Stranded welding wire hammering machine

A hammer forging machine and welding wire technology, applied in the field of stranded wire hammer forging machines, can solve the problems of unpublished production of multi-strand stranded welding wires, unsuitable cable stranding machines, etc., and reduce the requirements for the single wire drawing process and reduce deformation. The effect of high volume, single yarn lay length and wire diameter requirements are reduced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

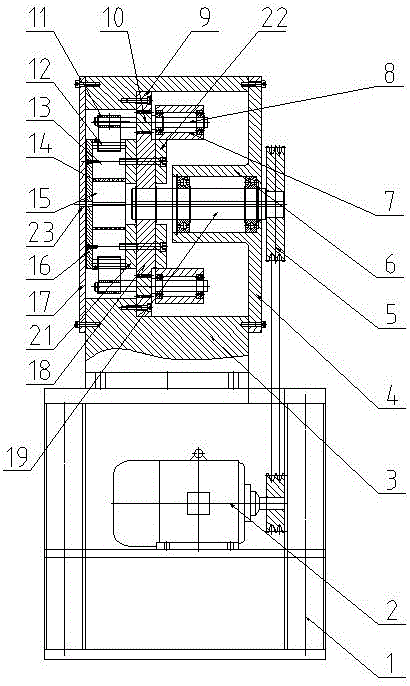

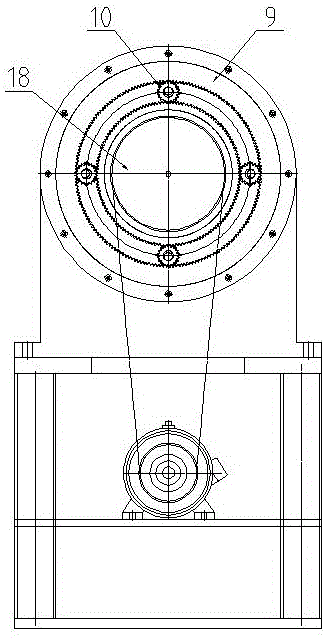

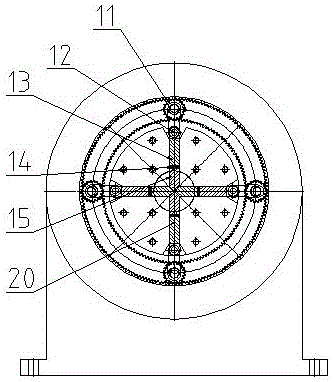

[0062] Such as figure 1As shown, a production equipment for forging stranded welding wire in this embodiment includes a base 1, on which a hammer forging base 3 is arranged, and a motor 2 is arranged under the hammer forging base 3, The left and right sealing plates 17 and 4 are respectively arranged on the left and right sides of the hammer forging machine base 3, and the first bearing seat 6 is arranged on the right sealing plate 4, and a core is mounted on the first bearing seat 6. Shaft 19, the left end of the mandrel 19 is provided with a large gear 18, and the periphery of the large gear 18 is provided with a ring gear 9, and the ring gear 9 is fixedly connected with the hammer forging machine base 3 through fasteners, and the mandrel 19 The right end is connected with the motor 2 through the pulley mechanism 5, and the left and right f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com