Method for eliminating edge squeezed-out resin of buried-copper-coin PCB

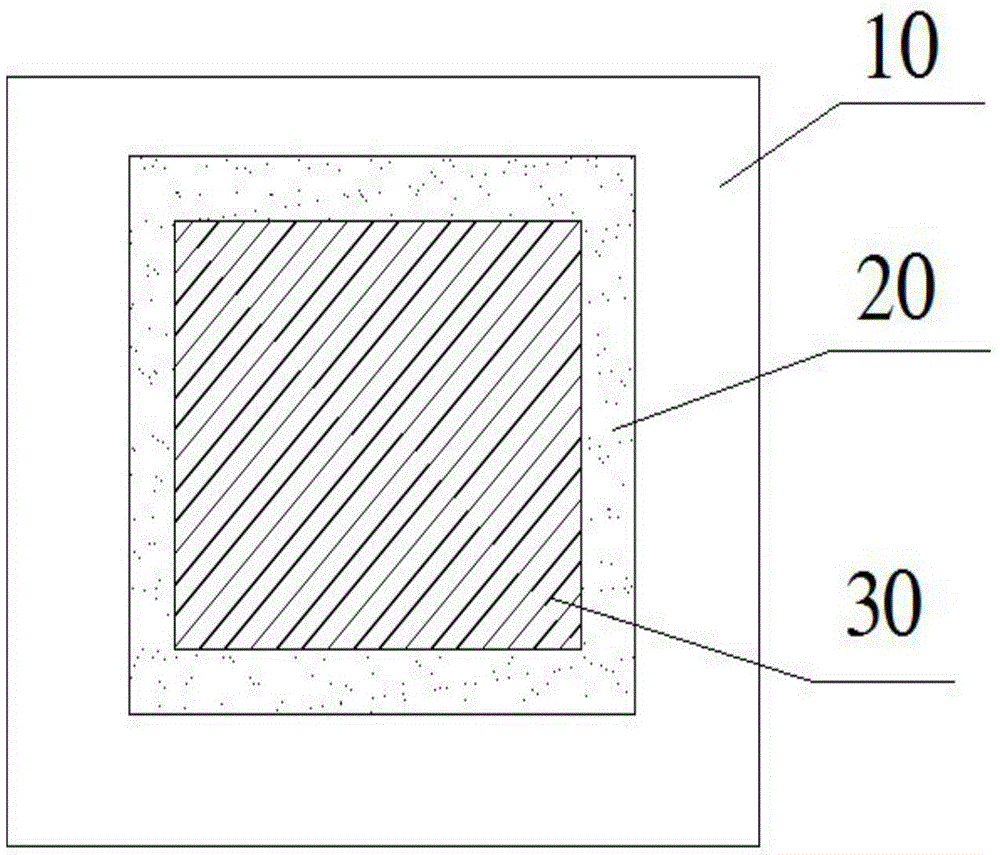

A copper block and glue overflow technology, which is applied in the secondary treatment of printed circuits, electrical components, printed circuits, etc., can solve the problems of cleaning, difficult glue overflow, grinding and leaking substrates, etc., so as to improve the quality of board making and reduce scrap rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

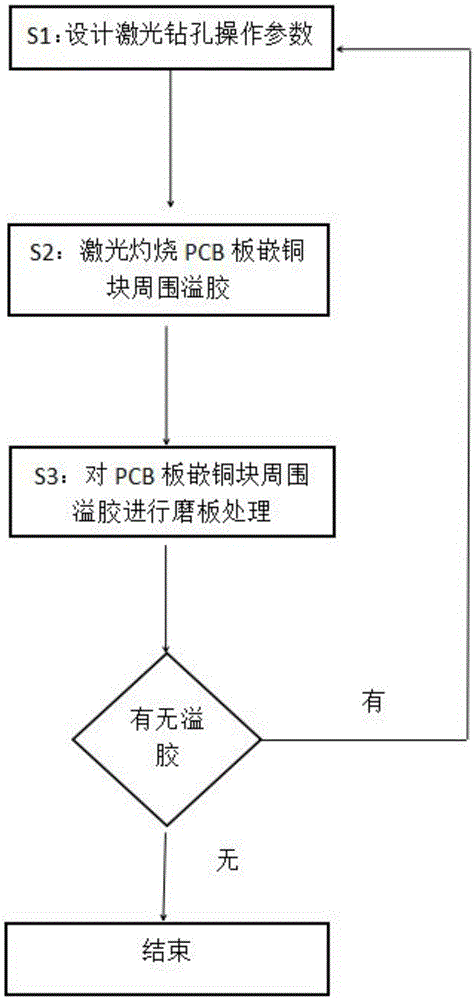

Method used

Image

Examples

Embodiment 1

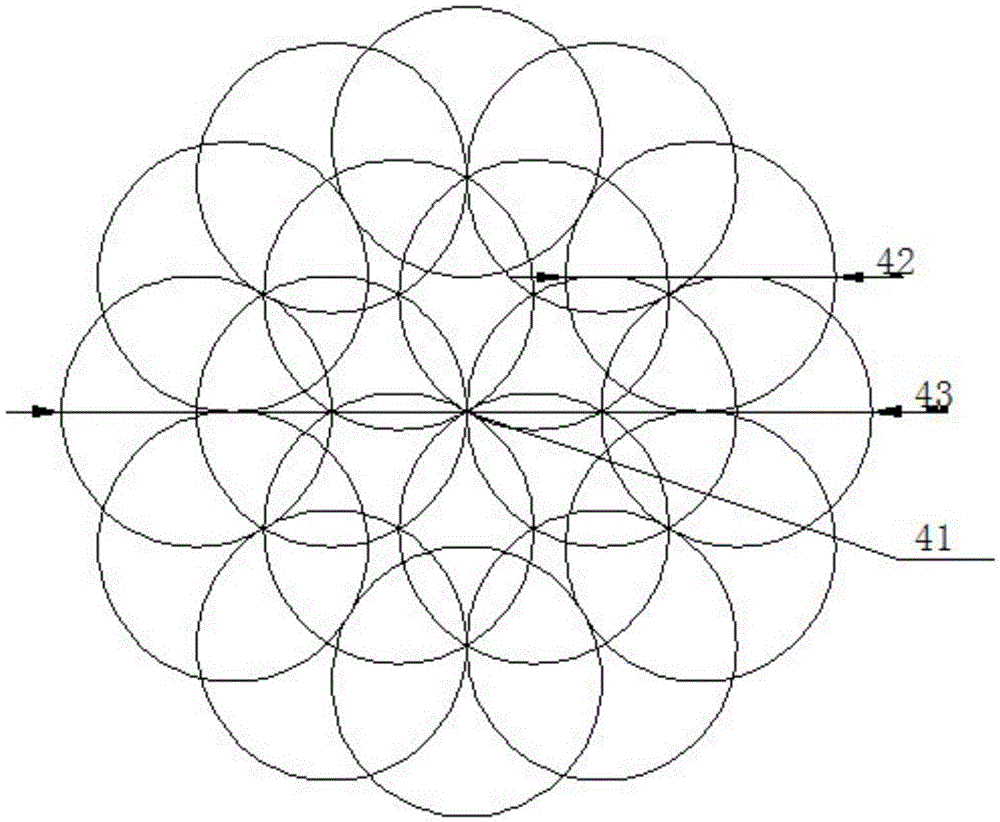

[0041] See image 3 In this embodiment, the hole diameter of the drill holes is 0.15mm, and the arrangement rules of the drill clusters are specifically as follows: each drill cluster includes the inner ring standard drilling and the outer ring standard drilling, the inner ring standard drilling The 6 standard boreholes are arranged in a circular arrangement. The standard boreholes of the inner ring all intersect at point O, and are symmetrical with point O as the center of symmetry. The overlap ratio of the standard boreholes of adjacent inner rings is 50%; The holes are arranged in a circular arrangement with 12 standard drilling holes. All outer ring standard drilling holes are symmetrical with point O as the center of symmetry. The distance from the center of all outer ring standard drilling holes to point O is twice the standard drilling radius. 42 is the standard drill diameter, 43 is the width of the drill cluster.

[0042] Using the above-mentioned arrangement rule of dri...

Embodiment 2

[0044] See Figure 4 In this embodiment, the hole diameter of the drill holes is 0.175mm, and the arrangement rules of the drill clusters are specifically as follows: each drill cluster includes the inner ring standard drilling and the outer ring standard drilling, the inner ring standard drilling consists of 3 The standard boreholes are arranged in a circular arrangement. All the standard boreholes in the inner ring intersect at point O, and are symmetrical with point O as the center of symmetry. The angle formed by the line connecting the center of adjacent standard boreholes and point O is 120°; The standard boreholes of the outer ring are arranged in a circular arrangement. All the standard boreholes of the outer ring are symmetrical with the point O as the center of symmetry. The standard boreholes of the adjacent outer ring are tangent. The distance from the center of the circle to point O is twice the standard drilling radius.

[0045] Using the above arrangement rule of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com