Mixing line

A technology of mixing materials and fodder, which is applied in the direction of mixers, applications, gardening, etc., can solve the problem of long length of mixing line, and achieve the effect of improving mixing effect, reducing occupation and reducing laying length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

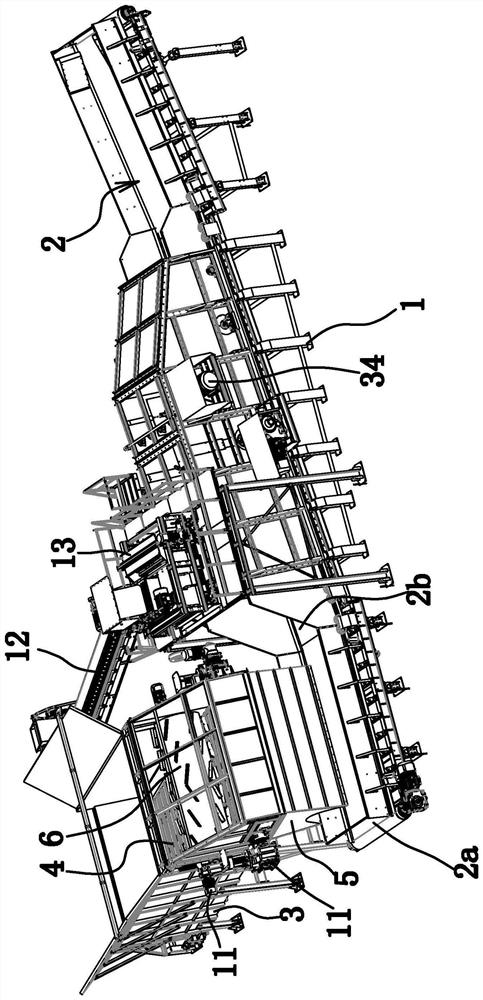

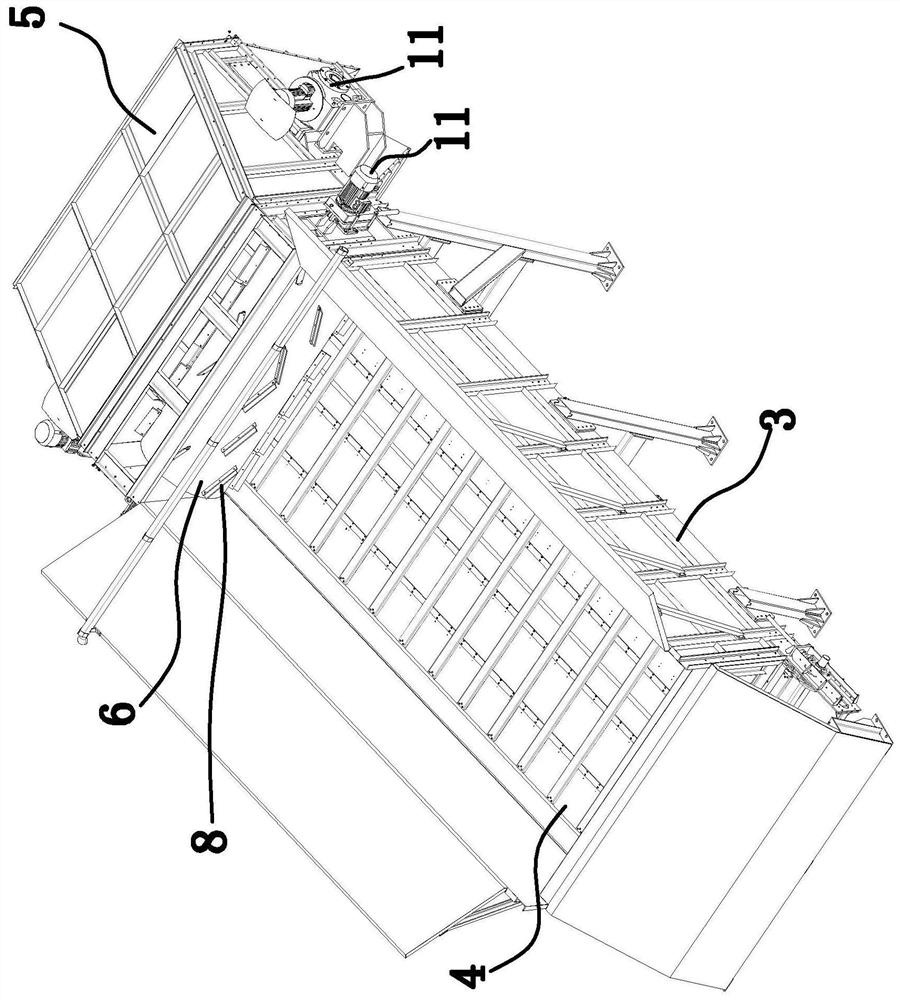

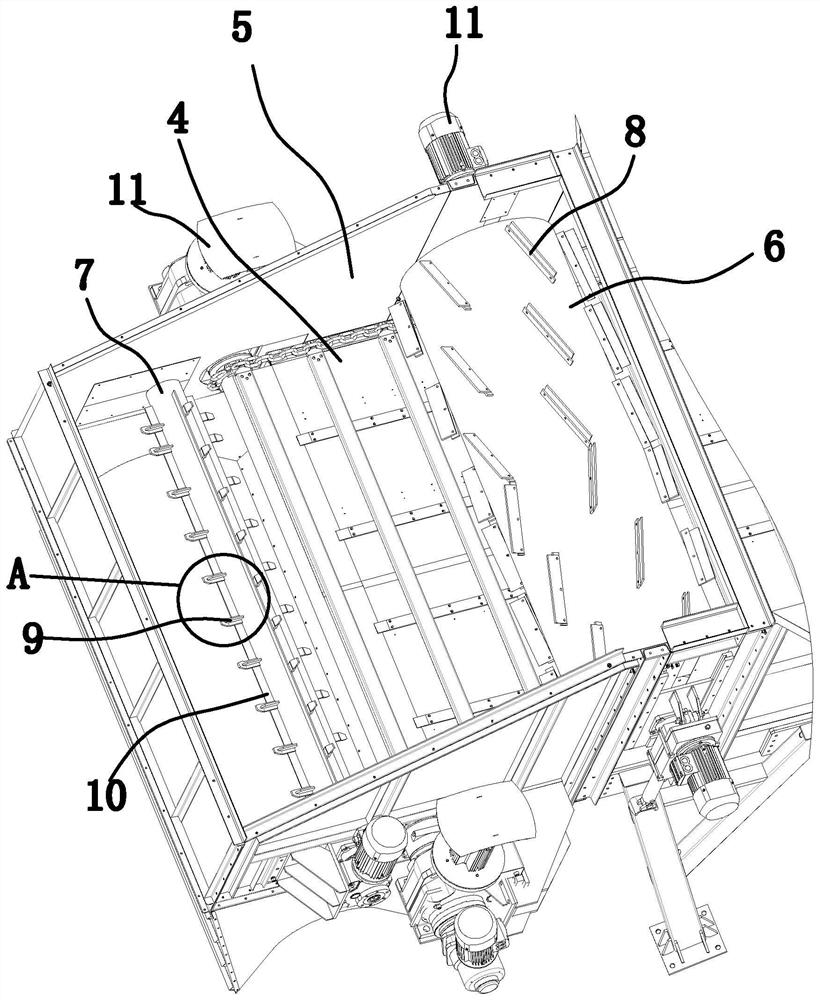

[0045] Such as figure 1 As shown, the mixing line includes a frame 1, a forage breaking mechanism, an auxiliary material breaking mechanism, a mixing mechanism for mixing forage and auxiliary materials, and a main conveyor belt 2 arranged on the frame 1, and the forage breaking mechanism The auxiliary material dispersing mechanism and the material mixing mechanism are distributed sequentially along the conveying direction of the main conveyor belt 2 .

[0046] Wherein, the main conveyor belt 2 is composed of a horizontal section 2a and an inclined section 2b, the horizontal section 2a and the inclined section 2b are continuously distributed along the conveying direction of the main conveyor belt 2, and the inclined section 2b is arranged obliquely upward relative to the horizontal section 2a. The forage breaking mechanism is arranged on one side of the horizontal section 2a, and the outlet of the forage breaking mechanism is directly above the belt surface of the horizontal se...

Embodiment 2

[0064] The structure and principle of this second embodiment are basically the same as that of the first embodiment. The difference is that the frame 1 includes an internally threaded pipe whose axis extends along the conveying direction of the side conveyor belt 12. There are two internally threaded pipes located at the conveying On both sides of the belt, a rod body is inserted into the two internally threaded pipes. The outer end of the rod protrudes from the internally threaded pipe and is fixedly connected with the baffle 17. The locking piece 21 is an external thread formed on the rod body, and the rod body and the internally threaded pipe pass through the internal thread Connected with external thread engagement.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com