Tray conveying device for liquid crystal module classified packaging

A liquid crystal module and conveying device technology, which is applied in the field of tray conveying devices for sorting and packaging liquid crystal modules, can solve the problems of tray conveying without sorting and packing devices, sorting and packing of liquid crystal modules of different sizes, etc., and achieves a small footprint , Easy to load and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements.

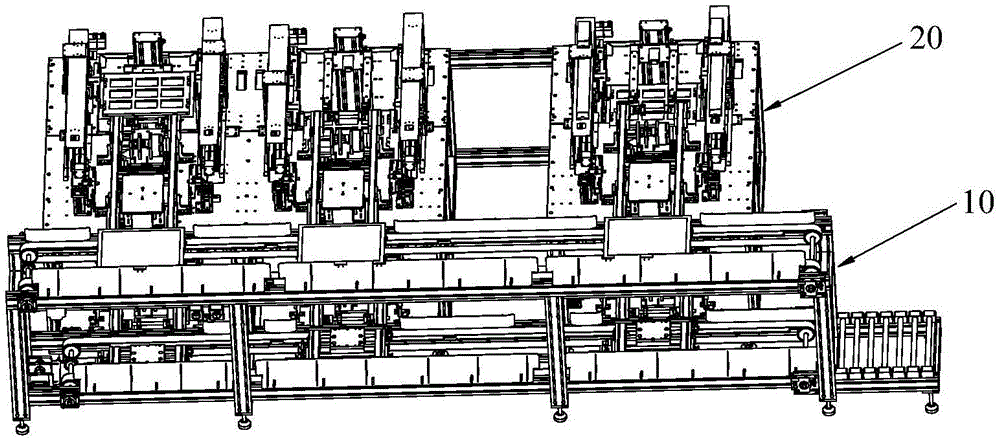

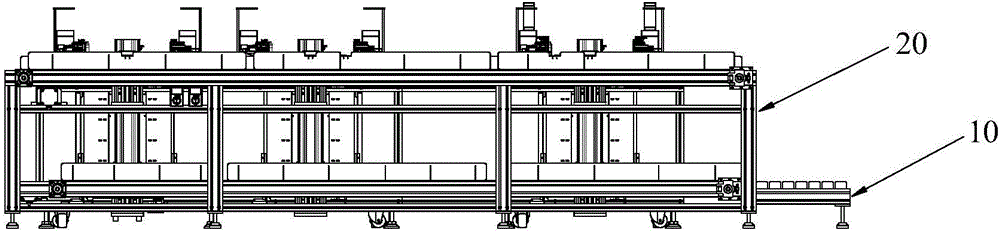

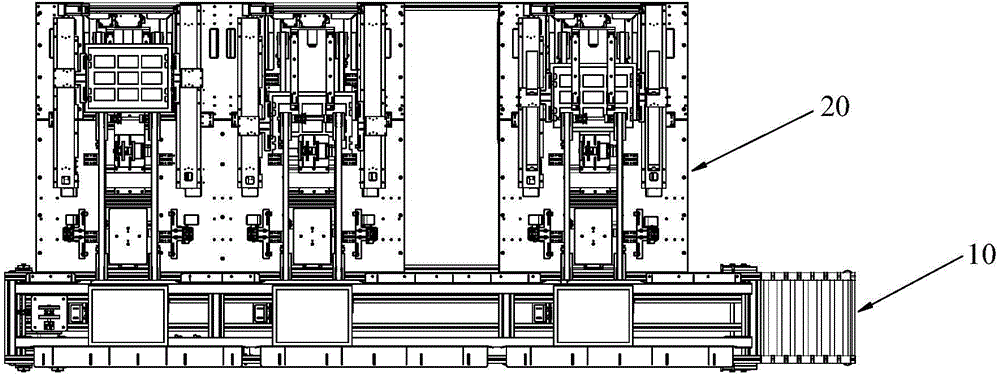

[0045] Such as Figure 1-3 As shown, the tray transfer device for sorting and packaging liquid crystal modules in this embodiment includes a tray input and output device 10 and a tray moving device 20 .

[0046] Such as Figure 4-8 As shown, the tray input and output device 10 includes a support 11 , a tray input mechanism 12 for transporting stacked empty trays, and a tray output mechanism 13 for transporting stacked trays full of liquid crystal modules. Specifically, the tray input mechanism 12 includes an input pulley assembly 121 and an input lifting assembly 122 .

[0047] The input pulley assembly 121 includes a pair of input belts 1211, two pairs of input pulleys 1212 and a pair of input connecting shafts 1213, and a pair of input connecting shafts 1213 are respectively installed on the two ends of the lower floo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com