Method for preparing nano composite diamond coating

A diamond coating and nano-composite technology, applied in metal material coating technology, coating, gaseous chemical plating, etc., can solve the problems of reduced coating deposition rate, complex equipment structure, unfavorable mass production, etc., to achieve low coating Effect of layer stress, high carbon ionization rate, and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

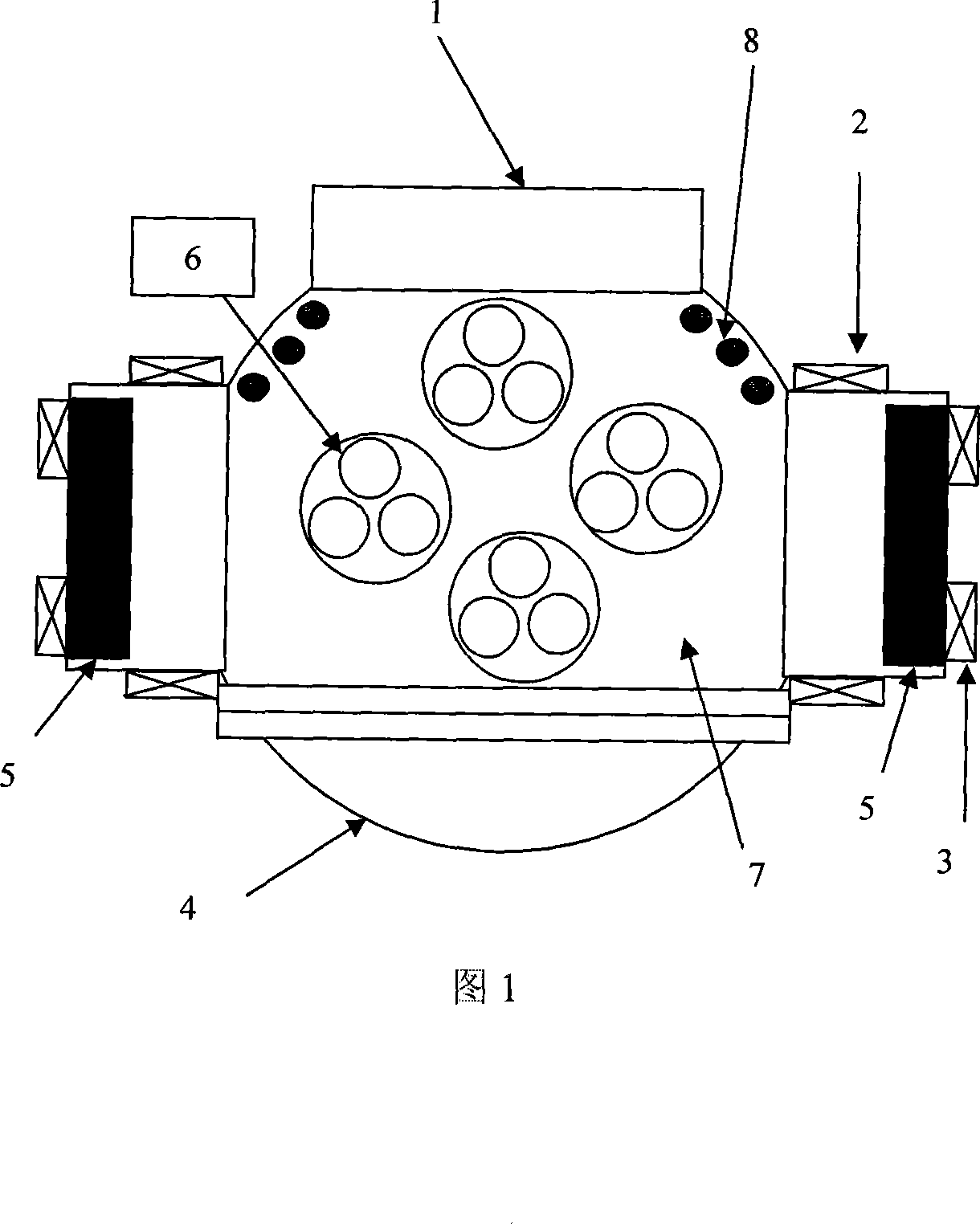

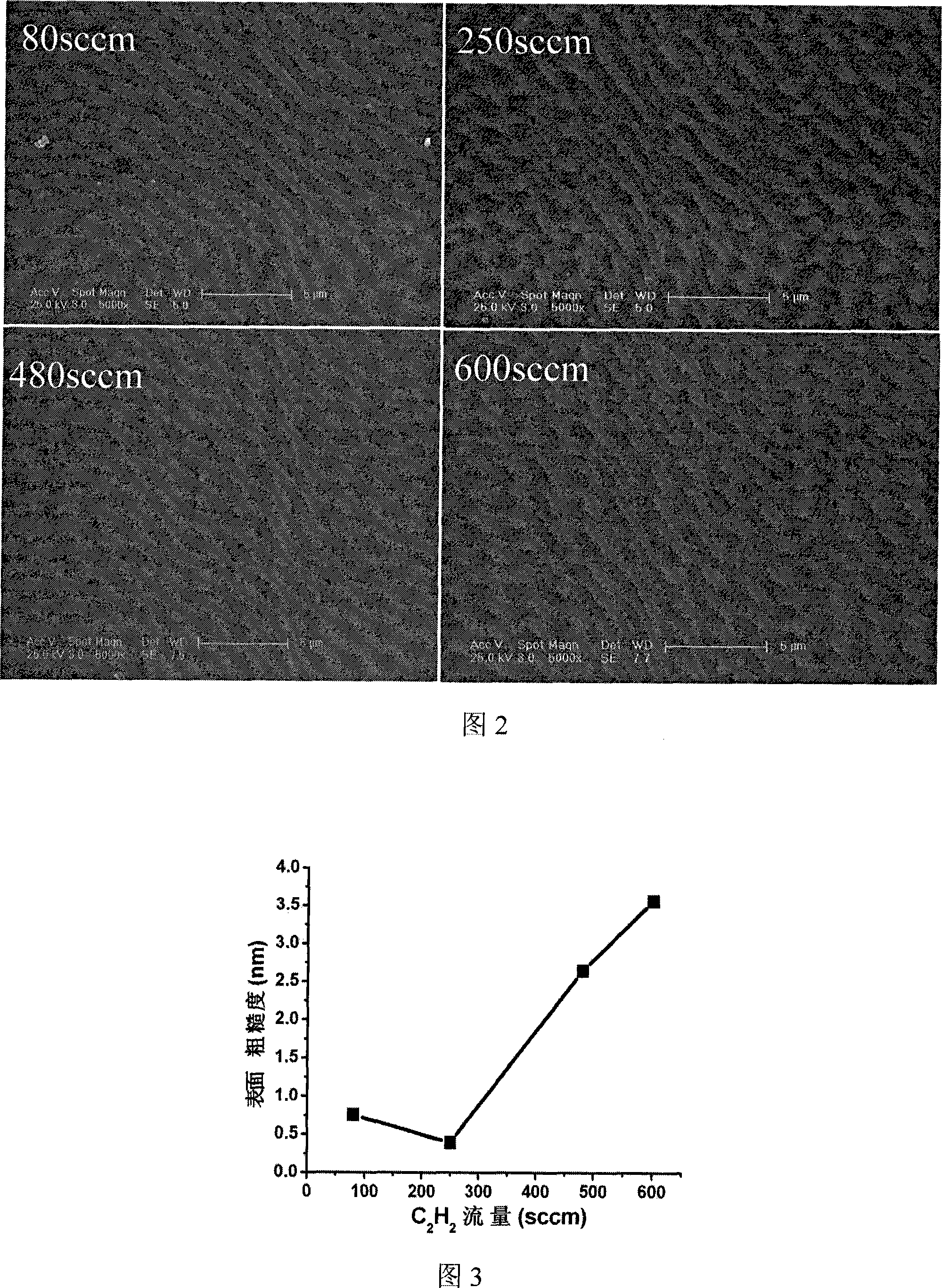

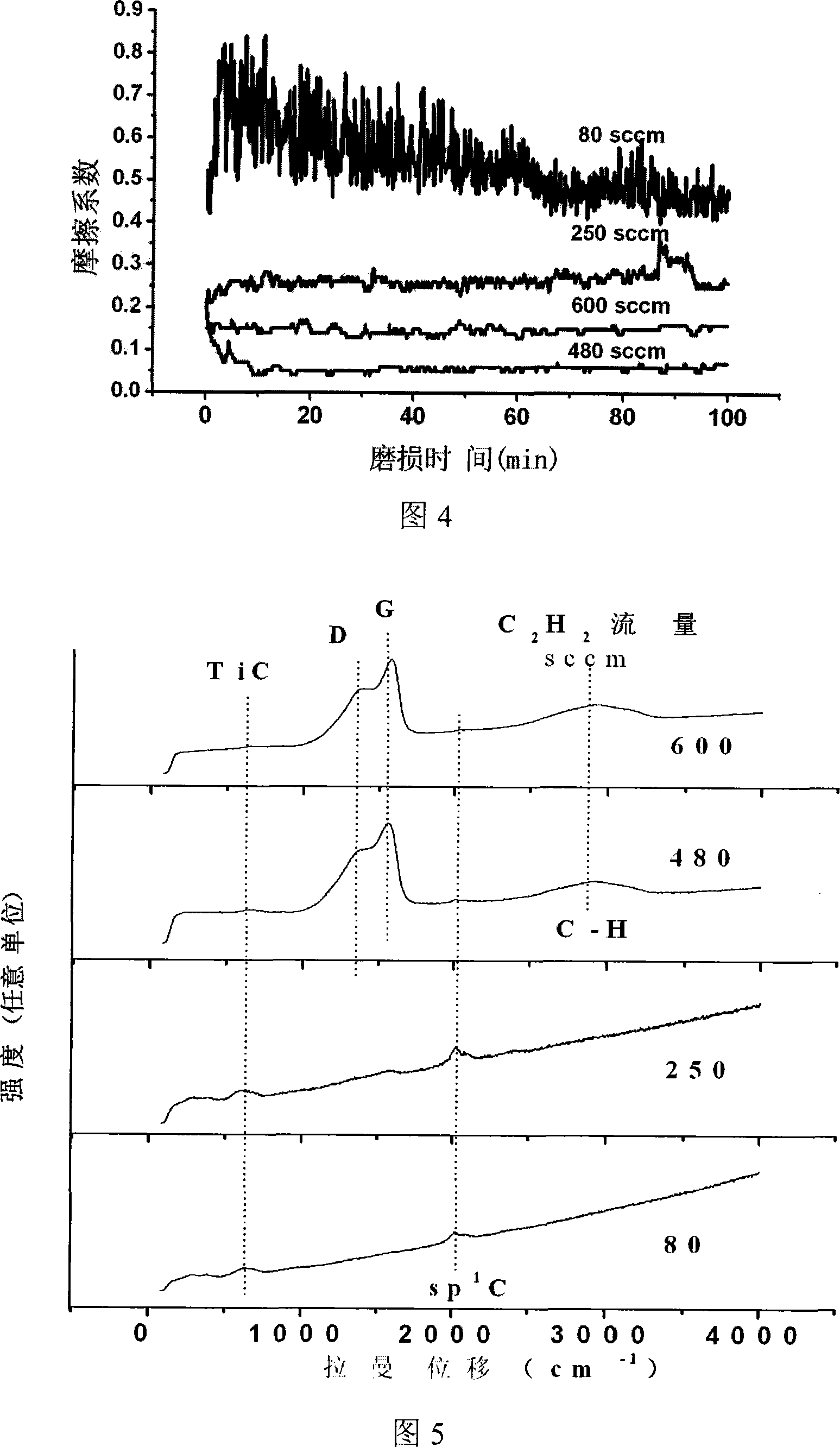

[0023] Example 1: Under the conditions of 2.5Pa and negative 100V bias, a Ti metal transition layer was prepared by arc discharge of a Ti metal target controlled by a magnetic field; then acetylene gas was introduced, and the acetylene and the surface of the Ti metal target reacted to form titanium carbide. Drag the arc to move on the target surface. When the arc moves on the target surface, metal carbides are evaporated from the target surface; the strong plasma ionization of acetylene gas generated by the arc discharge on the target surface produces highly ionized carbon ions; The metal titanium carbide evaporated on the target surface and the carbon ions produced by acetylene form a carbide-doped nanocomposite diamond-like carbon coating on the surface of the workpiece. The flow rate of the acetylene gas is 80-600 sccm; the current of the metal target is 180 amperes.

[0024] The above-mentioned magnetic field for controlling arc movement is generated by energizing a coil p...

Embodiment 2

[0027] Example 2: Under the conditions of 0.1Pa and negative 80V bias, the Cr metal transition layer was prepared by arc discharge of the Cr metal target controlled by the magnetic field; then acetylene gas was passed through, and the acetylene and the surface of the Cr metal target reacted to form chromium carbide. Drag the arc to move on the target surface, when the arc moves on the target surface, chromium carbide is evaporated from the target surface; use the strong plasma ionization acetylene gas generated by the arc discharge on the target surface to produce highly ionized carbon ions; The surface-evaporated chromium carbide and carbon ions produced by acetylene form a chromium carbide-doped nanocomposite diamond-like coating on the surface of the workpiece. The flow rate of the acetylene gas is 80-600 sccm; the current of the Cr target is 130 amperes.

[0028]The above-mentioned glow discharge cleaning is carried out at 150-200°C in an argon environment; after the glow ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Deposition thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com