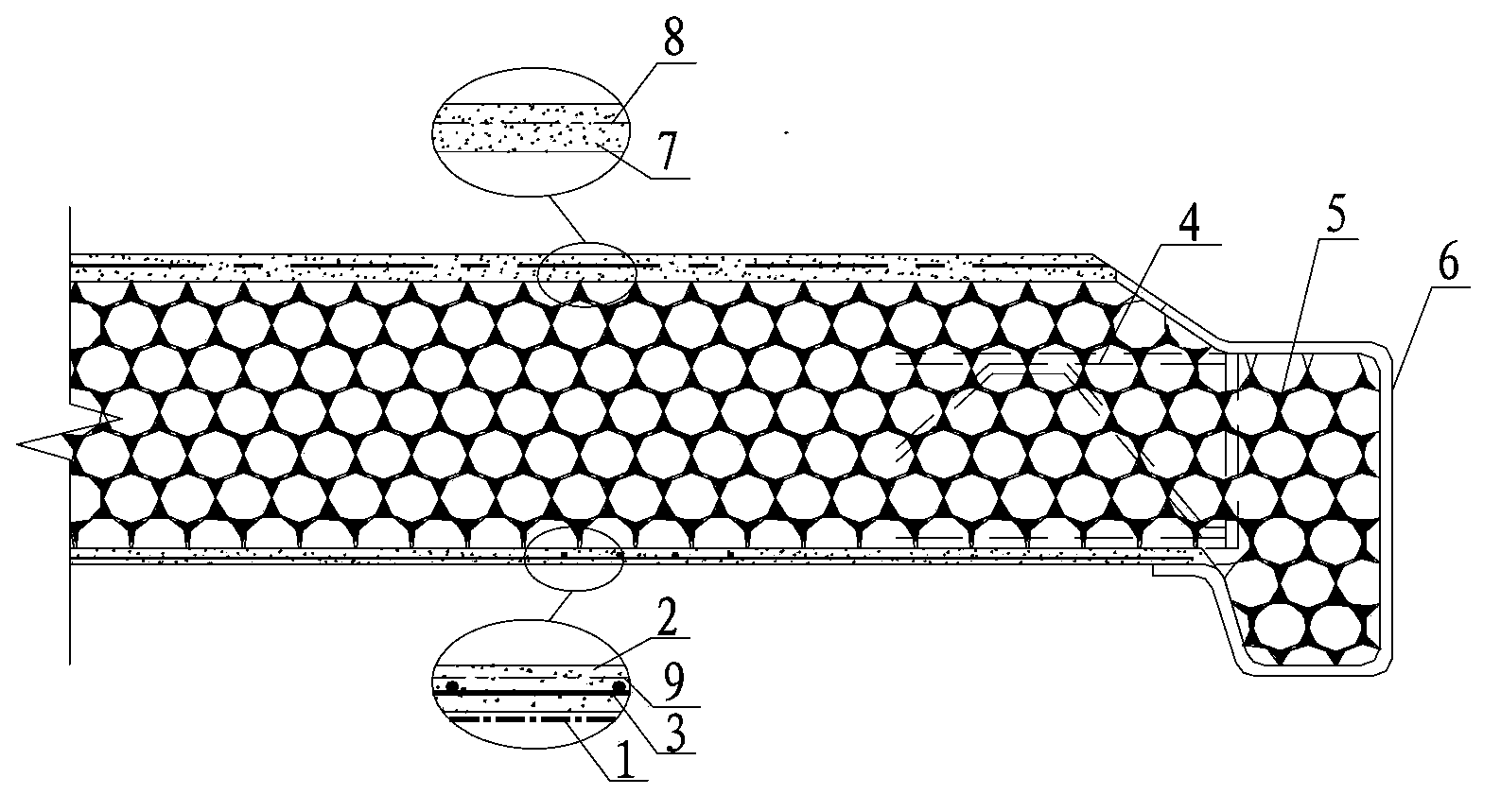

[0028] Embodiment 1: The lightweight high-strength roof panel of the present invention can be manufactured according to the following steps:

[0029] 1) Prepare materials, select 40 parts of cement, 50 parts of slag powder, 5 parts of nano-zinc dioxide, 8 parts of nano-magnesium dioxide, 10 parts of nano-leveling agent, and 4 parts of nano-leveling agent, of which nano-leveling agent uses nano-oxidation Aluminum and leveling agent configuration, nano hole introduction agent using nano titanium dioxide and PAC configuration.

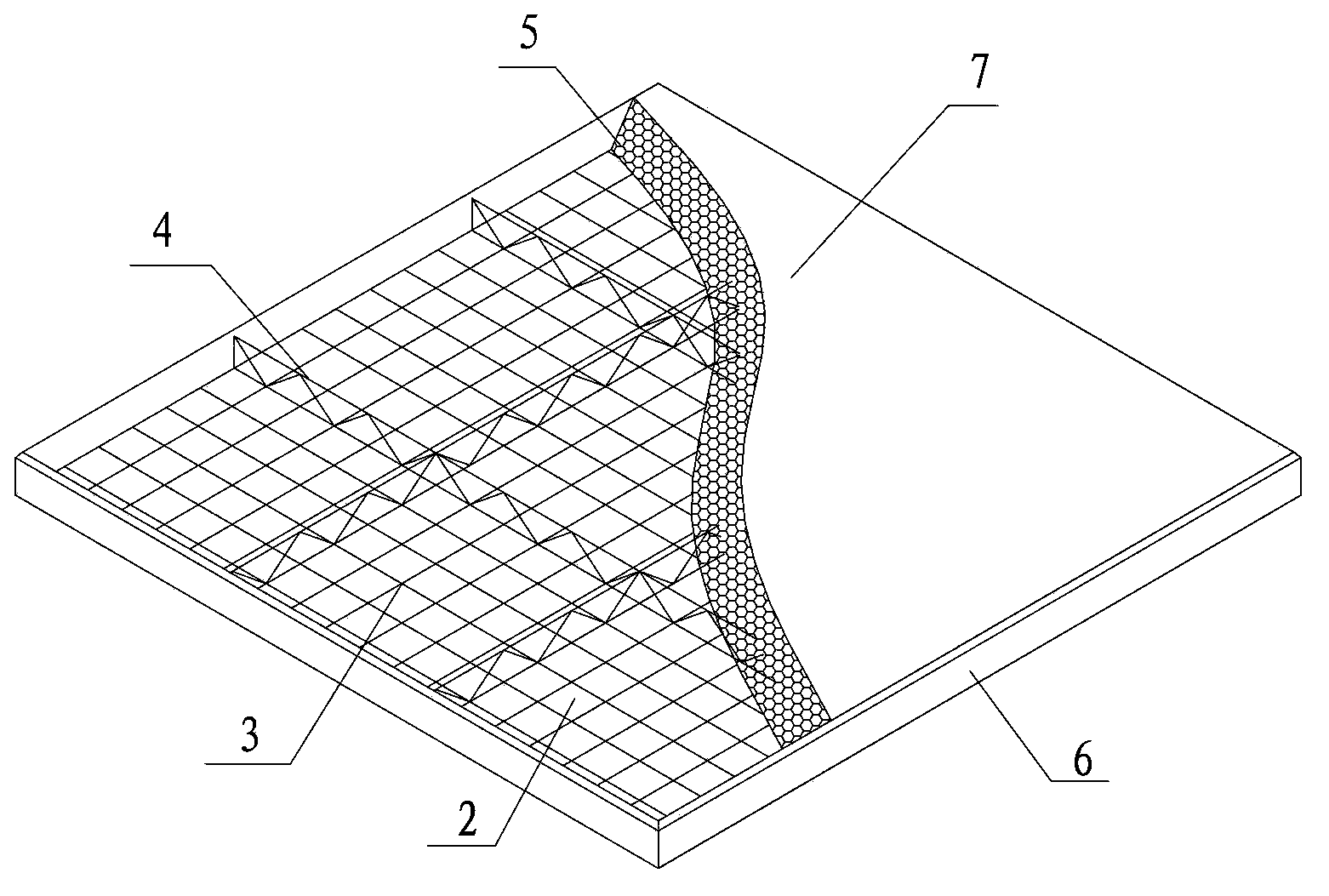

[0030] 2) First, weld the built-in steel bar 4 and steel wire mesh 3 with the light steel frame 6 respectively, and lay a layer of protective film on the bottom table; lay non-woven fabric 1 on it, and put the The light steel frame 6 is placed on the non-woven fabric 1, and the four sides of the light steel frame are sealed, and then a layer of glass fiber mesh cloth 9 is laid on the top of the steel wire mesh 3, and then the built-in steel bars, steel me...

Embodiment 2

[0034] Embodiment 2: The lightweight high-strength roof panel of the present invention can be manufactured according to the following steps:

[0035] 1) Prepare materials, choose 70 parts of cement, 40 parts of steel slag powder, 3 parts of nano-zinc dioxide, 5 parts of nano-magnesium dioxide, 6 parts of nano-leveling agent, and 1 part of nano-leveling agent, of which nano-leveling agent adopts nano-oxidation Aluminum and leveling agent configuration, nano hole introduction agent using nano titanium dioxide and PAC configuration.

[0036] 2) First, weld the built-in steel bar 4 and steel wire mesh 3 with the light steel frame 6 respectively, and lay a layer of protective film on the bottom table; lay non-woven fabric 1 on it, and put the The light steel frame 6 is placed on the non-woven fabric 1, and the four sides of the light steel frame are sealed, and then a layer of glass fiber mesh cloth 9 is laid on the top of the steel wire mesh 3, and then the built-in steel bars, st...

Embodiment 3

[0040] Embodiment 3: The lightweight high-strength roof panel of the present invention can be manufactured according to the following steps:

[0041] 1) Prepare materials, select 55 parts of cement, 30 parts of fly ash, 10 parts of nano-zinc dioxide, 1 part of nano-magnesium dioxide, 3 parts of nano-leveling agent, and 5 parts of nano-pore-introducing agent. Alumina and leveling agent configuration, nano hole introduction agent using nano titanium dioxide and PAC configuration.

[0042] 2) First, weld the built-in steel bar 4 and steel wire mesh 3 with the light steel frame 6 respectively, and lay a layer of protective film on the bottom table; lay non-woven fabric 1 on it, and put the The light steel frame 6 is placed on the non-woven fabric 1, and the four sides of the light steel frame are sealed, and then a layer of glass fiber mesh cloth 9 is laid on the top of the steel wire mesh 3, and then the built-in steel bars, steel mesh and glass fiber The grid cloth is fixedly c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com