Film manufacturing method

A thin film and sputtering technology, applied in ion implantation plating, metal material coating process, coating and other directions, can solve the problems of high demand, low deposition rate, small sputtering energy, etc., to prolong the process time, reduce Deposition rates, results for demanding needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

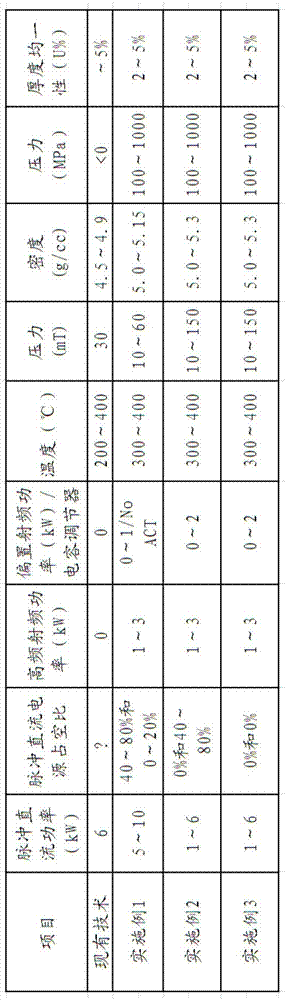

Embodiment 1

[0041] The film forming method is used to form a thin film by sputtering on a wafer, the wafer is located on a base, the base is placed at the bottom of a reaction chamber, and a target is arranged on the top of the reaction chamber.

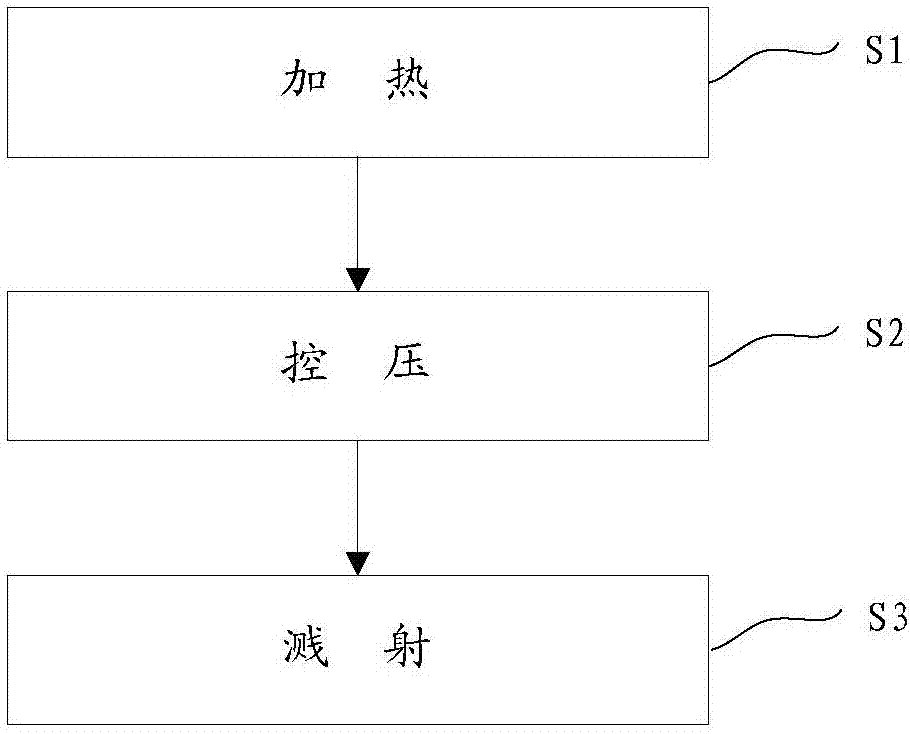

[0042] As an embodiment, a specific film-making method includes the following steps:

[0043]S11) Heating step: feeding the first gas into the reaction chamber, and controlling the flow of the first gas, so that the first air pressure in the reaction chamber remains constant; at the same time, heating the wafer to a set temperature.

[0044] Preferably, the first gas is argon, the first pressure is 1T-2T; the heating temperature is 300° C.-400° C., and the heating time is 1 min.

[0045] In this step, the wafer is introduced into the reaction chamber, Ar is introduced into the reaction chamber, the air pressure reaches 1T-2T, the susceptor temperature is set at 300°C-400°C, wait for about 1min, and the susceptor is aligned with the wafer. circl...

Embodiment 2

[0055] The film forming method is used to form a thin film by sputtering on a wafer, the wafer is located on a base, the base is placed at the bottom of a reaction chamber, and a target is arranged on the top of the reaction chamber.

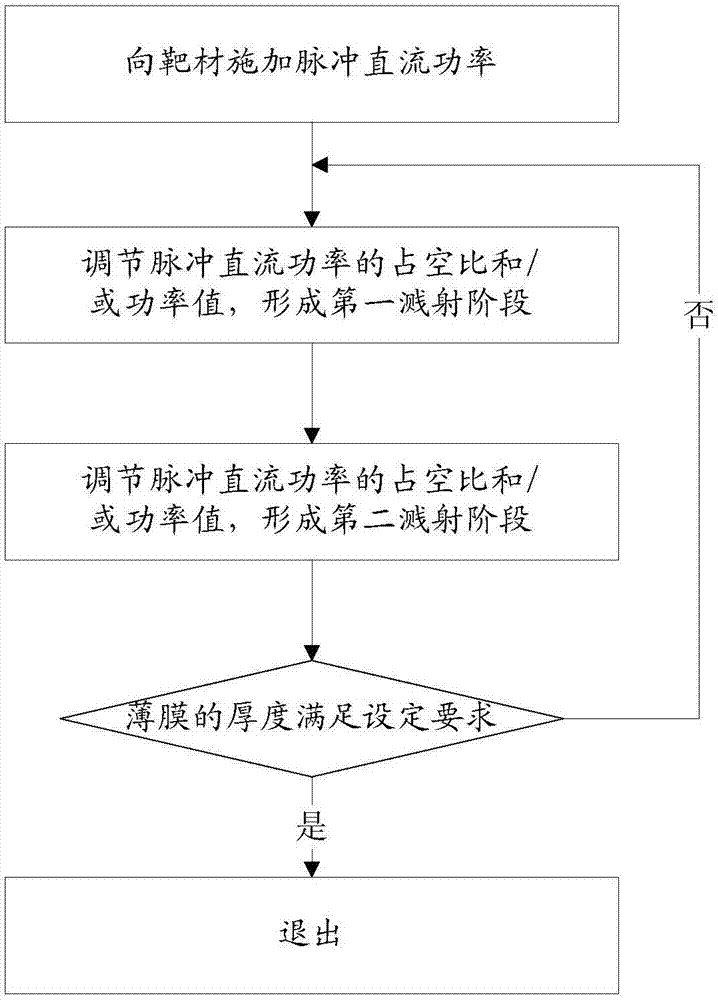

[0056] Compared with the previous embodiment, the film forming method in this embodiment differs in that: on the basis of pulsed DC power, RF power is further applied to the target, and RF power is applied to the target to start the ignition. The high-frequency radio frequency power is still maintained in the sputtering stage, and the high-frequency radio frequency power is turned off in the second sputtering stage.

[0057] As an embodiment, a specific film-making method includes the following steps:

[0058] S21) Heating step: feeding the first gas into the reaction chamber, and controlling the flow of the first gas, so that the first air pressure in the reaction chamber remains constant; at the same time, heating the wafer to a set temperatur...

Embodiment 3

[0073] The film forming method is used to form a thin film by sputtering on a wafer, the wafer is located on a base, the base is placed at the bottom of a reaction chamber, and a target is arranged on the top of the reaction chamber.

[0074] Compared with the previous embodiment, the film forming method in this embodiment differs in that: on the basis of pulsed DC power, RF power is further applied to the target, and RF power is applied to the target to start the ignition. Both the sputtering stage and the second sputtering stage maintain high frequency RF power.

[0075] As an embodiment, a specific film-making method includes the following steps:

[0076] S31) Heating step: feeding the first gas into the reaction chamber, and controlling the flow of the first gas so that the first air pressure in the reaction chamber remains constant; at the same time, heating the wafer to a set temperature.

[0077] Preferably, the first gas is argon, the first pressure is 1T-2T; the heat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com