Production method of silver coated nickel powder

A technology of silver-coated nickel powder and production method, which is applied in transportation and packaging, liquid chemical plating, coating, etc., can solve the problems of loose and non-dense coating, hinder the deposition of silver atoms, and complex process, etc., and achieve uniform and dense metal coating , slow down the deposition rate, good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The invention provides a kind of production method of silver-coated nickel powder, and concrete process is as follows:

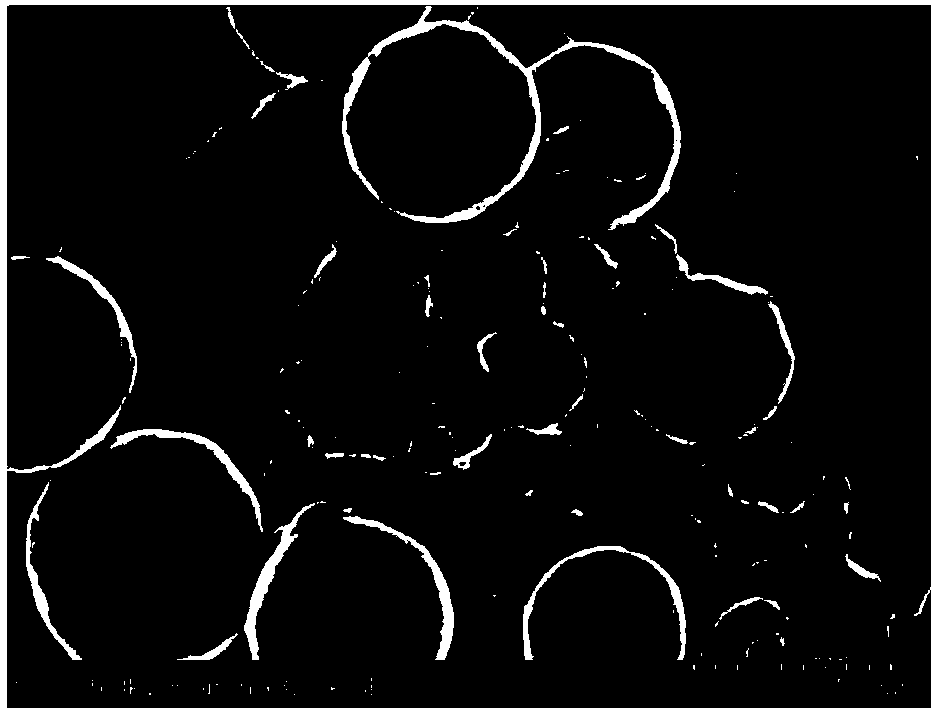

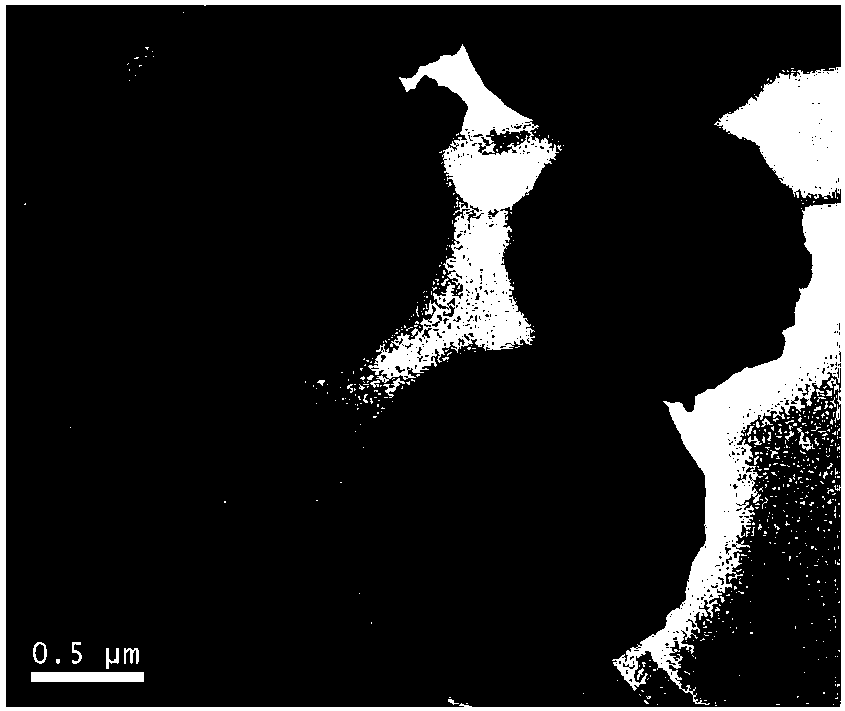

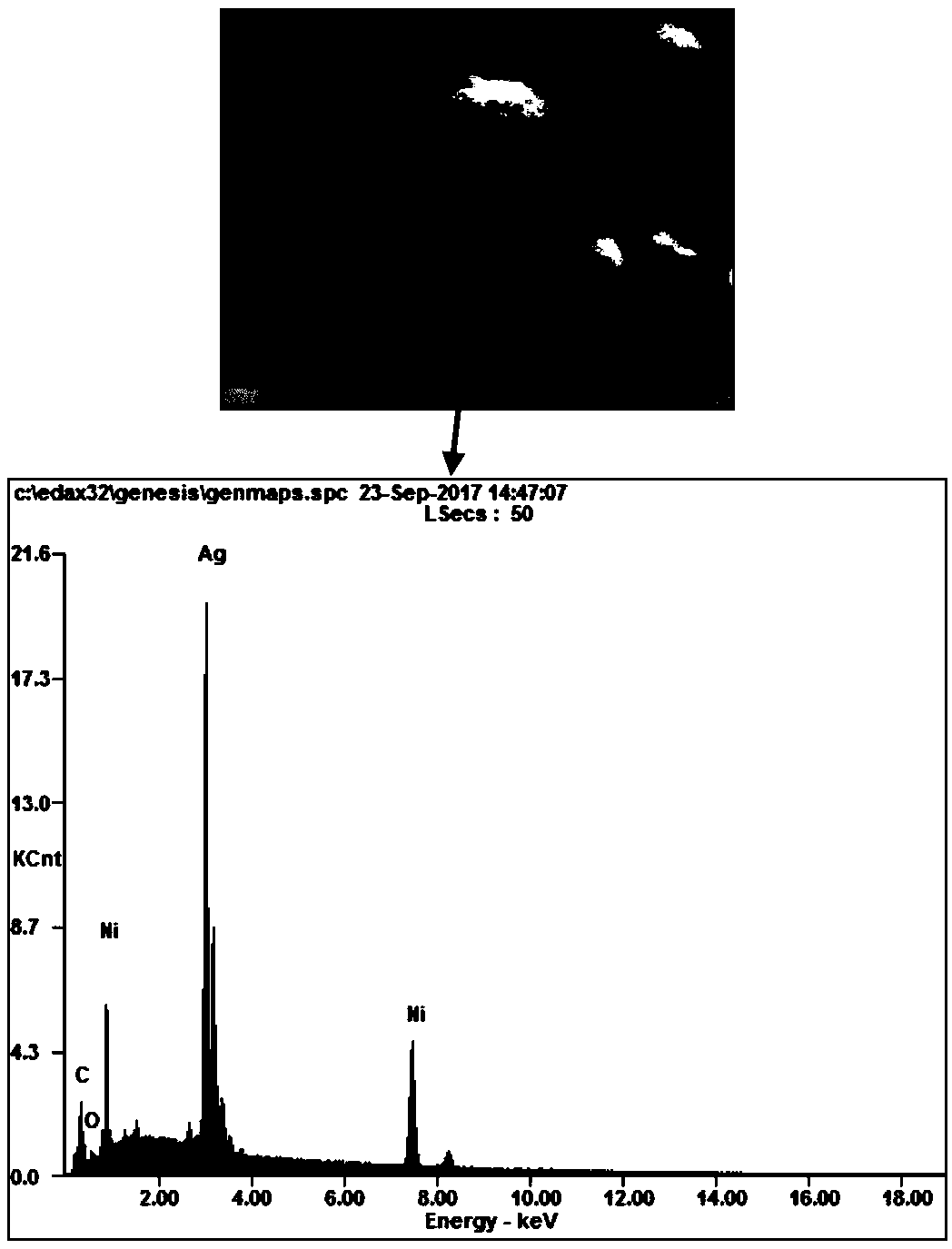

[0028] Pretreatment of S1 nickel powder: a. Weigh 300ml of water, 24g of citric acid and 2.5g of triethanolamine oleate to prepare a mixed solution for cleaning, weigh 10.5g of nickel powder (spherical nickel powder with a particle size of 1-5μm) and add to the mixture solution, then ultrasonically mechanically stirred for 30 minutes, then turned off the ultrasonic wave and continued to stir for 10 minutes. At the same time, the water temperature in the ultrasonic wave was required to be 40°C, and then washed with deionized water until the pH of the supernatant was neutral, and the nickel powder was filtered out; b Add the nickel powder to hydrogen peroxide In the alkaline solution, stir at 70° C. for 20 minutes and then wash and set aside; add the nickel powder finished in step b to an ethanol aqueous solution of 1.5% KH560 (in this example, Z6040 pro...

Embodiment 2

[0035] The invention provides a kind of production method of silver-coated nickel powder, and concrete process is as follows:

[0036] Pretreatment of S1 nickel powder: Weigh 300ml of water, 24g of malic acid and 3.5g of fatty alcohol polyoxyethylene ether to prepare a mixed solution for cleaning, weigh 10.5g of nickel powder (spherical nickel powder with a particle size of 5-10μm) and add In the mixed solution, then ultrasonic mechanically stirred for 30 minutes, then turned off the ultrasonic and continued to stir for 10 minutes. At the same time, the water temperature in the ultrasonic wave was required to be 40 ° C, and then washed with deionized water until the pH of the supernatant was neutral, and the nickel powder was filtered out; b. Add the nickel powder In 5% fructose solution, after stirring for 30 min at 75° C., wash and stand for use; add the nickel powder finished in b process into 5% KH550 (using Z6011 produced by U.S. Dow Corning in this embodiment) in an aqueo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| oxidation rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com