Rapid forming sand mold casting machine

A sand casting, fast technology, applied in the direction of molding machines, casting molding equipment, cleaning/processing machinery of casting materials, etc., can solve the problems of troublesome feeding, danger, manual removal, etc., to prolong the service life and maximize the degree of automation High degree, good molding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

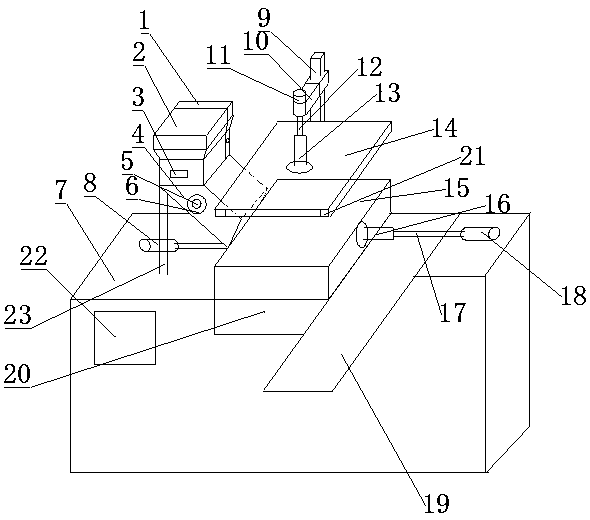

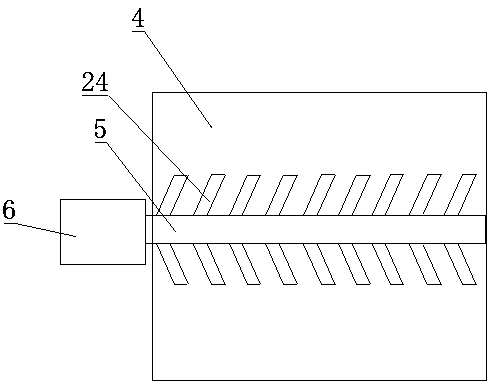

[0014] like Figure 1-2 As shown, a rapid prototyping sand casting machine includes a body 7, a support 23 is arranged above the body 7, and a liquid feed port 1 and a solid feed port 2 are provided above the support 23. A flowmeter 3 is arranged below the liquid feed port 1 and the solid feed port 2, and a mixing chamber 4 is connected to the bottom of the liquid feed port 1 and the solid feed port 2. The mixing chamber 4 is provided with a rotating shaft 5 that runs through the mixing chamber 4, one end of the rotating shaft 5 is connected to a motor 6, an impeller 24 is arranged outside the rotating shaft 5, and a sand box 15 is arranged below the mixing chamber 4, The left side of described sand box 15 is provided with the 3rd air cylinder 8, the right side of described sand box 15 is provided with conveyor belt 19, and the right side of described conveyor belt 19 is provided with second cylinder 18, and described second The inboards of the cylinder 18 and the third cylin...

Embodiment 2

[0017] like Figure 1-2 As shown, a rapid prototyping sand casting machine includes a body 7, a support 23 is arranged above the body 7, and a liquid feed port 1 and a solid feed port 2 are provided above the support 23. A flowmeter 3 is arranged below the liquid feed port 1 and the solid feed port 2, and a mixing chamber 4 is connected to the bottom of the liquid feed port 1 and the solid feed port 2. The mixing chamber 4 is provided with a rotating shaft 5 that runs through the mixing chamber 4, one end of the rotating shaft 5 is connected to a motor 6, an impeller 24 is arranged outside the rotating shaft 5, and a sand box 15 is arranged below the mixing chamber 4, The left side of described sand box 15 is provided with the 3rd air cylinder 8, the right side of described sand box 15 is provided with conveyor belt 19, and the right side of described conveyor belt 19 is provided with second cylinder 18, and described second The inboards of the cylinder 18 and the third cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com