Preparation method and application of three-dimensional graphene-based composite material

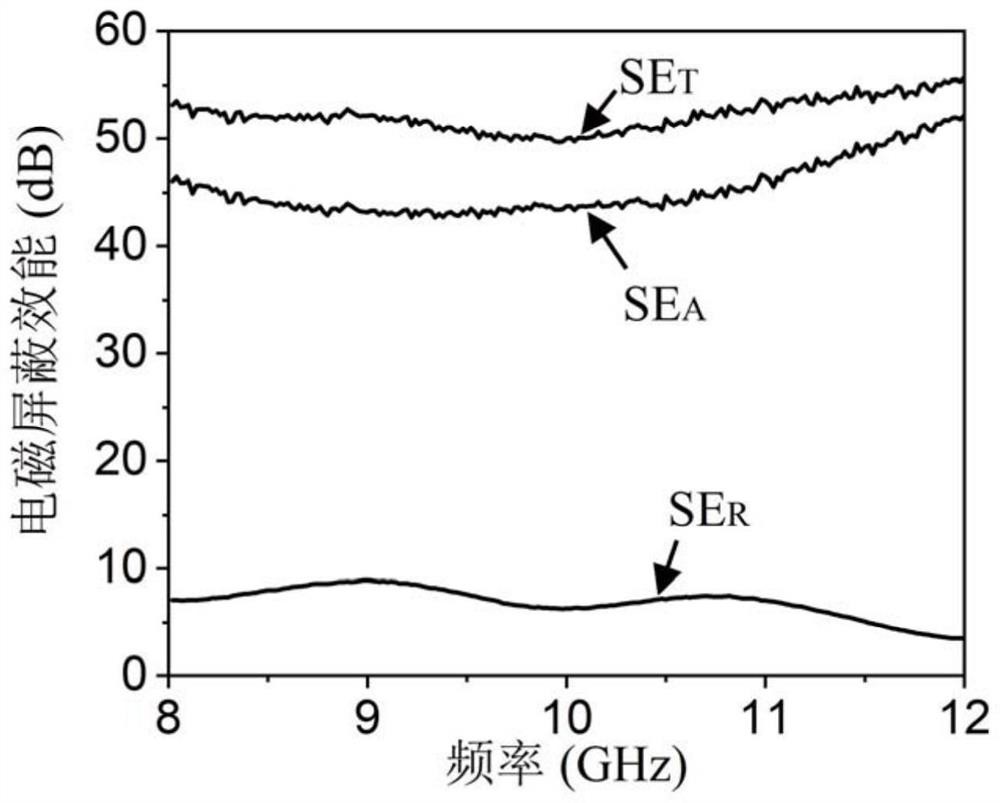

A composite material, graphene-based technology, applied in the fields of magnetic field/electric field shielding, electrical components, etc., can solve the problems of susceptibility to corrosion and oxidation, high density, etc., to achieve the effect of enhancing electromagnetic shielding efficiency and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] As an aspect of the technical solution of the present invention, it relates to a preparation method of a three-dimensional graphene-based composite material, comprising:

[0034] Immerse the foamed metal in a 5-25mg / ml graphene oxide solution for 20-40kHz ultrasonic treatment for 0.5-1.5h, and then dry to obtain a graphene oxide / foamed metal composite material;

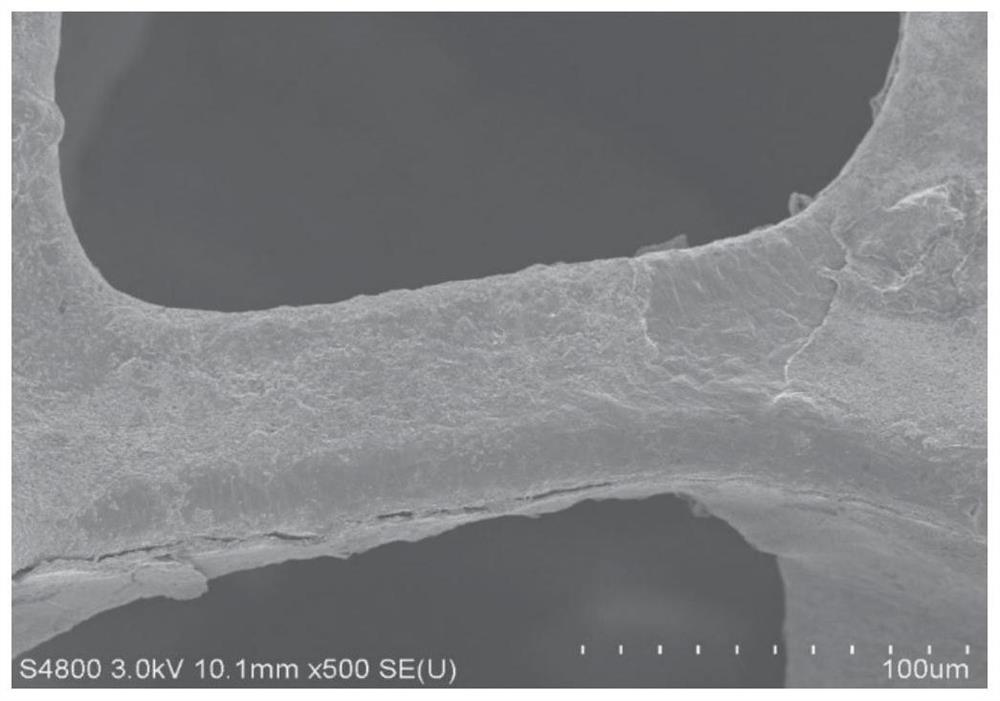

[0035] The graphene oxide / foamed metal composite material is etched with dilute mixed acid, and then dried to obtain three-dimensional graphene oxide;

[0036] annealing the three-dimensional graphene oxide in an inert gas / hydrogen mixed atmosphere to obtain three-dimensional high-quality thin-layer graphene;

[0037] Mixing the three-dimensional high-quality thin-layer graphene with the chiral microbial extract solution to obtain a three-dimensional graphene composite material loaded with the chiral microbial extract;

[0038] adding the three-dimensional graphene composite material loaded by the microorganis...

Embodiment 1

[0104] (1) get 1.5 mass parts of graphite flakes or graphite powder and place it in the ferric salt aqueous solution with a concentration of 0.8mol / L for etching 30h, then place it in the concentrated sulfuric acid of concentration 5mol / l, volume ratio 9:1 and In the beaker of the mixed acid of concentrated phosphoric acid, react at 60°C for 3h, place the beaker in a magnetic stirring pot that has been preset at 50°C, and slowly add 9 mass fraction of potassium permanganate powder to the beaker (adding time). Controlled at 45-90min), after the addition, the reaction system was continued to be heated at 50°C for 6h. After 6h, continue to slowly add a certain proportion of H diluted to the above system. 2 O 2 The solution is not added until the color of the solution changes from black to purple and then to golden yellow. The above reaction system was continued to be heated at 50° C. for 3 hours, then cooled down, washed by centrifugation, and freeze-dried to obtain graphene ox...

Embodiment 2

[0113] (1) Get 1.5 mass parts of graphite flakes or graphite powder and place it in a ferric salt aqueous solution with a concentration of 1.5 mol / L for etching for 20h, then place it in the concentrated sulfuric acid of 8 mol / 1, volume ratio 9:1 and In the beaker of the mixed acid of concentrated phosphoric acid, react at 90°C for 2h, place the beaker in a magnetic stirring pot that has been preset at 50°C, and slowly add 9 mass fractions of potassium permanganate powder to the beaker (adding time). Controlled at 45-90min), after the addition, the reaction system was continued to be heated at 50°C for 6h. After 6h, continue to slowly add a certain proportion of H diluted to the above system. 2 O 2 The solution is not added until the color of the solution changes from black to purple and then to golden yellow. The above reaction system was continued to be heated at 50° C. for 3 hours, then cooled down, washed by centrifugation, and freeze-dried to obtain graphene oxide.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com