Configuration method of gas station and boiler room with belt conveyor corridor as connection bond

A technology of conveying belts and configuration methods, which is applied in the configuration field of carbon factory production combined workshops, can solve the problems of rising factory infrastructure investment and production and operation costs, enlarged factory land area, increased road paving area and pipeline laying length, etc., to achieve The effect of reducing infrastructure investment and production and operation costs, and compact layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

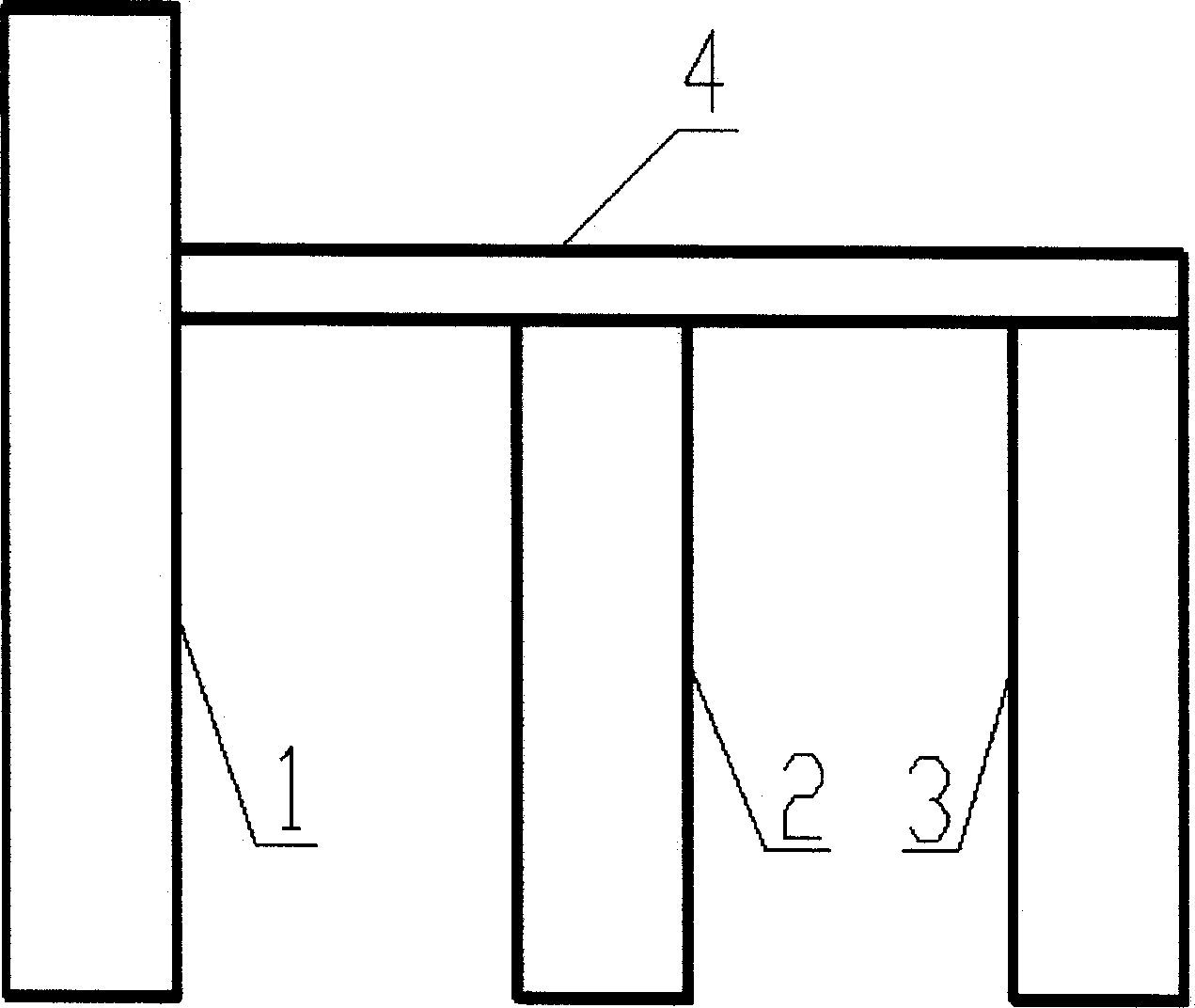

[0011] Embodiments of the present invention: according to the annual output of the carbon plant, determine the scale, specifications and various supporting facilities of the coal supply system 1, the boiler facility 2, the gas facility 3 and the conveyor belt gallery 4, and the coal supply system 1, the boiler facility 2 , gas facilities 3 are arranged in parallel, and the coal supply system 1, boiler facility 2, and gas facility 3 are connected by the conveyor belt gallery 4 to form an overall layout; the conveyor belt gallery 4 is connected to one end of the boiler facility 2 and the gas facility 3. Two belt conveyor lines are set in the belt gallery 4, one of which connects the coal supply system 1 and the boiler facility 2, and the other belt conveyor line connects the coal supply system 1 and the gas facility 3, forming a complete production system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com