Method for monitoring temperature of cable in fan based on optical fiber sensor

An optical fiber sensor and fan technology, which is applied in the electric power field, can solve the problems of missed reports of smoke and obstructions, susceptible to electromagnetic interference, and high false alarm rate, and achieves the effect of shortening the fault processing period, reducing the length of the installation, and reducing the investment cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

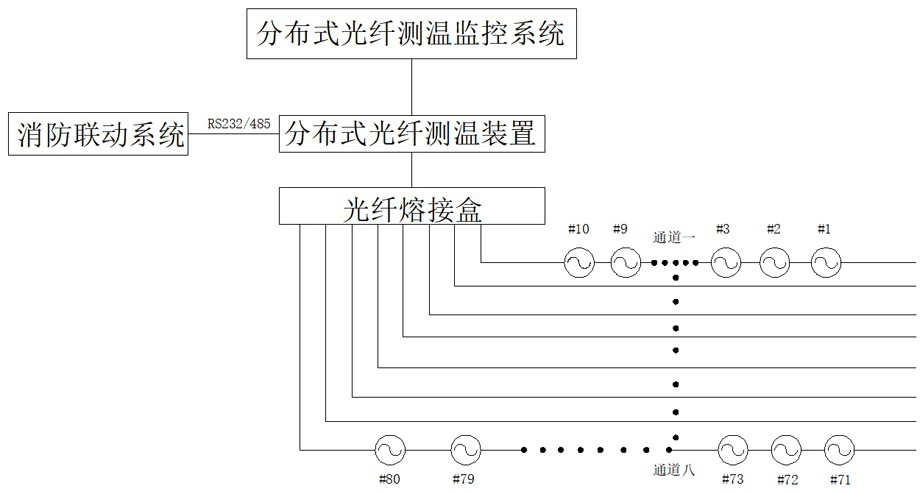

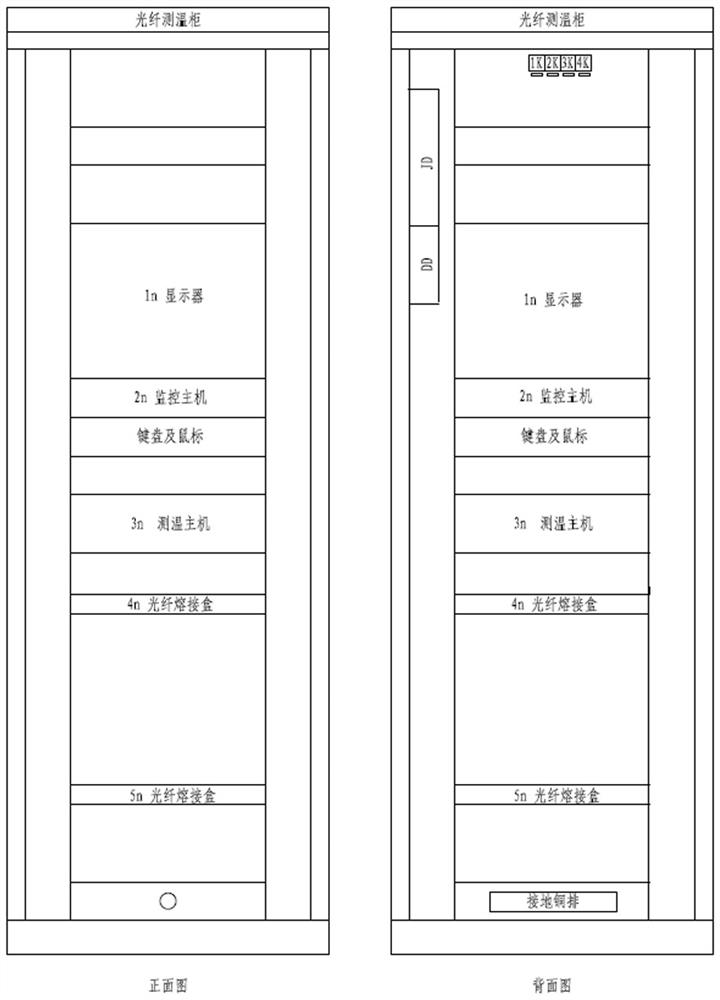

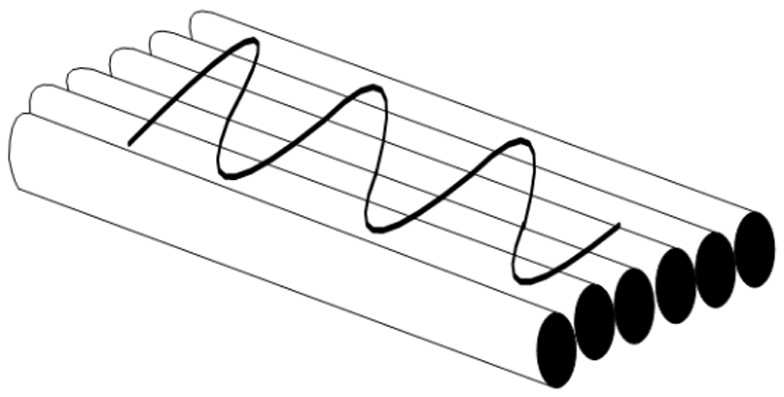

[0019] Such as Figure 1-4 As shown, the present invention provides a technical solution: a method for monitoring the temperature of cables in a fan based on an optical fiber sensor, including a distributed optical fiber temperature measurement and monitoring system, a distributed optical fiber temperature measurement device, and a fire linkage system. The temperature device is connected to the distributed optical fiber temperature measurement and monitoring system, and the fire linkage system is connected to the distributed optical fiber temperature measurement and monitoring system. The distributed optical fiber temperature measurement device includes a temperature measurement host, a temperature-sensing optical cable, a monitoring host, monitoring software, display screen a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com