Oil repellents

A technology of oil-displacing agent and main agent, which is applied in the field of oil-displacing agent, can solve the problems that oil-containing industrial circulating cooling water and oil-containing industrial wastewater cannot be effectively applied, and application is not considered, and achieve strong surface activity and penetration ability, and use Simple and effective, good oil displacement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Prepare the oil displacing agent according to the following ratio:

[0049] 400Kg of sodium N-octyl p-iminobenzene sulfonate as the main agent, 0Kg of sodium bicarbonate (the pH value in the treated water quality is 8.9), 120kg of polyacrylic acid, 200kg of sodium sulfate, and 280Kg of deionized water. The total amount of oil displacement agent is 1000Kg.

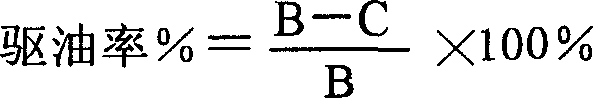

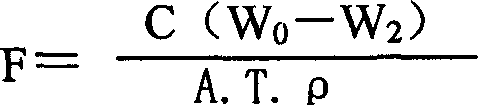

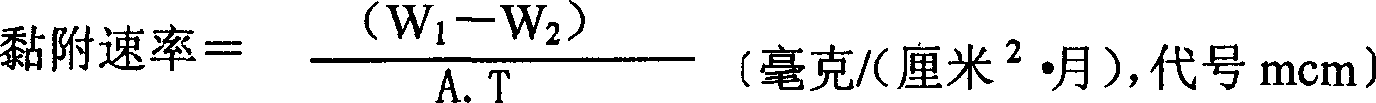

[0050] The oil content of the cooling water system is 200mg / l. Add 100mg / l of this oil displacement agent into the cooling water system, and monitor the corrosion and adhesion rate of the A3 steel heat exchange test tube with the on-site monitoring heat exchanger. The results are shown in Table 1:

[0051] Corrosion rate (mm / a)

Embodiment 2

[0053] Prepare the oil displacing agent according to the following ratio:

[0054] 550Kg of sodium N-dodecyl p-iminobenzenesulfonate, 60Kg of sodium carbonate, 150kg of sodium tripolyphosphate, 220kg of sodium sulfate, and 20Kg of deionized water. The total amount of oil displacement agent is 1000Kg.

[0055] The oil content in industrial treatment wastewater is 800mg / l. Add 100 mg / l of this oil displacement agent into the cooling water system, and the analysis results of the oil displacement effect are shown in Table 2:

[0056] Dirty oil content (mg / l)

Embodiment 3

[0058] Prepare the oil displacing agent according to the following ratio:

[0059] N-octadecyl sodium iminobenzenesulfonate is 420Kg, sodium bicarbonate 50Kg (recirculating water system PH=7.2 needs to add a certain amount of alkali), hydroxyethylidene diphosphonic acid 180kg, sodium sulfate 260kg, remove Ionized water 90Kg. The total amount of oil displacement agent is 1000Kg.

[0060] Oil leaked from the primary cooling water system of the refinery, with an oil content of 320mg / l. Add 100mg / l of this oil-displacing agent into the cooling water system, and monitor the corrosion and adhesion rate of the A3 steel heat exchange test tube with the on-site monitoring heat exchanger. The results are shown in Table 3:

[0061] Corrosion rate (mm / a)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com