Method for preparing cylinder hollow macroporous ordered colloidal crystal

A technology of orderly macropores and colloidal crystals, applied in crystal growth, colloidal chemistry, colloidal chemistry, etc., can solve the problem of high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

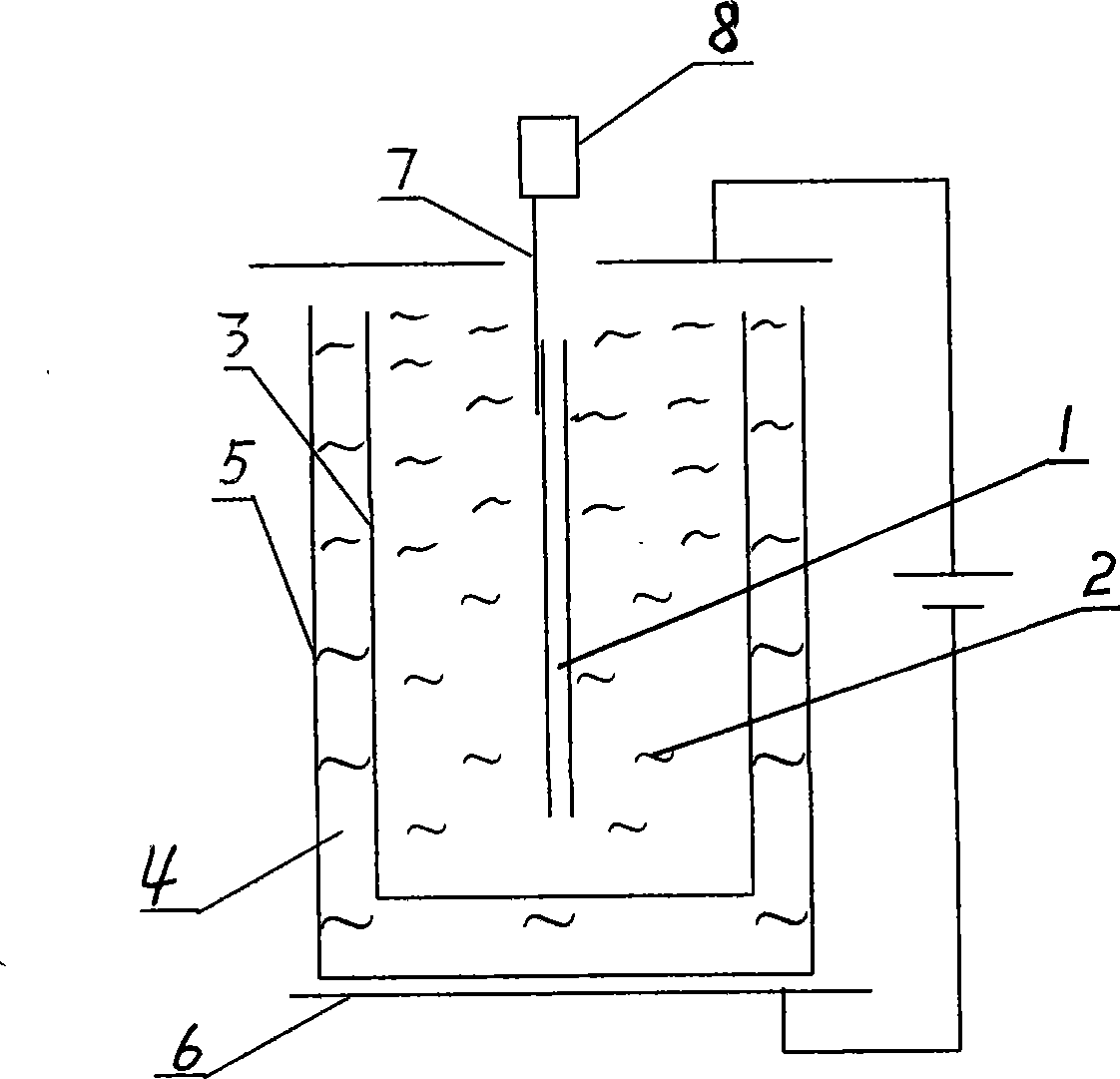

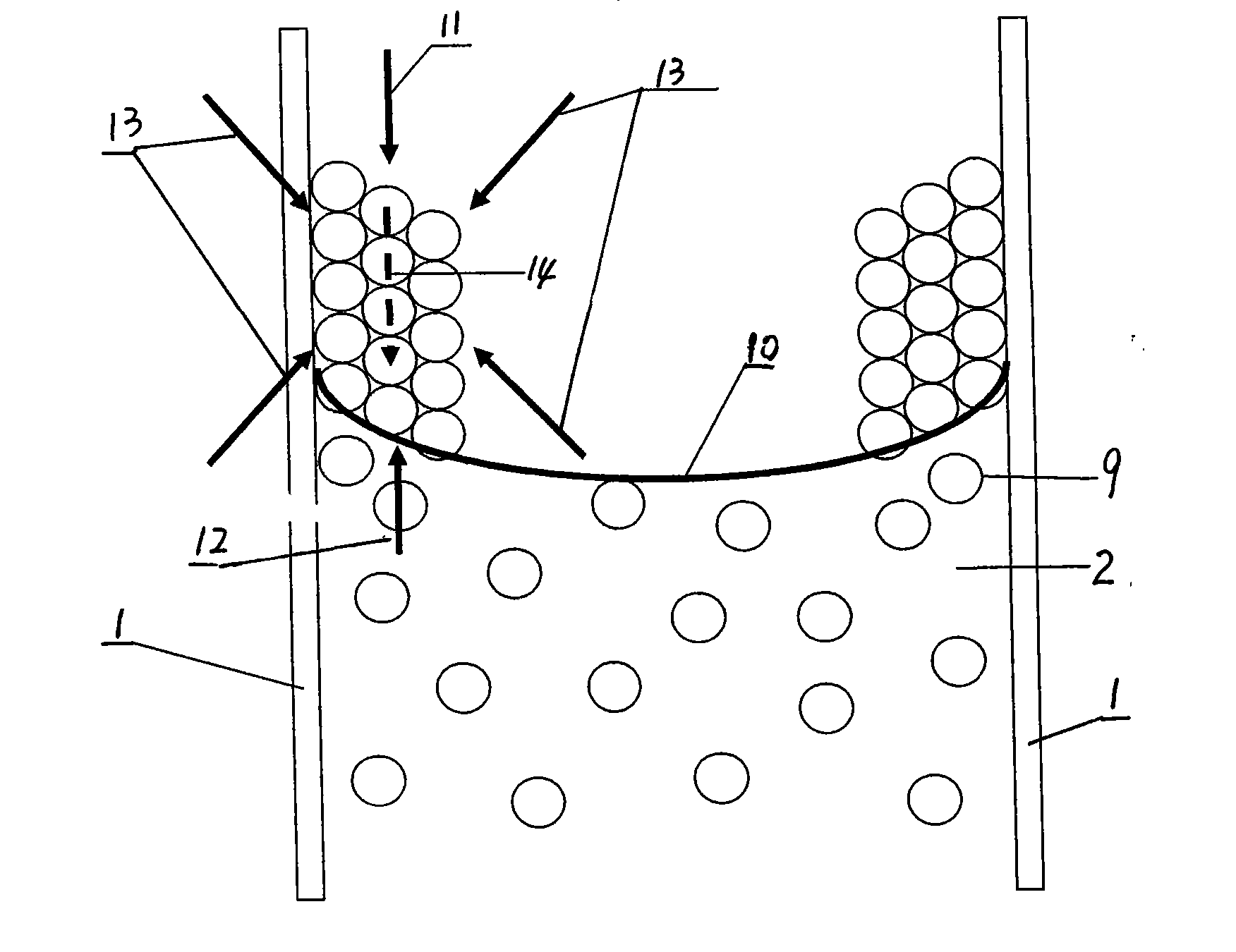

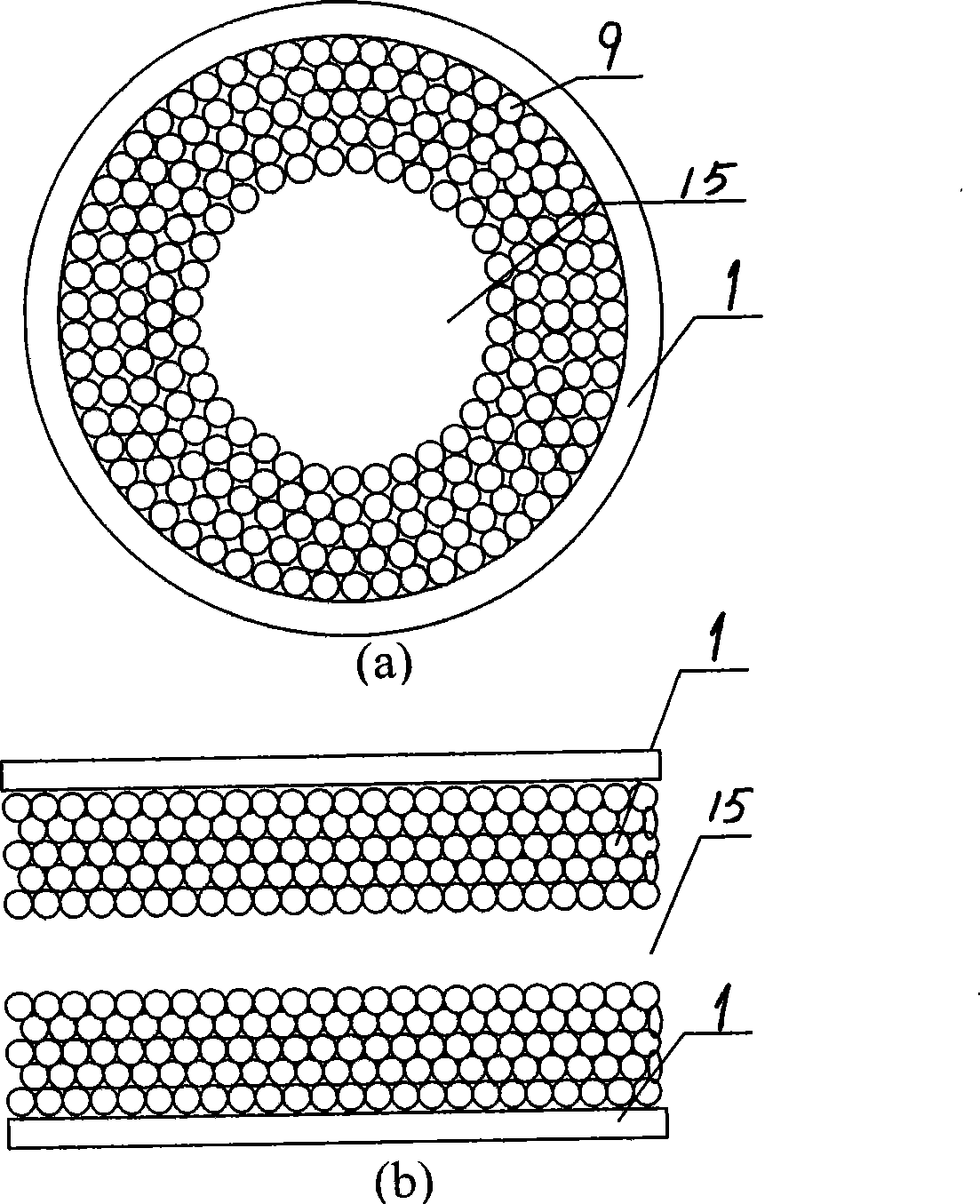

[0022] Embodiment 1, using the method of the present invention to prepare colloidal crystals with symmetrical cylindrical hollow type macropore order, its preparation process steps are as follows:

[0023] A. Use hydrochloric acid (HCl), acetone, and deionized water to repeatedly clean the capillary glass tube in an ultrasonic cleaner;

[0024] B. Configure an aqueous solution of colloidal microspheres. The colloidal microsphere aqueous solution has a microsphere diameter of 700nm, (diameter deviation / average diameter) ×%<0.2%, and a concentration (mass percentage) of 2%;

[0025] C. Insert the cleaned capillary glass tube vertically into the glass bottle filled with colloidal microsphere aqueous solution, fix the upper end of the capillary glass tube on a wire, and let it stand for 20 minutes;

[0026] D. The metal wire is controlled by a stepping motor to move up and down vertically at a speed of 1 micron / second; thus the capillary glass tube moves up and down vertically, w...

Embodiment 2

[0029] Embodiment 2, using the method of the present invention to prepare colloidal crystals with symmetrical cylindrical hollow macropores, the preparation process steps are as follows:

[0030] A. Use hydrochloric acid (HCl), acetone, and deionized water to repeatedly clean the capillary glass tube in an ultrasonic cleaner;

[0031] B. Configure an aqueous solution of colloidal microspheres. The colloidal microsphere aqueous solution has a microsphere diameter of 700nm, (diameter deviation / average diameter) ×%<0.2%, and a concentration (mass percentage) of 8%;

[0032] C. Insert the cleaned capillary glass tube vertically into the glass bottle filled with colloidal microsphere aqueous solution, fix the upper end of the capillary glass tube on a wire, and let it stand for 10 minutes;

[0033] D. The metal wire is controlled by a stepping motor to move up and down vertically at a speed of 30 microns / second; thus the capillary glass tube moves up and down vertically, which is ...

Embodiment 3

[0036] Embodiment 3, using the method of the present invention to prepare colloidal crystals with symmetrical cylindrical hollow type macropores, the preparation process steps are as follows:

[0037] A. Use hydrochloric acid (HCl), acetone, and deionized water to repeatedly clean the capillary glass tube in an ultrasonic cleaner;

[0038] B. Configure an aqueous solution of colloidal microspheres. The colloidal microsphere aqueous solution has a microsphere diameter of 700nm, (diameter deviation / average diameter) ×%<0.2%, and a concentration (mass percentage) of 5%;

[0039] C. Insert the cleaned capillary glass tube vertically into the glass bottle filled with colloidal microsphere aqueous solution, fix the upper end of the capillary glass tube on a wire, and let it stand for 15 minutes;

[0040] D. The metal wire is controlled by a stepping motor to move vertically up and down at a speed of 15 microns / second; thereby the capillary glass tube moves vertically up and down, w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com