Collocation method for factory combing factory building

A configuration method and plant technology, applied in the direction of industrial buildings, etc., can solve the problems of increased factory area, increased pipeline laying length, increased factory infrastructure investment and production and operation costs, and achieve the effect of compact layout and saving land area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

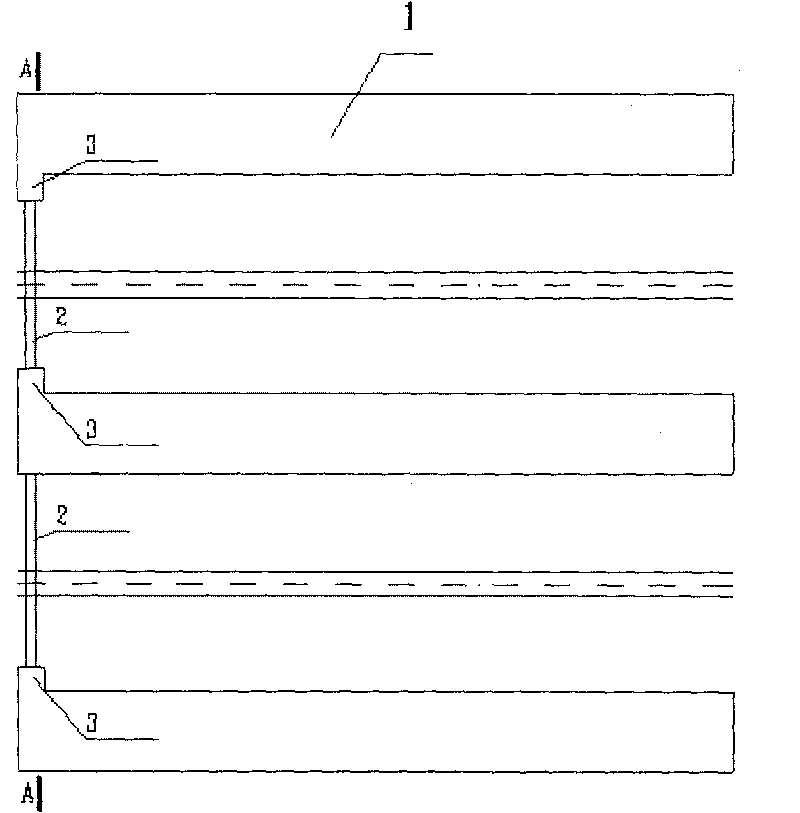

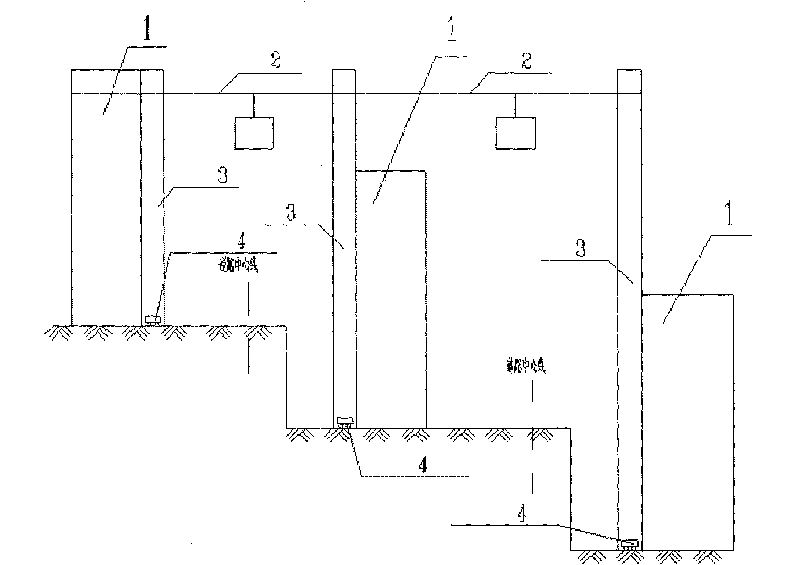

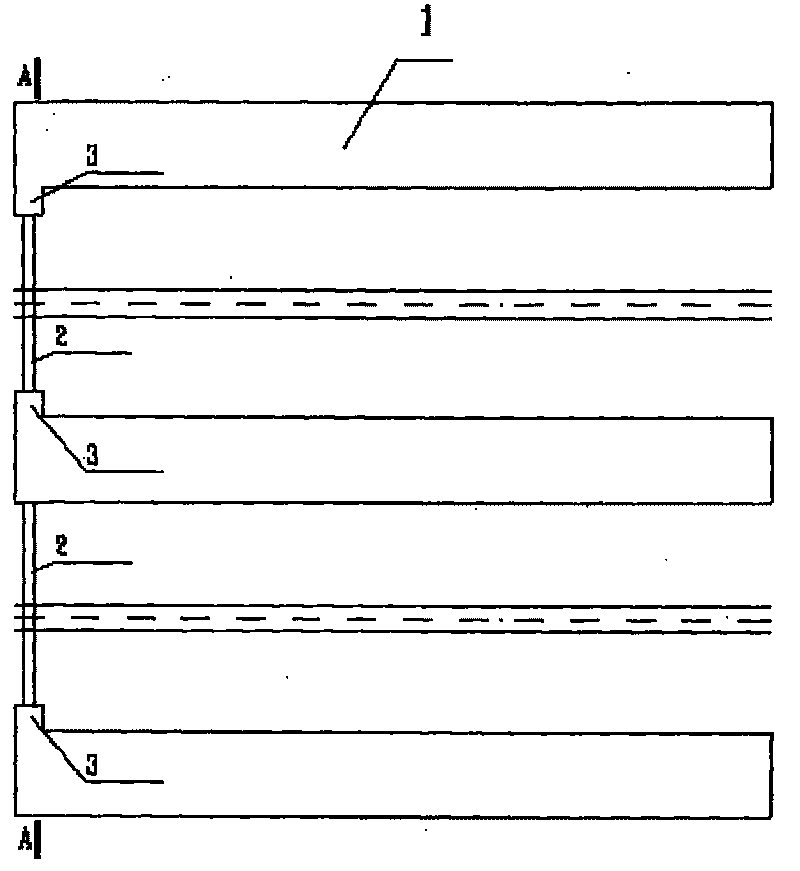

[0014] Embodiment of the present invention: the width between the workshops 1 is determined according to the national fire prevention code, the road width, and the width required by the comprehensive pipeline.

[0015] The vertical distance between the workshops 1 is determined according to the terrain conditions, the allowable slope of the road, the clearance between the bottom surface of the cargo box 6 of the aerial ropeway 2 and the road 4 .

[0016] Set up a transfer station 3 at one end of the workshop 1, connect the transfer stations of the two workshops with the aerial ropeway 2 (the transfer stations of N production workshops can be connected at the same time), and transport the goods in the workshop 1 to the other by air transportation workshop, and then use the lifting mobile platform 5 to deliver the goods to the designated location.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com