Combined regenerated lead oxygen-enriched three-blowing energy-saving smelting furnace

A regenerated lead, assembled technology, applied in furnaces, furnace components, energy efficiency improvement and other directions, can solve the problems of poor stirring effect of the melt in the furnace pool, high energy consumption, uneven feeding, etc., to improve energy utilization Efficiency, improve heat utilization efficiency, increase the effect of preheating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below by specific implementation, in conjunction with accompanying drawing, the present invention will be further described:

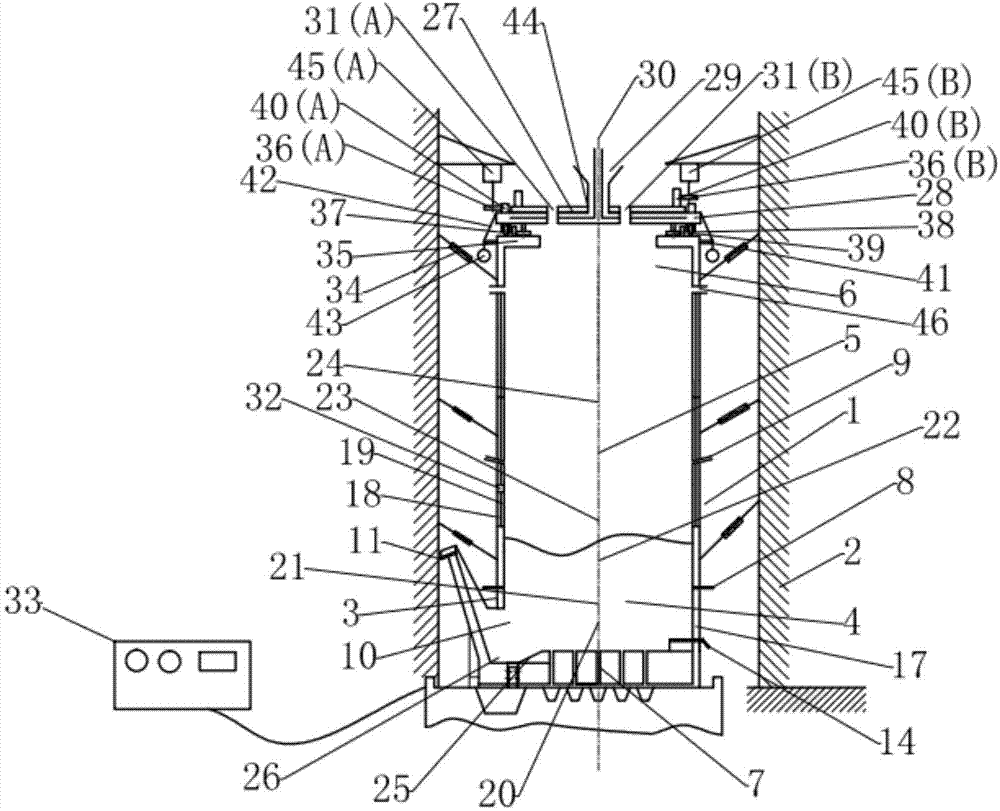

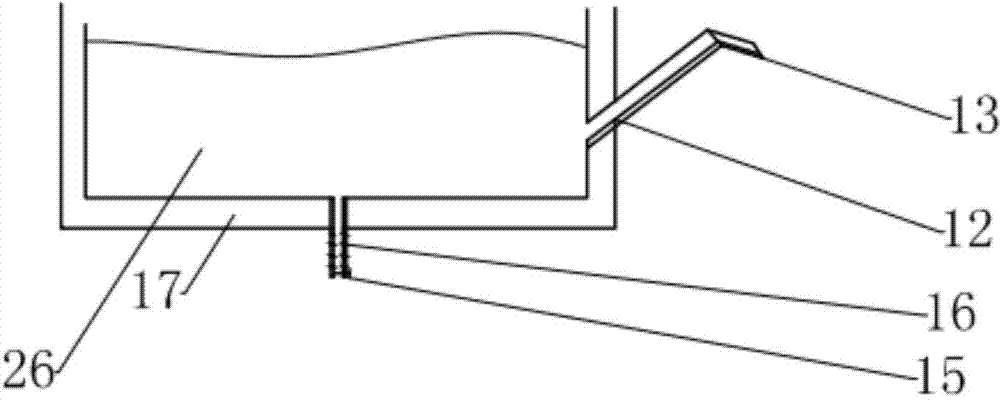

[0022] see figure 1 and figure 2 , an assembled regenerated lead oxygen-enriched three-blowing energy-saving smelting furnace. The furnace body 1 is vertically arranged. The furnace body 1 is divided into three parts: the lower section, the middle section and the upper section. The lower section is the smelting zone 4, and the lower section is from bottom to top. The upper part is further divided into static zone 20, bubbling zone 21 and reduction zone 22; the middle part is the waste heat utilization zone 5, the lower half of the waste heat utilization zone is the secondary combustion zone 23, and the upper half of the waste heat utilization zone is the raw material preheating zone 24; The upper part is the smoke exhaust and feeding area 6, the three parts of the furnace body are installed by hoisting and combination, the lower part is copper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com