Vacuum coating machine baffle with adjustable deposition rate

A vacuum coating and deposition rate technology, applied in vacuum evaporation coating, sputtering coating, ion implantation coating, etc., can solve the problems of inconvenient production process, high technical requirements, etc., achieve high practicability, increase aggregation density, Effect of Good Optical Properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the embodiments and accompanying drawings, but the protection scope of the present invention should not be limited thereby.

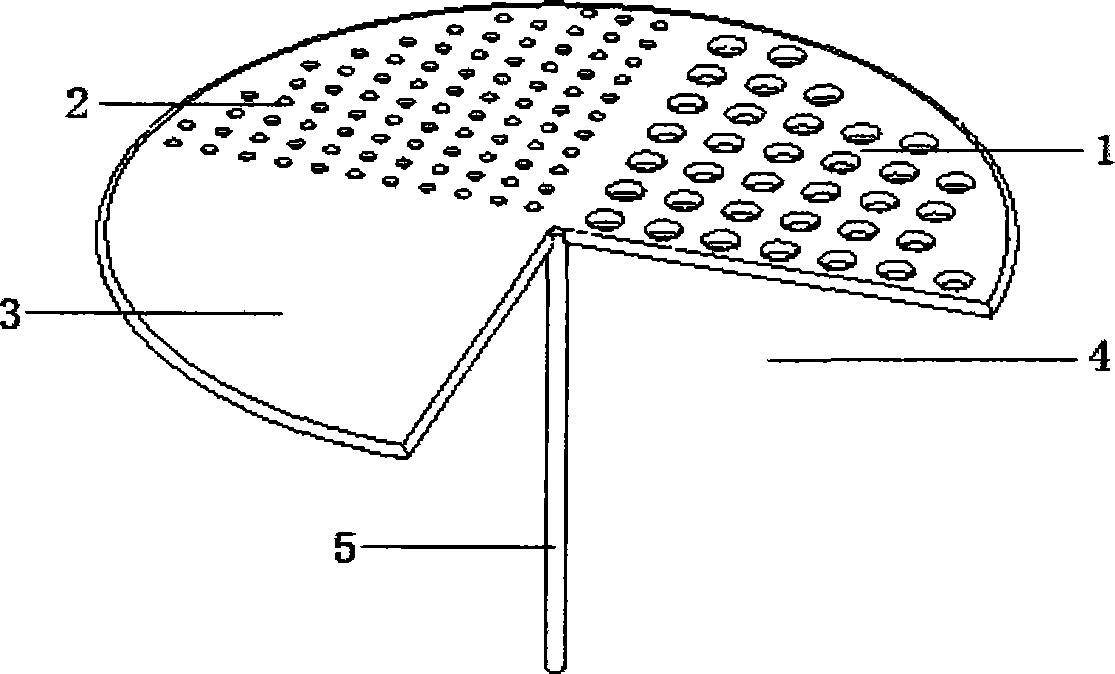

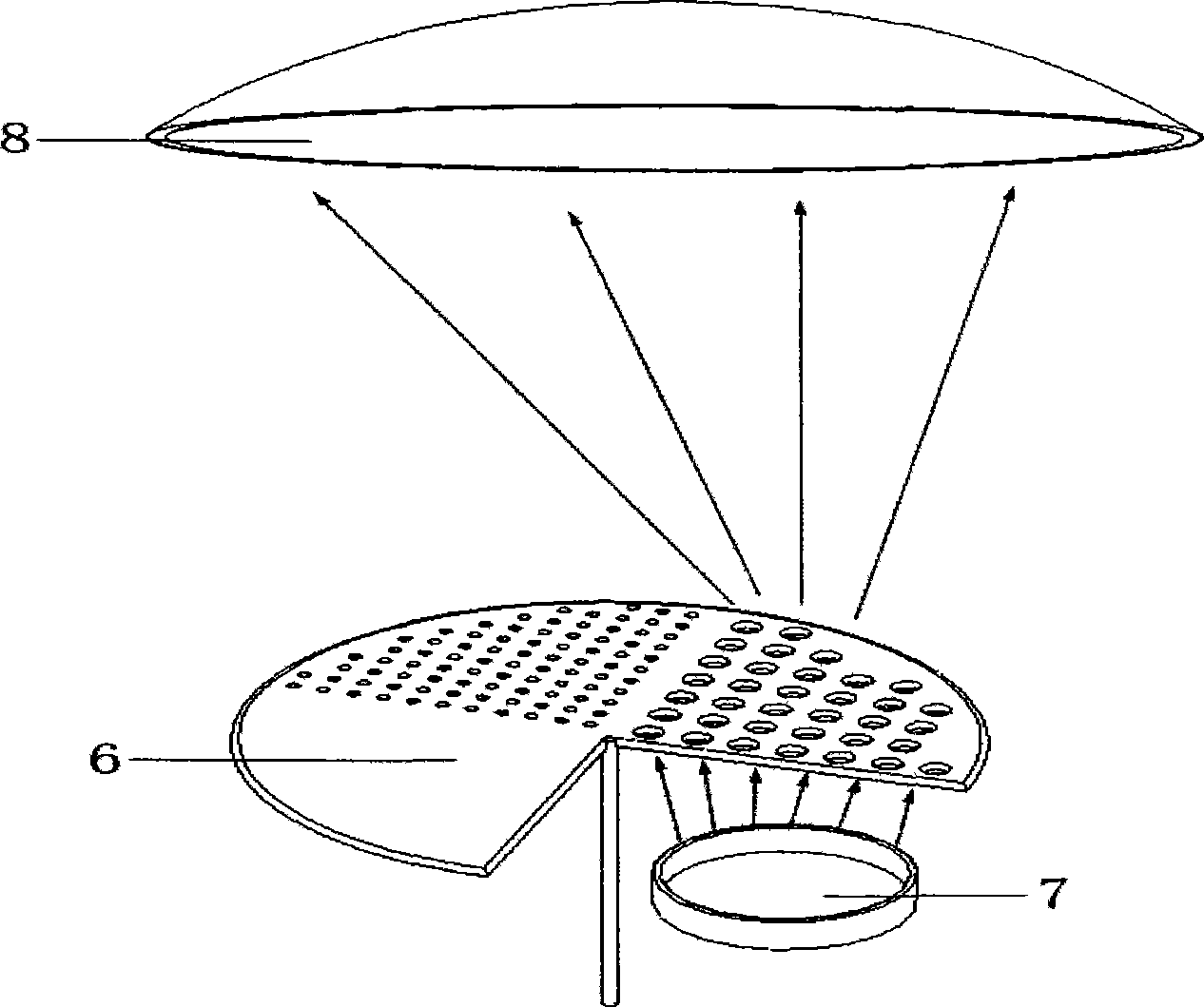

[0019] see first figure 1 , figure 1 It is a structural schematic diagram of an embodiment of the baffle plate of the vacuum coating machine with adjustable deposition rate in the present invention. As can be seen from the figure, the baffle plate of the vacuum coating machine with adjustable deposition rate of the present invention includes a high-temperature-resistant disc 6, the center of the disc 6 is vertically connected to a rotating shaft 5, and the lower end of the rotating shaft is connected to a driving device. The circular plate 6 is divided into 4 sectors radially from the center of the circle, and these sectors are followed by a full blocking area 3, a non-blocking area 4, and more than one blocking area 1, 2 whose blocking degree changes from small to large, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com