Frostless refrigerator capable of defrosting through coupling of ultrasonic waves and super-hydrophobic materials, and control method of frostless refrigerator

A control method, ultrasonic technology, applied in the field of ultrasonic systems, can solve the problems of inconvenient storage of large items, affect the quality of food storage, and increase the heat load of the freezer, so as to reduce the frosting on the surface of the air duct system and evaporator , Improve the level of intelligent control and reduce the effect of frosting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

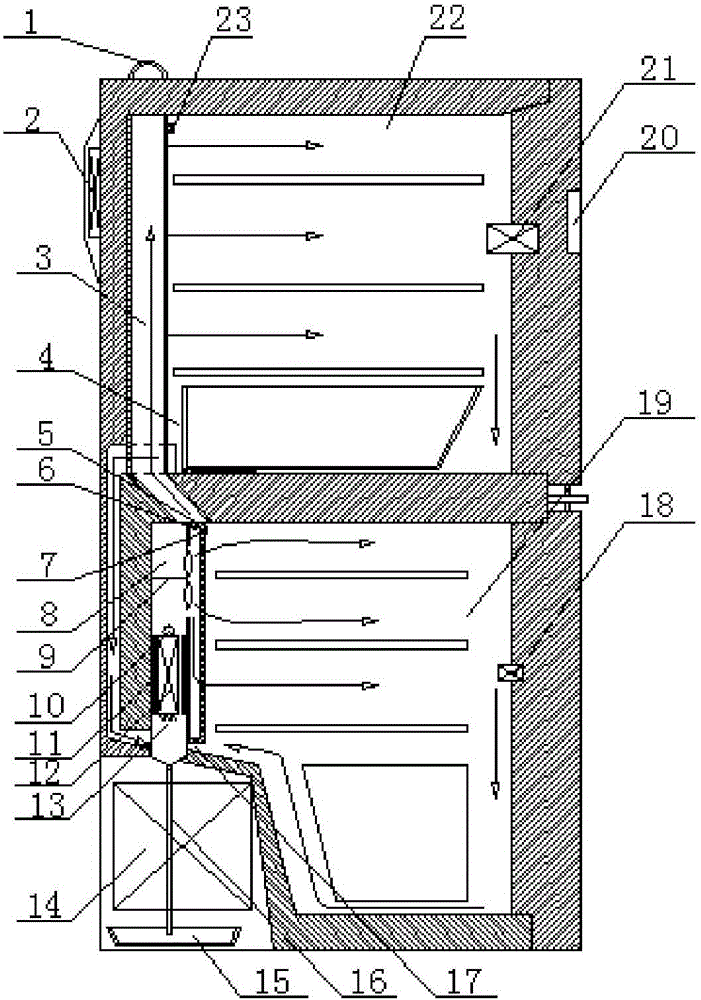

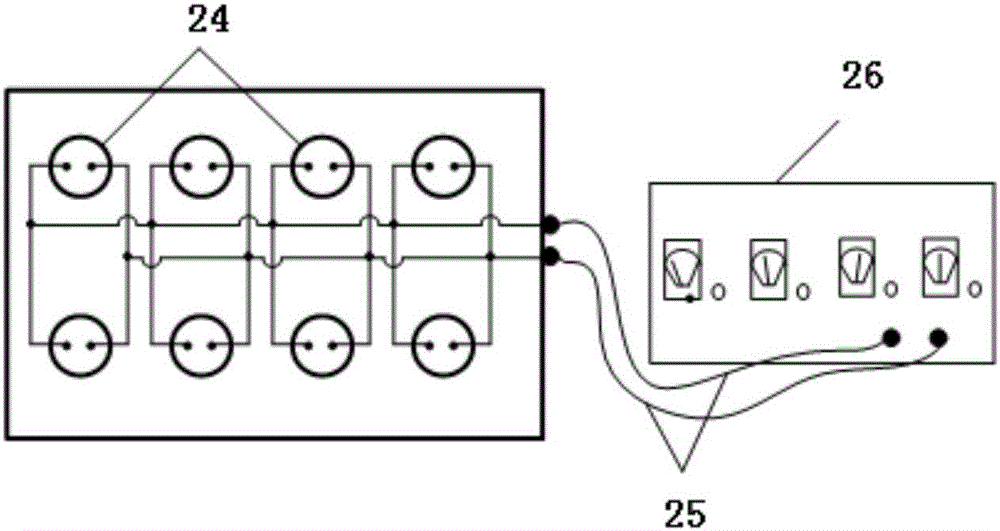

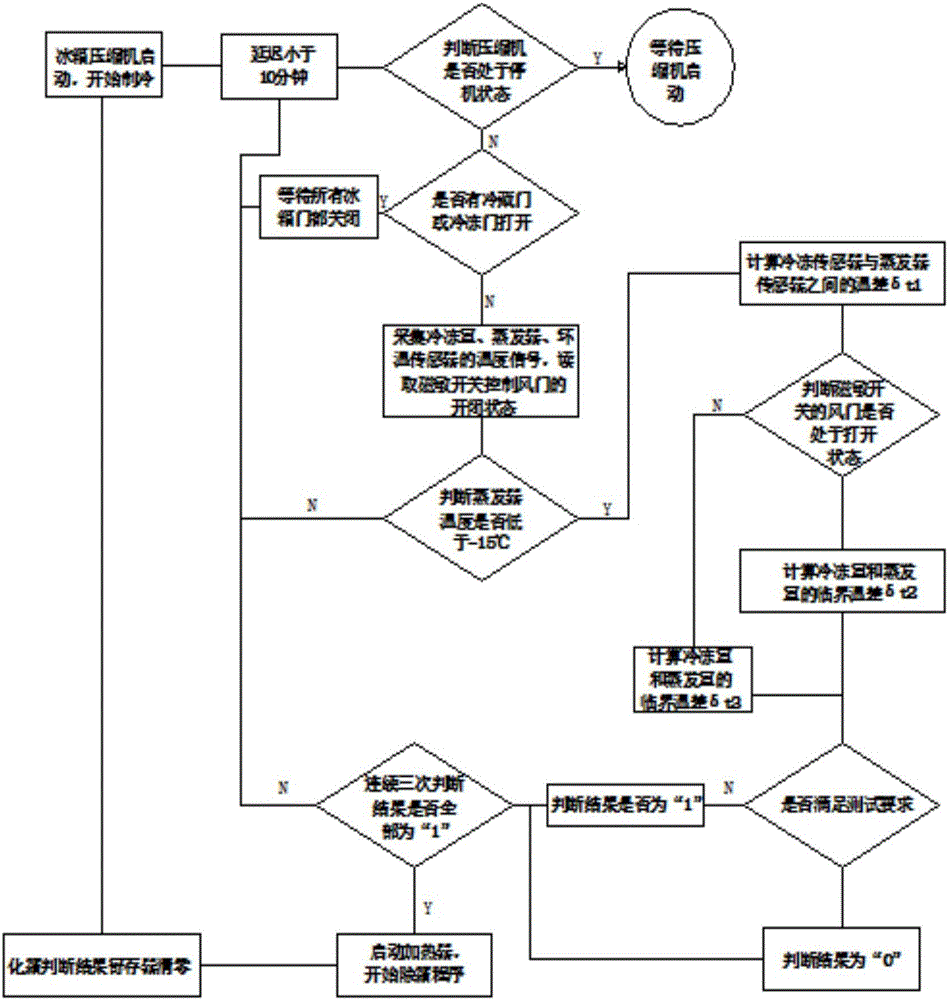

[0049] Such as figure 1 As shown, the frost-free refrigerator using ultrasound and superhydrophobic material coupling defrosting in this embodiment includes an ambient temperature sensor 1, a main controller 2, a magnetically sensitive switch door 5, an evaporation chamber 8, a freezing chamber 19, a refrigerating chamber 22, and a compression chamber. Machine 14 and drainage device; Wherein, the ultrasonic oscillation system 11 and the electric heater 13 that are arranged in the evaporation chamber 8 are defrost devices; The evaporator 12, the freezer air duct 6, the freezer air return port 17, the refrigerator air duct 3 and the refrigerator return air duct 4) use chemically etched fluorosilane-modified aluminum-based surface super-hydrophobic materials.

[0050] Wherein, refrigerating room 22 is positioned at the top of refrigerator, and refrigerati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com