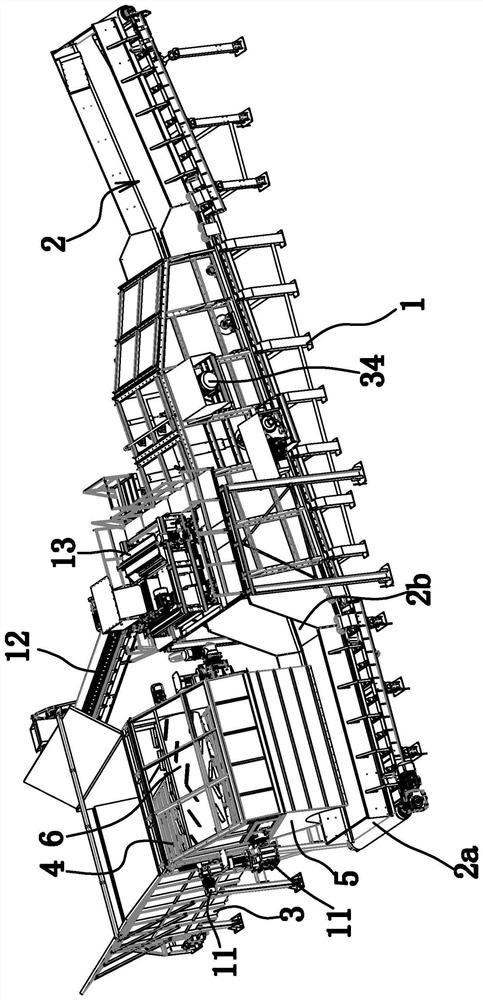

a mixing line

A technology for mixing materials and forages, applied in the directions of mixers, transportation and packaging, plant cultivation, etc., can solve the problems of long length of mixing lines, and achieve the effect of improving mixing effect, reducing laying length, reducing material waste and environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

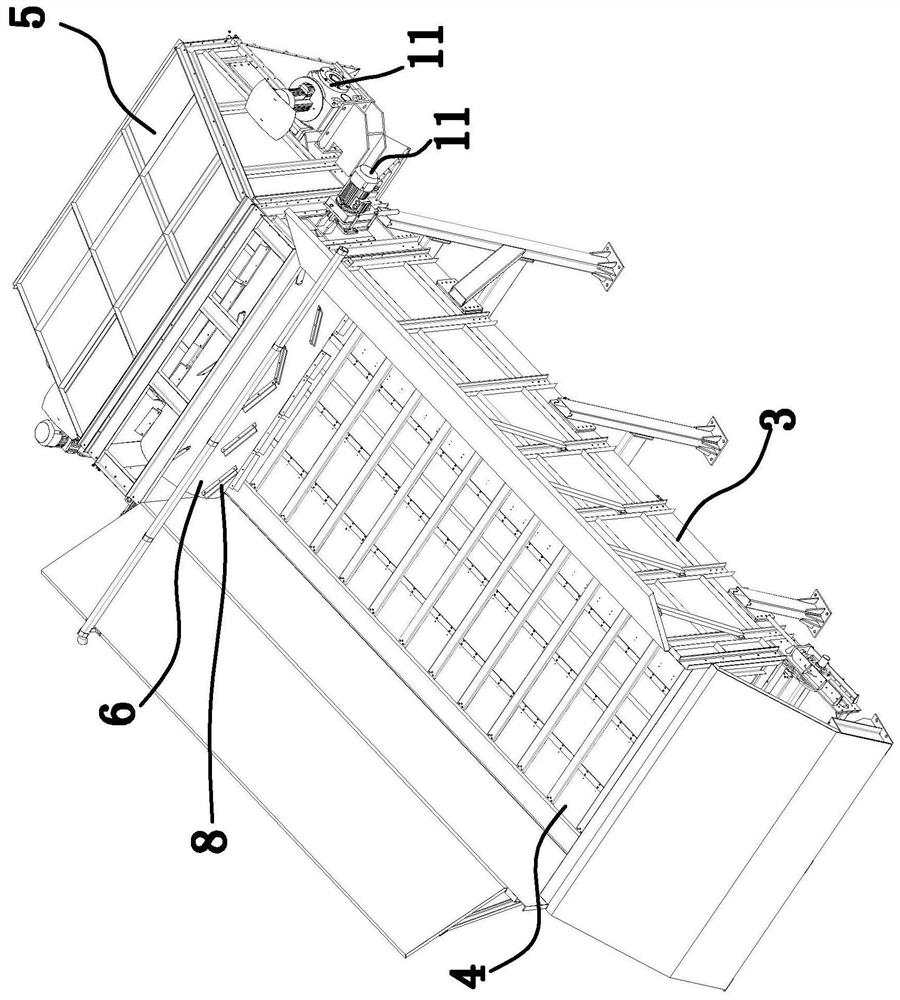

Examples

Embodiment 1

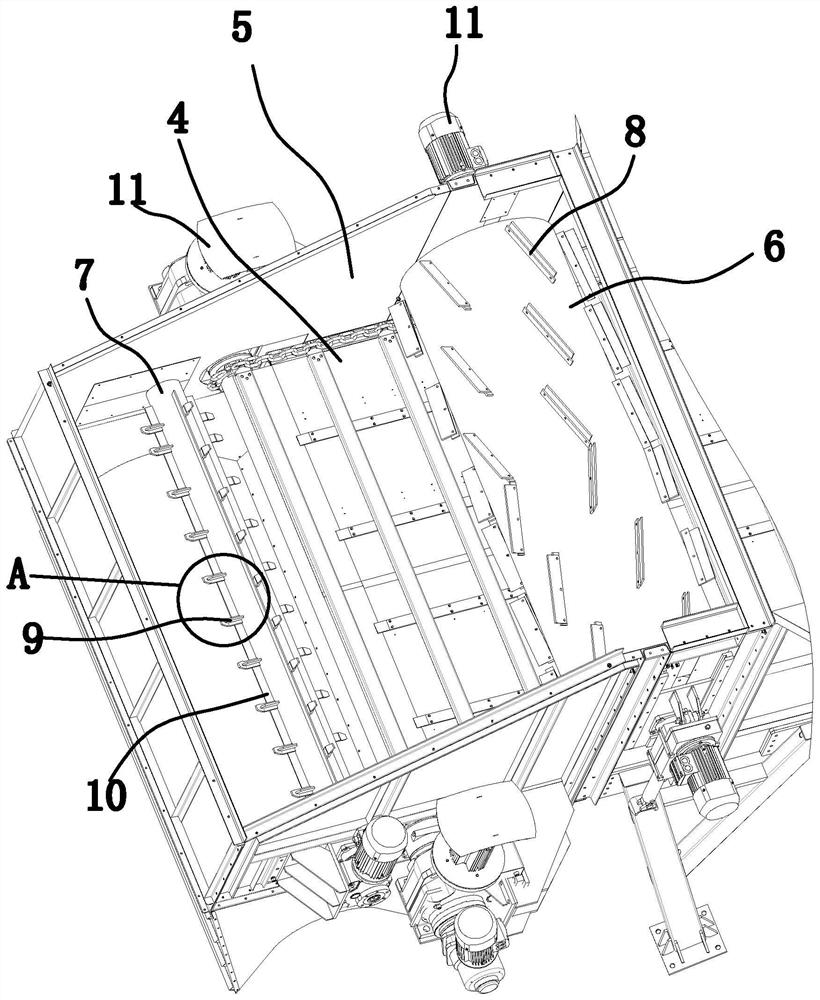

[0049] Further description,

[0050] The specific structure and arrangement of the main paddle 8 are as follows: the main paddle 8 is strip-shaped and inclined relative to the axis of the main shaft 6. many

[0052] The driving source includes two motors-11, and the two motors-11 drive the main shaft 6 and the secondary shaft 7 to rotate respectively. motor and shaft

[0056] In this embodiment, the baffle 17 is slidably connected and locked as follows: the frame 1 includes a conveyor belt along the side of the axis

[0057] The dispersing assembly one includes a plurality of connecting shafts 22 that are evenly spaced around the axis of the drive shaft-16, and the axis of the connecting shaft 22 is along the

[0061] As shown in Figure 8 and Figure 9, the mixing mechanism includes a drainage pipe 28 arranged above the inclined section 2b and both are arranged in the drainage pipe

[0062] Further description, there are three drainage pipes 28, and the remaining two drainage pipe...

Embodiment 2

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com