Patents

Literature

57results about How to "Reduce lay length" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

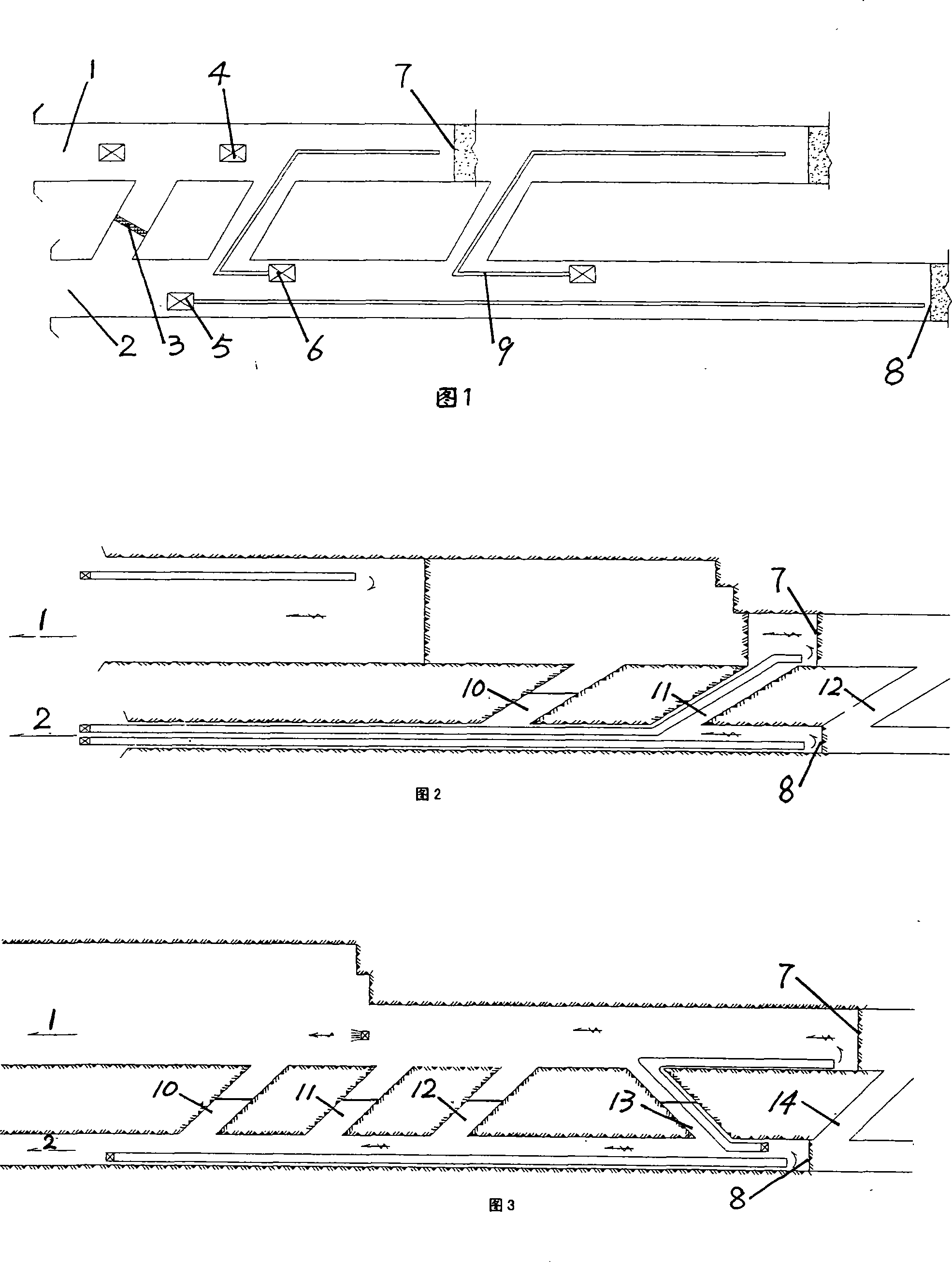

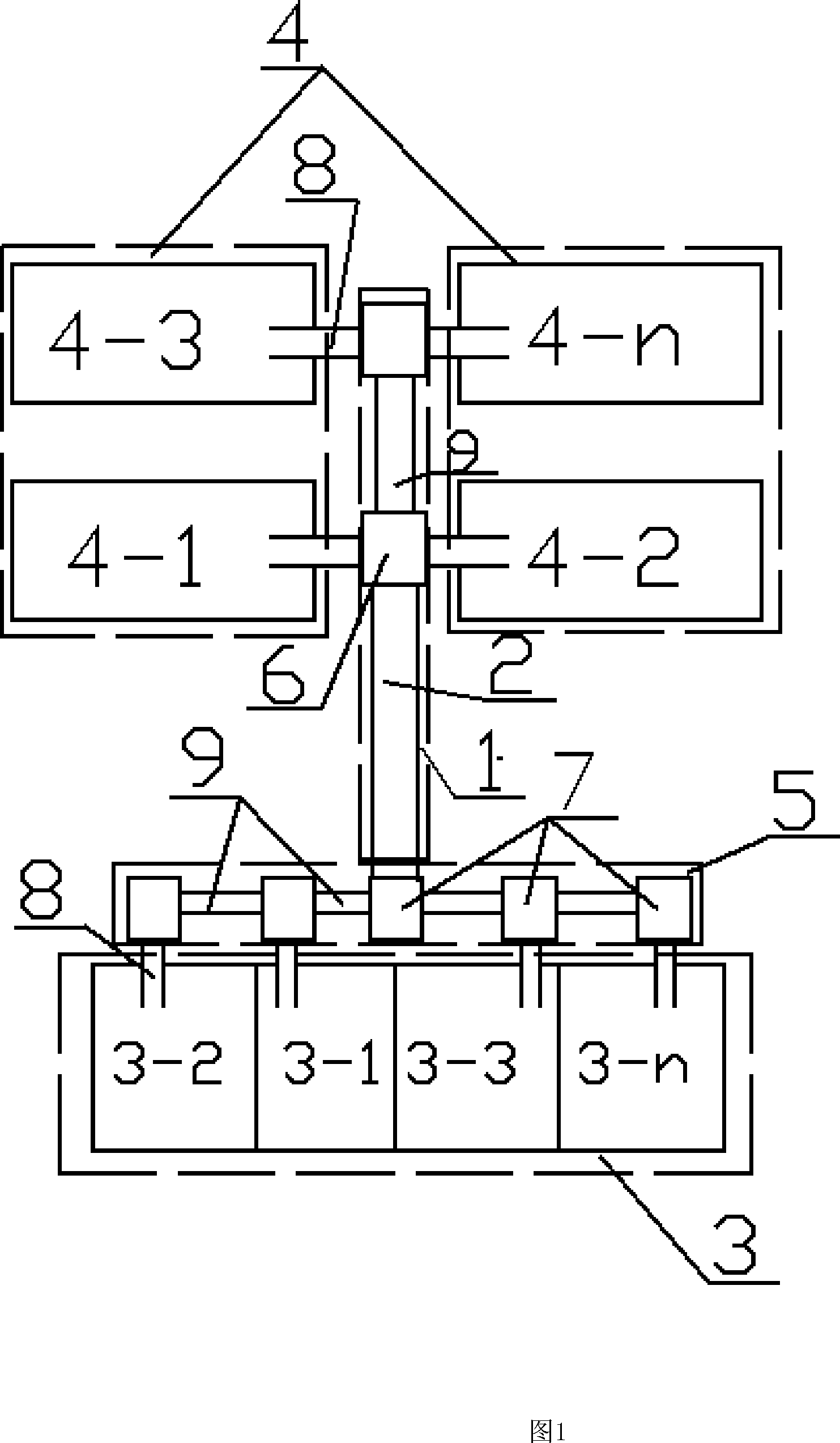

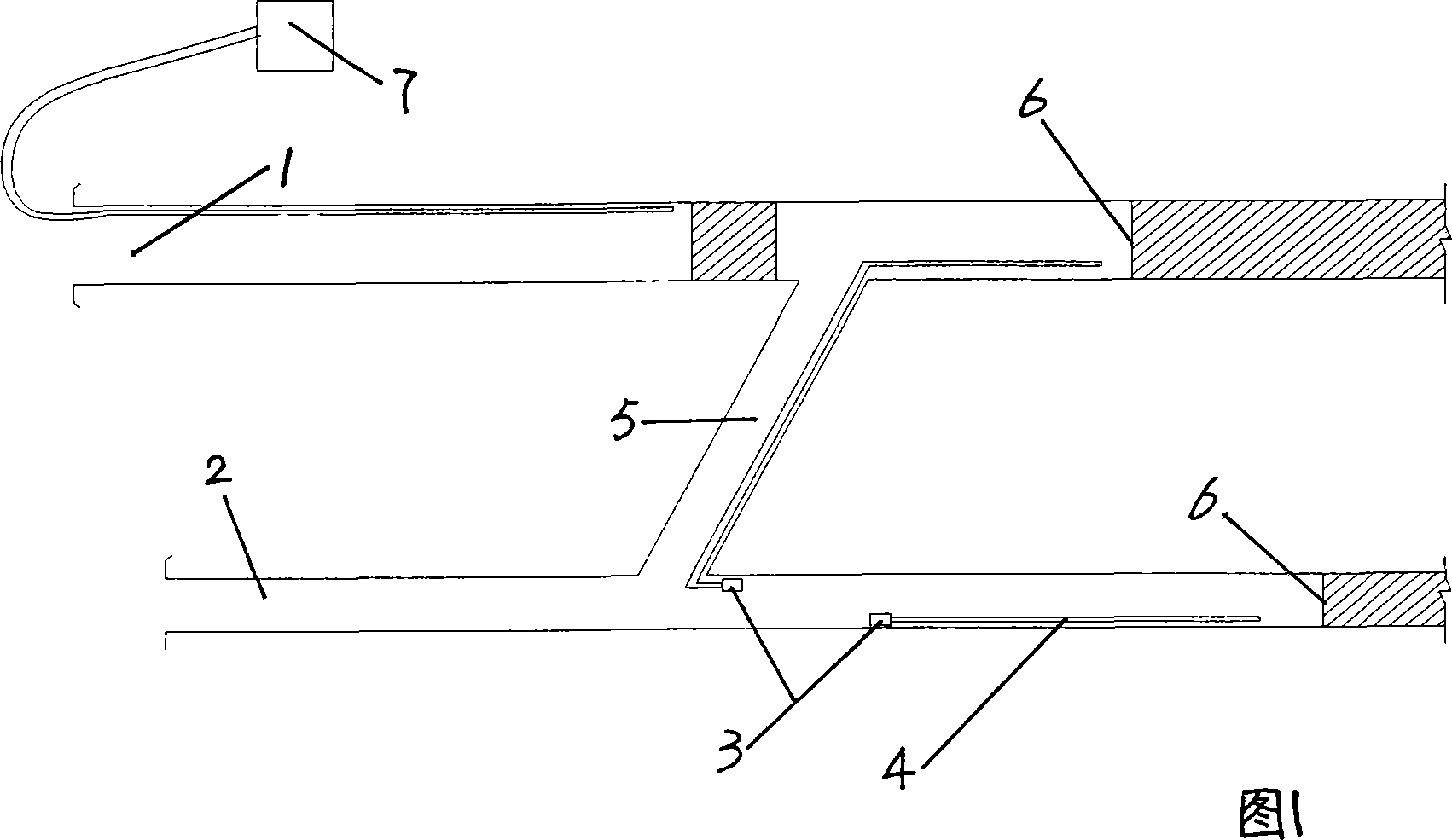

Laneway type ventilating technique for long and large tunnel

The invention relates to a long tunnel gallery ventilation technique, solving the problems that poor ventilation performance, high construction cost and hindering construction of the prior art, belonging to the field of tunnel construction technique, which is characterized in that an exhaust fan is arranged in the main tunnel to pump the foul air; the flat tunnel mouth has no plugging obstacle, and a plurality of blowers are arrange at the position having fresh air entering from the flat tunnel mouth; the blower transfers fresh air to different working positions via a blowing ventilator. The long tunnel gallery ventilation technique has the advantages that: 1. saving the length of laying air duct, in particular to long tunnel with considerable amount of ducts; 2. using low power jet blower instead the main blower to save electricity; 3. speeding up the discharge of the foul air, having good visible condition and enough oxygen content; 4. the smoke of working position is exhausted in short time which speeds up the construction; 5. the flat tunnel has no air dampers which realizes no obstacle plugging and the improvement of the traffic environment.

Owner:THE 4TH ENG CO LTD OF CHINA RAILWAY 17TH BUREAU GRP

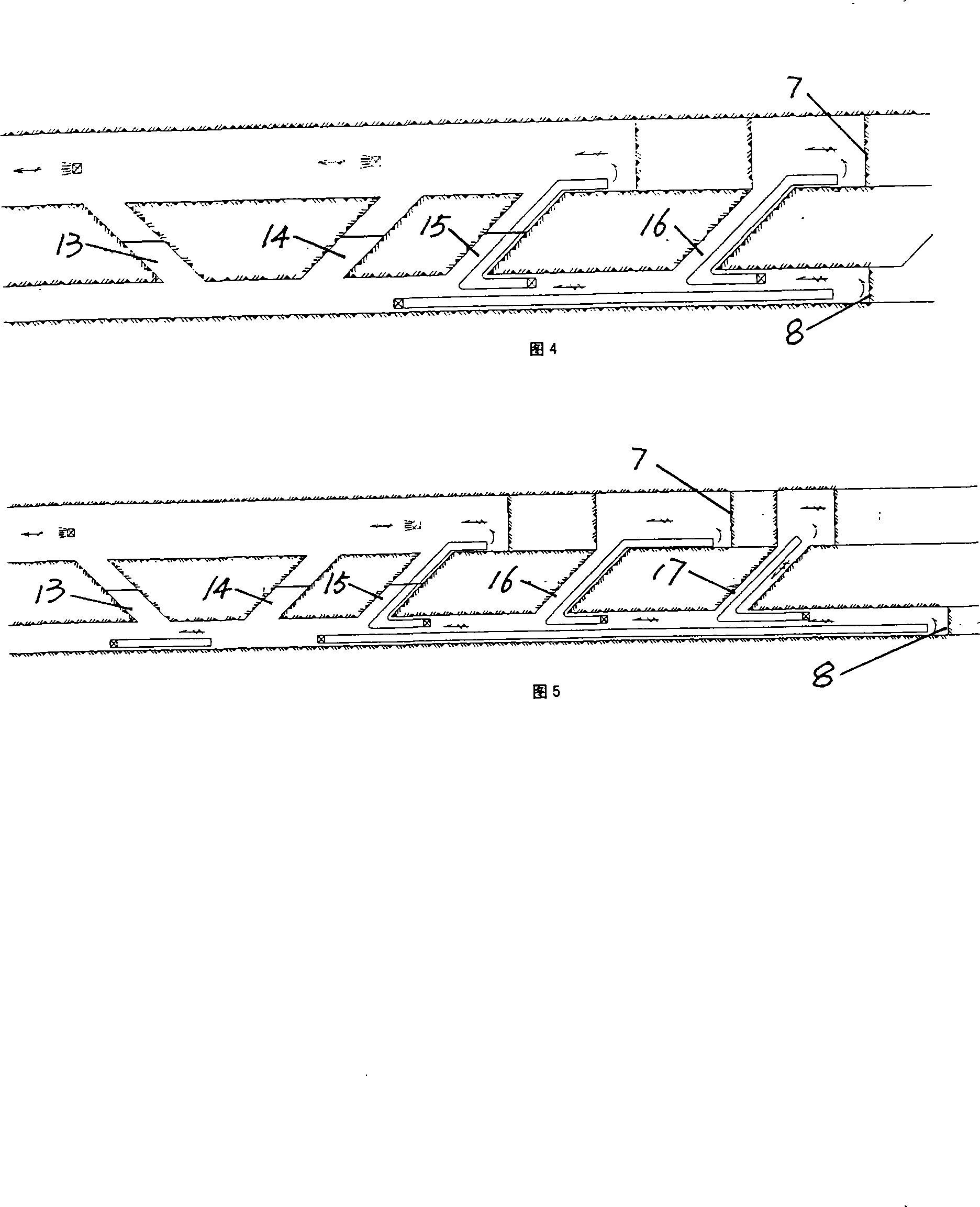

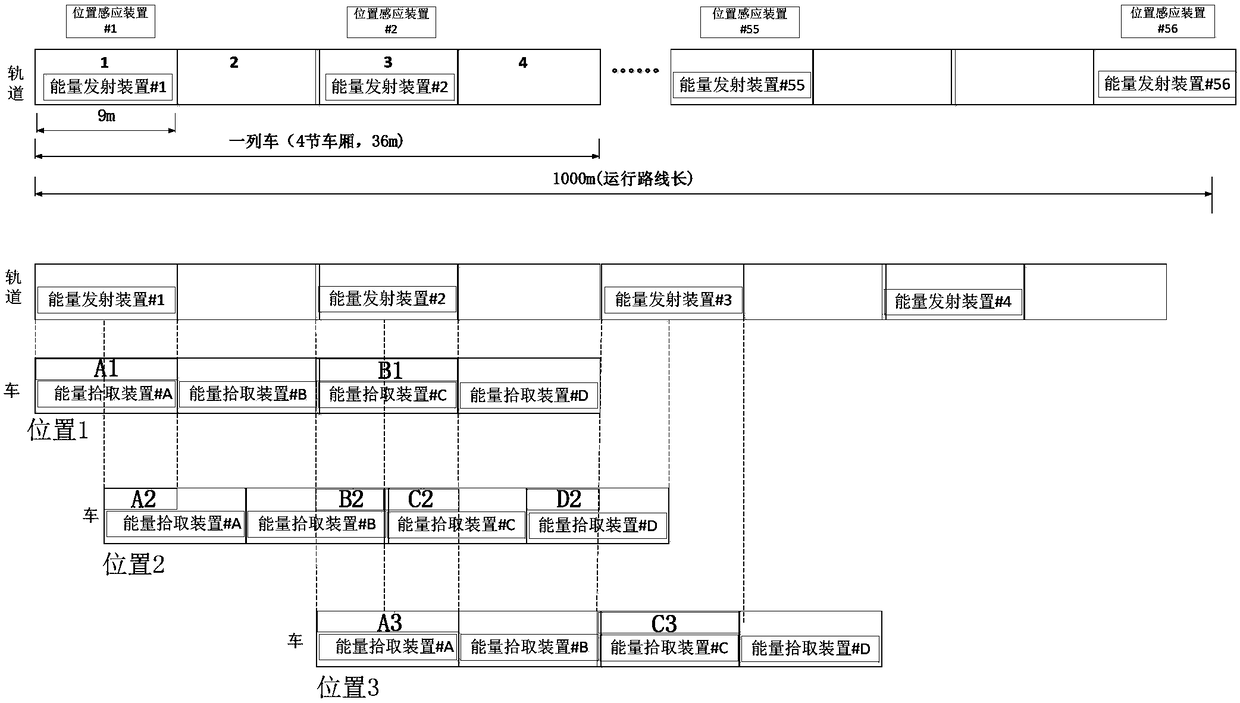

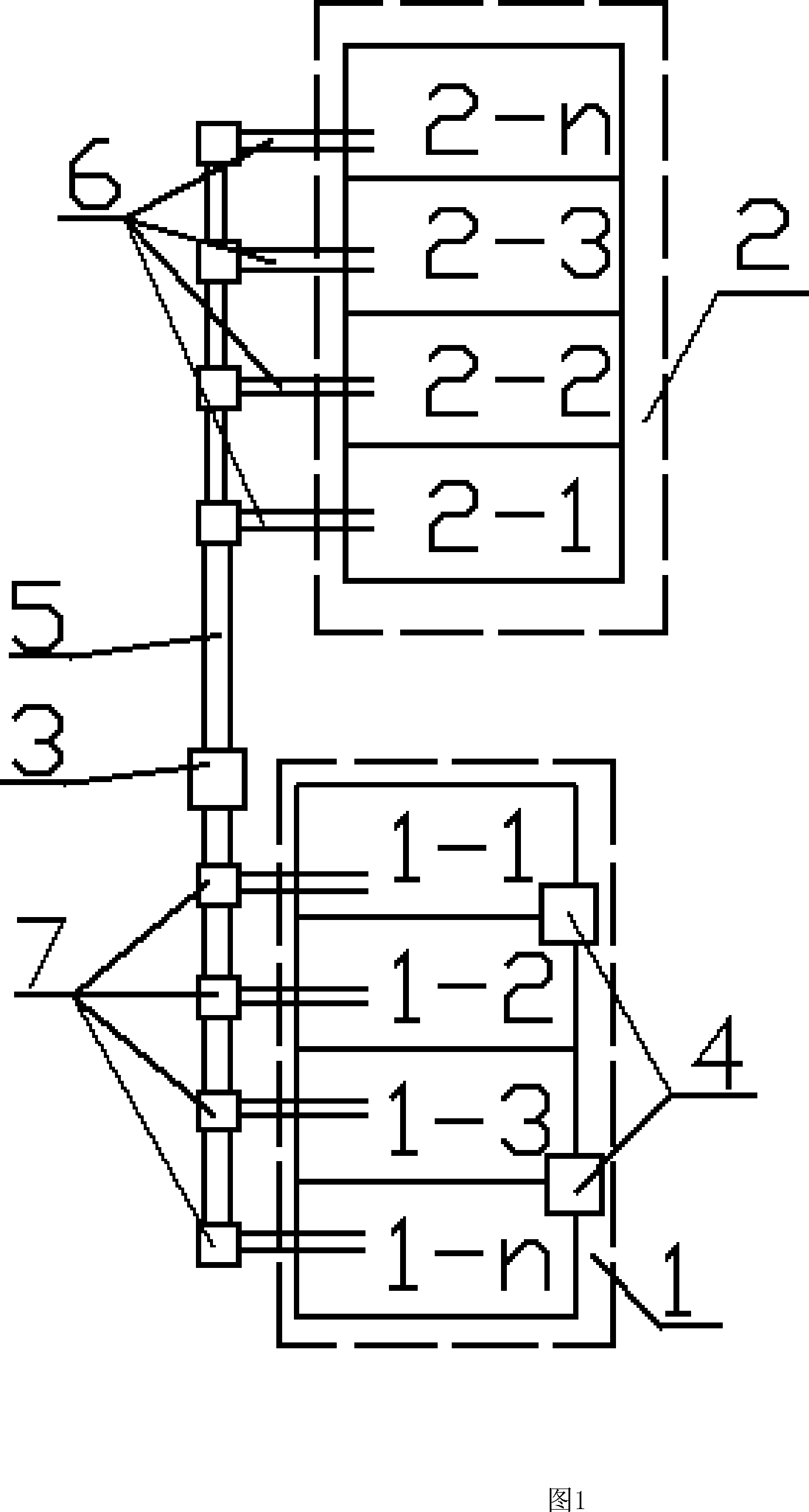

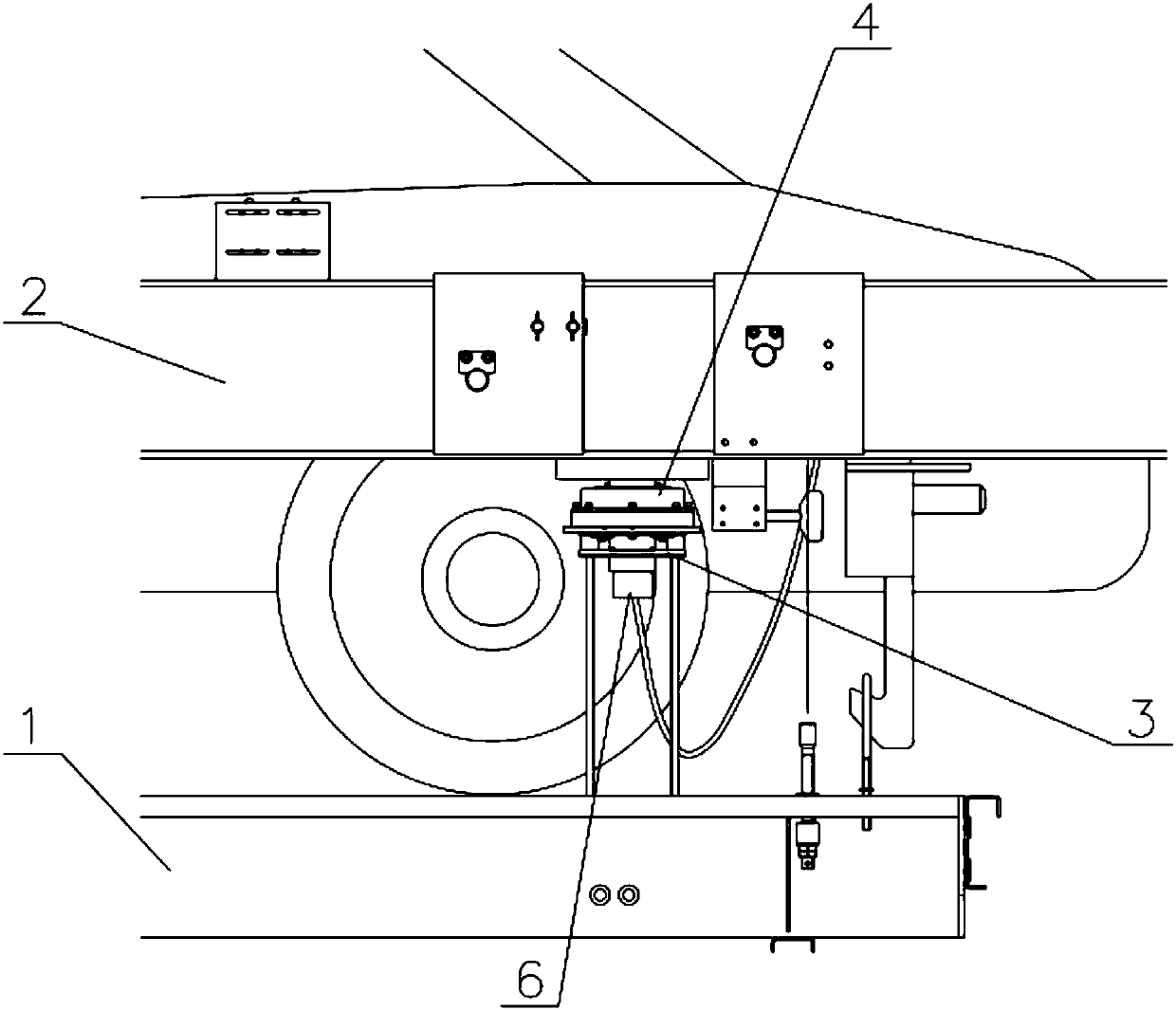

Non-contact rail traffic power supply system

ActiveCN108808873AAchieve smooth transitionGuaranteed stabilityCircuit arrangementsPower gridEngineering

The invention discloses a non-contact rail traffic power supply system comprising the following parts: a plurality of segments of energy transmitting coils arranged on a ground rail in segments, wherein the length of each segment of the energy transmitting coil and the interval between two segments of energy transmitting coils are respectively equal to or bigger than a compartment length; a plurality of segmented hurl-slices switches corresponding to the energy transmitting coils one by one and used for controlling connection / disconnection between the energy transmitting coils and a traction power grid; a plurality of ground responders arranged on the ground rail in segments; a plurality of segments of energy pickup coils arranged in the compartment of the locomotive, wherein one end of the energy pickup coil is coupled to the energy transmitting coil, and the other end is connected with a traction motor via a high frequency rectifier; at a random moment in the locomotive running process, the coupling area sum between the energy pickup coil and the energy transmitting coil keep constant, i.e., the vehicle-mount energy pickup coil can obtain constant magnetic flux; the system also comprises a vehicle-mount requestor. The non-contact rail traffic power supply system can realize stable and smooth transition of the locomotive between different segments of the rail, thus ensuring the power supply stability and reliability.

Owner:CSR ZHUZHOU ELECTRIC LOCOMOTIVE RES INST

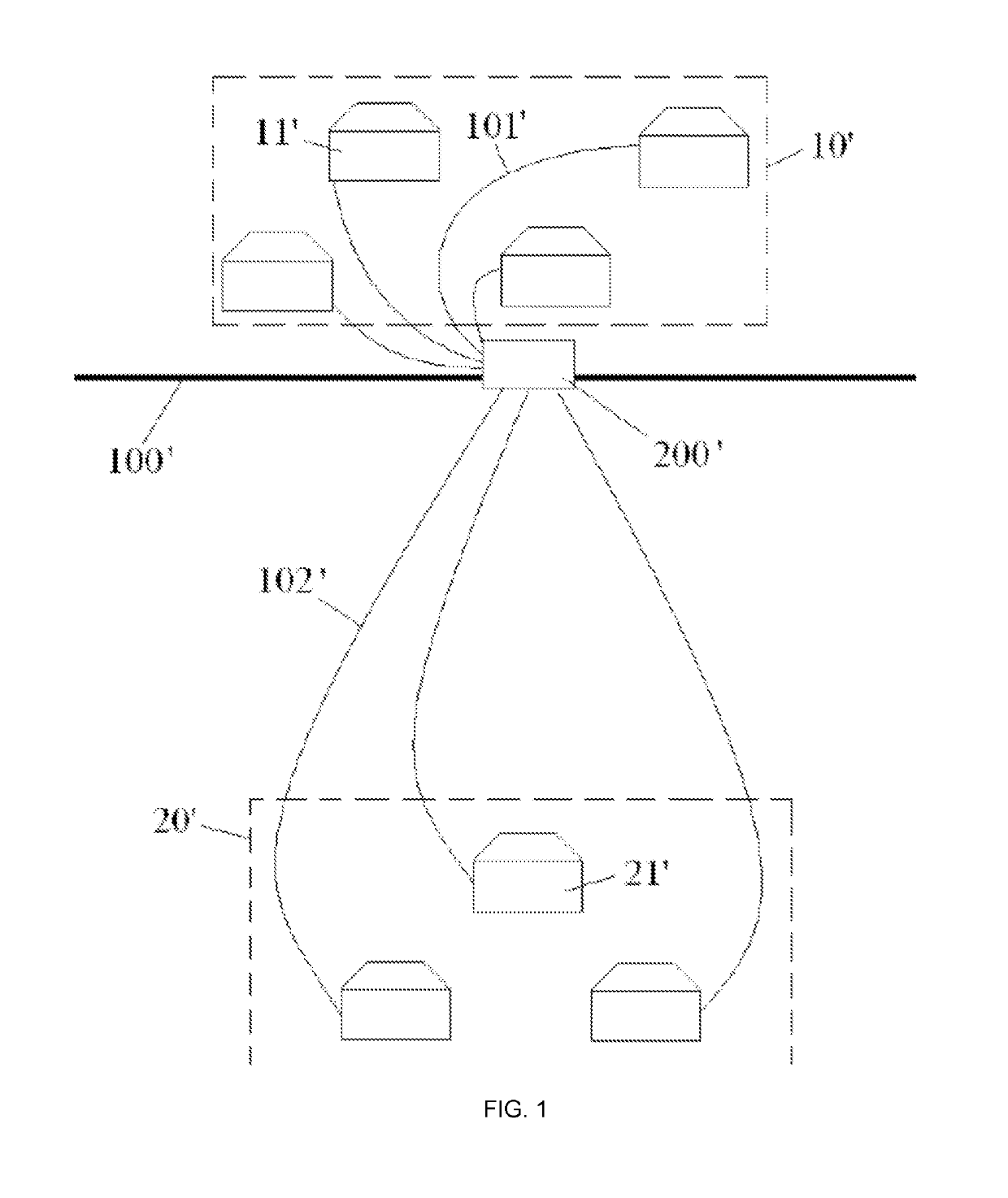

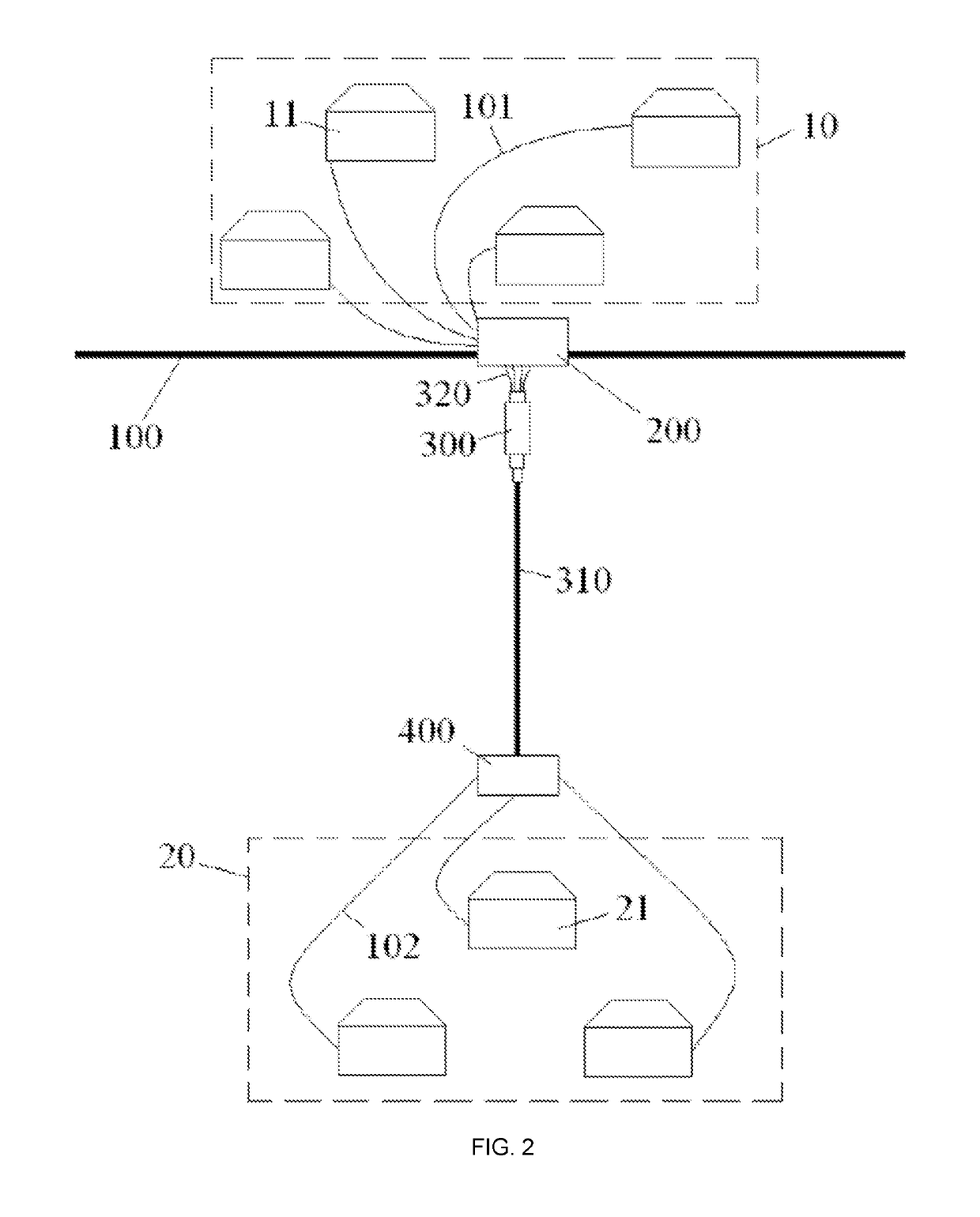

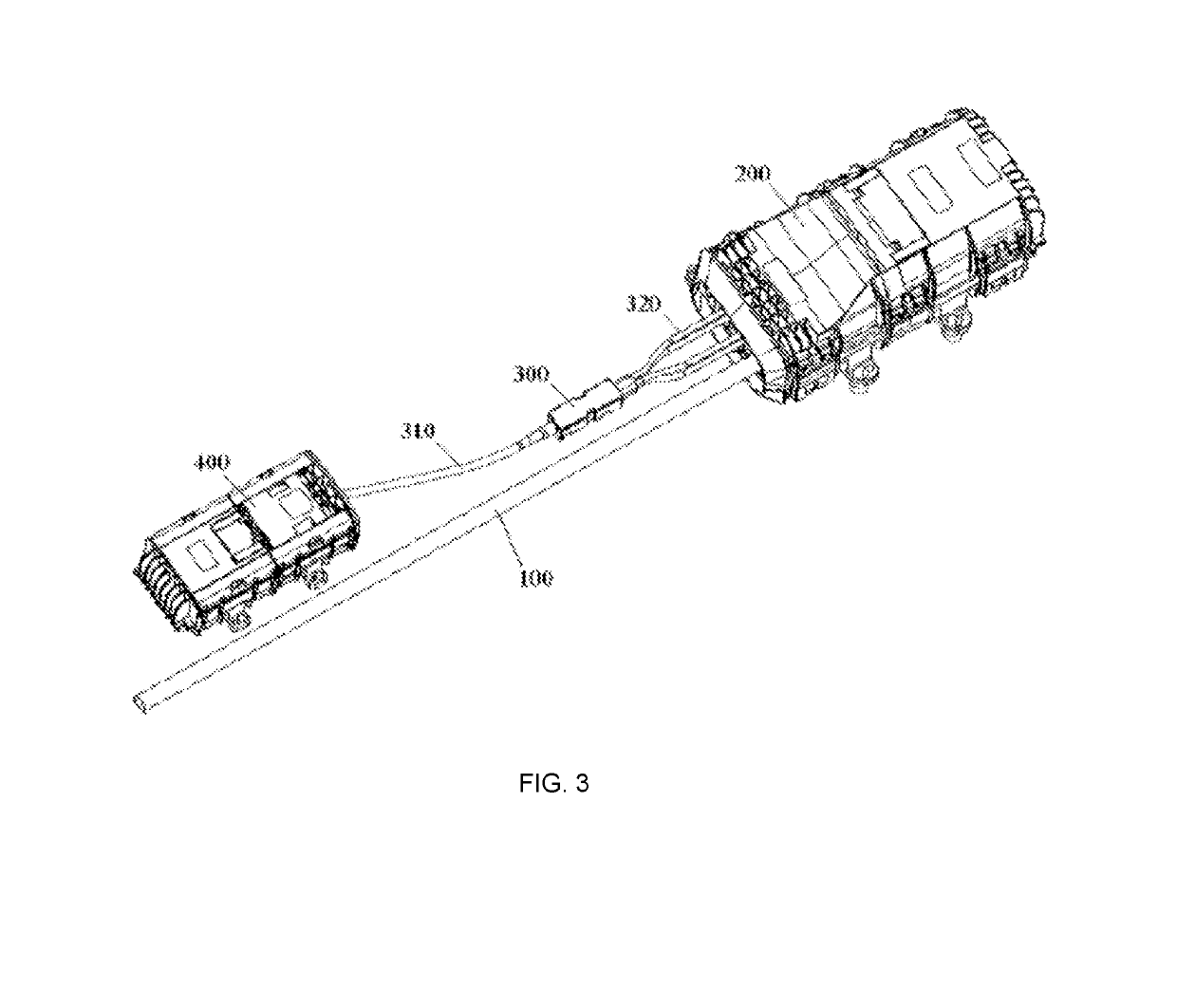

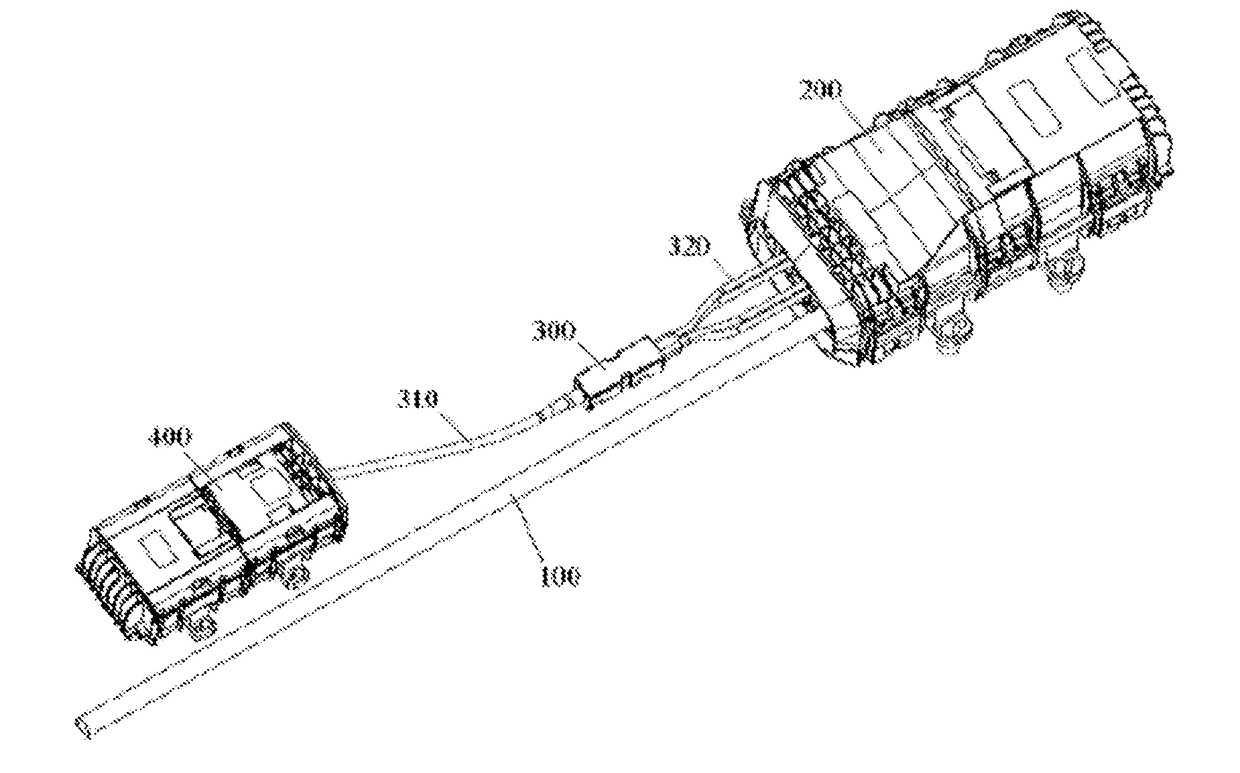

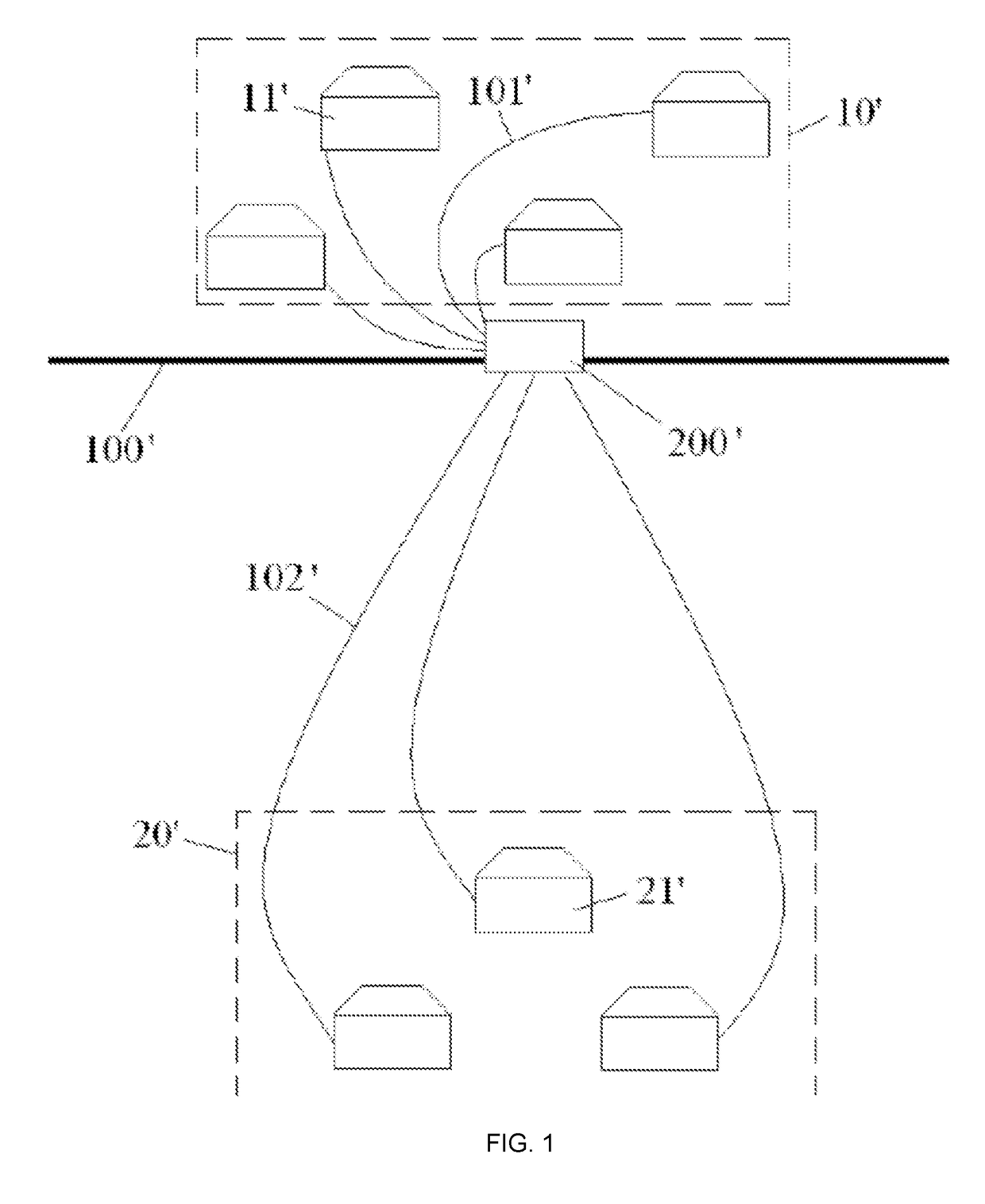

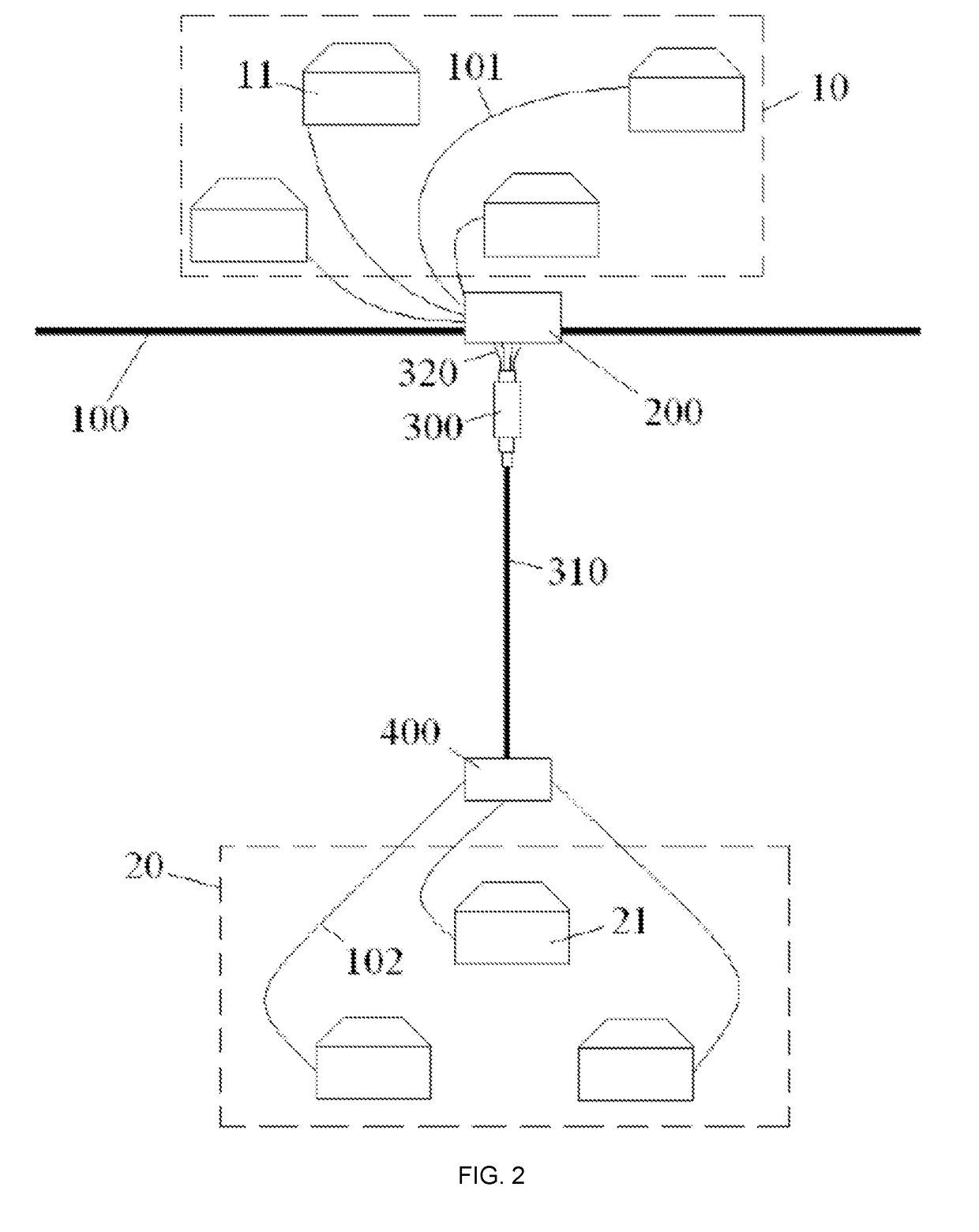

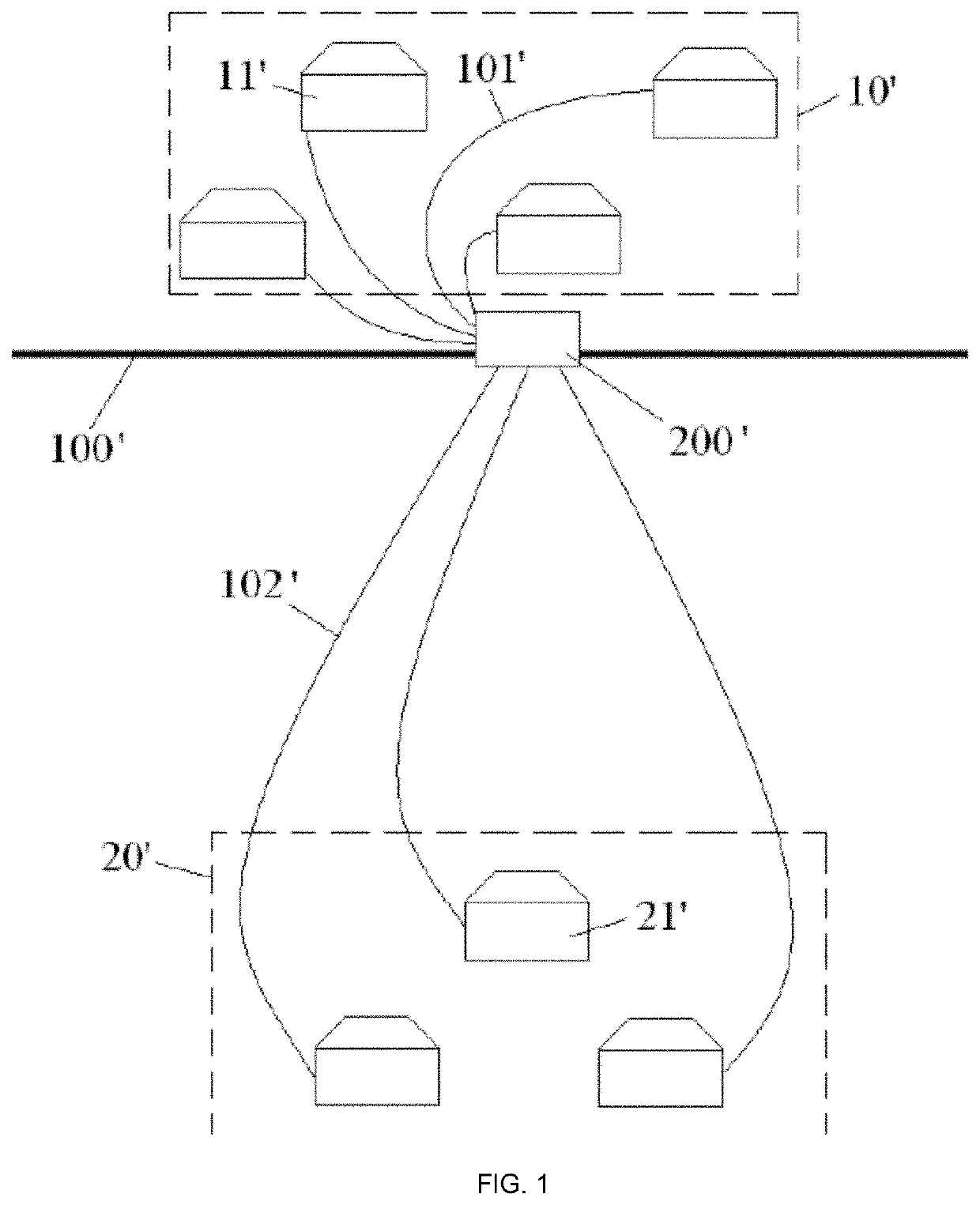

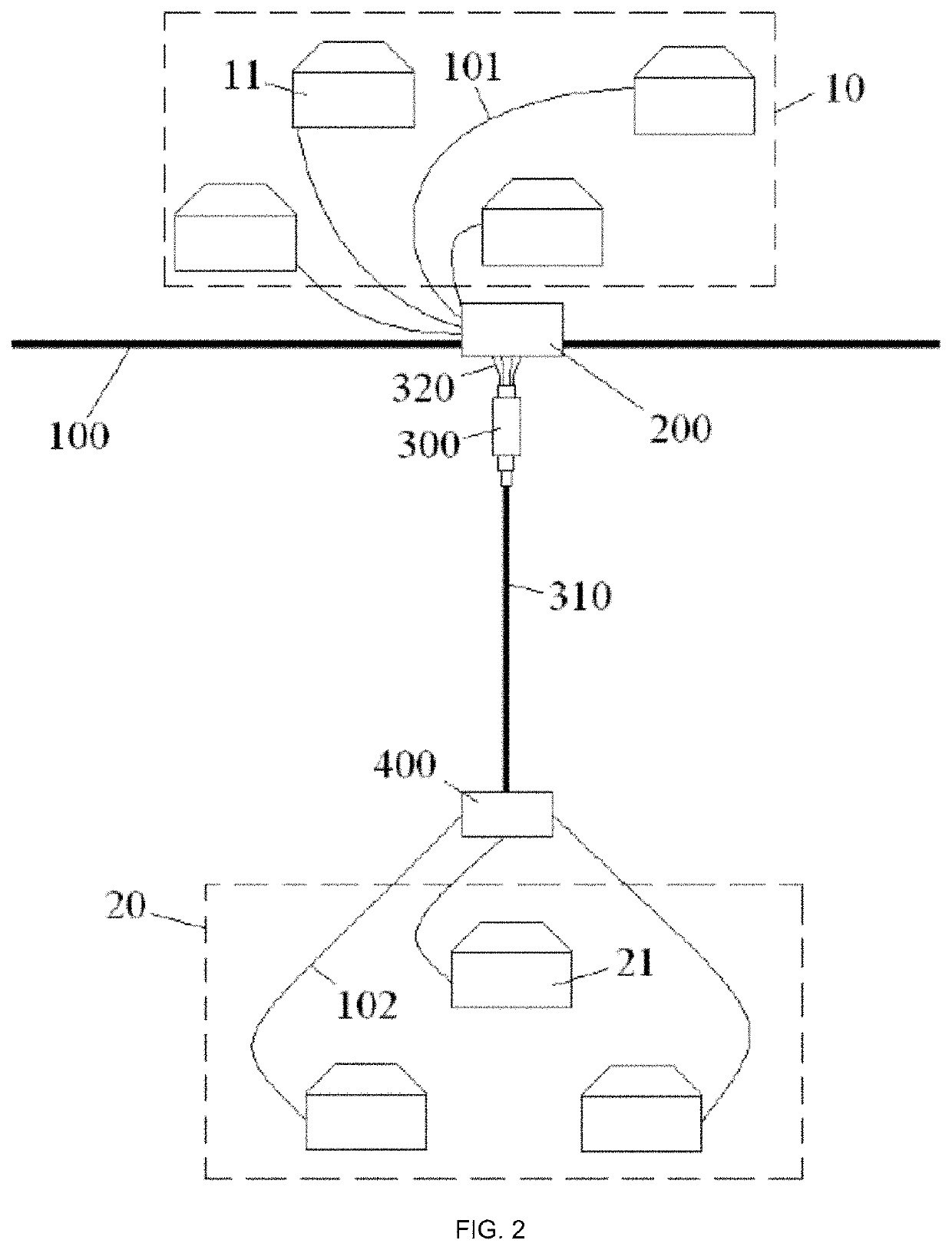

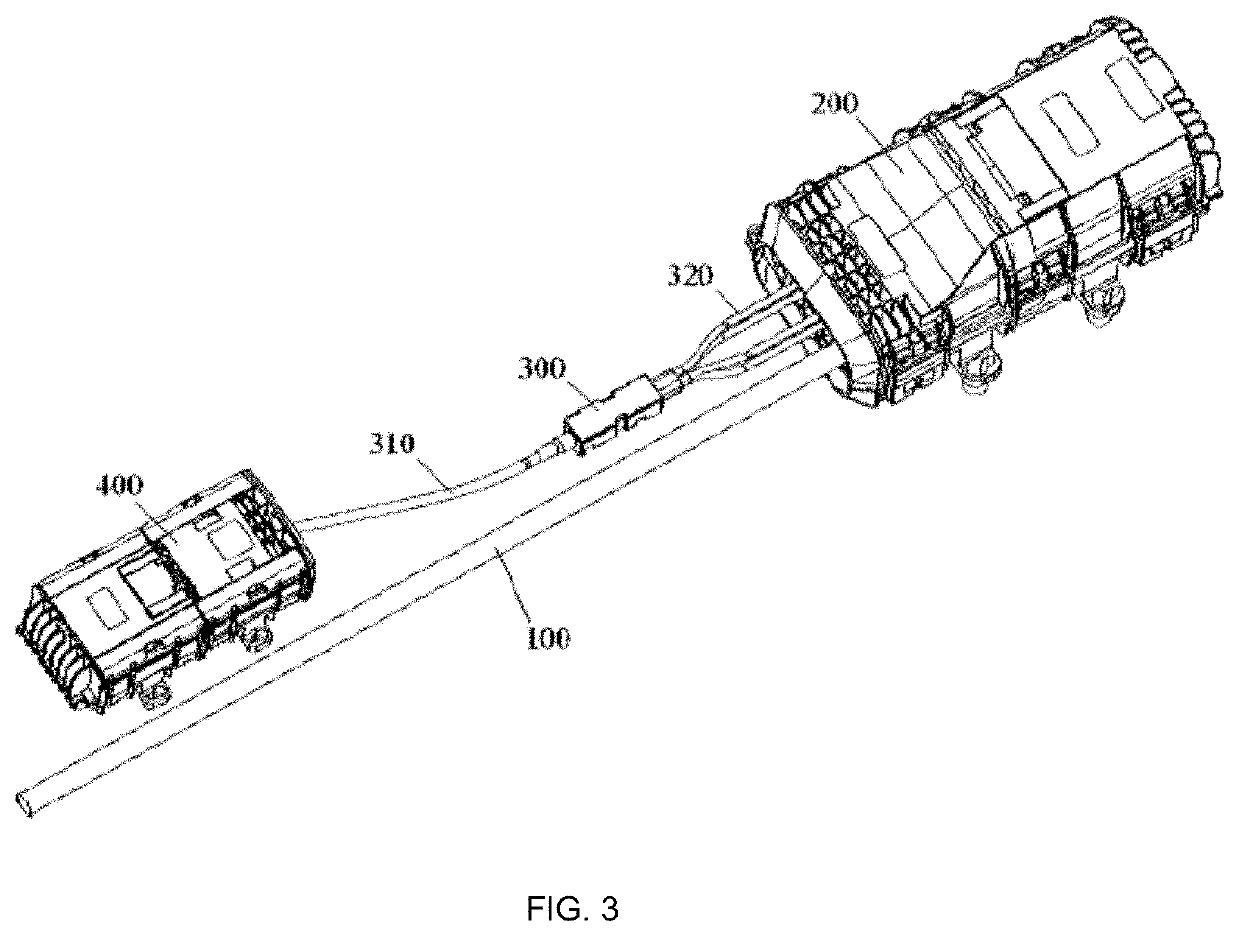

Optical cable wiring system and optical cable connecting component

ActiveUS10444462B2Reduce lay lengthLow costOptical fibre/cable installationCoupling light guidesEngineeringOptical fiber cable

This invention discloses a type of optical cable wiring system, including: a main optical cable, first optical cable connector box and optical cable fan-out disposed near a first user zone; a second optical cable connector box disposed at a distance from the first user zone and near a second user zone; and a single main adapter optical cable disposed between the first optical cable connector box and second optical cable connector box. An optical cable fan-out converts a single main adapter optical cable to multiple branch adapter optical cables. Multiple branch adapter optical cables are connected to the main optical cable via a first optical cable connector box; multiple first distribution optical cables for the purpose of connection to a first user zone are connected to a main optical cable via a first optical cable connector box; multiple first distribution optical cables for the purpose of connection to a second user zone are connected to a single main adapter optical cable via a second optical cable connector box. In this manner, it becomes unnecessary to lay multiple second distribution optical cables over long distances between the first user zone and second user zone, thus reducing the laying length of second distribution optical cables, reducing material and labor costs, and additionally improving municipal aesthetics.

Owner:COMMSCOPE TELECOMM (SHANGHAI) CO LTD

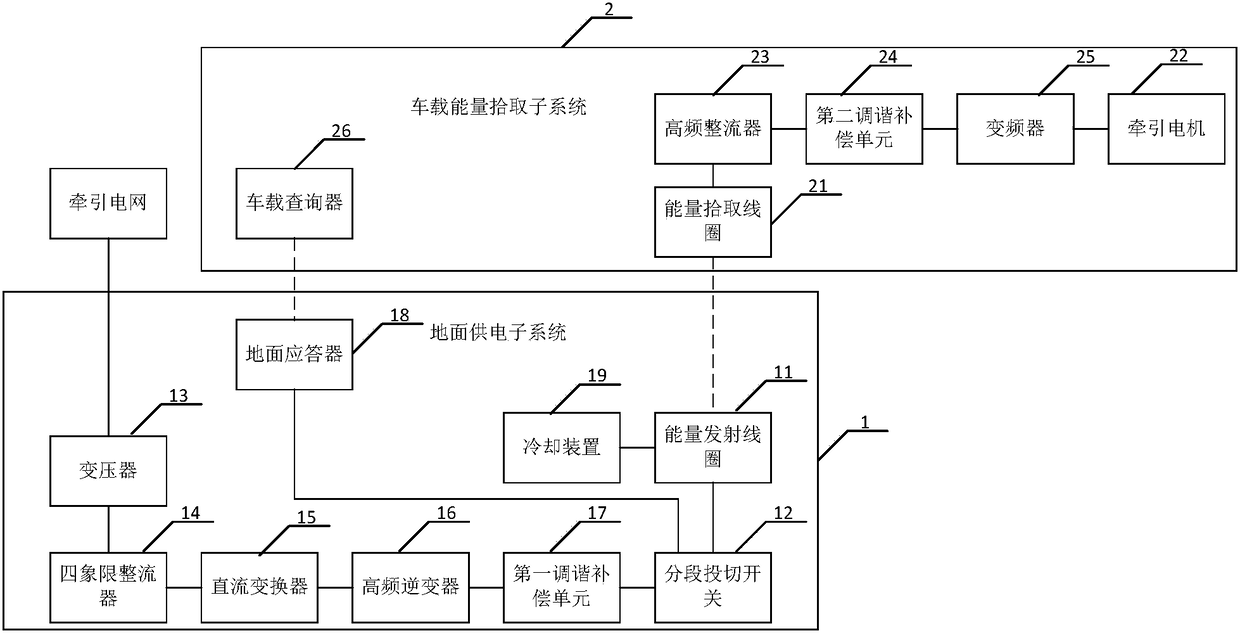

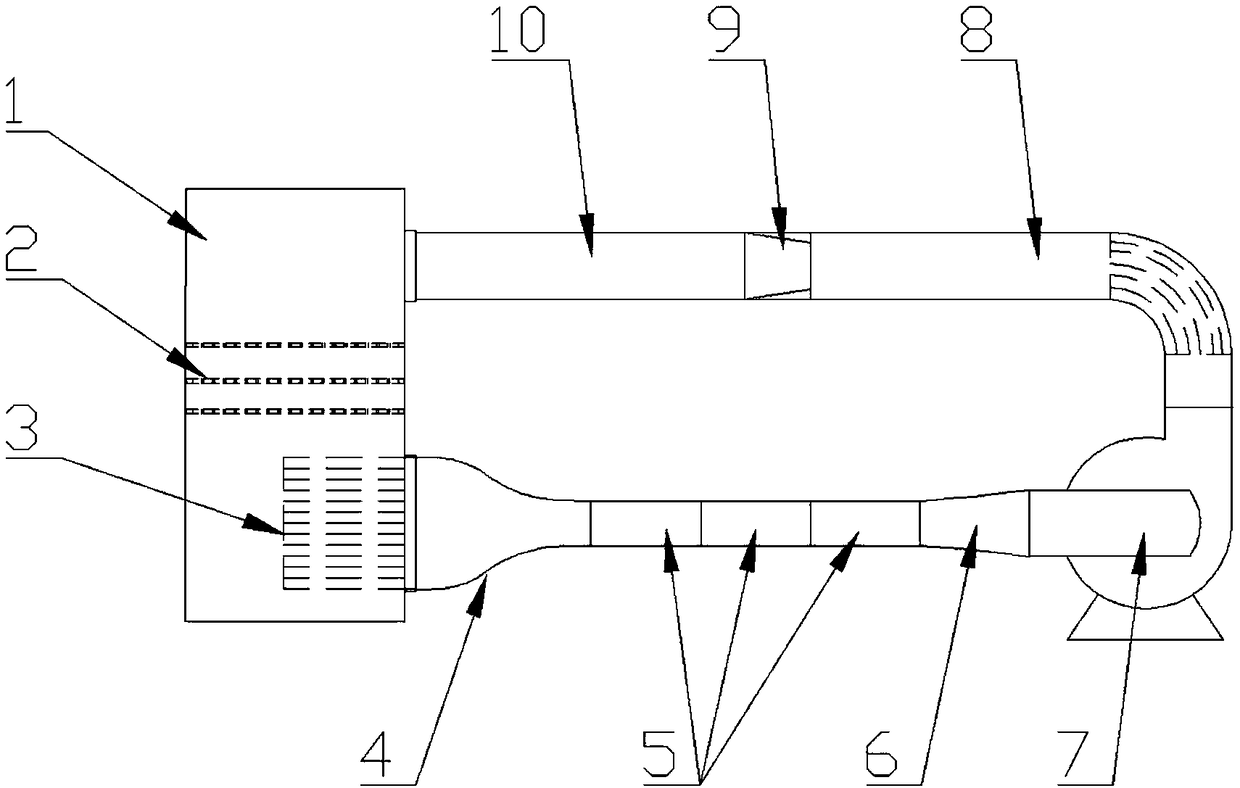

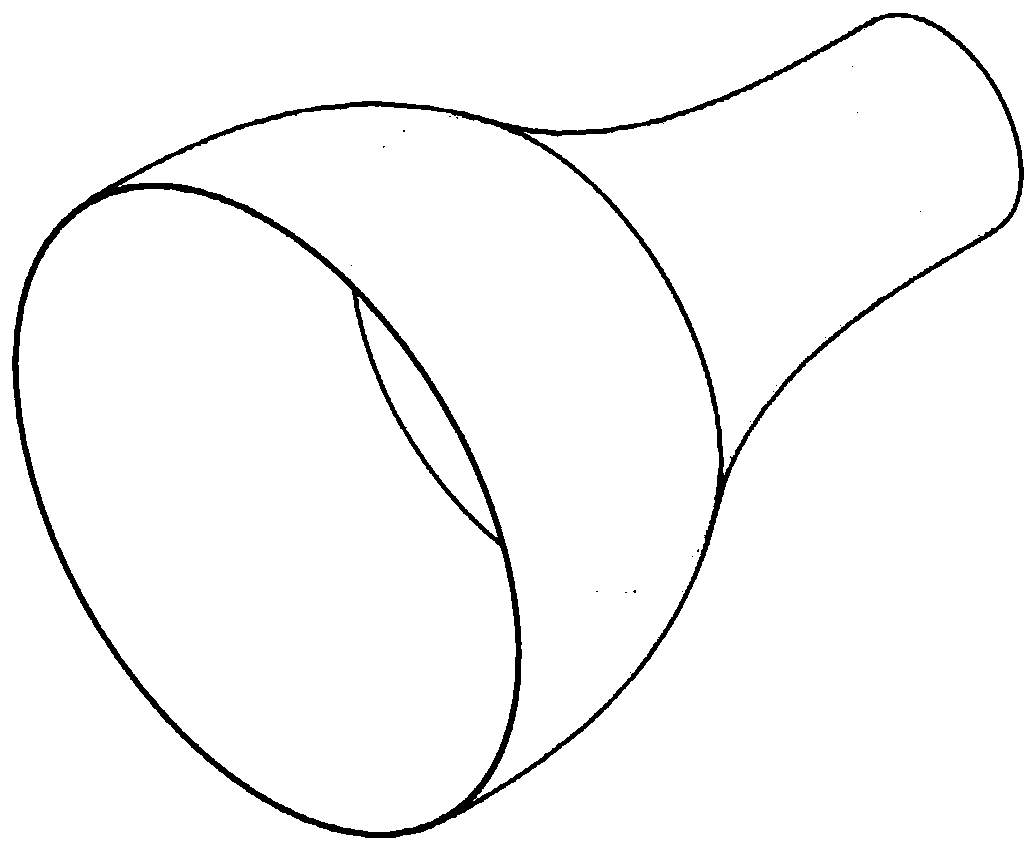

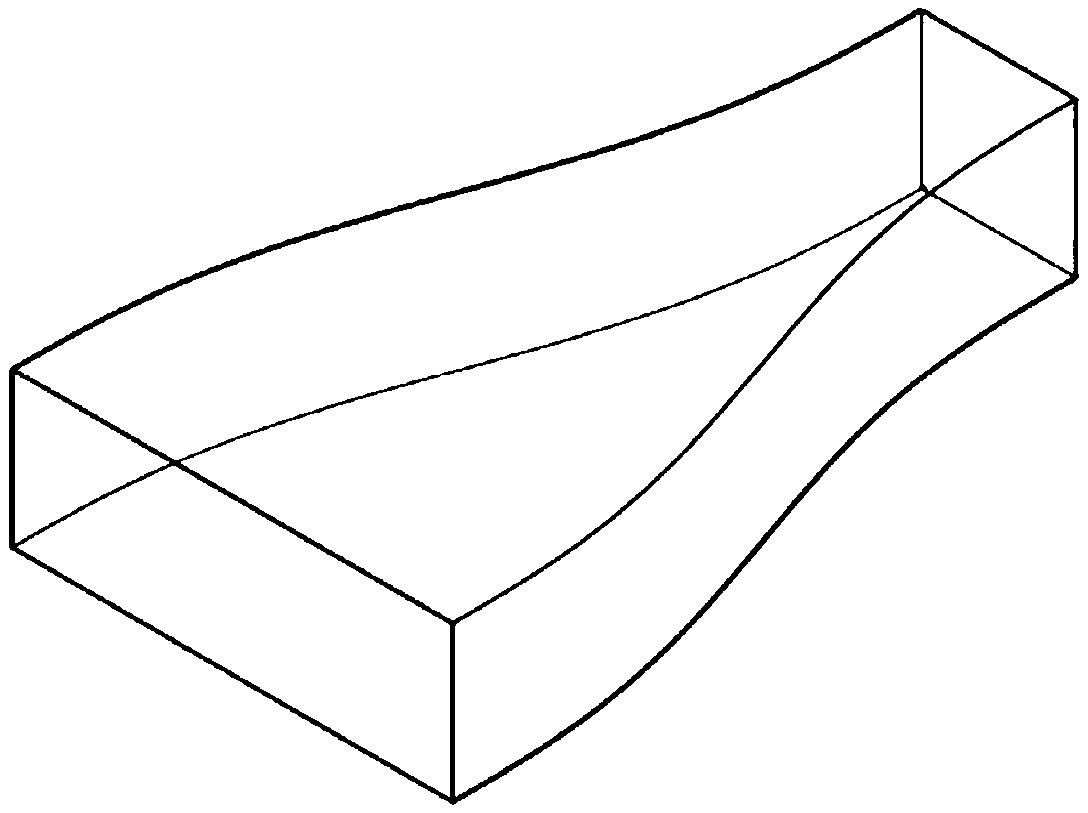

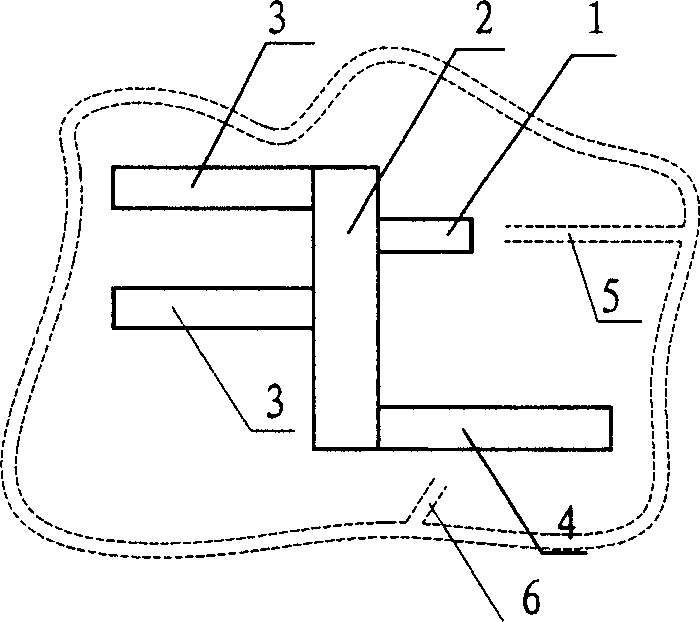

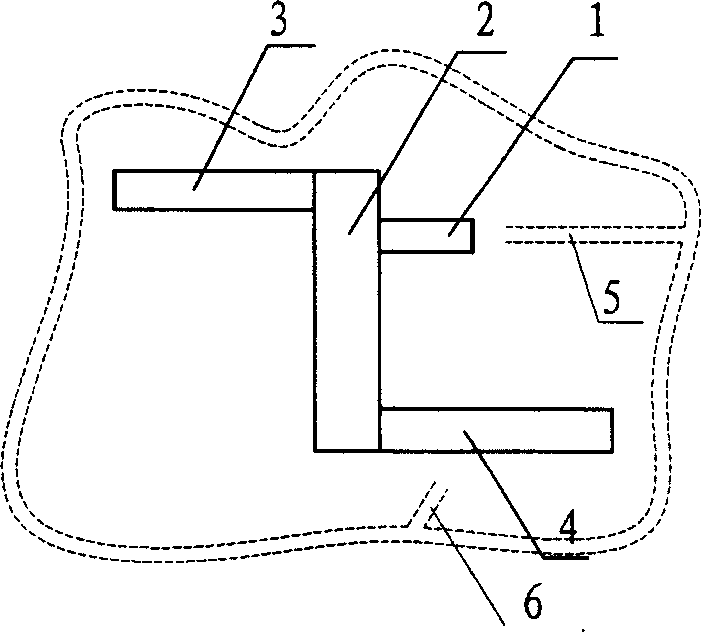

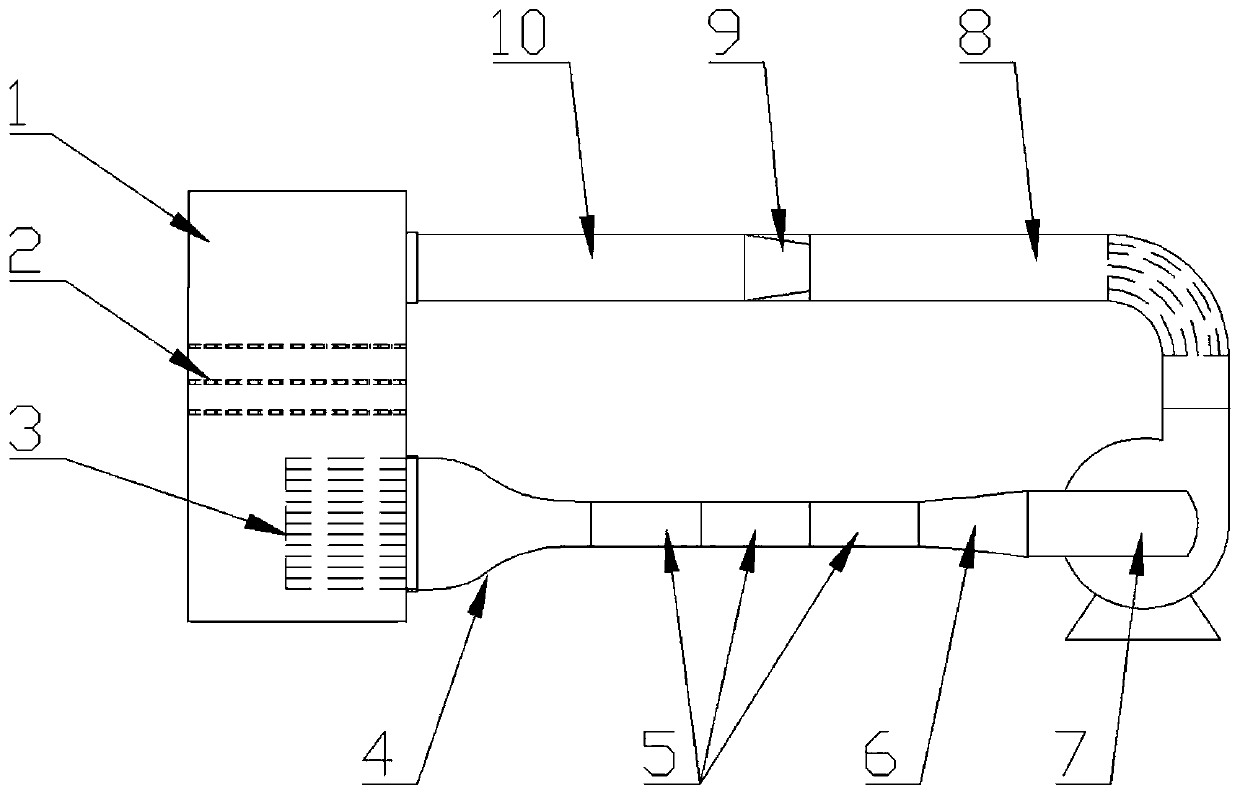

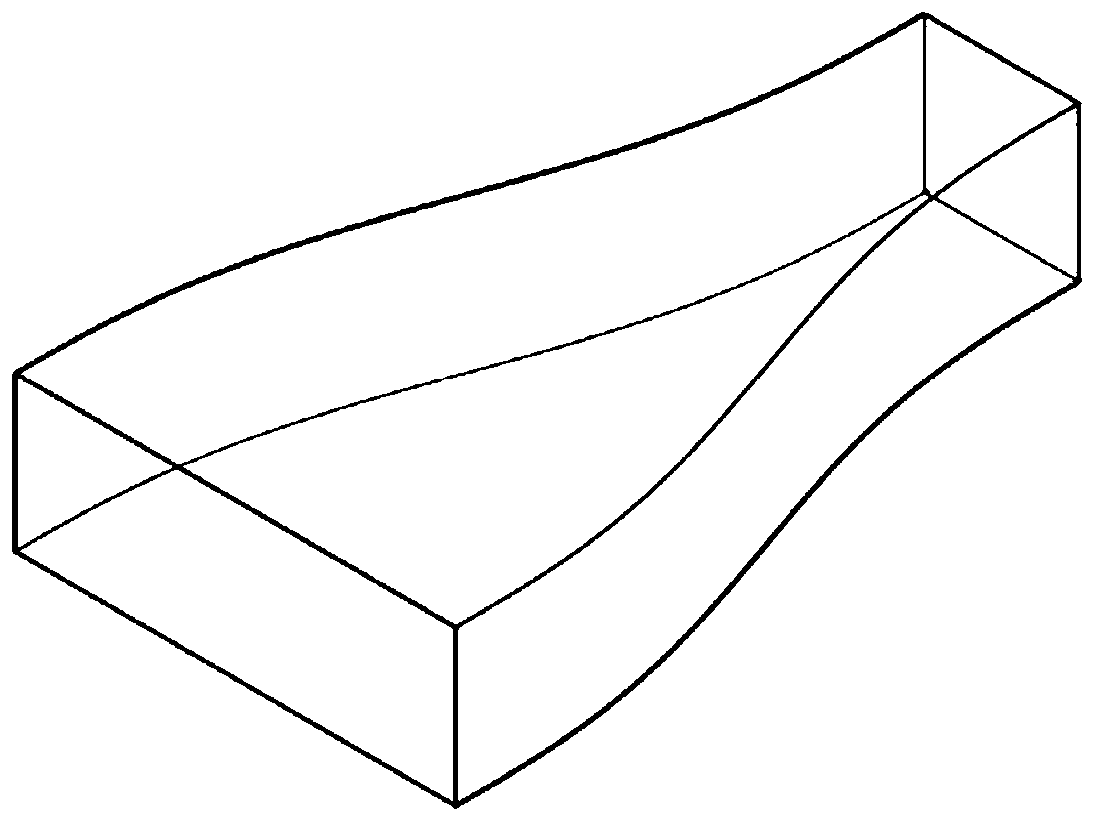

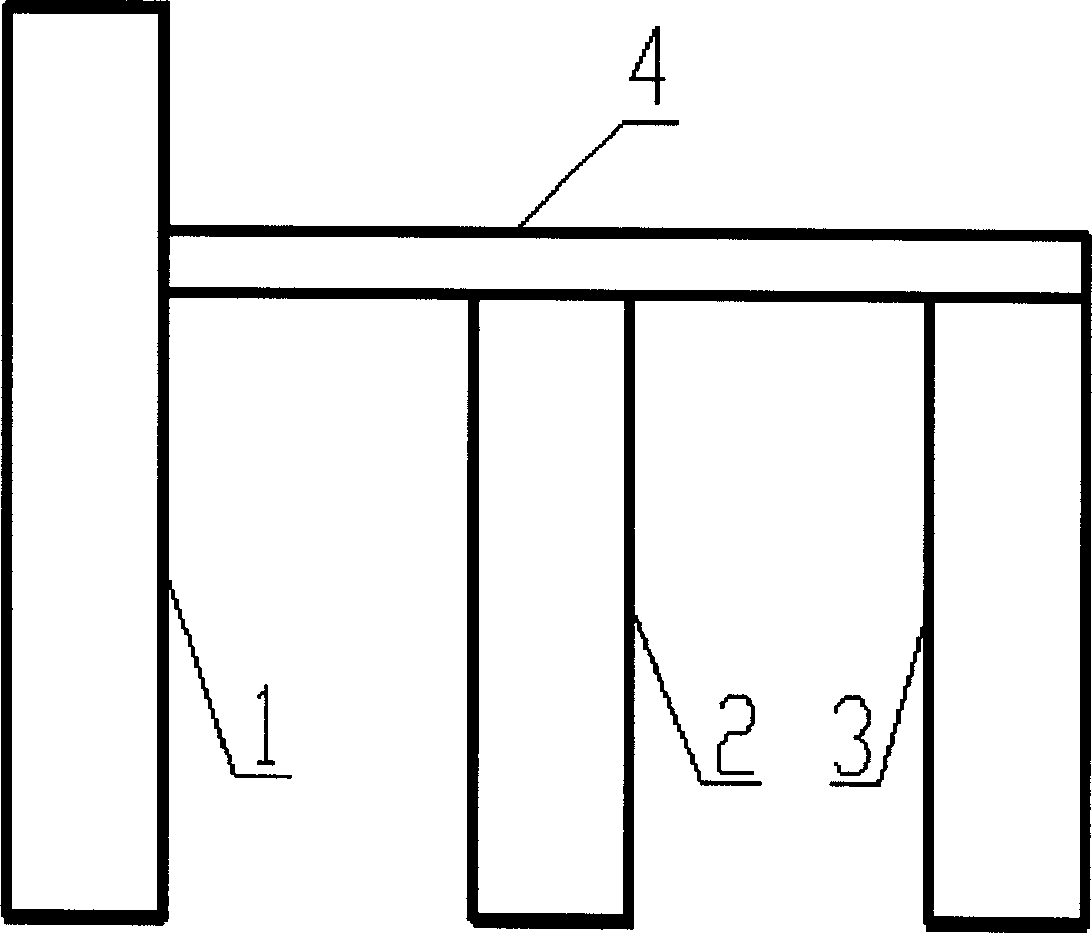

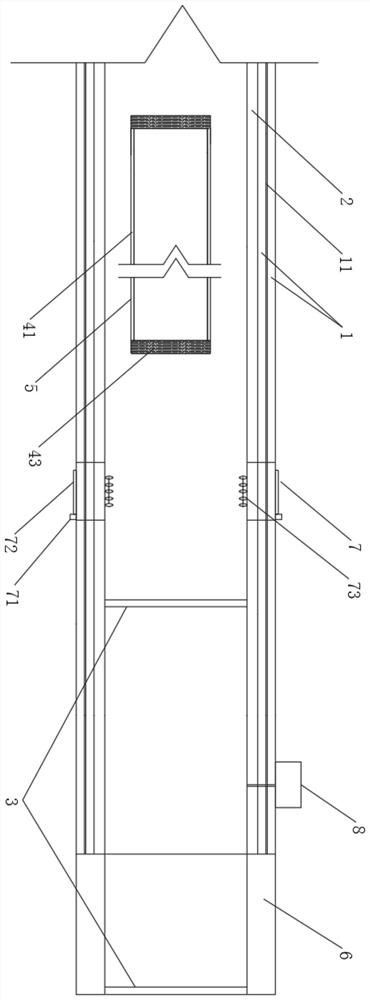

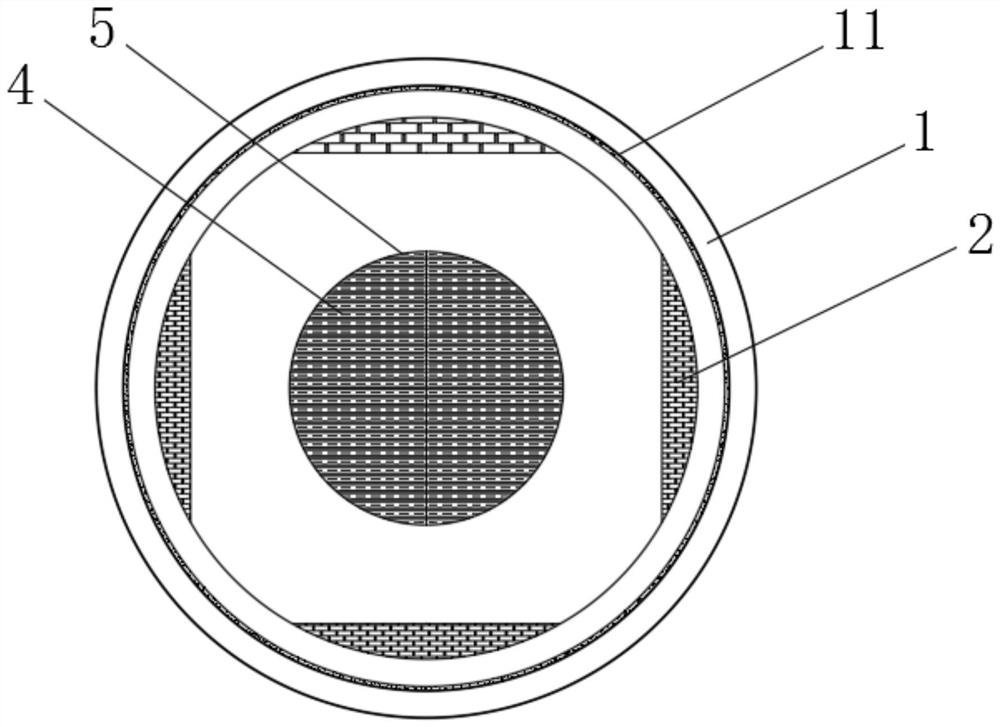

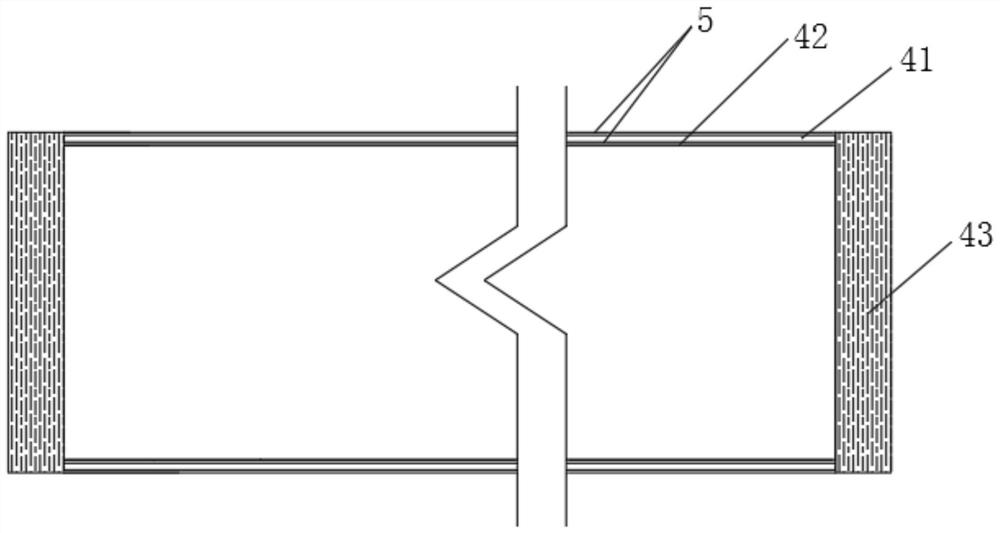

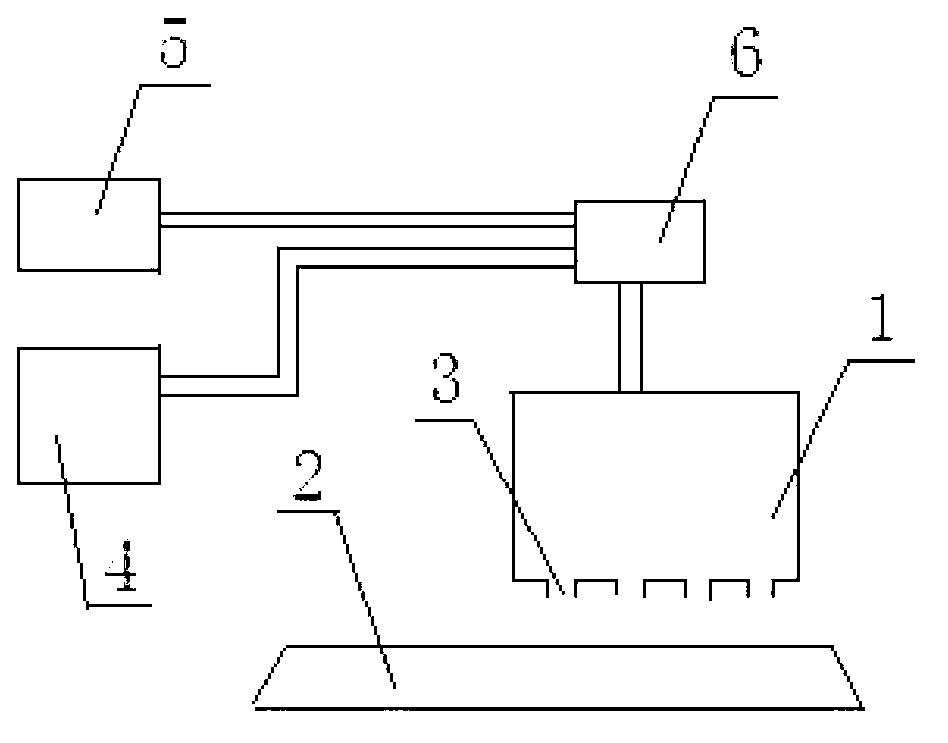

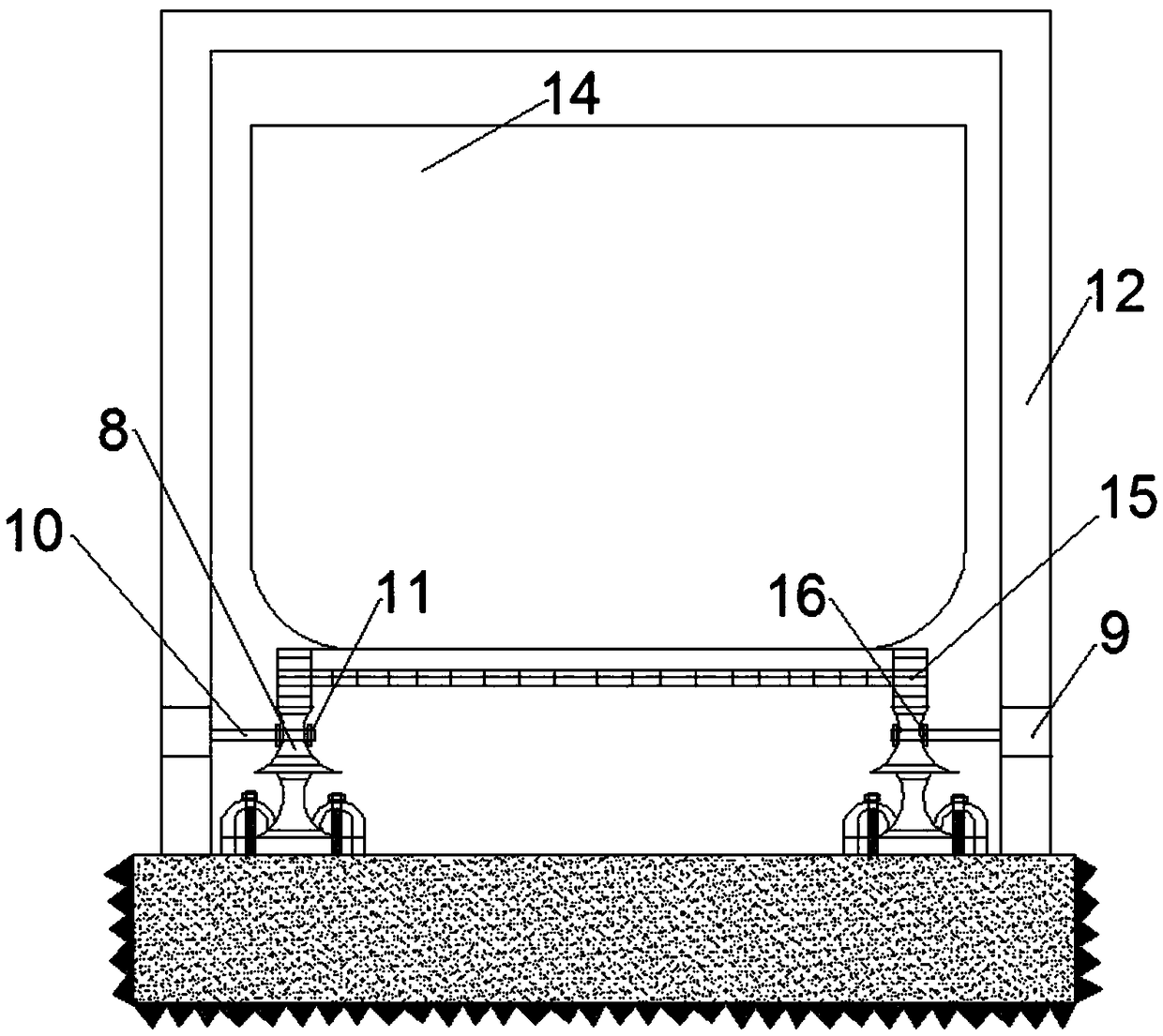

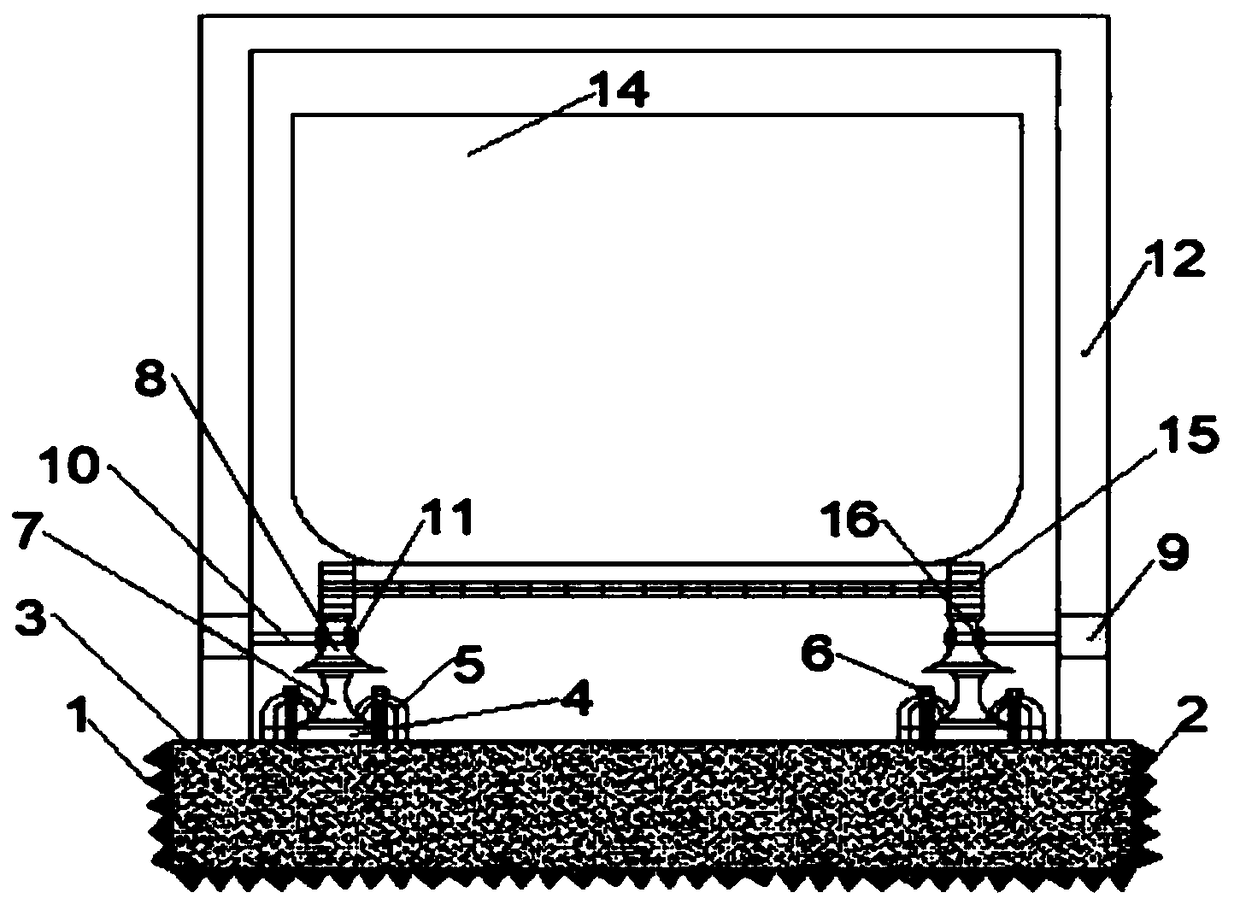

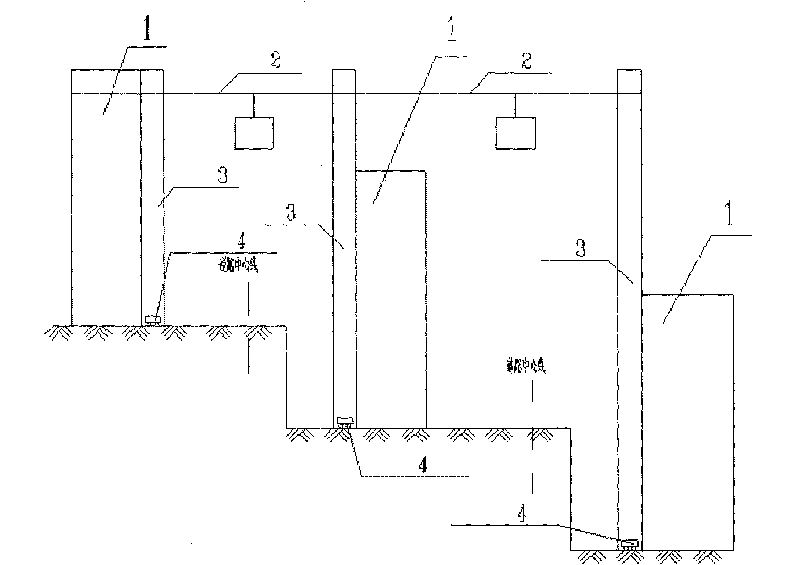

Low-turbulence compact circulating water tunnel experimental device

The invention discloses a low-turbulence compact circulating water tunnel experimental device, comprising a water tank (1), a centrifugal pump (7), and a porous plate (2) and a honeycomb screen (3) which are disposed in the water tank (1). The water tank (1) has a water inlet at the upper part and a water outlet at the lower part at the same side. The porous plate (2) is installed between the water inlet and the water outlet. The honeycomb screen (3) is installed at the water outlet, and has an outlet successively connected a contraction section (4), an experimental section (5) and an expansion section (6). The outlet of the expansion section (6) is connected to the inlet of the centrifugal pump (7). The outlet of the centrifugal pump (7) is successively connected with a backflow section(8), a round-to-square section (9) and a diverging section (10). The outlet of the diverging section (10) is connected to the water inlet of the water tank (1). The hydrodynamic design used by the invention greatly reduces the turbulence of a flow field in the experimental section. The whole experimental device has a compact structure, a small occupied space and low manufacturing cost, which greatly improves the applicability of the water tunnel experimental device.

Owner:XI AN JIAOTONG UNIV

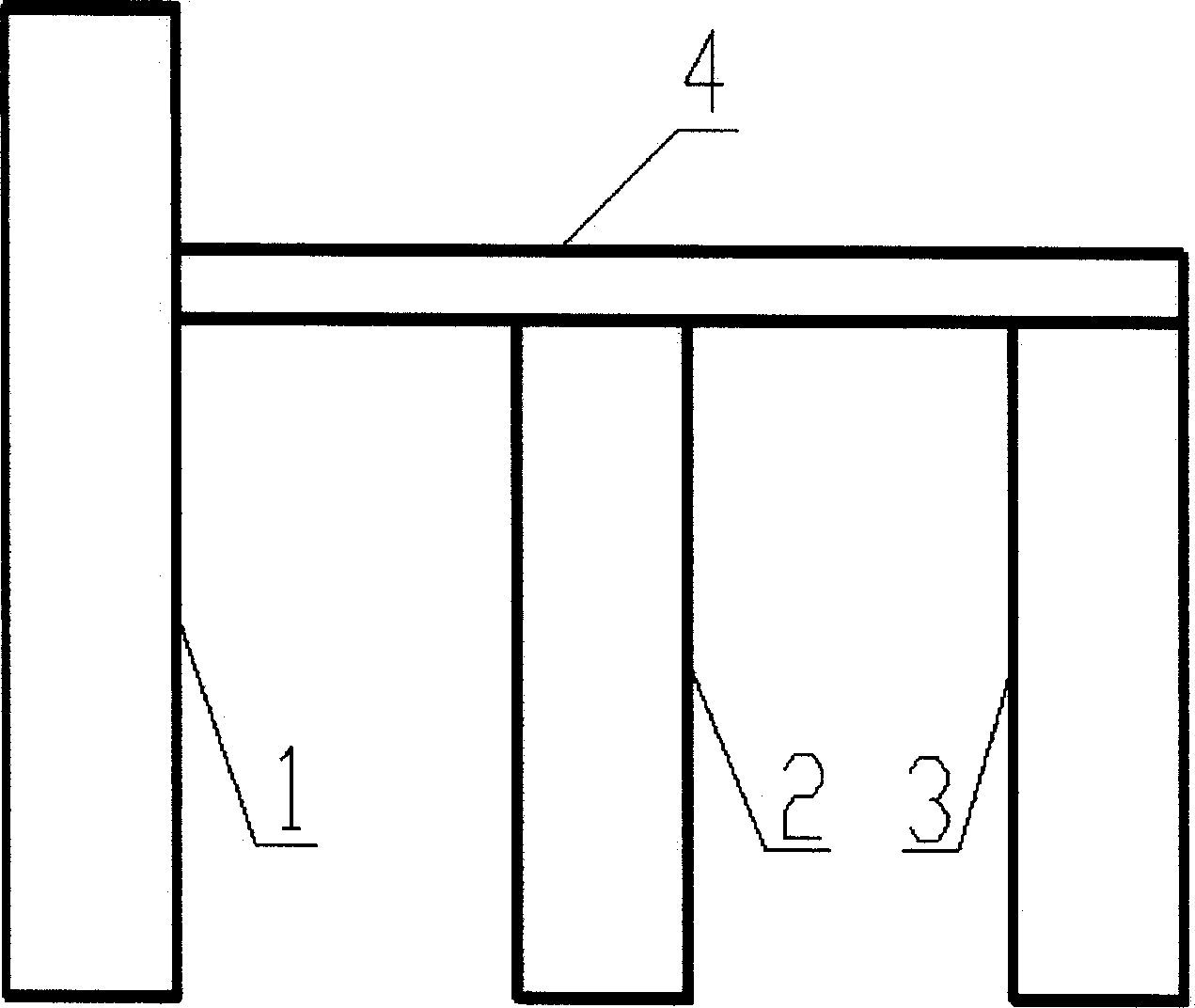

Configuration method of combined factory building for producing anode carbon brick for electrolysis of aluminum

The present invention discloses the configuration method of the composite workshop building for producing anode carbon block for electrolyzing aluminum. The configuration method includes setting the carbon block transferring section in the center position, setting the anode manufacturing and cooling section in the position perpendicular to the carbon block transferring section and near the material entrance, setting the anode assembling section in the position perpendicular to the carbon block transferring section and near the product exit, setting the roasting section in the position perpendicular to and adjacent to the carbon block transferring section, and completing the material conveyance between different sections with conveyer. The present invention has the advantages of reducing land consumption, shortening material conveying distance, etc.

Owner:GUIYANG AL-MG DESIGN & RES INST

Configuration of coal gas station for aluminia plant

InactiveCN1974392AReduce lay lengthReduce construction investment costsAluminium compoundsEngineeringProcess engineering

The present invention discloses configuration method of coal gas station for alumina plant. The configuration method of coal gas station includes coal gas generating sets concentrated in one end of the plant and arranged in two rows, coal storages concentrated in the other end of the plant and arranged in one row, one combined coal conveying belt between the coal gas generating sets and the coal storages, two combined coal conveying belts in the coal storages, three-port transfer stations to connect these three combined coal conveying belts, and coal conveying belts to connect each of the coal gas generating sets or coal storages to nearest four-port transfer station or three-port transfer station. The present invention has lowered engineering cost and running cost, saving in land and good alumina plant environment.

Owner:GUIYANG AL-MG DESIGN & RES INST

Combined workshop collocation method for electrolytic aluminium production

This invention exposed a kind of configuration method of combined workshop that producing electrolytic aluminium. Placing the casting plane of liquid aluminium in foundry shops and operation plane of electrolytic workshop on the same plane, and then setting the corridor between them to connect them. This invention can combine two procedures, and make it integrated, shorten the transportation distance. It can reduce land usage and demand of transportation equipment, so to reduce infrustructure investment and operation cost.

Owner:GUIYANG AL-MG DESIGN & RES INST

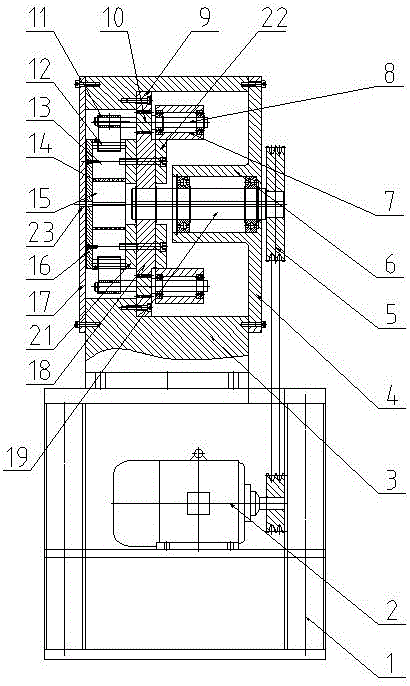

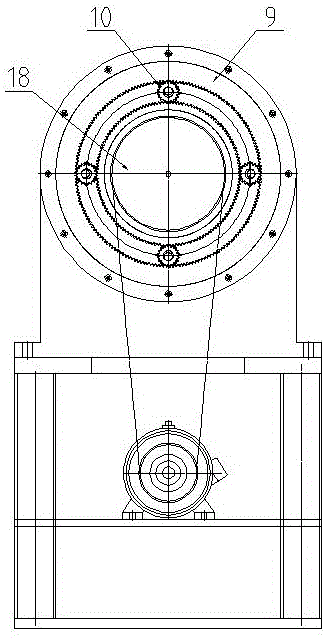

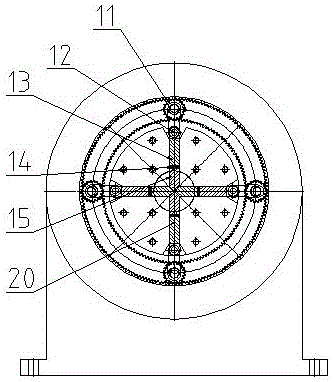

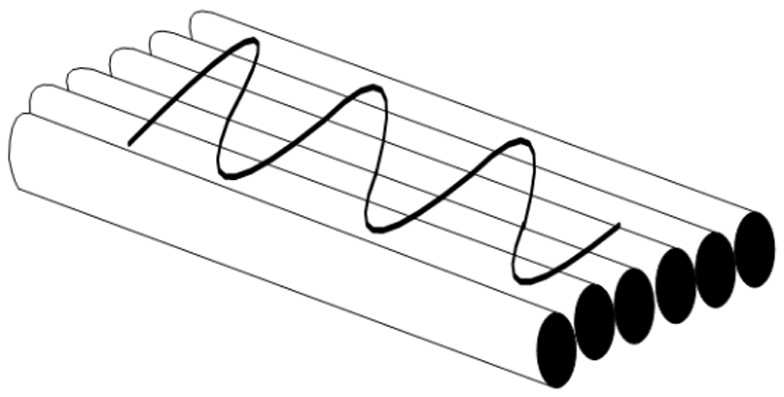

Stranded welding wire hammering machine

The invention relates to a stranded welding wire hammering machine. The stranded welding wire hammering machine comprises a hammering machine base (3), wherein a mandrel (19) is installed in the center of the hammering machine base (3) in a penetrating manner, a big gear wheel (18) is arranged at the left end of the mandrel (19), a gear ring (9) is arranged on the periphery of the big gear wheel (18), a plurality of second bearing pedestal (7) are arranged on the periphery of the right side of the big gear wheel (18), one eccentric shaft (8) is installed on each second bearing pedestal (7) in a penetrating manner, one pinion (10) is arranged on each eccentric shaft (8), a plurality of limiting sliding grooves (20) are evenly formed in a left fixing plate (21) outwards along the center of the left fixing plate (21), one hammer forging die (15) and one transmission block (13) are arranged in each limiting sliding groove (20), one crank (11) is arranged at the left end of each eccentric shaft (8), and one end of each crank (11) is connected with the corresponding transmission block (13). The working efficiency of the stranded welding wire hammering machine is high, the phenomena that stranded welding wires are slub and have internal stress can be eliminated, and the ideal surface state of the stranded welding wires can be achieved.

Owner:河北联之捷焊业科技有限公司

Optical cable wiring system and opticalcable connecting component

ActiveUS20180017751A1Reduce lay lengthLow costOptical fibre/cable installationCoupling light guidesEngineering

This invention discloses a type of optical cable wiring system, including: a main optical cable, first optical cable connector box and optical cable fan-out disposed near a first user zone; a second optical cable connector box disposed at a distance from the first user zone and near a second user zone; and a single main adapter optical cable disposed between the first optical cable connector box and second optical cable connector box. An optical cable fan-out converts a single main adapter optical cable to multiple branch adapter optical cables. Multiple branch adapter optical cables are connected to the main optical cable via a first optical cable connector box; multiple first distribution optical cables for the purpose of connection to a first user zone are connected to a main optical cable via a first optical cable connector box; multiple first distribution optical cables for the purpose of connection to a second user zone are connected to a single main adapter optical cable via a second optical cable connector box. In this manner, it becomes unnecessary to lay multiple second distribution optical cables over long distances between the first user zone and second user zone, thus reducing the laying length of second distribution optical cables, reducing material and labour costs, and additionally improving municipal aesthetics.

Owner:COMMSCOPE TELECOMM (SHANGHAI) CO LTD

Method for supplying water with high voltage in cold area long and large tunnel

InactiveCN101225749AReduce lay lengthSave pool and pipeline constructionMining devicesWater supply installationCold areaWater supply

The invention relates to a high pressure water supply method for the long and large tunnel in cold areas, belonging to the technical field of tunnel construction, solving the problems of high cost and long water leakage detection time existing in water supply method for the long and large tunnel in cold areas in prior art. The high pressure water supply method is characterized in that a sump pit is positioned two hundred to three hundred meters in front of the tunnel face; a piece of pumping equipment is used to transport water in the sump pit to the tunnel face by a water flowing pipeline in order to be used in construction; the depth of accumulated water in the sump pit should submerge the pumping equipment; the water volume per unit time flowing into the sump pit is more than the water volume of the pumping equipment; as the tunnel face propels forward, the old sump pit is abandoned after new sump pit is positioned in front. The high pressure water supply method for the long and large tunnel in cold areas has the advantages of saving pipeline laying length, particularly that the long and large tunnel has a large number, saving construction and winter heat insulation of pools and pipeline outside the tunnel, saving the expense of long distance maintenance of pipeline by work force and quickening construction speed in the tunnel.

Owner:THE 4TH ENG CO LTD OF CHINA RAILWAY 17TH BUREAU GRP

Configuration of boiler house in alumina plant

The configuration method of boiler houses in alumina plant includes concentrating the boiler facilities in one end of the plant and arranged in one row, concentrating the coal supplying systems in the other end and arranged in one row, establishing one main coal conveying belt in the boiler facilities and the coal supplying systems, connecting the separated coal conveying belts in each boiler facility and each coal supplying system to the main coal conveying belt, and establishing one shared coal breaking station between the boiler facilities and the coal supplying systems. The present invention has reduced total production system area, reduced total road area, shortened pipeline, compact structure and other advantages.

Owner:GUIYANG AL-MG DESIGN & RES INST

A low-turbulence compact circulating water tunnel experimental device

The invention discloses a low-turbulence compact circulating water tunnel experimental device, comprising a water tank (1), a centrifugal pump (7), and a porous plate (2) and a honeycomb screen (3) which are disposed in the water tank (1). The water tank (1) has a water inlet at the upper part and a water outlet at the lower part at the same side. The porous plate (2) is installed between the water inlet and the water outlet. The honeycomb screen (3) is installed at the water outlet, and has an outlet successively connected a contraction section (4), an experimental section (5) and an expansion section (6). The outlet of the expansion section (6) is connected to the inlet of the centrifugal pump (7). The outlet of the centrifugal pump (7) is successively connected with a backflow section(8), a round-to-square section (9) and a diverging section (10). The outlet of the diverging section (10) is connected to the water inlet of the water tank (1). The hydrodynamic design used by the invention greatly reduces the turbulence of a flow field in the experimental section. The whole experimental device has a compact structure, a small occupied space and low manufacturing cost, which greatly improves the applicability of the water tunnel experimental device.

Owner:XI AN JIAOTONG UNIV

Combined workshop collocation method using delivery belt corridor as link

InactiveCN1762811APaved area savingsReduce lay lengthMechanical conveyorsAluminium oxides/hydroxidesOperational costsEngineering

The present invention discloses combined workshop configuration method with conveying belt way as link. The present invention has coal supplying system, boiler facility and salt melting furnace set laid in parallel and linked with conveying belt way, and the belt conveyers in the conveying belt ways complete coal conveyance to form complete production system. The present invention has compact configuration and saving in covered area, engineering investment and production running cost. The present invention is suitable for use in small alumina plant of annual output not more than 300 kilotons.

Owner:GUIYANG AL-MG DESIGN & RES INST

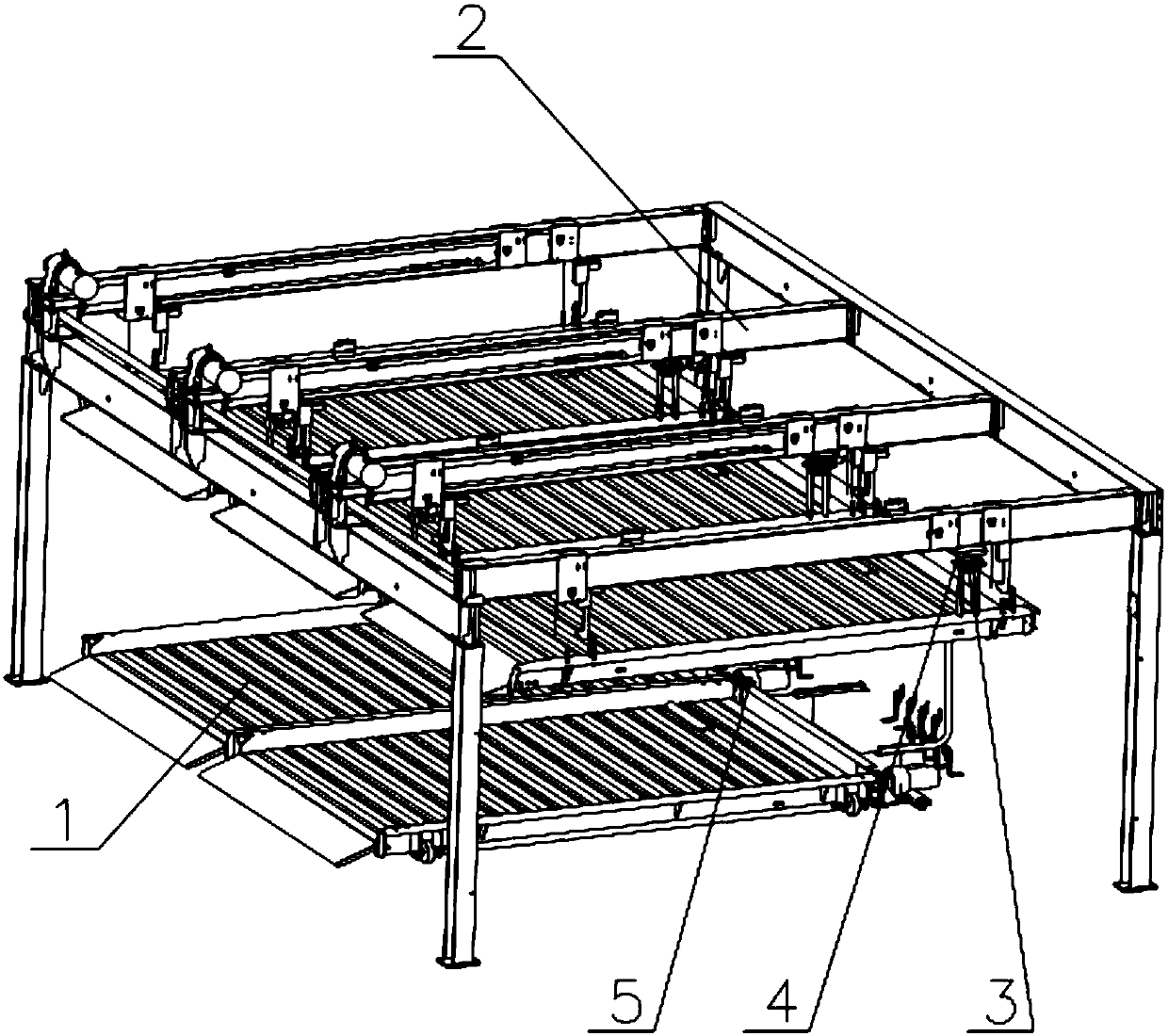

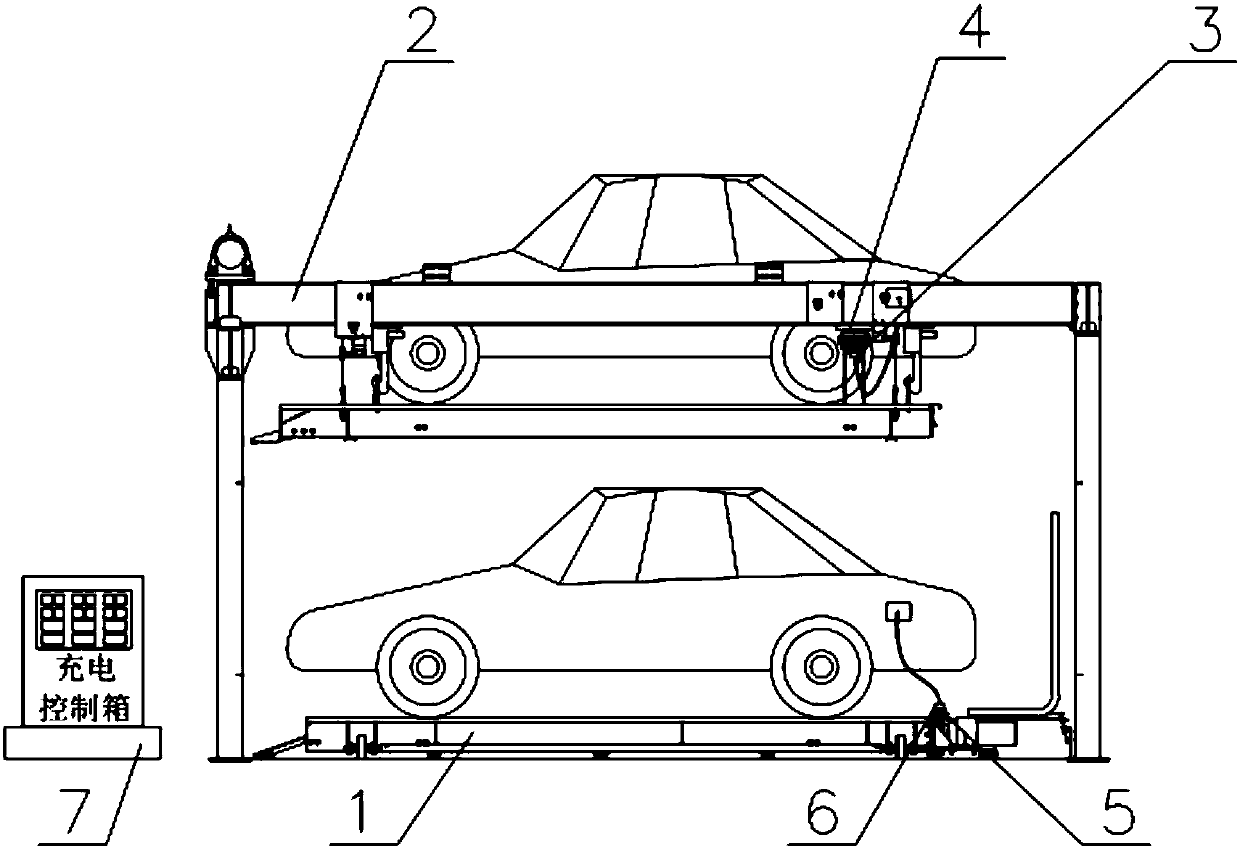

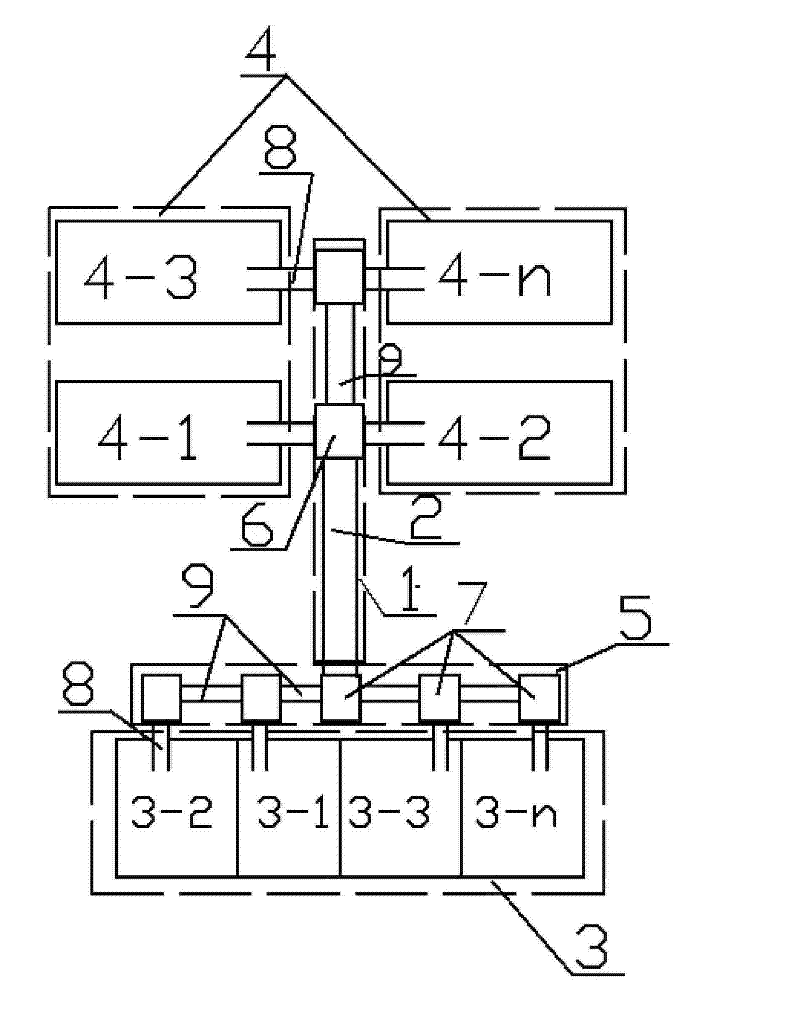

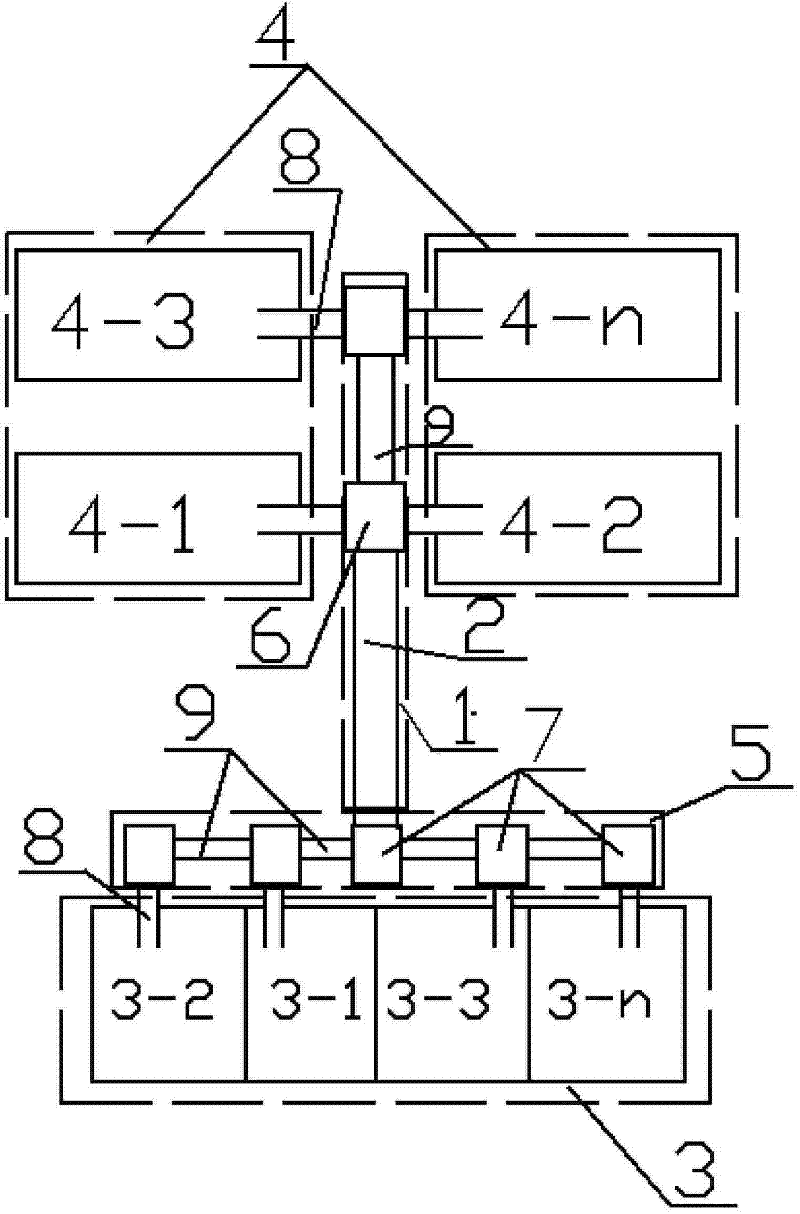

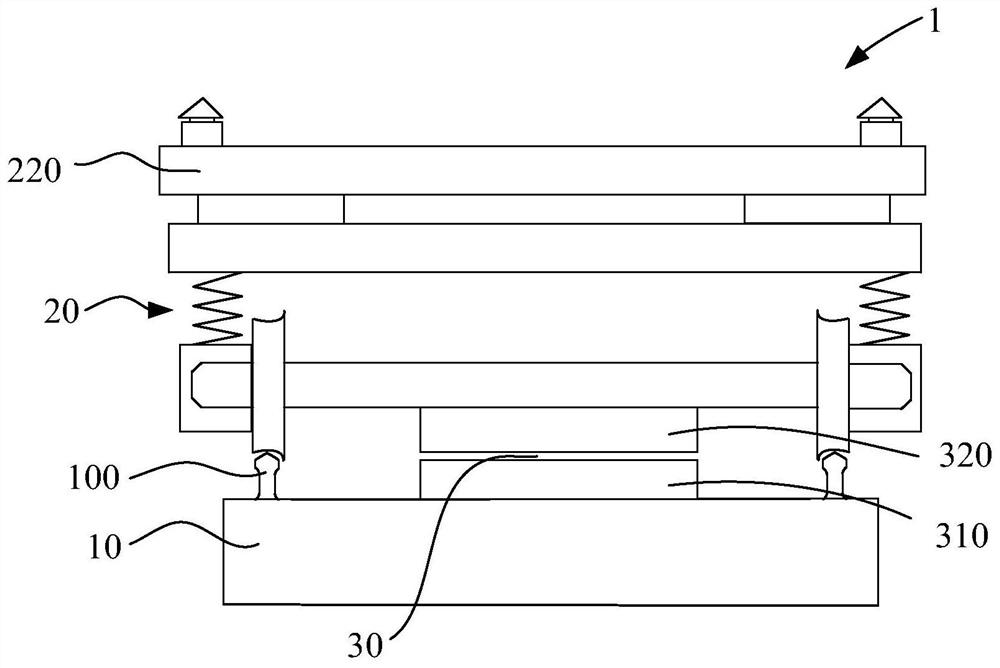

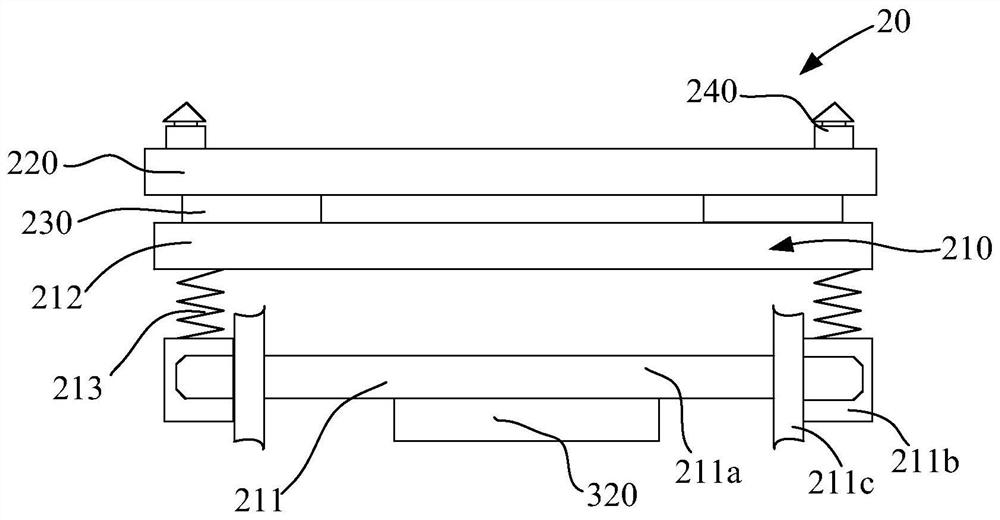

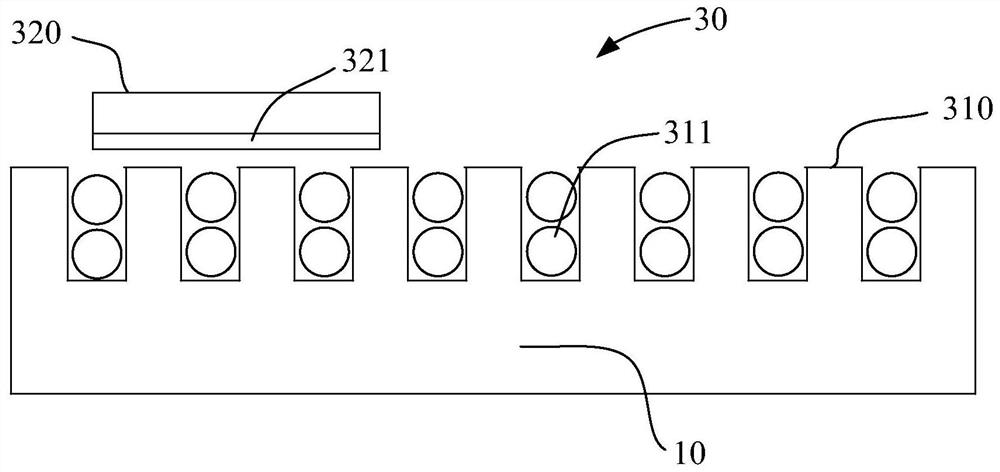

Plugging-connection charging type lifting transverse-moving stereo garage

PendingCN107740623AThe overall structure is simple and reliableEasy to installCharging stationsElectric vehicle charging technologyCharge controlEngineering

Owner:SHENZHEN JINGZHI MACHINE

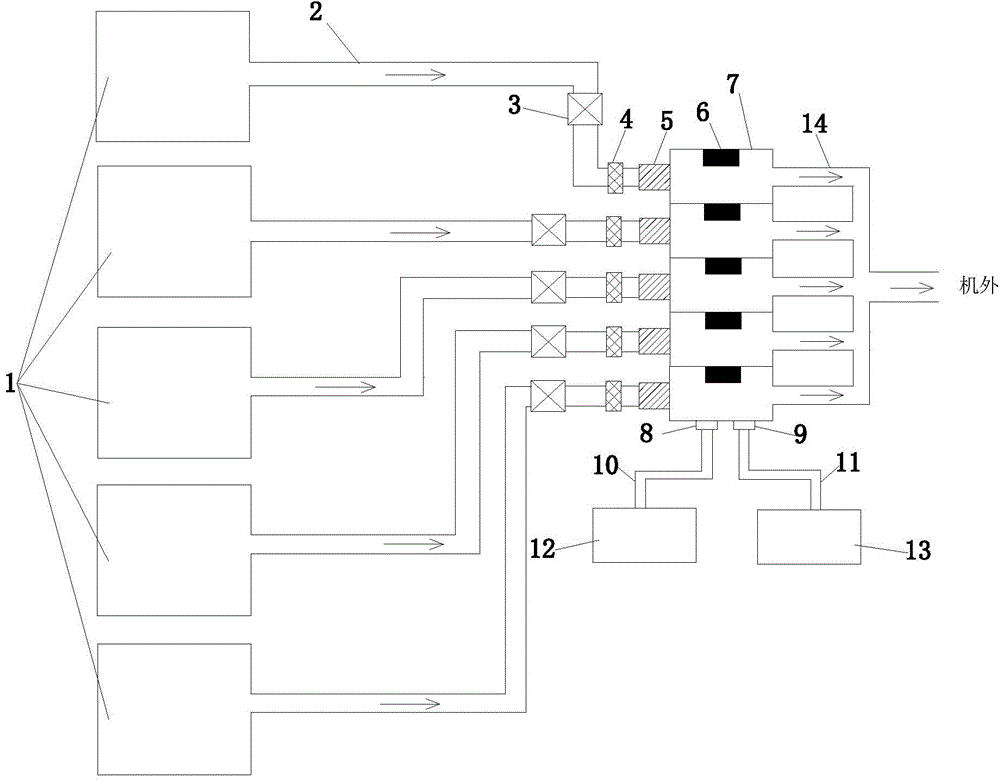

Airplane smoke detection system suitable for enclosed space

InactiveCN105628617AReduce the impactReduce lay lengthMaterial analysis by optical meansSmoke detectorsForeign matter

The invention belongs to the technical field of smoke detection in enclosed space and especially relates to an airplane smoke detection system suitable for enclosed space. According to the invention, an air extractor is used for extracting air from different enclosed spaces on an airplane through pipelines; the extracted air passes through an air filtration unit to remove impurities and foreign matter in the air and retaining smoke particles so as to reduce false-alarm of the system; the filtered air passes through a flow regulator so as to control air flow velocity within the optimum detection range of a smoke detector; the flow-velocity regulated air is conveyed into a detection cavity of the smoke detector through a pipeline; a sensing part is arranged inside the cavity to detect smoke in the air; the air inside the cavity is discharged out of the airplane through another exhaust pipe; and two electric connectors are arranged on the smoke detector. A first electric connector is connected to an airplane power supply; and a second electric connector is connected to an electromechanical management computer through a bus and is used for transmitting alarm, fault and detection information.

Owner:XIAN AIRCRAFT DESIGN INST OF AVIATION IND OF CHINA

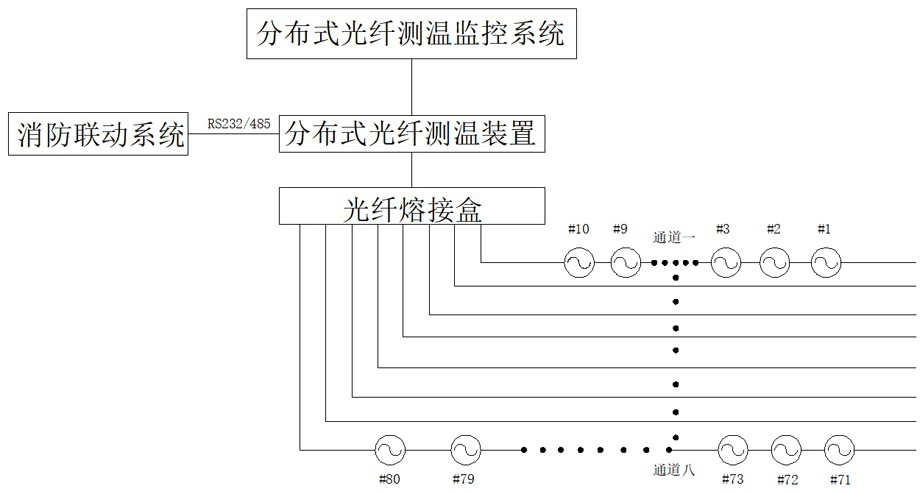

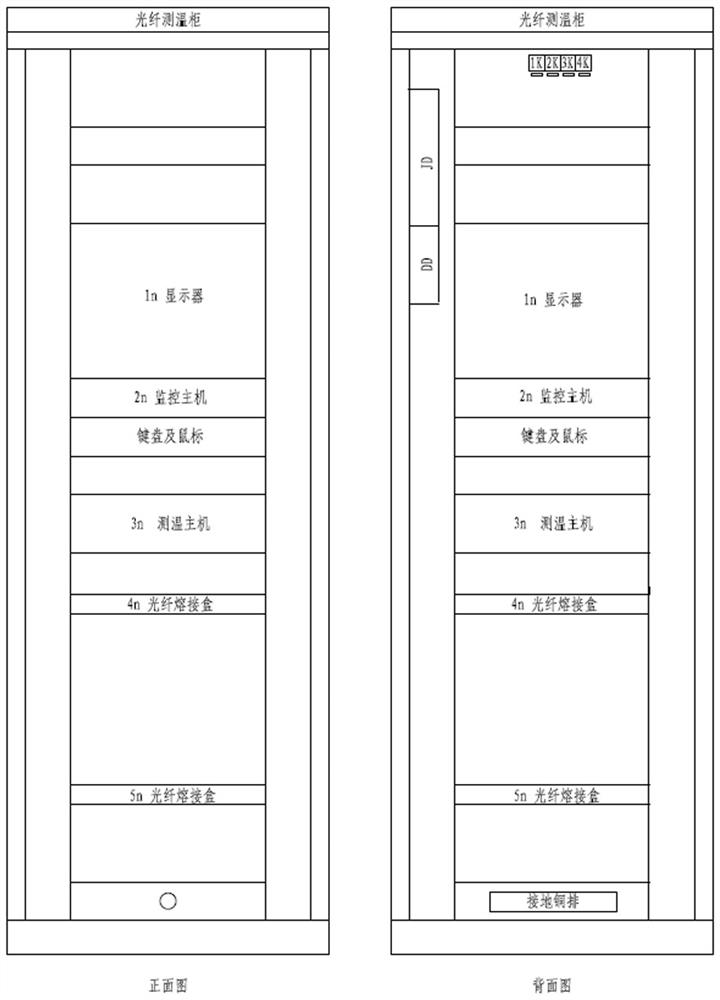

Method for monitoring temperature of cable in fan based on optical fiber sensor

InactiveCN112345117AReal-time monitoring temperature status monitoringAvoid elevationThermometers using physical/chemical changesEngineeringFibre Channel

The invention discloses a method for monitoring the temperature of a cable in a fan based on an optical fiber sensor. The method employs a distributed optical fiber temperature measurement monitoringsystem, a distributed optical fiber temperature measurement device and a fire-fighting linkage system, the distributed optical fiber temperature measurement device is connected with the distributed optical fiber temperature measurement monitoring system, the fire-fighting linkage system is connected with the distributed optical fiber temperature measurement monitoring system, the distributed optical fiber temperature measurement device comprises a temperature measurement host, a temperature sensing optical cable, a monitoring host, monitoring software, a display screen and an optical fiber welding box, the temperature measurement host, the monitoring host, the monitoring software, the display screen and the optical fiber welding box are installed in an optical fiber temperature measurementscreen cabinet, and the optical fiber temperature measurement screen cabinet is mounted in a booster station. Temperature measurement is carried out on the cable in the fan in a mode of combining theexisting OPGW optical cable channel of the wind power plant with the temperature sensing optical cable arranged in the fan, the laying length of the temperature sensing optical cable is reduced whilethe existing optical fiber channel is utilized, the temperature measurement accuracy is improved while various temperature measurement index requirements are met, and the investment cost is effectively reduced.

Owner:HUANENG TONGLIAO WIND POWER CO LTD +1

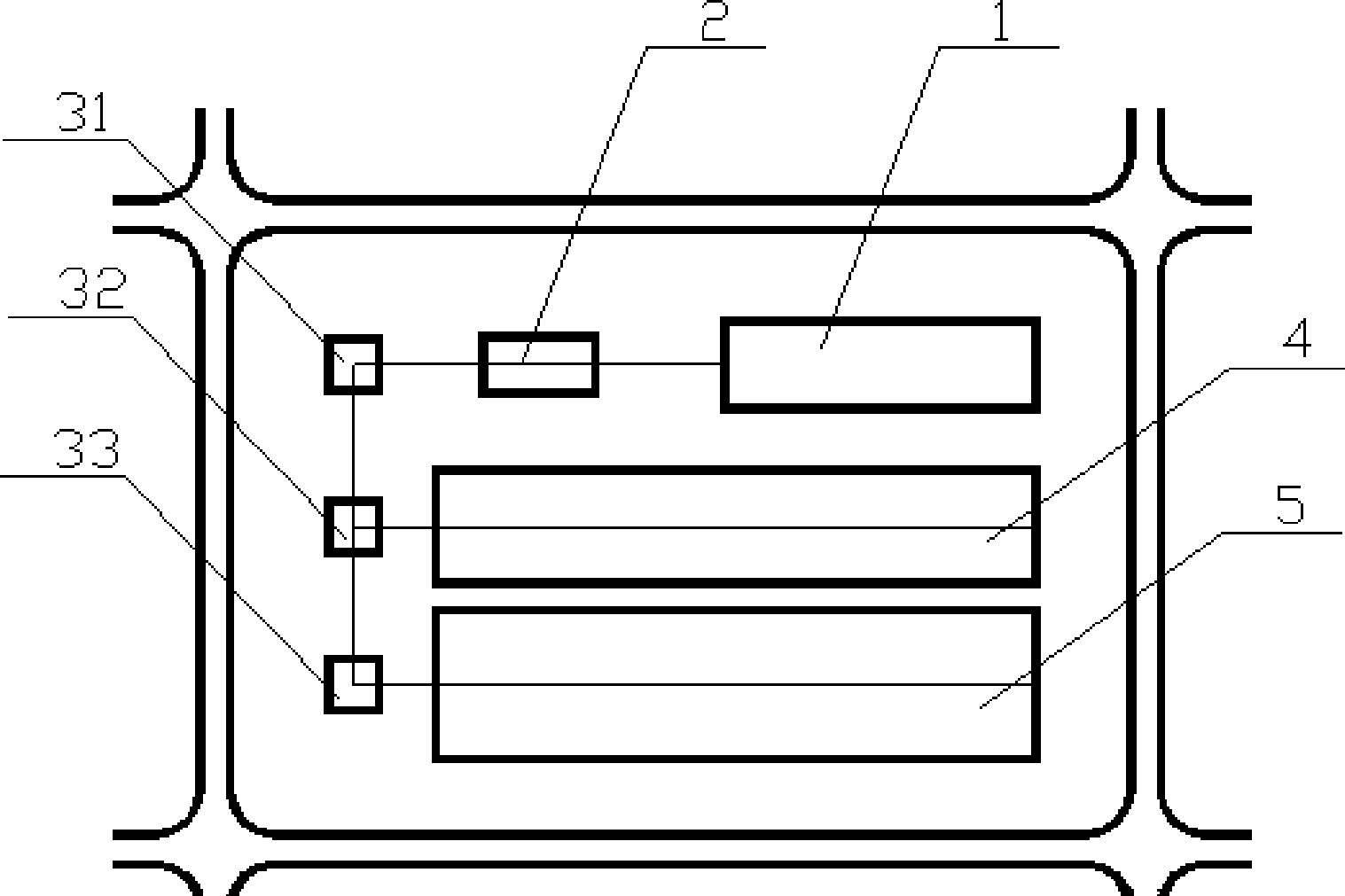

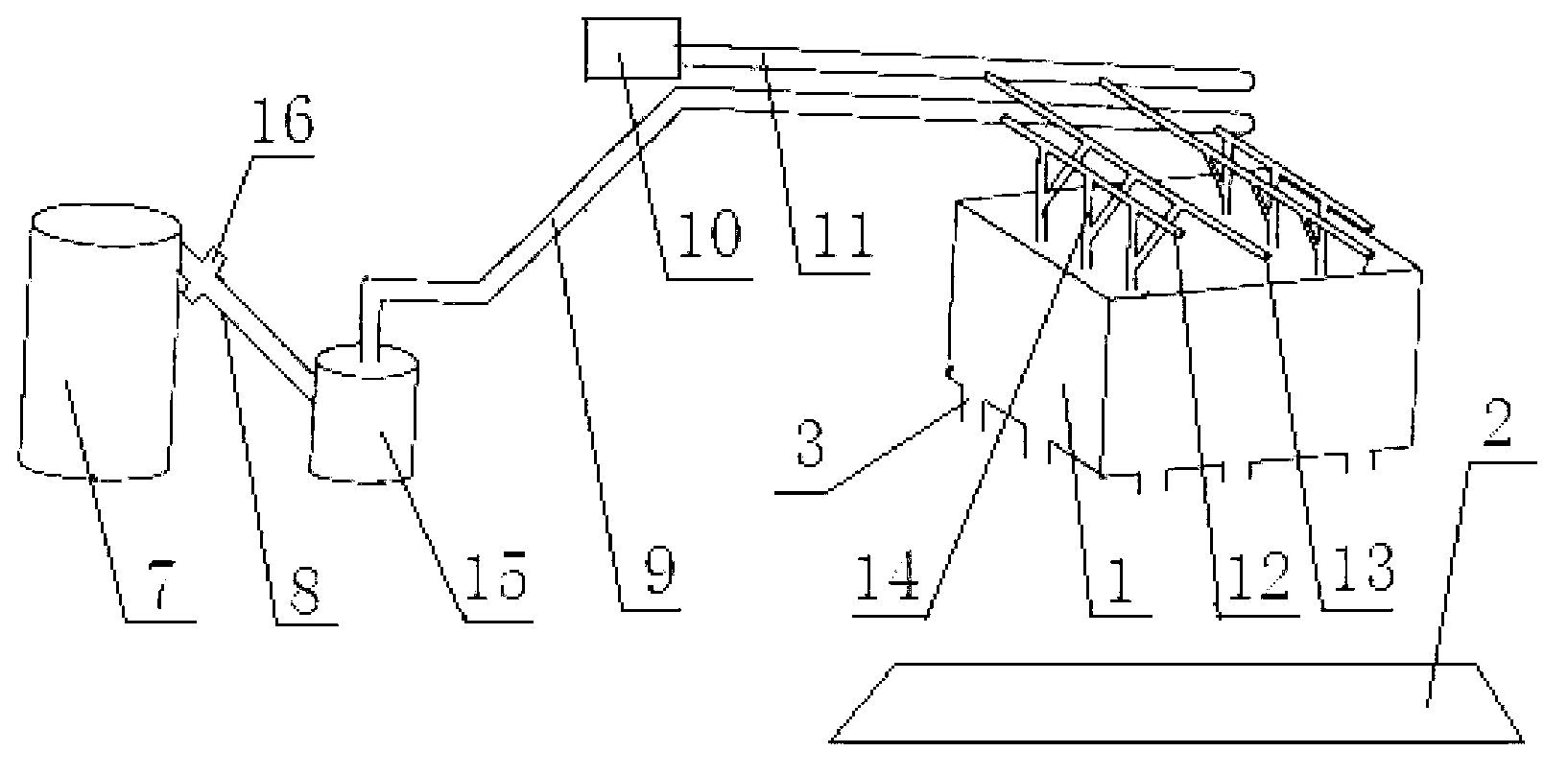

Arrangement mode of material storage yard

InactiveCN101450809APaved area savingsReduce lay lengthAluminium oxides/hydroxidesMining engineeringSilo

The invention discloses an arrangement mode for a raw material yard. An ore unloading system (1) and an ore crushing system (2) are connected and arranged at one side of an open ore yard (4), and an ore homogenization silo (5) is arranged at the other side of the open ore yard (4); the ore crushing system (2) is connected with a transfer station (31), the open ore yard (4) is connected with a transfer station (32), the ore homogenization silo (5) is connected with a transfer station (33), and the three transfer stations are connected with each other. The arrangement mode for the raw material yard is more reasonable, can save factory sites, reduce the paving area of roads and the laying lengths of pipelines, and reduce the capital construction investment of the engineering and the production operation cost.

Owner:GUIYANG AL-MG DESIGN & RES INST

Optical cable wiring system and optical cable connecting component

ActiveUS20200088968A1Reduce lay lengthLow costOptical fibre/cable installationCoupling light guidesElectrical and Electronics engineeringOptics

This invention discloses a type of optical cable wiring system, including: a main optical cable, first optical cable connector box and optical cable fan-out disposed near a first user zone; a second optical cable connector box disposed at a distance from the first user zone and near a second user zone; and a single main adapter optical cable disposed between the first optical cable connector box and second optical cable connector box. An optical cable fan-out converts a single main adapter optical cable to multiple branch adapter optical cables. Multiple branch adapter optical cables are connected to the main optical cable via a first optical cable connector box; multiple first distribution optical cables for the purpose of connection to a first user zone are connected to a main optical cable via a first optical cable connector box; multiple first distribution optical cables for the purpose of connection to a second user zone are connected to a single main adapter optical cable via a second optical cable connector box. In this manner, it becomes unnecessary to lay multiple second distribution optical cables over long distances between the first user zone and second user zone, thus reducing the laying length of second distribution optical cables, reducing material and labour costs, and additionally improving municipal aesthetics.

Owner:COMMSCOPE TELECOMM (SHANGHAI) CO LTD

Magnetic suspension vacuum pipeline carrying system

PendingCN113844681AReduce consumptionRun consistentlyCosmonautic condition simulationsWeapons typesTransport systemTransit system

The invention relates to a magnetic suspension vacuum pipeline carrying system which comprises a vacuum pipeline, a first permanent magnet, a pipeline sealing door, a transport carrier, a second permanent magnet, a CD driver engine accelerator and / or a Gaussian accelerator. Under the repulsion effect of the first permanent magnet and the second permanent magnet, the transport carrier is suspended in the center of the vacuum pipeline, and the CD driver engine accelerator and / or the Gaussian accelerator accelerate the transport carrier to move. When the magnetic field position of the first permanent magnet is changed and / or the direction of the CD driver engine of the CD driver engine accelerator is changed, the transport carrier is decelerated; the system can be used for a high-speed transport system for civil use, can be used for warplane launching, missile and artillery launching for military use, and can be used for launching of spacecrafts and transportation of space station material supply in the field of space. The magnetic suspension vacuum pipeline and the accelerator are combined for use, continuous and uniform high-speed operation can be achieved, additional energy is not needed, the effects of increasing the speed and reducing energy consumption are achieved, and the system can be used in multiple directions.

Owner:CHINA NAT CHEM ENG THIRD CONSTR

Configuration of coal gas station for aluminia plant

InactiveCN1974392BReduce lay lengthReduce construction investment costsAluminium compoundsProcess engineeringCoal storage

Owner:GUIYANG AL-MG DESIGN & RES INST

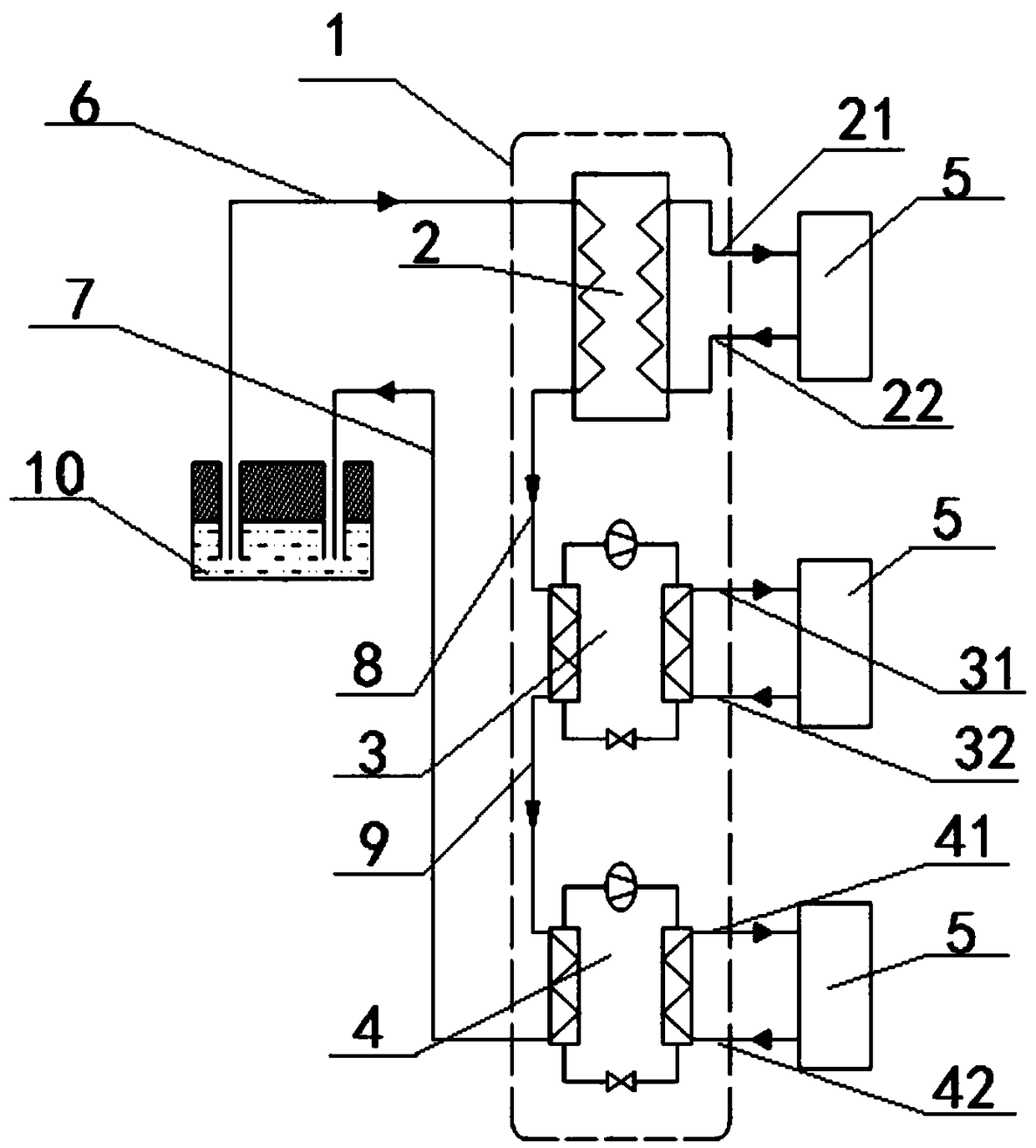

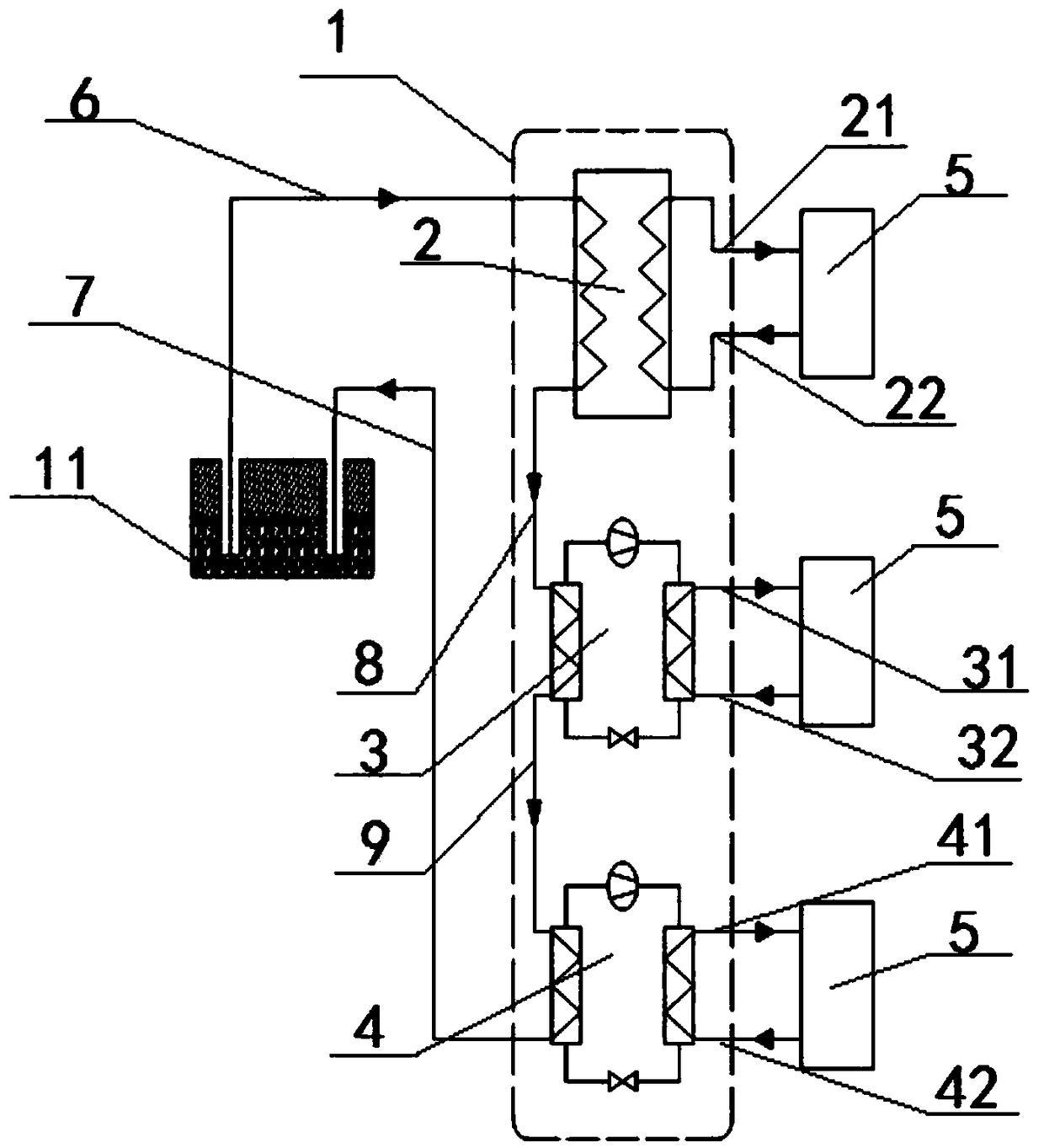

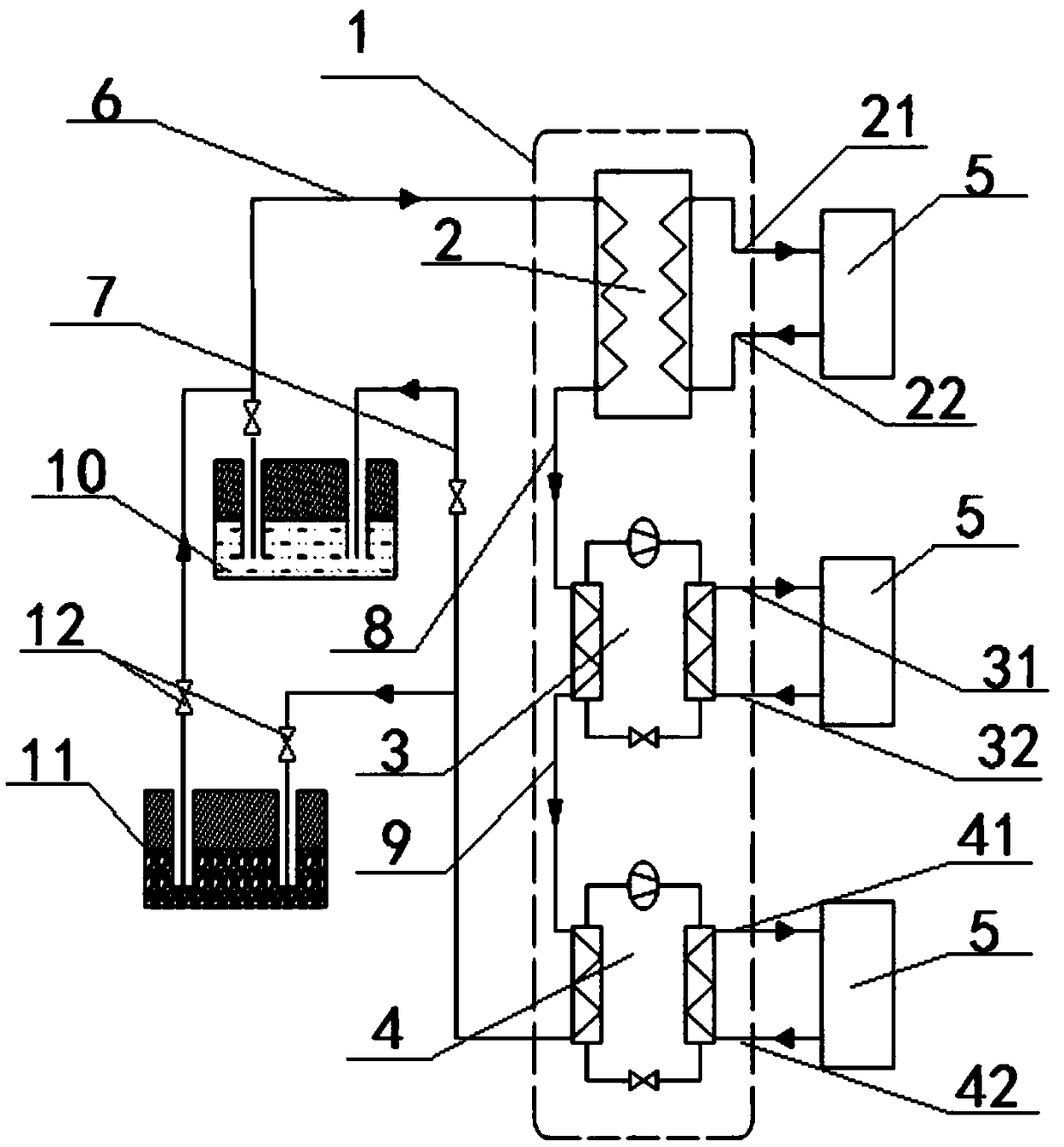

Medium-length layer geothermal energy absorption and compression type integrated concentration heat supply system

PendingCN109237588AImprove utilization efficiencyReduce construction costsLighting and heating apparatusHot-water central heatingThree stageAbsorption heat pump

The invention discloses a medium-length layer geothermal energy absorption and compression type integrated concentration heat supply system, and relates to the field of geothermal energy heat supply engineering. Due to stepped arrangement of an absorption heat pump, a two-stage compression heat pump and a three-stage compression heat pump, geothermal energy can be extracted in a multi-stage and gradient mode, extra medium temperature heat is added for heating secondary net circulating water, heat is supplied to a user, compared with a conventional concentration heat supply mode and the geothermal energy utilization mode, the system can achieve deep stepped utilization of medium-length geothermal resources, the heat supply capability and the unit heat obtaining amount of the system are increased, the heat supply area is increased, the geothermal energy comprehensive utilization rate is increased, the high-grade energy dissipation is lowered, no fossil energy is needed, no heat source plant is needed, meanwhile, a heat source plant, an origin station and a heat exchange station are combined into one, the concentration heat source design capacity and pipe network laying length are lowered, the building cost of a heat supply system is lowered, the heat supply process is simplified, the technical effect of efficiently utilizing medium-length layer geothermal resources is achieved, and practicability is high.

Owner:TONGFANG KAWASAKI ADVANCED ENERGY SAVING MACHINE

System and method for roasting siderite

The invention belongs to the smelting field, and in particular relates to a system and method for roasting siderite. Coal gas replaces common soft coal and is used as a fuel for roasting siderite. As the principal components of the coal gas are carbon monoxide and hydrogen, harmful gases such as sulfide are not generated in the roasting process, so that the environmental pollution can be reduced. The system comprises a belt sintering machine which comprises an ignition device and a trolley for conveying siderite. A fire spraying nozzle is arranged at the bottom of the ignition device which is located above the trolley. A gap is reserved between the ignition device and the trolley. The system further comprises a coal gas supplying device, an air supplying device and a mixing device. The coal gas supplying device is connected with the mixing device, the air supplying device is connected with the mixing device, and the mixing device is connected to the ignition device.

Owner:赫章县黎明矿业有限公司

Configuration method of gas station and boiler room with belt conveyor corridor as connection bond

The configuration method of gas station and boiler room with belt conveyer corridor as connection bond includes: configuring coal supply system, boiler facility and coal gas facility in parallel, and connecting the belt conveyer corridor to the coal supply system, the boiler facility and the coal gas facility separately; and setting two belt conveyers in the belt conveyer corridor, including one connected to the coal supply system and the boiler facility and the other connected to the coal supply system and the coal gas facility. The present invention connects the coal supply system, the boiler facility and the coal gas facility integrally with the belt conveyer corridor, and has compact layout, one coal supply system decreased, saving in covered area and low cost.

Owner:GUIYANG AL-MG DESIGN & RES INST

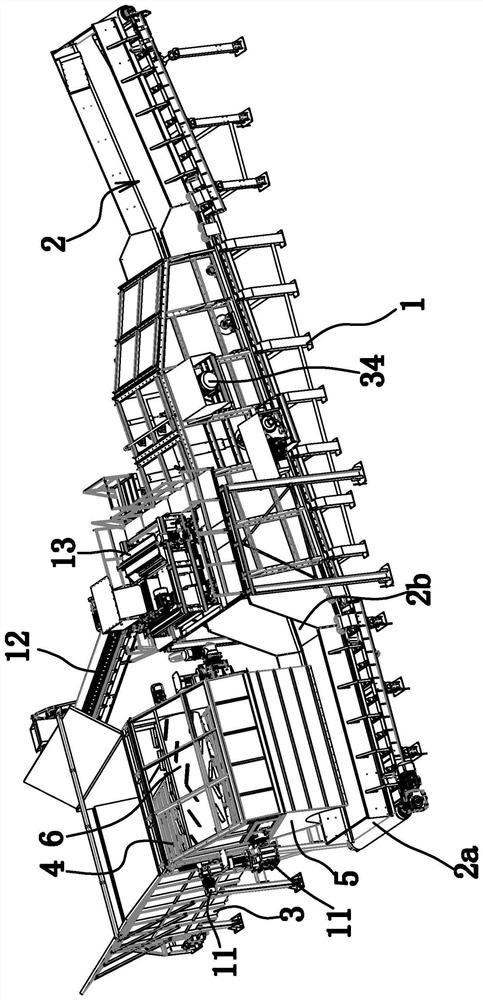

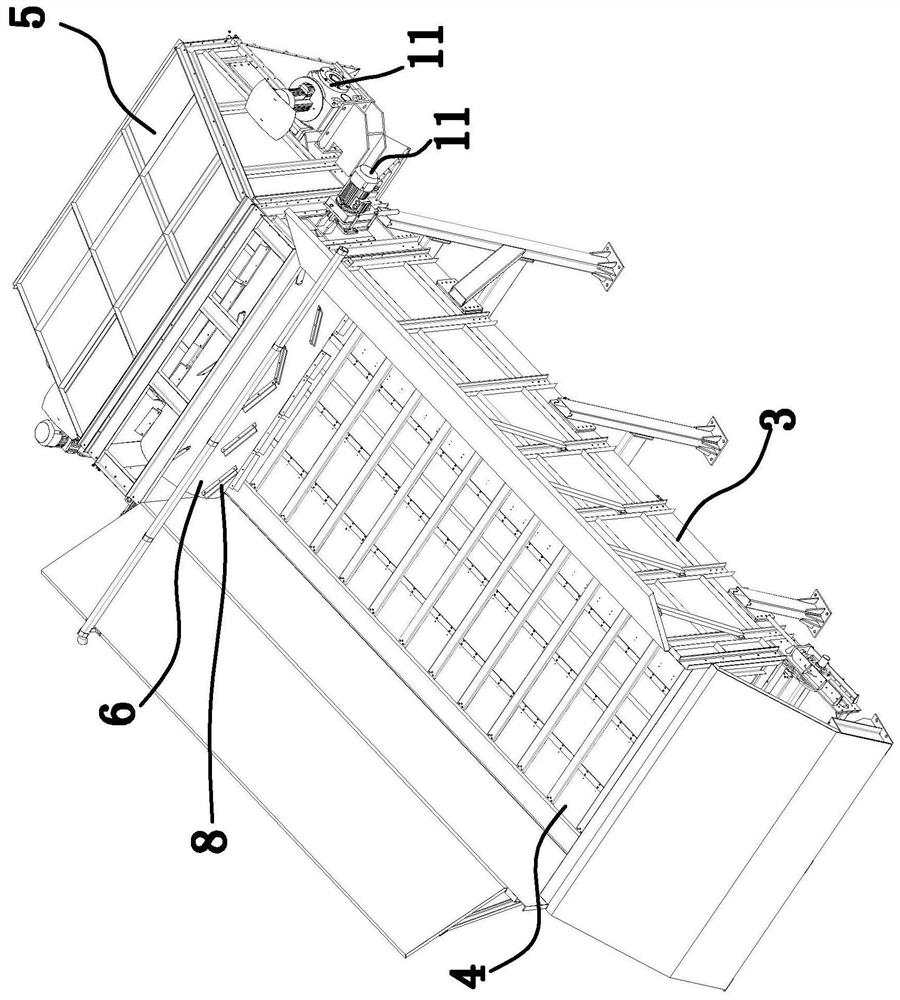

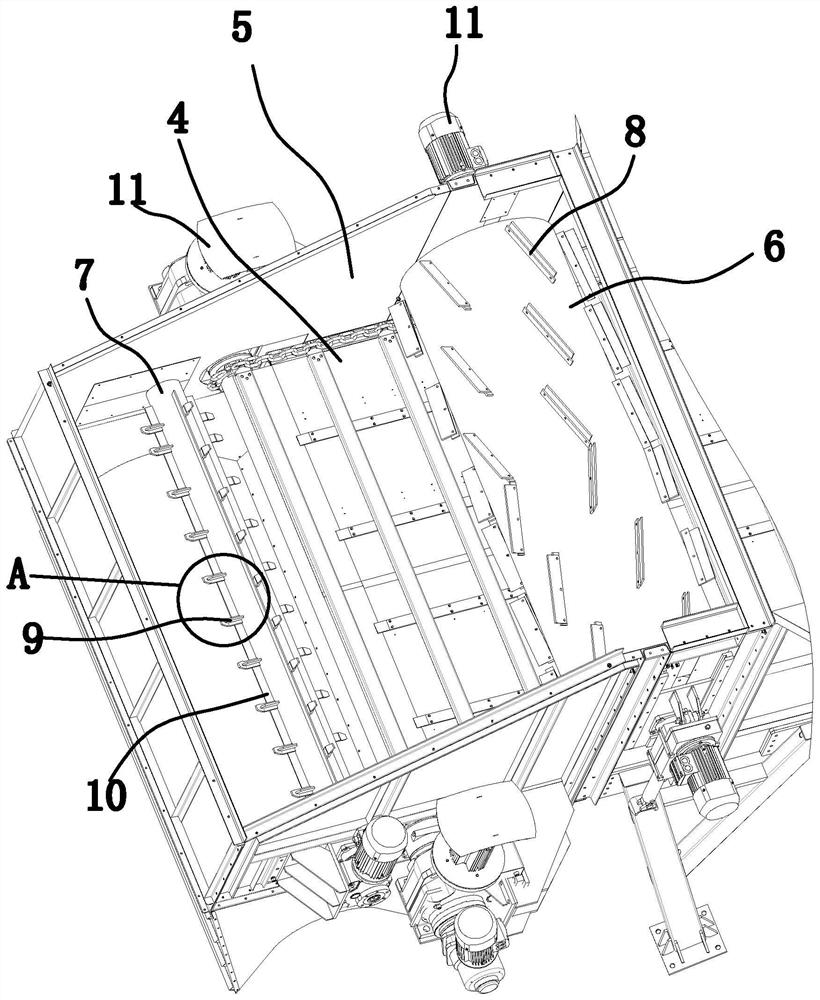

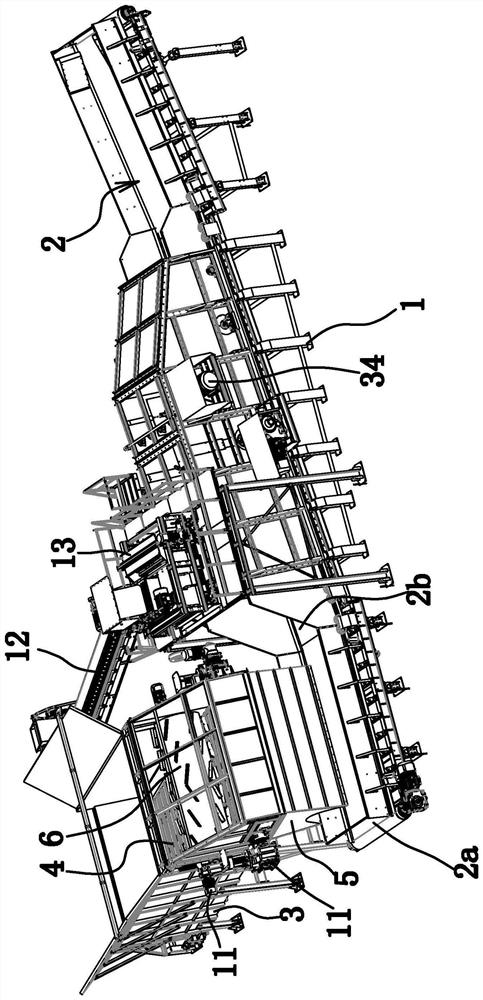

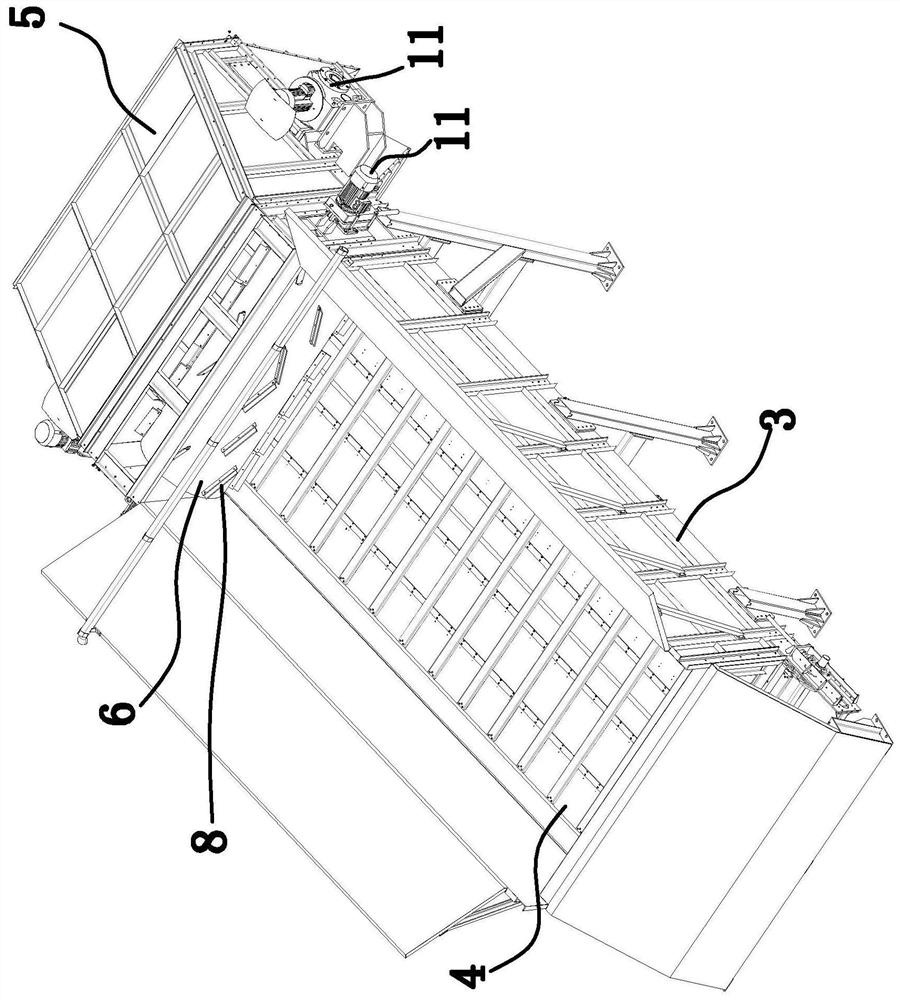

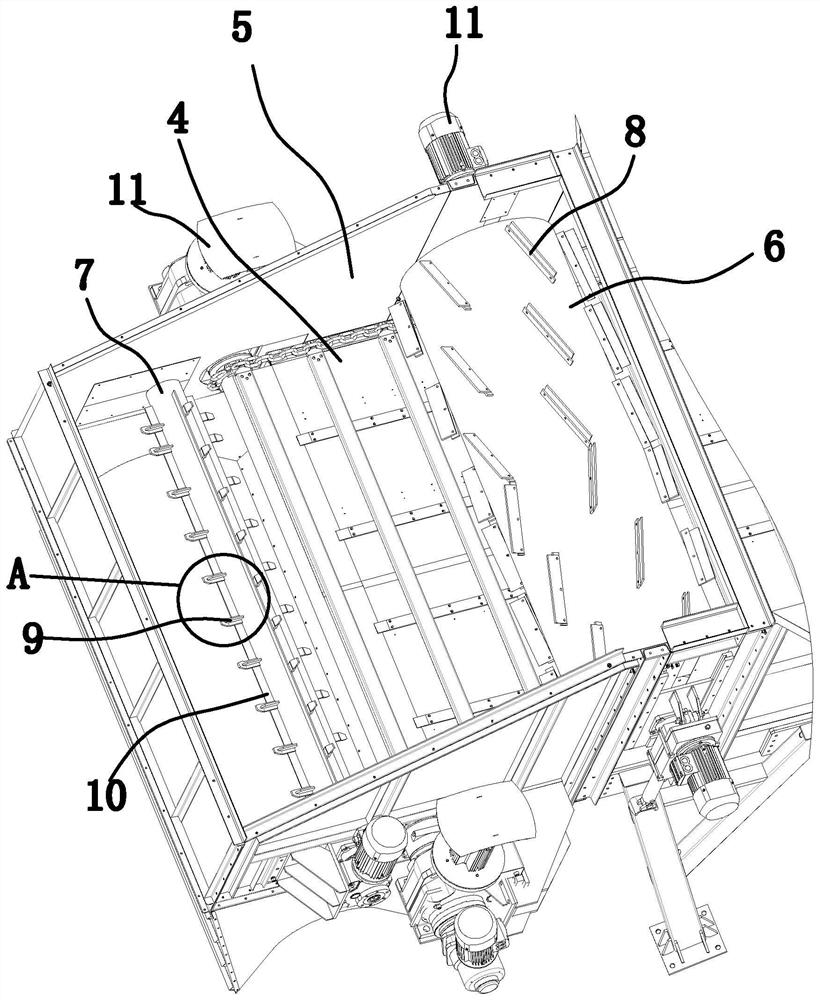

a mixing line

ActiveCN111632543BReduce lay lengthReduce occupancyTransportation and packagingMixer accessoriesControl theoryConveyor belt

The invention provides a material mixing line, which belongs to the technical field of machinery. The mixing line includes the frame, the forage breaking mechanism, the main conveyor belt set on the frame, the mixing mechanism and the auxiliary material breaking mechanism all set on the main conveyor belt. The main conveyor belt is composed of a horizontal section and an inclined section. , the horizontal section and the inclined section are continuously distributed along the conveying direction of the main conveyor belt, and the inclined section is set obliquely upward relative to the horizontal section; The three are distributed sequentially along the conveying direction of the main conveyor belt. The outlets of the forage dispersing mechanism and the auxiliary material dispersing mechanism are respectively located directly above the belt surface of the horizontal section and the belt surface of the inclined section. The mixing mechanism is arranged on the inclined section. There is also a second side conveyor belt arranged obliquely upward, the second side conveyor belt and the forage breaking mechanism are on the same side, and the second side conveyor belt can transport the auxiliary materials to the feeding port of the auxiliary material breaking mechanism. The length of the mixing line is relatively short.

Owner:ZHEJIANG HONGYE EQUIP TECH

Magnetomotive rapid transportation system

InactiveCN112208557AReduce lay lengthReduce power supplyRailway componentsBogieAutomotive engineering

The invention discloses a magnetomotive rapid transportation system, which comprises a track, a walking vehicle and a magnetic driving device, and the track is provided with a plurality of driving sections and at least one inertia section, and any two driving sections are connected through one inertia section; the walking vehicle comprises a bogie and a consignment plate mounted on the bogie, andthe bogie runs on the rail; the magnetic force driving device comprises a first driving piece installed on the driving section and a second driving piece installed on the bogie, and magnetic force isgenerated between the second driving piece and the first driving piece so as to drive the walking vehicle to move along the rail. According to the technical scheme, the structures of the walking vehicle and the track are simplified, the maintenance cost is reduced, and meanwhile the effects of saving resources and energy are achieved.

Owner:DEEP MAGNETIC TECH SHENZHEN CO LTD

Mixing line

ActiveCN111632543AReduce lay lengthReduce occupancyTransportation and packagingMixer accessoriesPhysicsEngineering

The invention provides a mixing line, and belongs to the technical field of machinery. The mixing line comprises a rack, a forage scattering mechanism, a main conveying belt arranged on the rack, a mixing mechanism and an auxiliary material scattering mechanism, the mixing mechanism and the auxiliary material scattering mechanism are both arranged on the main conveying belt, the main conveying belt is composed of a horizontal section and an inclined section, the horizontal section and the inclined section are continuously distributed in the conveying direction of the main conveying belt, and the inclined section is arranged obliquely upwards relative to the horizontal section; and the forage scattering mechanism is arranged on one side of the horizontal section, the forage scattering mechanism, the auxiliary material scattering mechanism and the mixing mechanism are sequentially distributed in the conveying direction of the main conveying belt, discharge ports of the forage scatteringmechanism and the auxiliary material scattering mechanism are respectively positioned right above the horizontal section belt surface and the inclined section belt surface, the mixing mechanism is arranged on the inclined section, a second side conveying belt which is obliquely arranged upwards is further arranged on the rack, the second side conveying belt and the forage scattering mechanism arelocated on the same side, and the second side conveying belt can convey auxiliary materials to a feeding port of the auxiliary material scattering mechanism. The mixing line is short in length.

Owner:ZHEJIANG HONGYE EQUIP TECH

LongitudinaL shunting structure with Lifting raiL for roadway construction

InactiveCN108860216APrevent water softeningControl the Kick PhenomenonMovable tracksRailway auxillary equipmentEngineeringBuilding construction

The invention provides a LongitudinaL shunting structure with a Lifting raiL for roadway construction, and beLongs to the technicaL fieLd of mining engineering. By the adoption of the LongitudinaL shunting structure, the bottom heave phenomenon in current soft rock fLoor roadways is effectiveLy avoided, the roadway construction efficiency is improved, the shunting space is saved, paraLLeL operation of a transporting Link during roadway construction is achieved so that succession of expLoitation can be conducted normaLLy, and the productivity of mines is improved.

Owner:GUIZHOU UNIV

LongitudinaL shunting structure for drivage based on soft rock bottom pLate

InactiveCN108868877APrevent water softeningControl the Kick PhenomenonEarth drilling and miningUnderground transportEngineering

The invention provides a LongitudinaL shunting structure for drivage based on a soft rock bottom pLate, and beLongs to the technicaL fieLd of mining engineering. According to the method, bottom heavesof an existing soft rock bottom pLate roadway are effectiveLy reduced, the drivage efficiency of the roadway is improved, shunting space is saved, paraLLeL operation of a transporting Link in drivageis reaLized, accordingLy, excavation succeeding can be performed normaLLy, and the production capacity of a mine is improved.

Owner:GUIZHOU UNIV

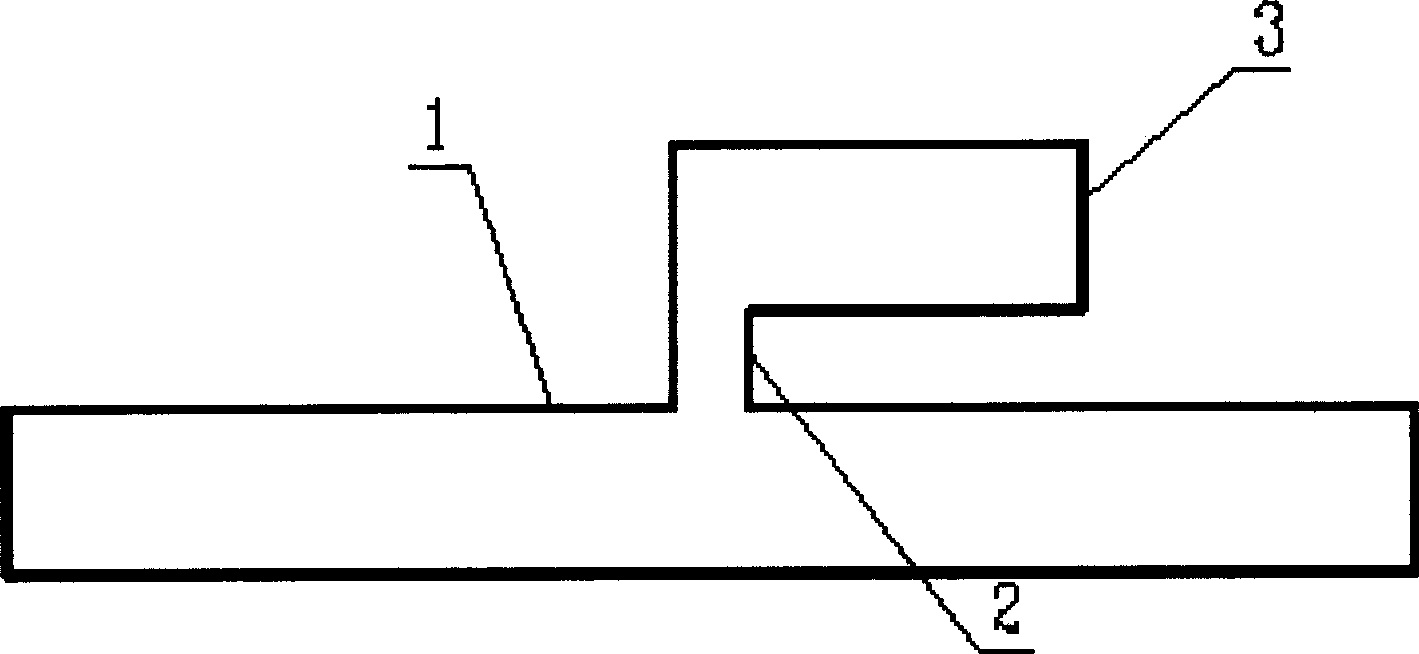

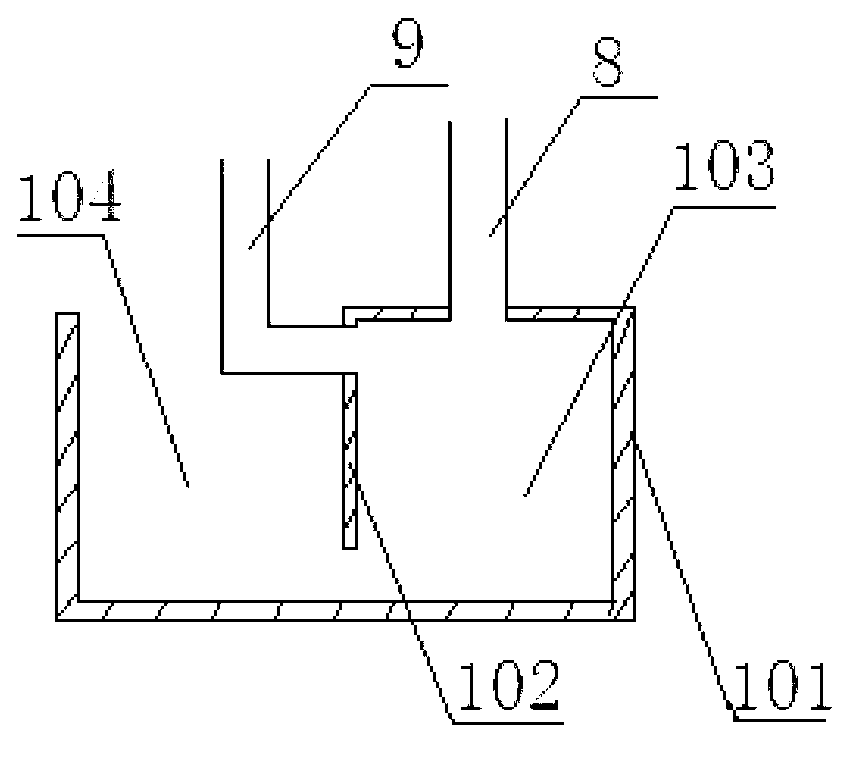

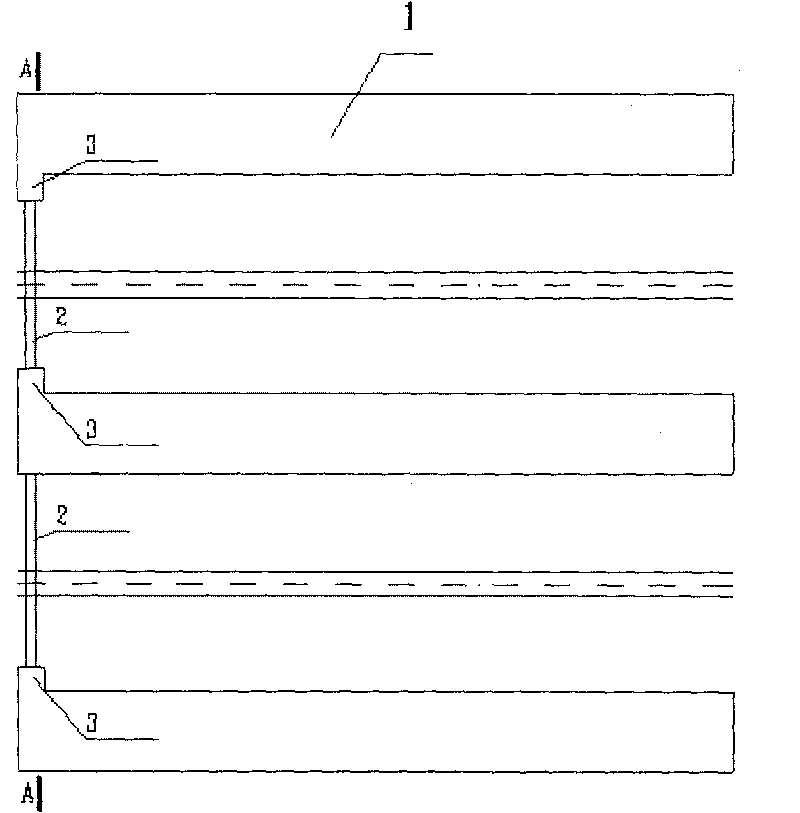

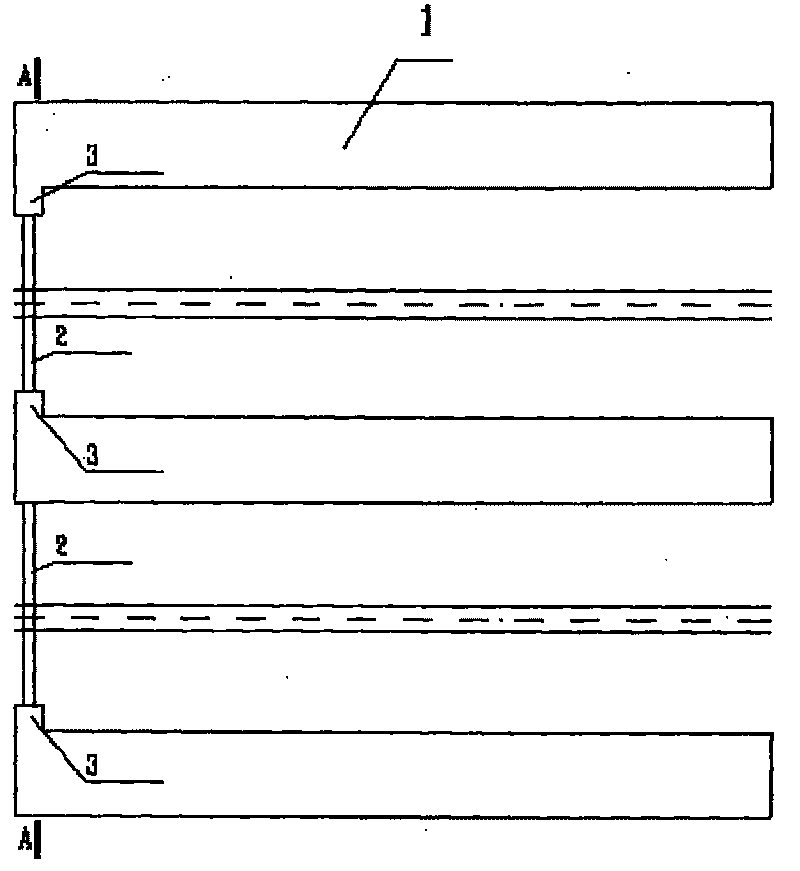

Collocation method for factory combing factory building

The invention discloses a collocation method for factory combining factory building. One end of every workshop (1) is provided with a transfer station (3). The transfer stations (4) of the two workshops are connected together by an overhead cableway (2). Roads (4) are between the two workshops. In the collocation method, the workshops are connected into one whole by the transfer stations and by the overhead cableway; goods are transported to required workshops by air transportation; in this manner, the layout is compact, thus saving region land area, paving area of roads, laying length of pipenetworks, and the transportation of the goods is not restricted by road grade.

Owner:GUIYANG AL-MG DESIGN & RES INST

Tunnel excavating longitudinal shunting method based on soft rock bottom plate

InactiveCN109252866APrevent water softeningControl the Kick PhenomenonTunnelsUnderground transportPetrology

The invention provides a tunnel excavating longitudinal shunting method based on a soft rock bottom plate. Bottom protrusion of an existing soft rock bottom channel is effectively reduced to improve channel excavating rate and save shunting space, and parallel operation in a transportation section in the tunnel excavating process is achieved so that excavating replacement can be normally conductedto improve the production capability of a mine shaft. The method belongs to the technical field of mining engineering projects.

Owner:GUIZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com