Patents

Literature

70results about How to "Improve flow field quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

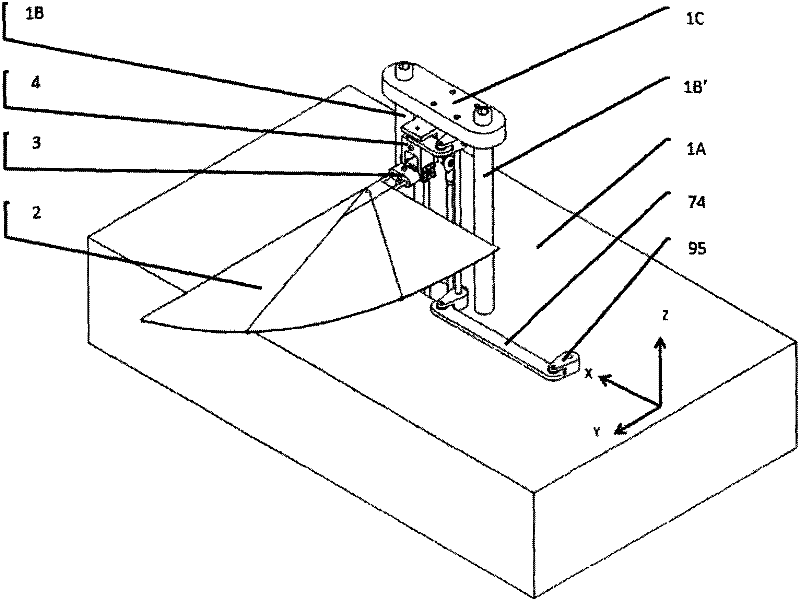

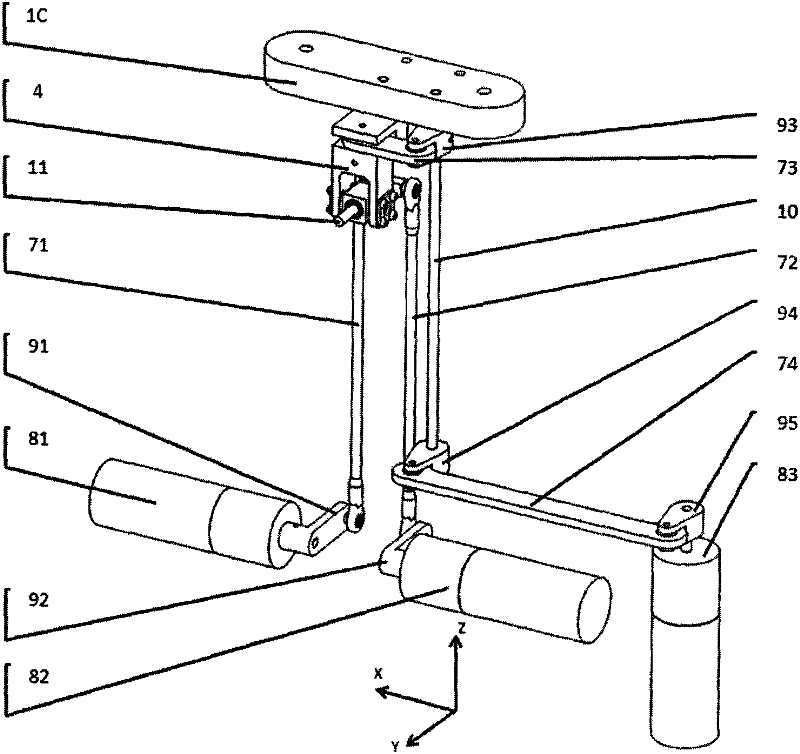

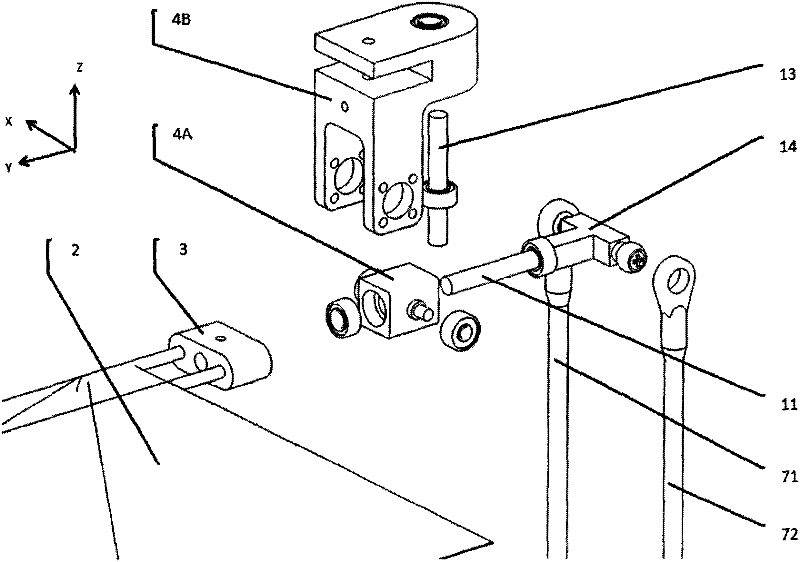

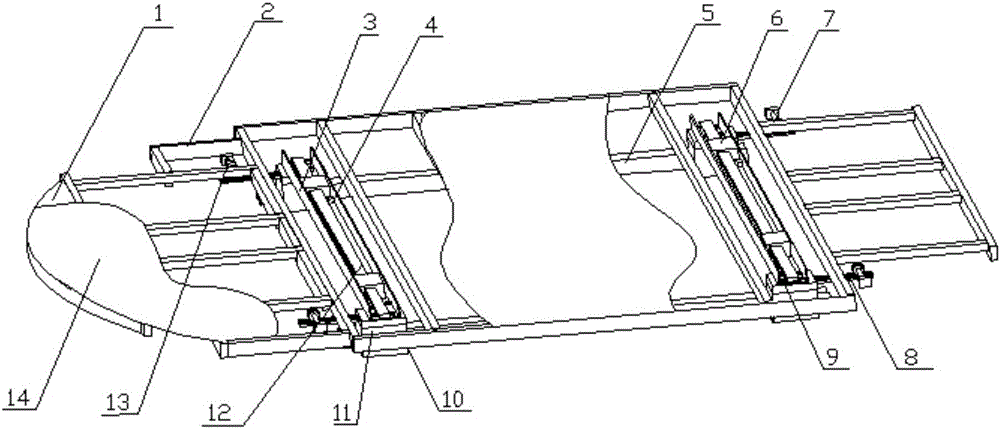

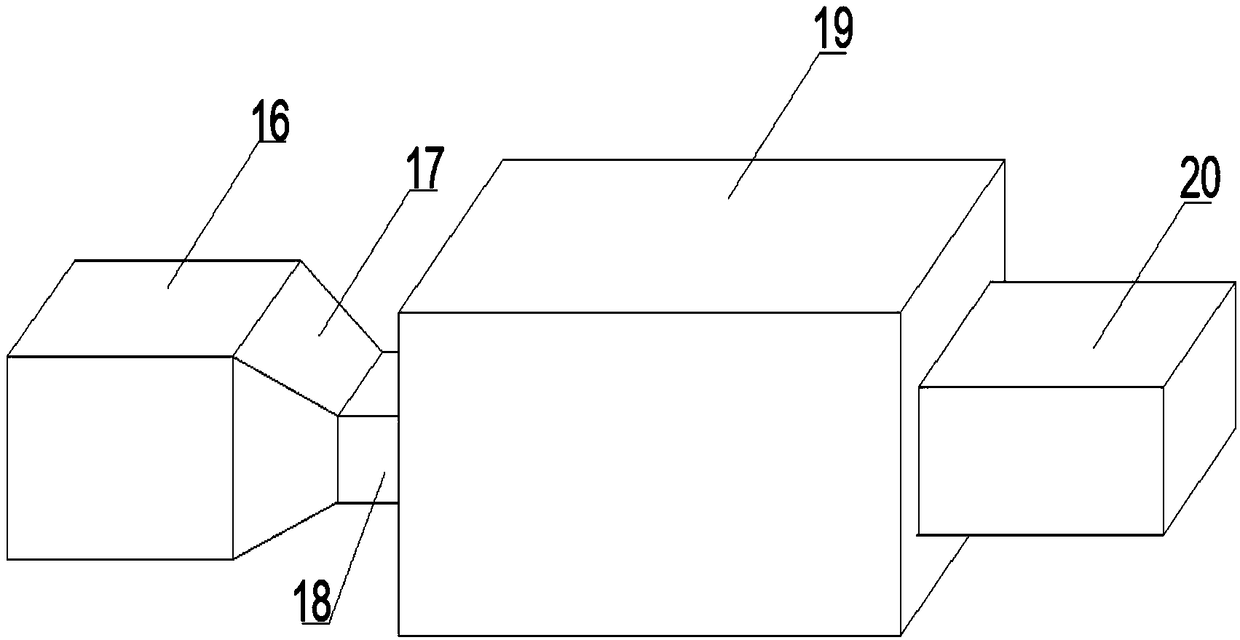

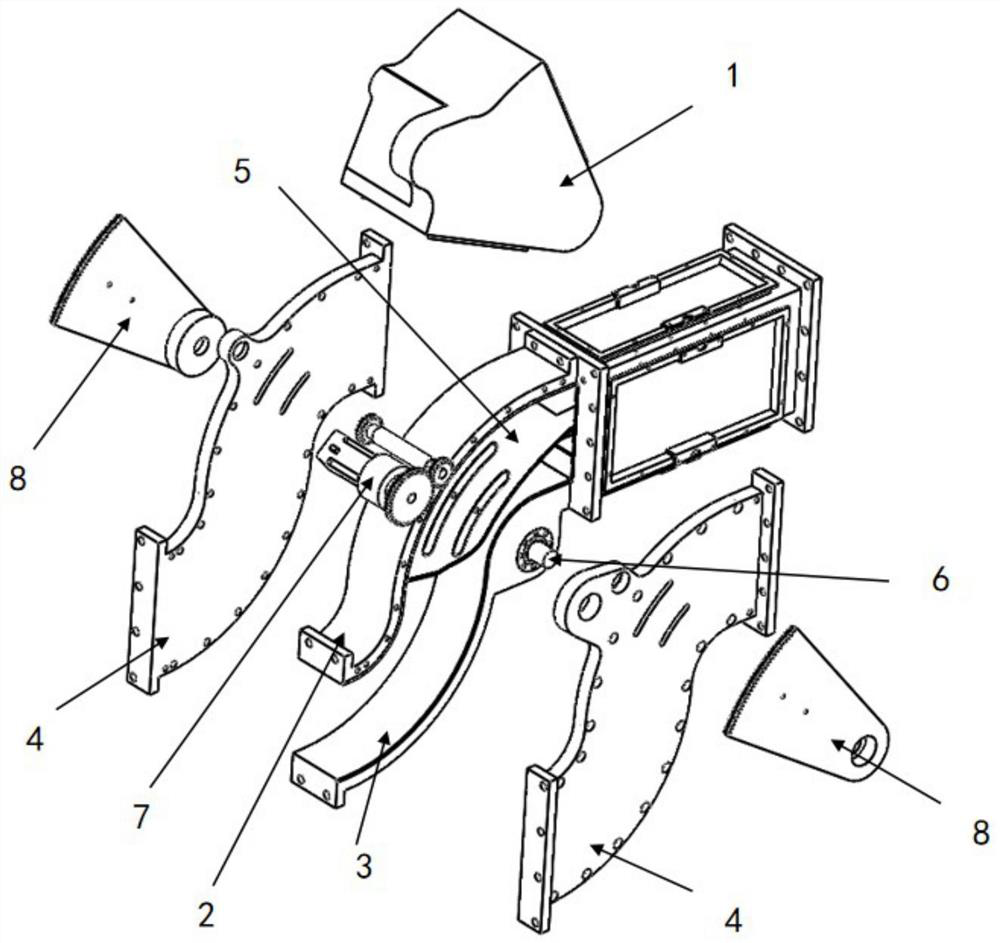

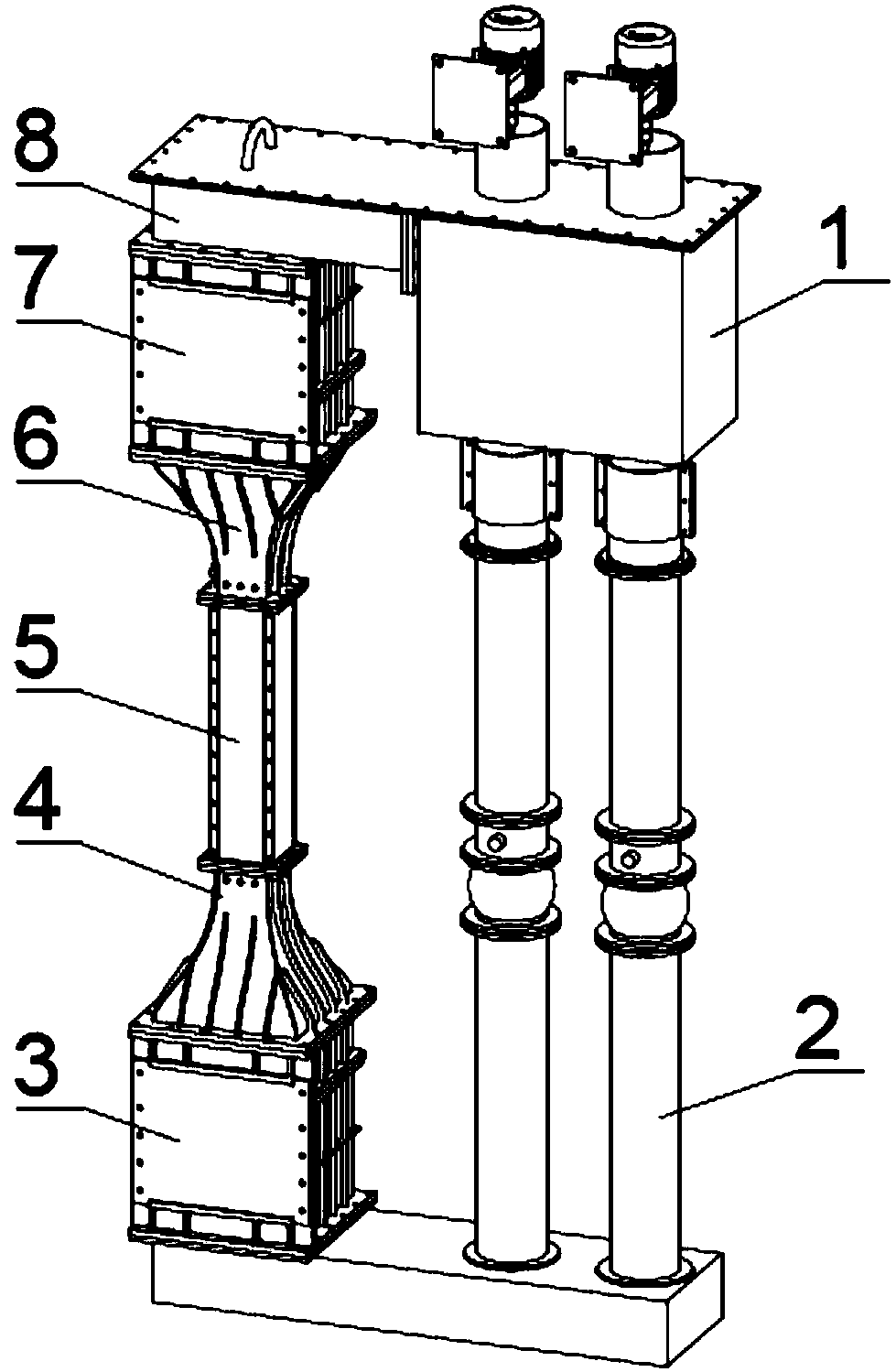

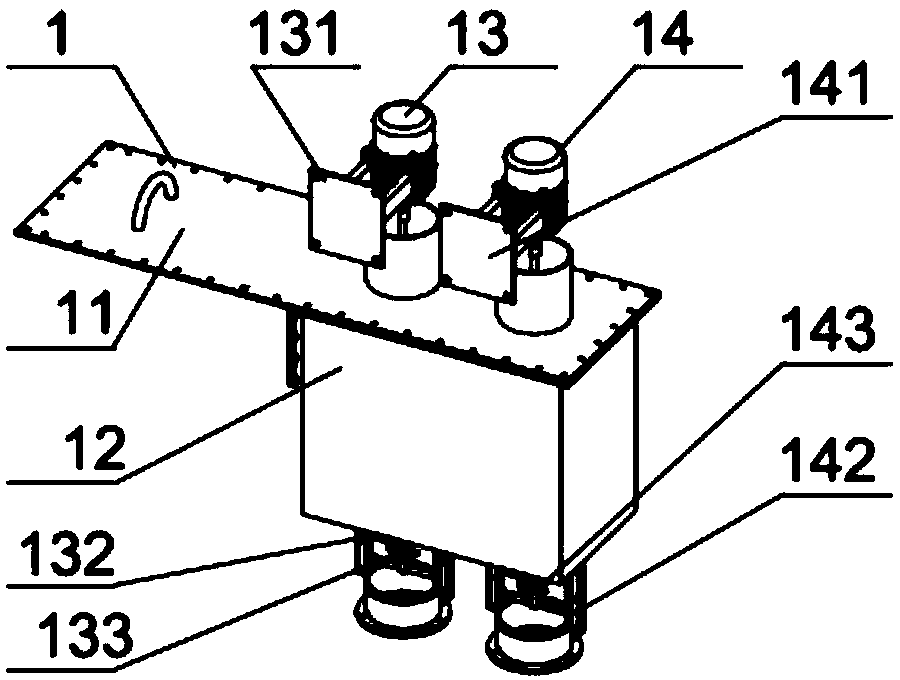

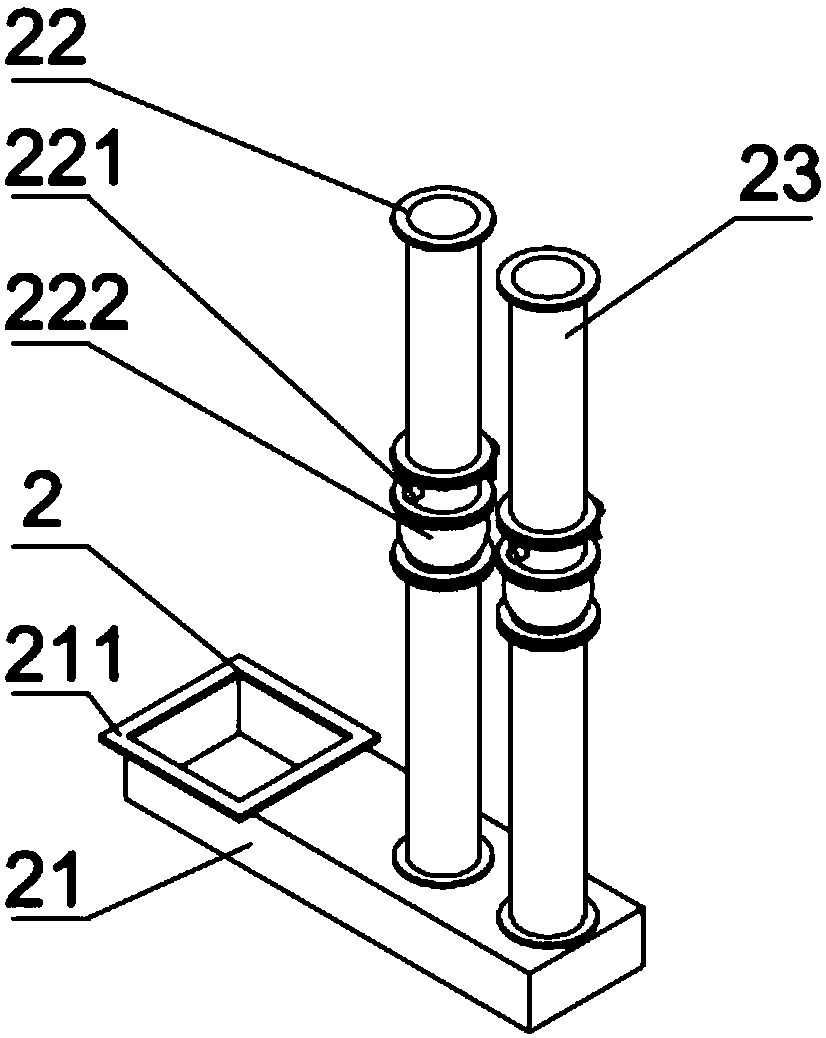

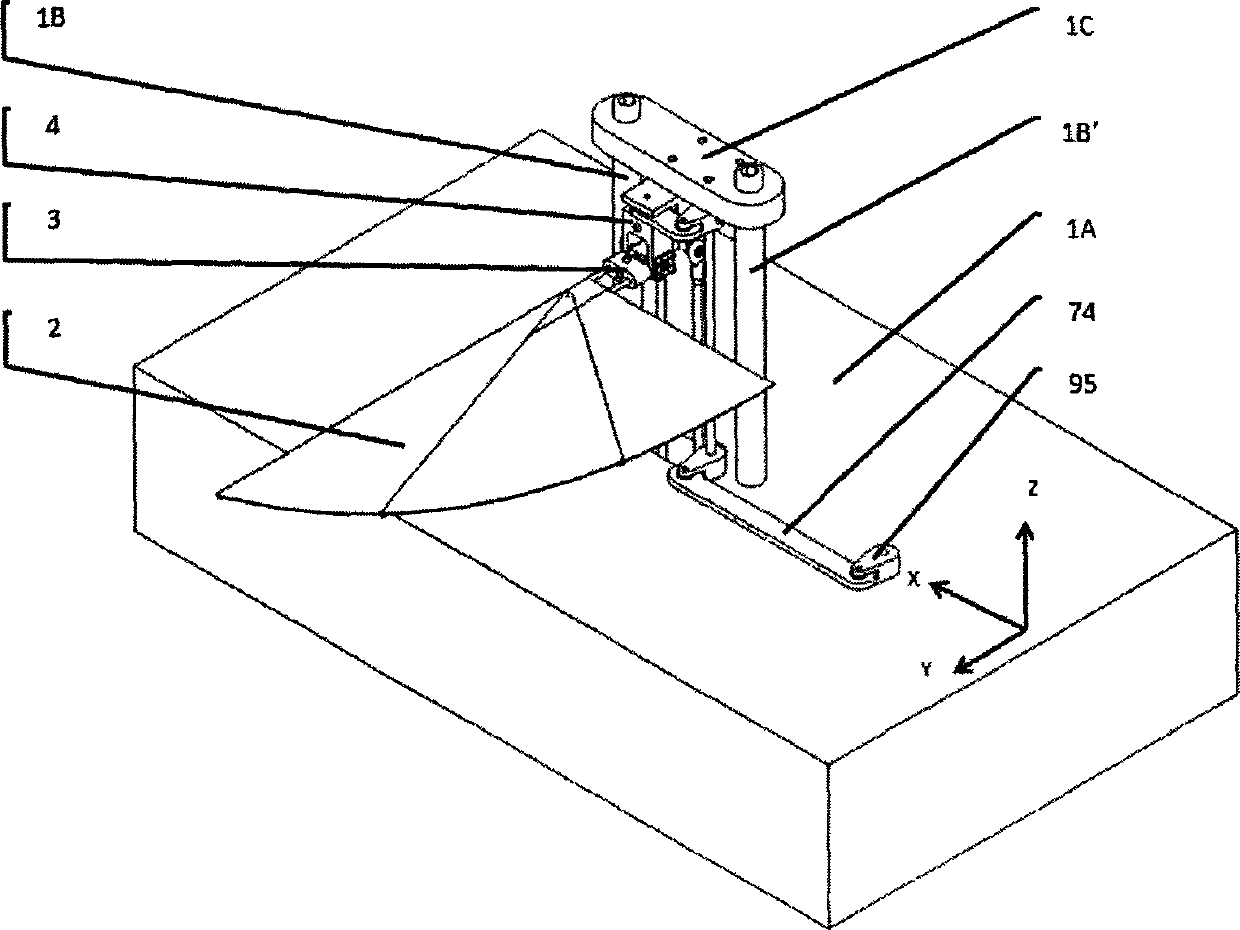

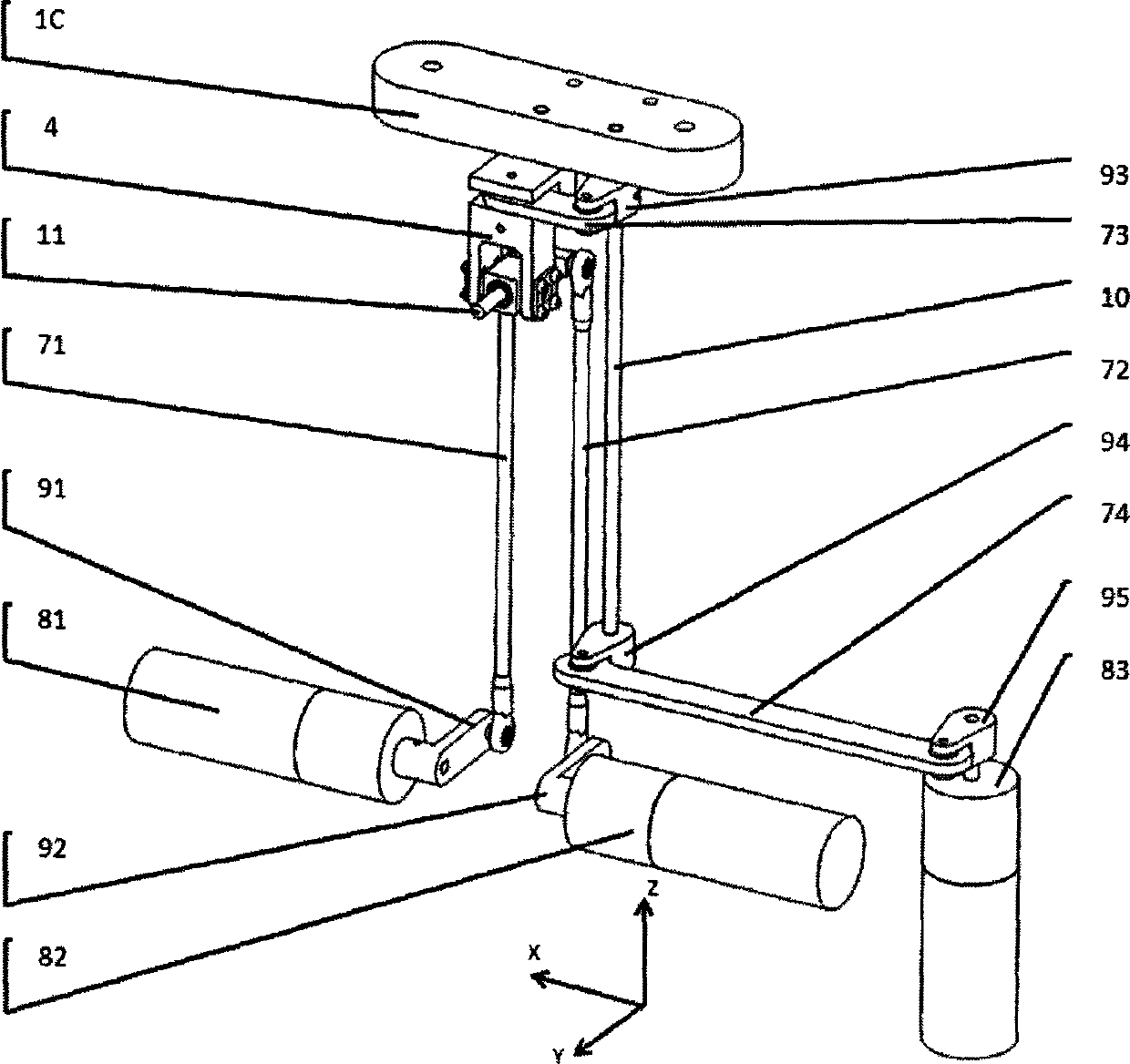

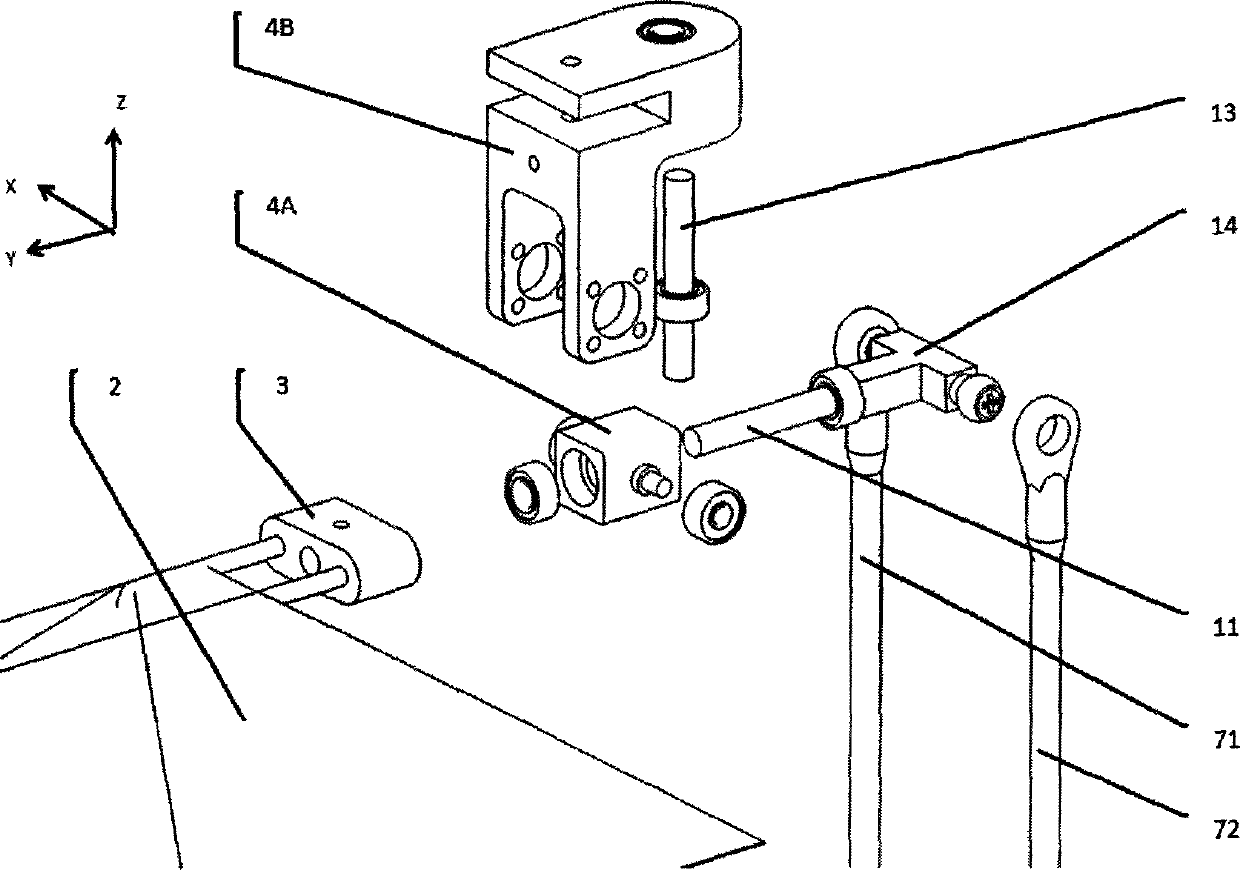

Three-freedom-degree flapping-wing comprehensive experiment platform

InactiveCN102338690AUp and down flutterSweep forward and backwardAerodynamic testingFlapping wingThree degrees of freedom

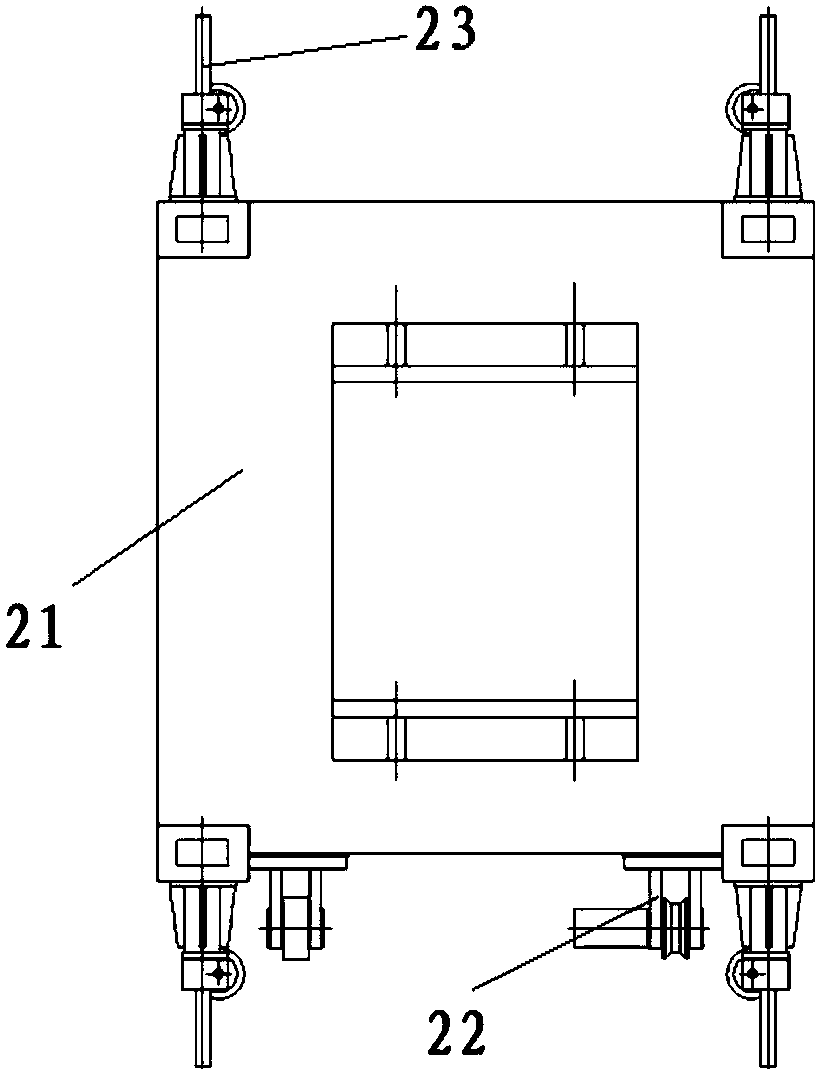

The invention discloses a three-freedom-degree flapping-wing comprehensive experiment platform which comprises a rack, a driving motor, a transmission mechanism, flapping wings and a control system, wherein a box-type structure is adopted under the rack and is used for installing the driving motor and the control system; two universal bearings are symmetrically arranged by a cross beam supported by vertical columns, so that one pair of flapping wings have three rotating freedom degrees; and the transmission mechanism transmits the rotation of the driving motor to the flapping wings to realize three-freedom-degree compound flapping, and measures the flapping force and the torque characteristic of the flapping wings by a sensor. According to the three-freedom-degree flapping-wing comprehensive experiment platform, any three-freedom-degree preset flapping law of the up-down flapping, the front-back sweeping and twisting can be accurately realized, and the direct real-time measurement is carried out on the force and moment in the flapping process. The three-freedom-degree flapping-wing comprehensive experiment platform is suitable for analysis and verification of the wind tunnel test for the complex moving law of the flapping wings.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

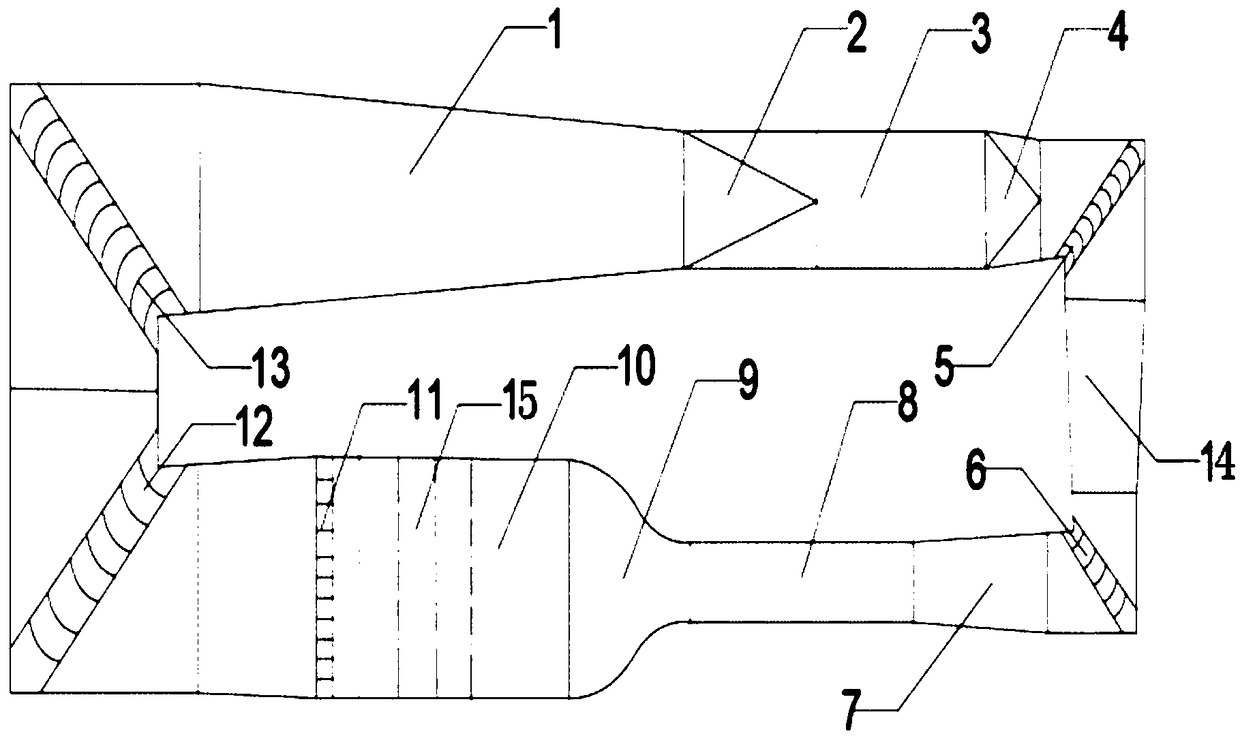

Asymmetric supersonic velocity spray pipe and design method thereof

ActiveCN102323961AHigh precisionImprove qualitySpecial data processing applicationsThroatMethod of characteristics

The invention provides an asymmetric supersonic velocity spray pipe and a design method thereof. The design method of the supersonic velocity spray pipe comprises the following steps: according to an inlet coordinate and a throat area, determining a subsonic velocity segment curve; according to the subsonic velocity segment curve and a throat radius of curvature, determining a characteristic line in a transonic velocity area; according to one end point of the characteristic line and a corresponding supersonic velocity area outlet end point, determining a first wall surface curve; and according to an initial characteristic line and the Mach number distribution of the first wall surface curve, determining a second wall surface curve by mass conservation with a characteristic line method. With the design method of the asymmetric supersonic velocity spray pipe, concentrated compression wave in the flow field of the asymmetric supersonic velocity spray pipe can be reduced or eliminated, the quality of the flow field of the spray pipe is greatly improved, equipment performance is improved, and research funds can be saved. According to the asymmetric supersonic velocity spray pipe disclosed by the invention, the design method of the asymmetric supersonic velocity spray pipe is adopted.

Owner:NAT UNIV OF DEFENSE TECH

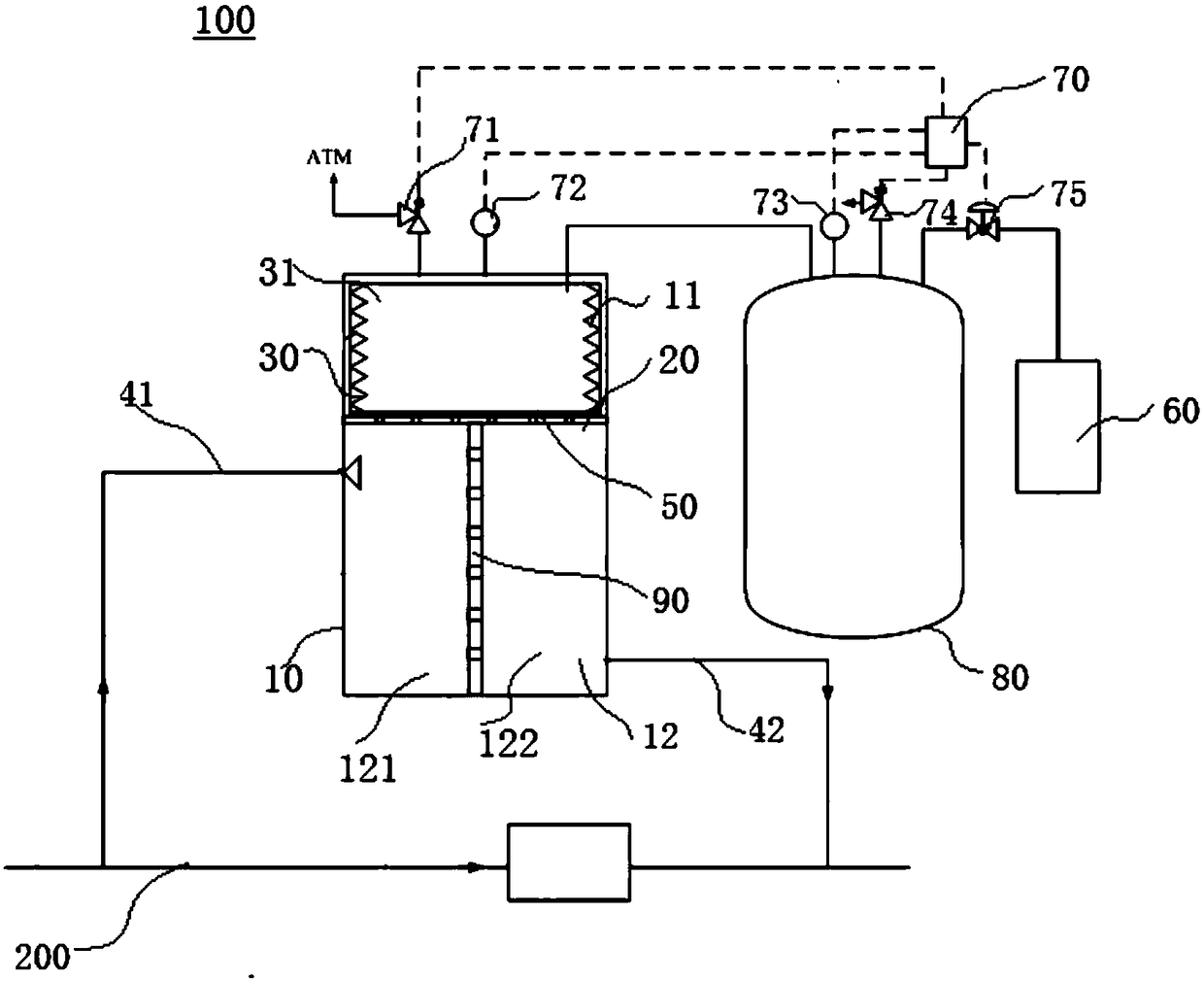

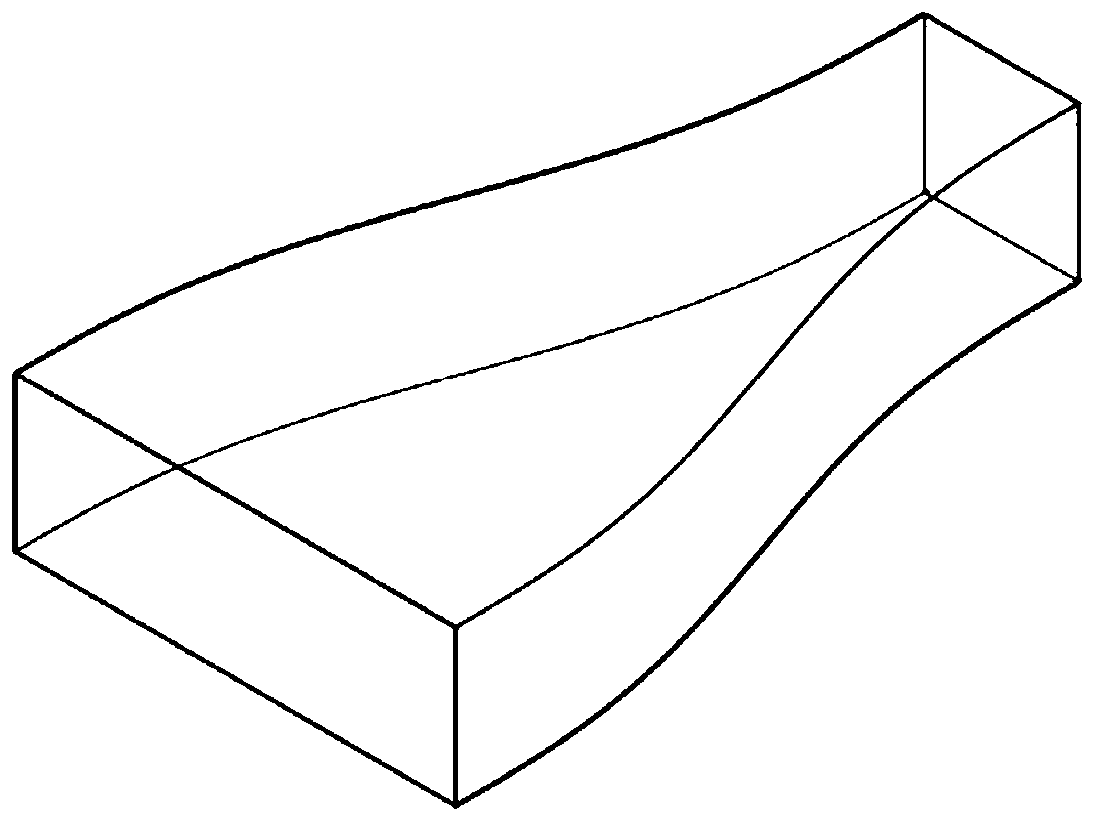

Test device and method for forming high-speed stable flow field

The invention provides a test device for forming a high-speed stable flow field. The test device comprises a water tank, wherein an outlet is formed at the side wall of the water tank; the outlet is connected with a horizontal flow channel through a pipeline; the horizontal flow channel comprises a drainage section, a stabilizing section, a contraction section, a test section and an expansion section; the water tank is connected with an air supply system and a pressure control system through a pipeline, wherein the air supply system comprises an air source pressure tank and an air compressor, the air source pressure tank is connected with the water tank through an air inlet pipeline, and a flow control valve is formed on the air inlet pipeline; and the pressure control system comprises the flow control valve, a PLC (programmable logic controller), a pressure transmitter and the water tank, and the pressure transmitter is arranged on an outlet axis of the water tank. A method for forming the high-speed stable flow field comprises the following steps of: driving the flow through high-pressure air, and controlling the high-pressure air by the pressure control system, namely controlling the pressure of an inlet of the horizontal flow channel to be stable, so as to obtain the stable flow velocity at the test section. Through the device and the method, a high-speed and stable test flow field with excellent flow field quality can be formed.

Owner:中国船舶重工集团公司第七〇二研究所

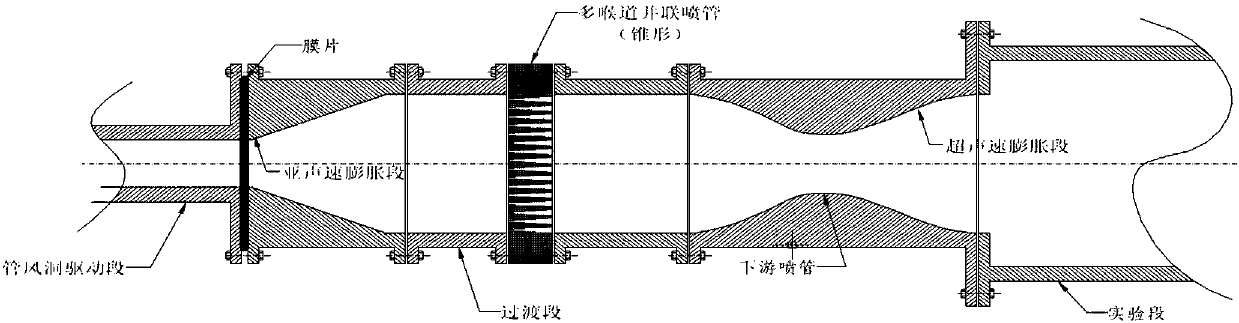

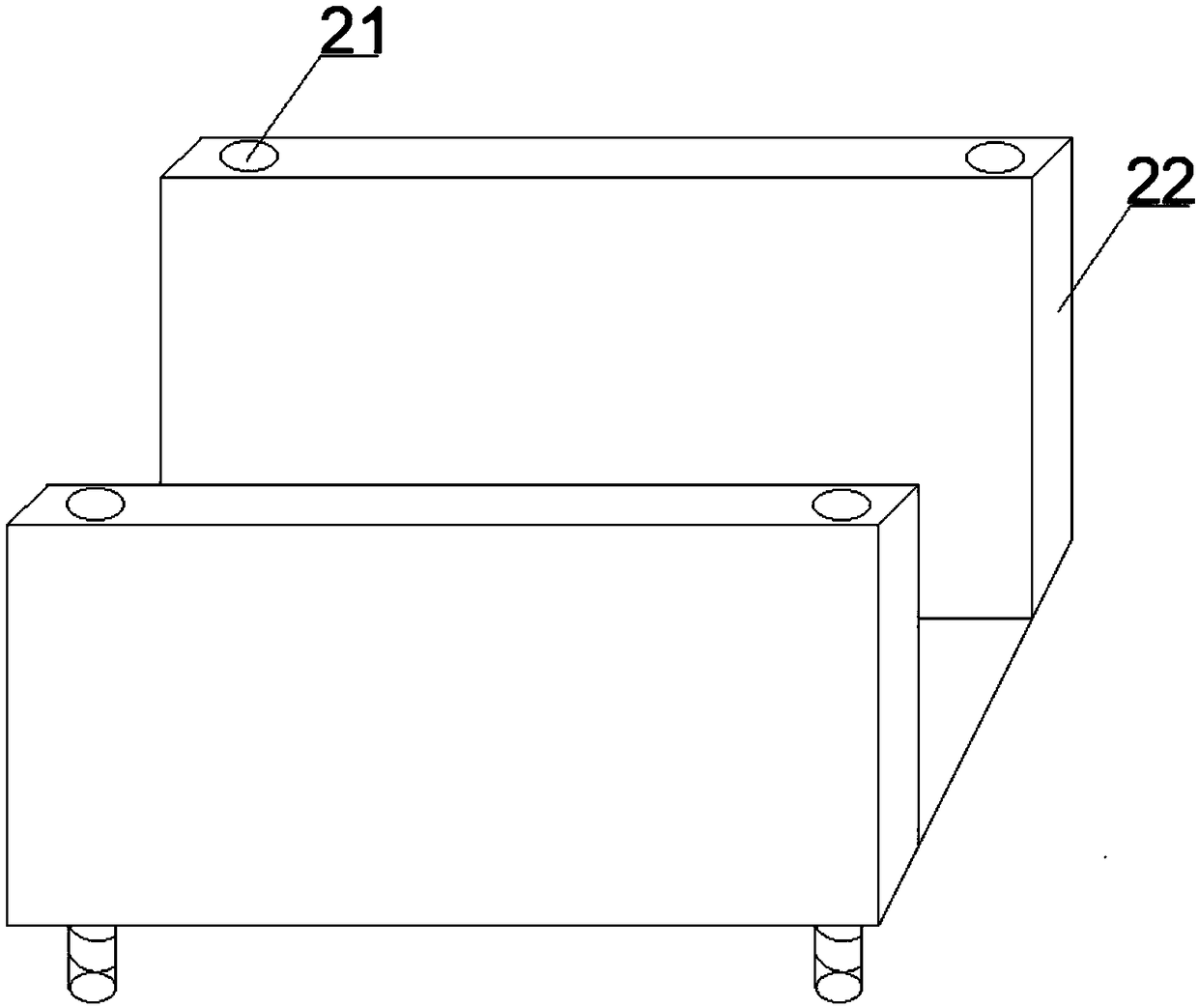

Throat structure capable of improving Reynolds number of tube wind tunnel test

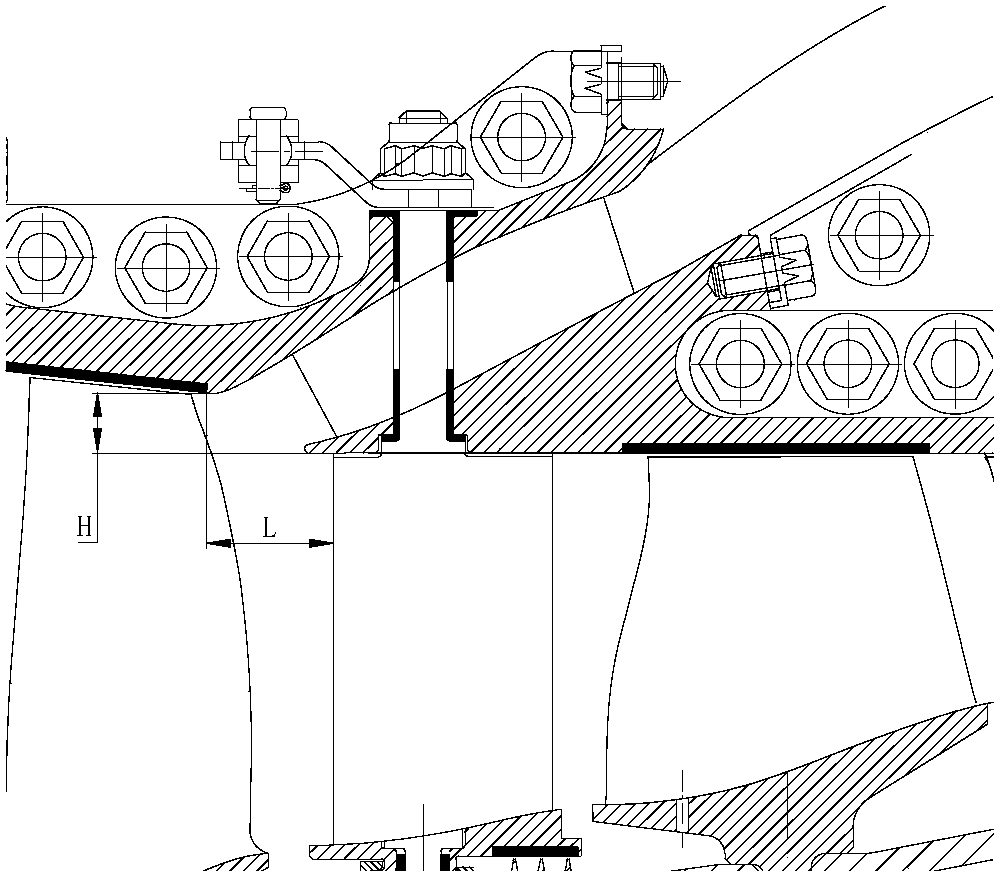

ActiveCN108168832ASimple structureReduce startup timeAerodynamic testingFluid dynamicsEngineeringFlange

The invention relates to a throat structure capable of improving the Reynolds number of a tube wind tunnel test. An upstream section, a transition section and a downstream section constitute the throat structure from left to right; the upstream section, the transition section and the downstream section are fixed together by flanges; the throat structure is arranged between the tube wind tunnel driving section and test section of a wind tunnel test; the throat structure at the upstream section is a subsonic speed expansion section in a conical structure form; the middle of the transition section comprises a multi-throat parallel spray tube structure; the middle of the downstream section is a contracted downstream spray tube; and the right end of the downstream section is a supersonic expansion section. According to the throat structure of the present invention, it only requires to make local modification on a tube wind tunnel, and requirements can be met by means of an aerodynamic principle; and a rectifying device is additionally arranged in the transition section, so that the startup time of the wind tunnel can be shortened, and the quality of the flow field of the test section can be improved.

Owner:AVIC SHENYANG AERODYNAMICS RES INST

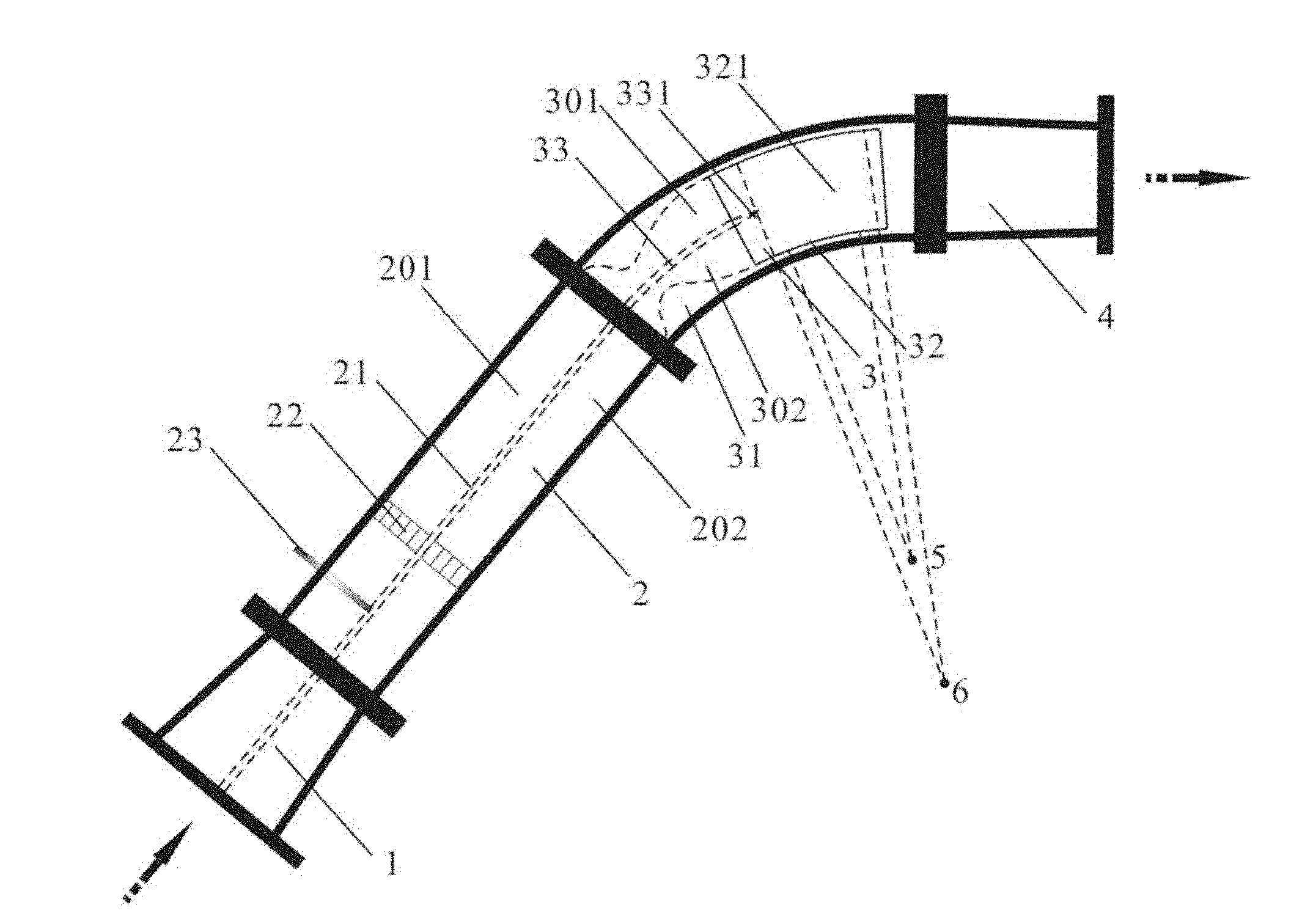

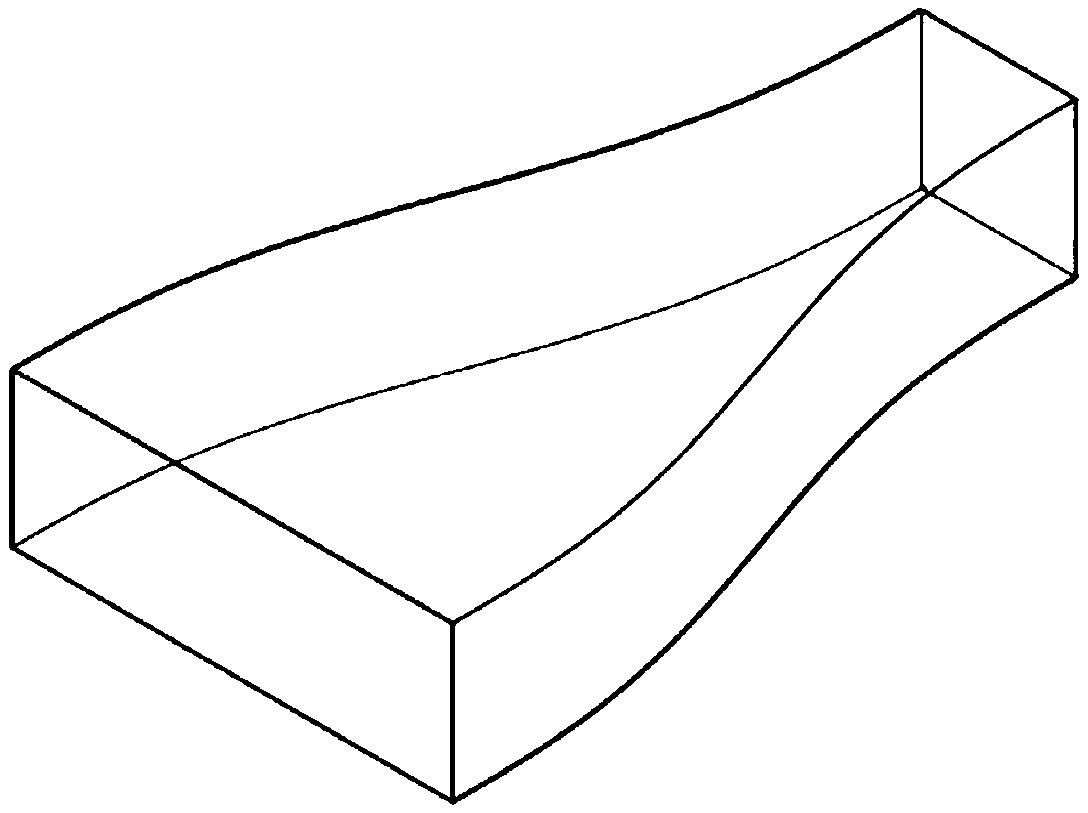

Supersonic free vortex mixing layer wind tunnel

ActiveCN102023079AFlow field characteristics researchEasy to implementAerodynamic testingEngineeringAirflow

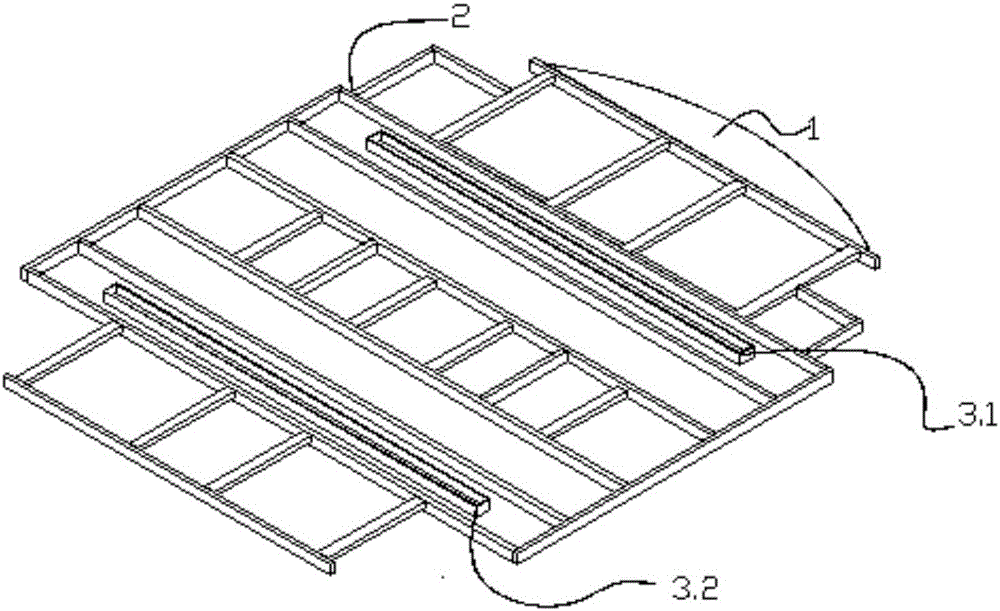

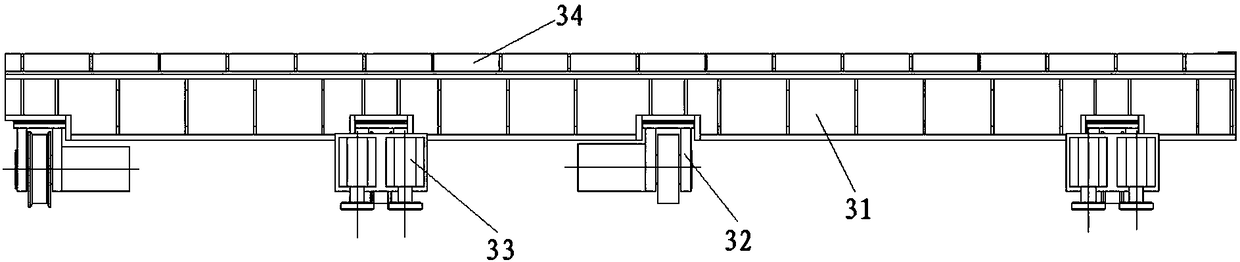

The invention provides a supersonic free vortex mixing layer wind tunnel. The wind tunnel comprises a transition section (1), a stabilizing section (2) and a spray pipe experimental section (3), wherein the transition section (1) is used for introducing air flow; the stabilizing section (2) is connected to the downstream side of the transition section (1) and is provided with a first separation plate (21) for separating the introduced air flow into two strands of air flow; the spray pipe experimental section (3) is connected to the downstream side of the stabilizing section (2) and comprises a spray pipe part (31) and a mixing experimental part (32); a transparent window is formed on the peripheral wall of the spray pipe experimental section (3); the spray pipe part (31) has a double free vortex spray pipe structure and is used for accelerating the two strands of air flow to form a free vortex state respectively; the mixing experimental part (32) is positioned on the downstream side of the spray pipe part (31) and is used for mixing the two strands of air flow in the free vortex state to form a free vortex mixing layer, so that velocity fields of the two strands of air flow at an inlet of the experimental part of the wind tunnel meet the requirement of supersonic free vortex distribution; therefore, an ideal supersonic free vortex mixing layer can be obtained in the wind tunnel.

Owner:NAT UNIV OF DEFENSE TECH

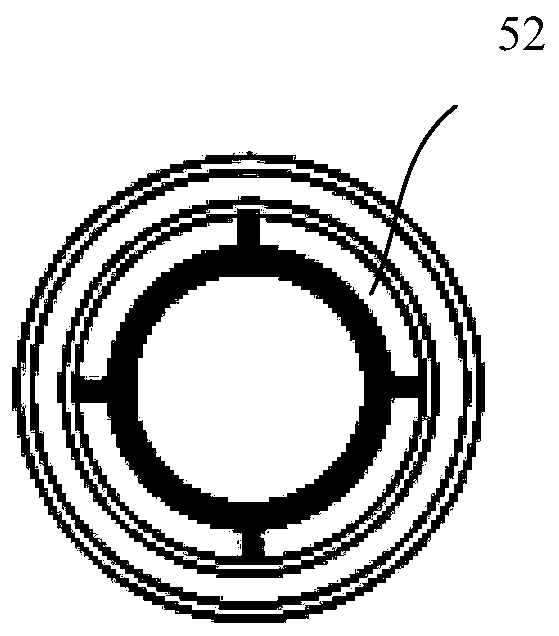

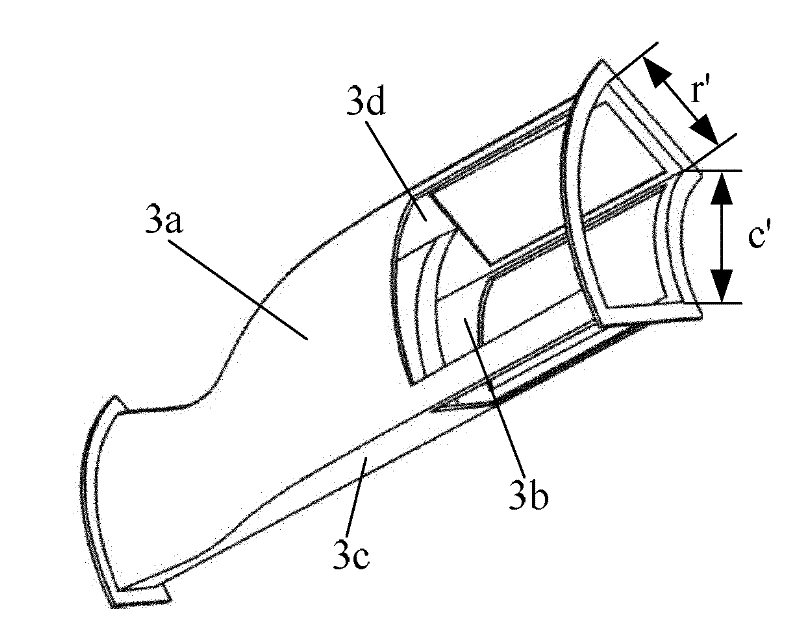

Annular supersonic velocity spray pipe and design method thereof

ActiveCN102302990AGuaranteed uniformityHigh precisionSpray nozzlesMethod of characteristicsEngineering

The invention provides an annular supersonic velocity spray pipe and a design method thereof. The design method for the annular supersonic velocity spray pipe comprises the following steps of: predicting a flow field parameter in a transonic velocity segment area, and extracting an initial characteristic line from the flow field parameter; determining the mach number distribution of a supersonic velocity upright wall of the spray pipe according to design requirements; and determining a supersonic velocity curved wall molded surface of the spray pipe by a characteristic line method according to the initial characteristic line and the mach number distribution of the supersonic velocity upright wall. According to the design method for the annular supersonic velocity spray pipe, compression waves are not concentrated in a flow field of the designed annular supersonic velocity spray pipe, the distribution of the flow field parameter can be optimized according to actual application, and thequality of the flow field of the annular supersonic velocity spray pipe can be greatly improved. According to the annular supersonic velocity spray pipe, the design method for the annular supersonic velocity spray pipe is utilized.

Owner:NAT UNIV OF DEFENSE TECH

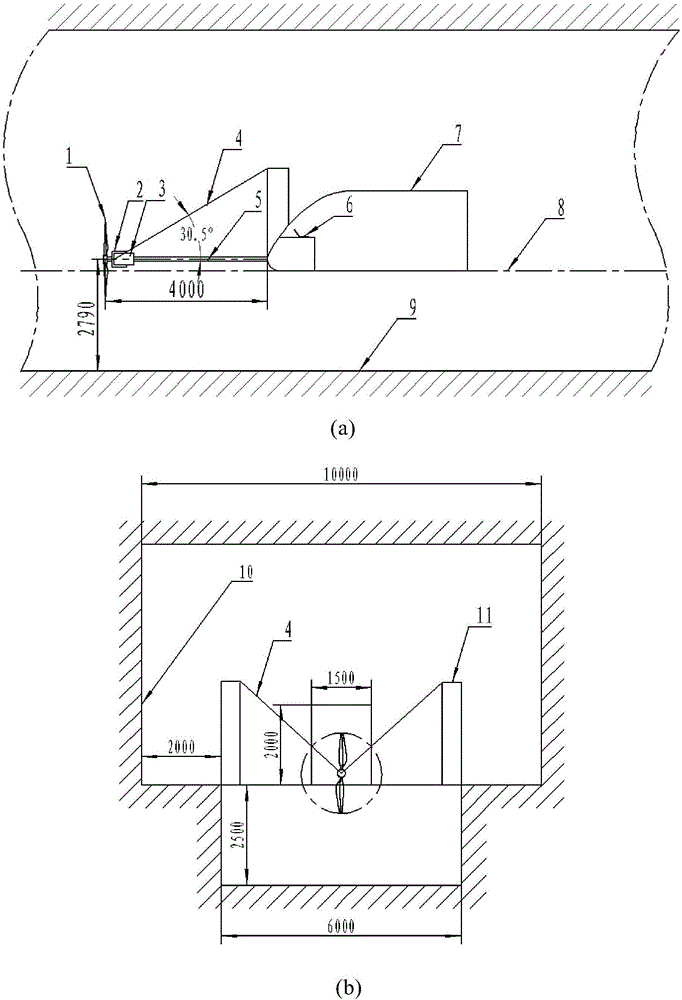

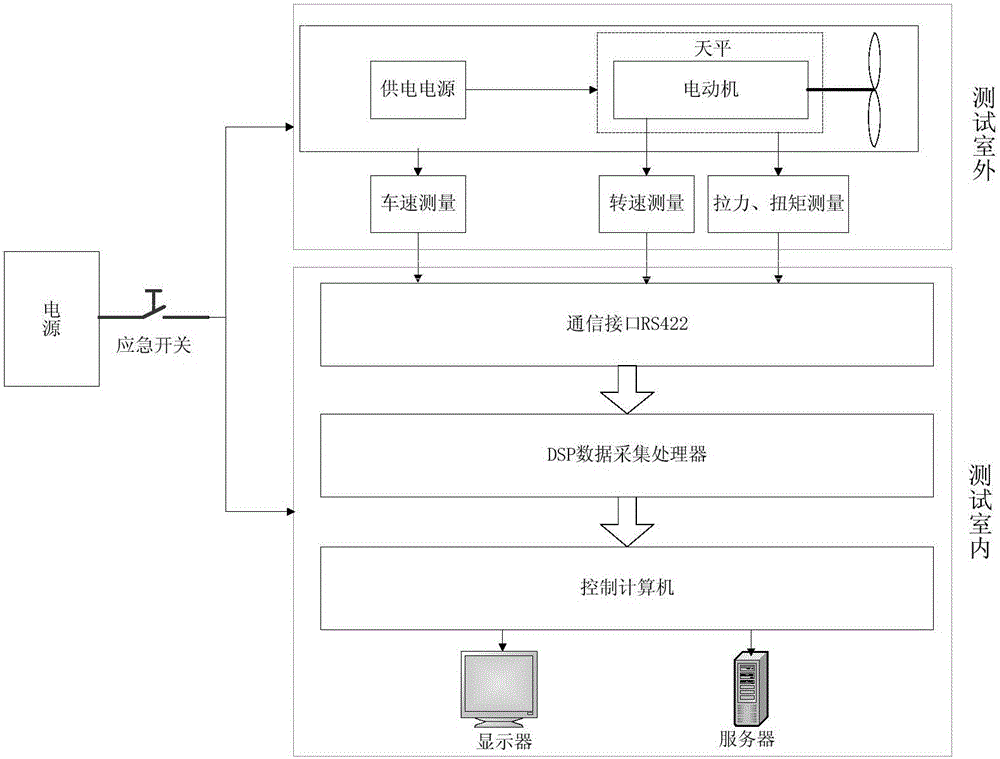

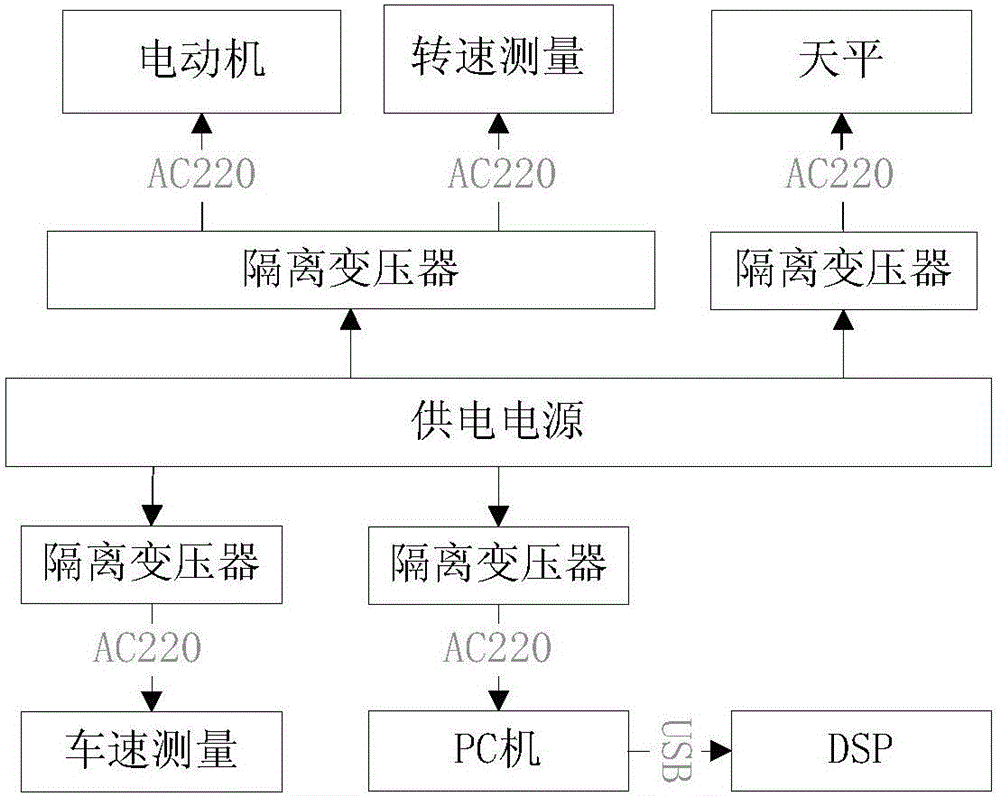

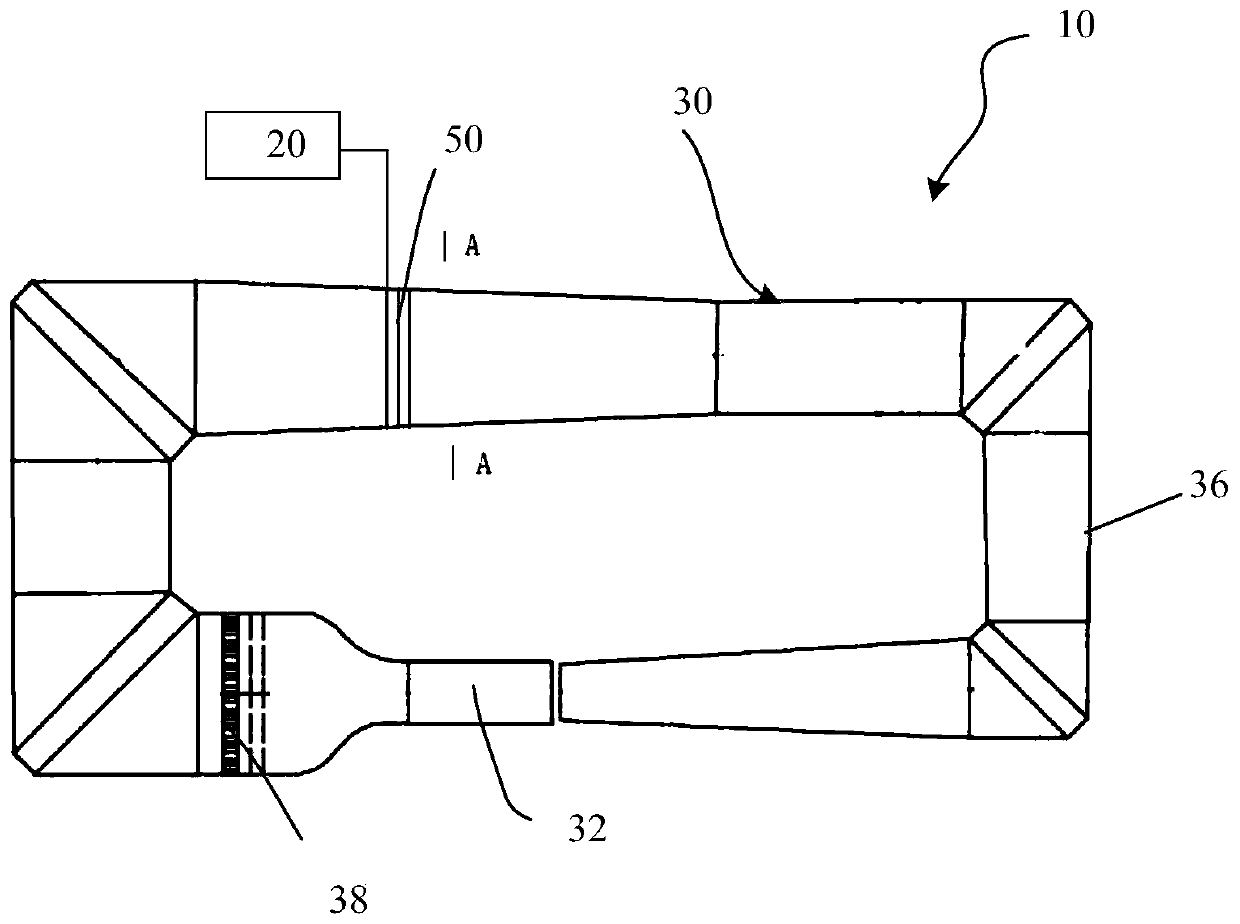

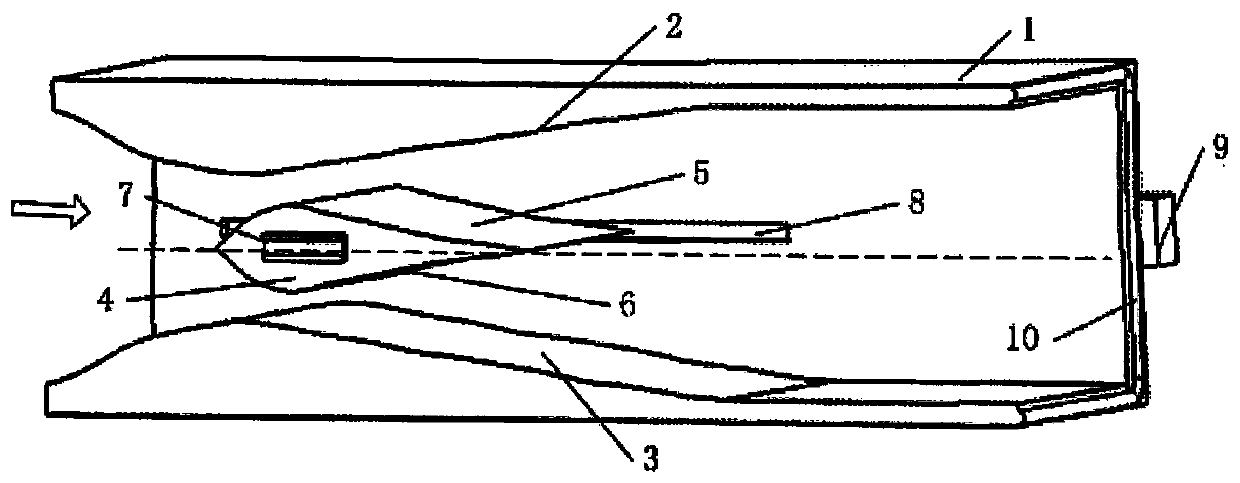

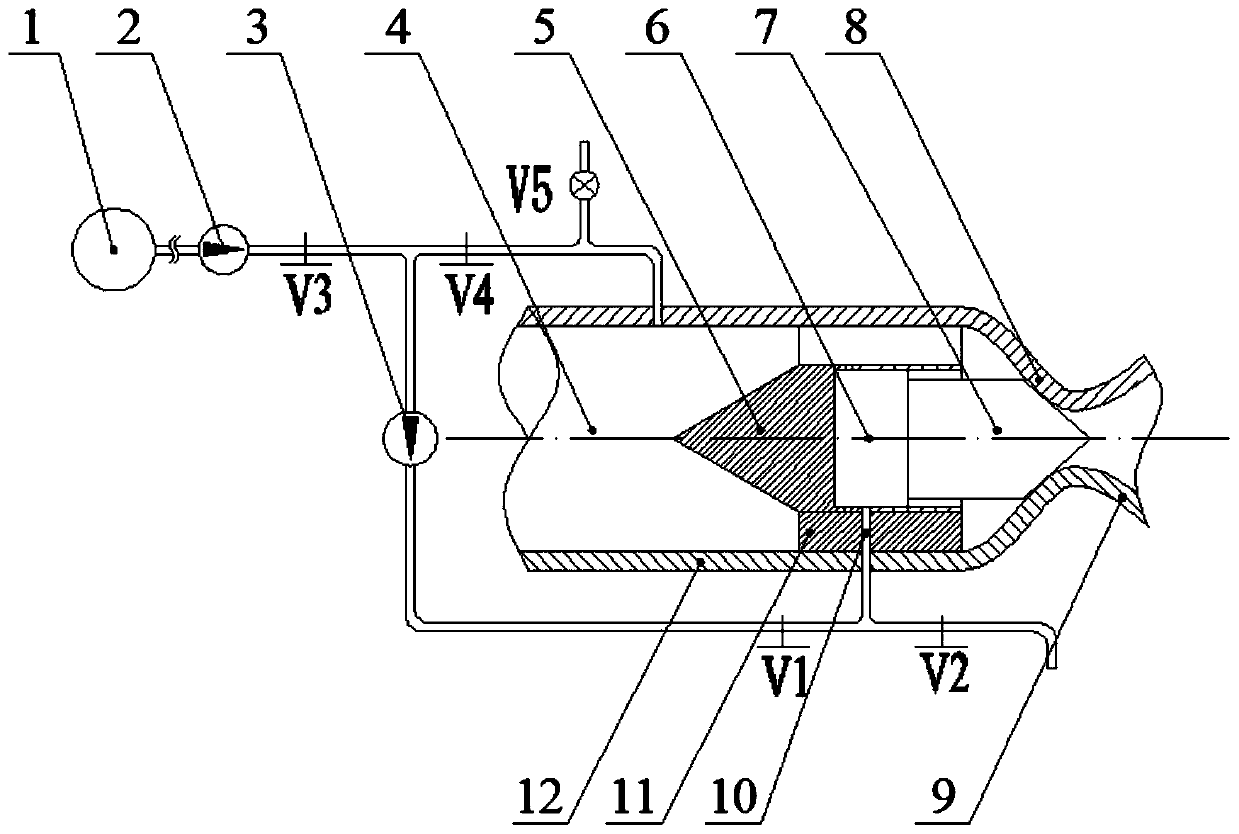

Testing system and testing method for propeller ground test in near space

InactiveCN106596033AAchieve aerodynamicsIncrease the cross-sectional areaAerodynamic testingControl systemSpeed control system

The invention discloses a testing system and a testing method for the propeller ground test in the near space. The system comprises an incoming flow simulation system, a propeller rotating speed control system, a data measurement system and a support. The data measurement system comprises a two-component balance and a data acquisition and control module. The forward velocity and the rotating speed of a propeller are respectively and precisely controlled by a trailer and a motor. The propeller rotating speed control system comprises a motor, wherein the motor is fixed inside the two-component balance. The end portion of the output shaft of the motor extends out of the two-component balance. The propeller is fixed at the end portion of the output shaft of the motor and is driven by the motor to rotate. The support is of a cantilever beam structure, and the rear end of the cantilever beam structure is fixed at the front end of the head part of the trailer and is extending forwardly. The two-component balance is fixed at the front end of the support. According to the technical scheme of the invention, the test state is simulated by utilizing a track trailer. The forward velocity of the trailer is relatively low and the velocity control precision of the trailer is relatively high. Therefore, a stable incoming-flow environment is provided for the propeller.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

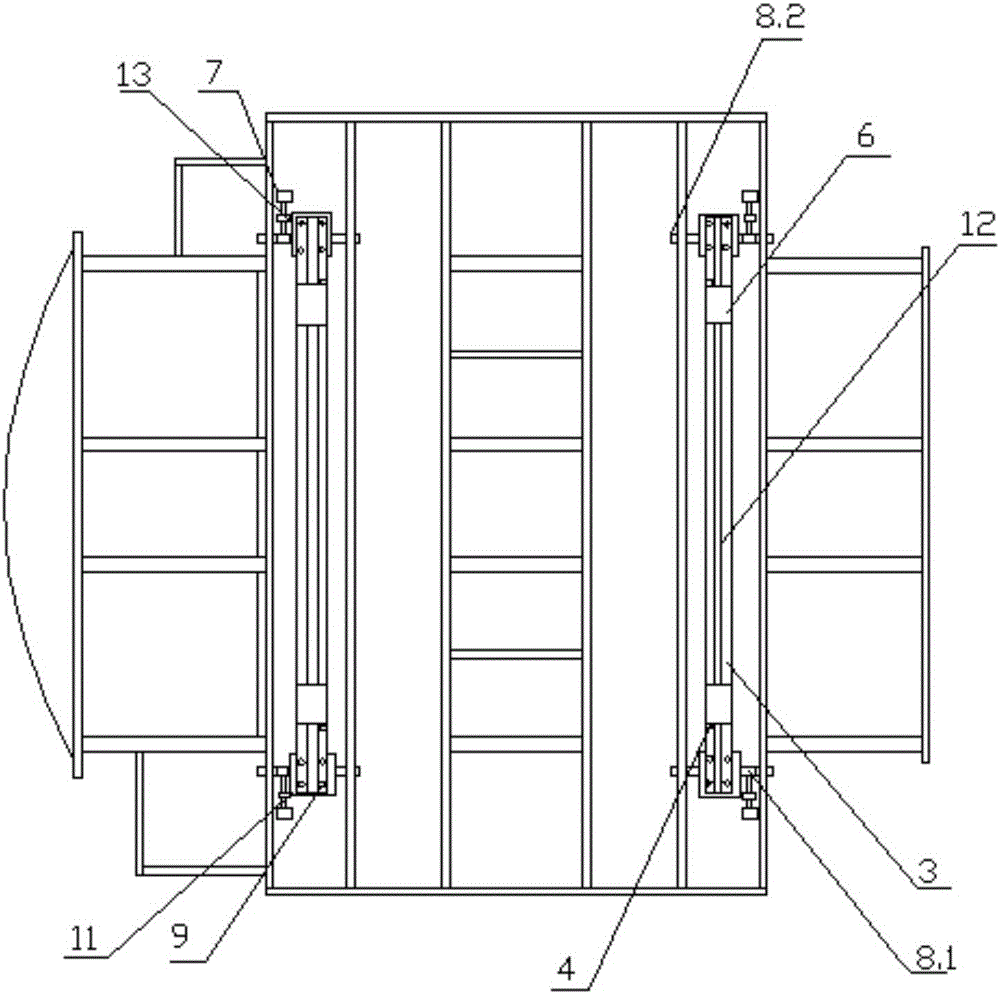

Automatic adjustable automobile wind tunnel testing platform with function of interference elimination

InactiveCN105953999AEliminate distractionsEliminate the effects of trialsVehicle testingAerodynamic testingAxial displacementProcess quality

The invention discloses an automatic adjustable automobile wind tunnel testing platform with the function of interference elimination. The testing platform comprises a testing bench, an automatic wheel base adjusting part, and a tread adjusting part. The testing bench is installed on a wind tunnel testing segment floor and covers a balance support. The automatic wheel base adjusting part is installed at the lower part of the balance support; and the tread adjusting part is installed in the balance support. The automatic wheel base adjusting part consists of a wheel base displacement sensor, a gear rack driving device, a drive motor, a wheel base adjustment support and a guide rod; the wheel base adjustment support is fixed at the bottom of the balance support; the guide rod passes through the wheel base adjustment support and the is connected with a balance floating frame; the wheel base adjustment support can move axially along the guide rod; the wheel base displacement sensor is arranged on the wheel base adjustment support; and the wheel base adjustment support is connected with the drive motor by the gear rack driving device. According to the invention, the interference on the process quality by the support exposed in the flow field in wind tunnel testing can be eliminated; and supports of vehicles with different wheel bases and threads can be realized.

Owner:JILIN UNIV

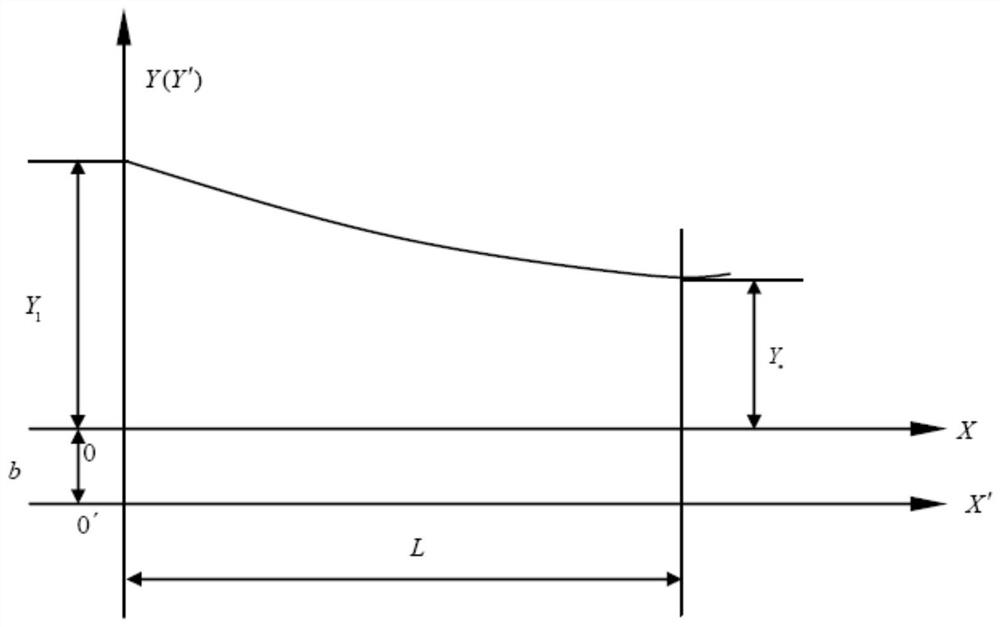

Method for calculating hypersonic wind tunnel axisymmetric nozzle inner profile

ActiveCN111859520AMach Number ConsistentHigh Mach number accuracyGeometric CADSustainable transportationMATLABMechanics

The invention discloses a method for calculating an inner profile of an axisymmetric nozzle of a hypersonic wind tunnel. The method comprises the following steps: 1, giving initial condition parameters; 2, calculating subsonic velocity profile coordinates of the axisymmetric nozzle; 3, calculating supersonic velocity profile coordinates of the axisymmetric nozzle, including the steps: calculatingthroat area profile parameters, calculating wave-front airflow parameters along the radial direction, calculating Mach number distribution on the center line of the conversion area, calculating parameters of a wave absorbing area, calculating a molded surface by utilizing an axisymmetric characteristic line grid, and calculating wall surface coordinates of the axisymmetric nozzle; 4, carrying outcorrection calculation on the boundary layer of the supersonic velocity section bit flow profile of the axisymmetric nozzle. According to the nozzle profile designed through the method, Mach numbers needed by flow fields are consistent, Mach number distribution of a nozzle outlet is uniform, MATLAB software programming can be conveniently adopted for achieving, the profile coordinates can be rapidly obtained, and the universality is achieved when the axisymmetric nozzle profile is calculated.

Owner:INST OF HIGH SPEED AERODYNAMICS OF CHINA AERODYNAMICS RES & DEV CENT

Intelligent wind tunnel with variable section of test section

The invention relates to an intelligent wind tunnel with a variable section of a test section, wherein the inlet of the test section of the wind tunnel is connected to a contraction compressed gas retaining structure of a contraction section, and the outlet of the test section is connected to a steady flow section front end structure of a steady flow section; the test section is integrally in a rectangular structure and is composed of upper and lower two parts which are nested with each other, the upper part can move up and down in the lower part under the action of the telescopic structure, and the height of the lower end surface of the upper part is not greater than the distance from the upper ends of the outlet and the inlet to the top when the test section dose not stretch out and drawback; a rubber airbag plate is arranged on the inner wall side of the cavity of the test section, a plurality of rubber airbags are arranged on the rubber airbag plate, the inflation and deflation states of each rubber airbag are controlled by an air pump and a corresponding control valve; the above-mentioned telescopic structure, the air pump and the control valve are all connected to a controlsystem in a wind tunnel control room. The wind tunnel can automatically change the cross-sectional area and volume according to various data of the real scene as needed, which realizes intelligent useof the wind tunnel, and completes various pneumatic tests efficiently and reliably.

Owner:HEBEI UNIV OF TECH

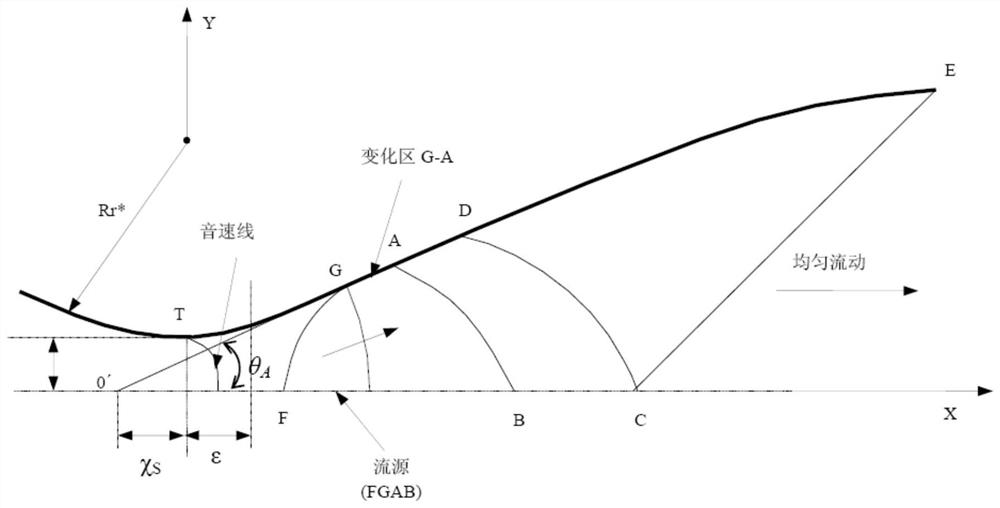

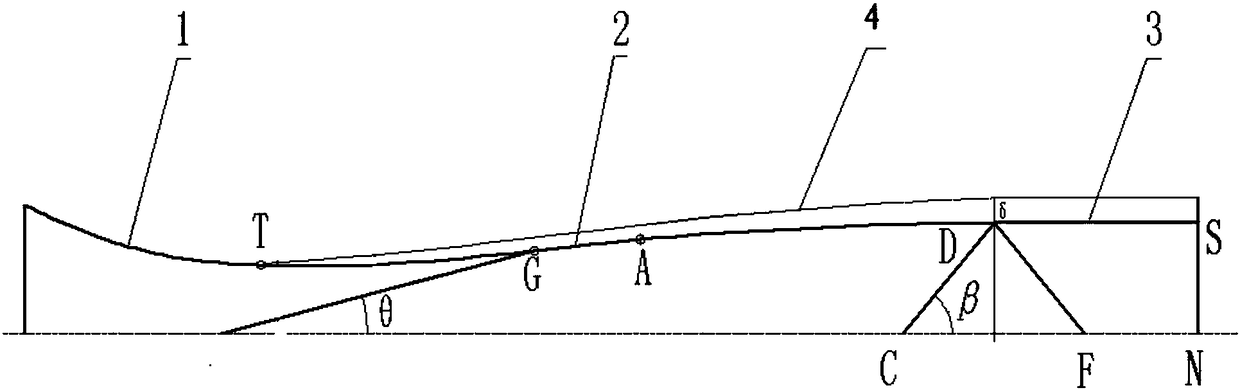

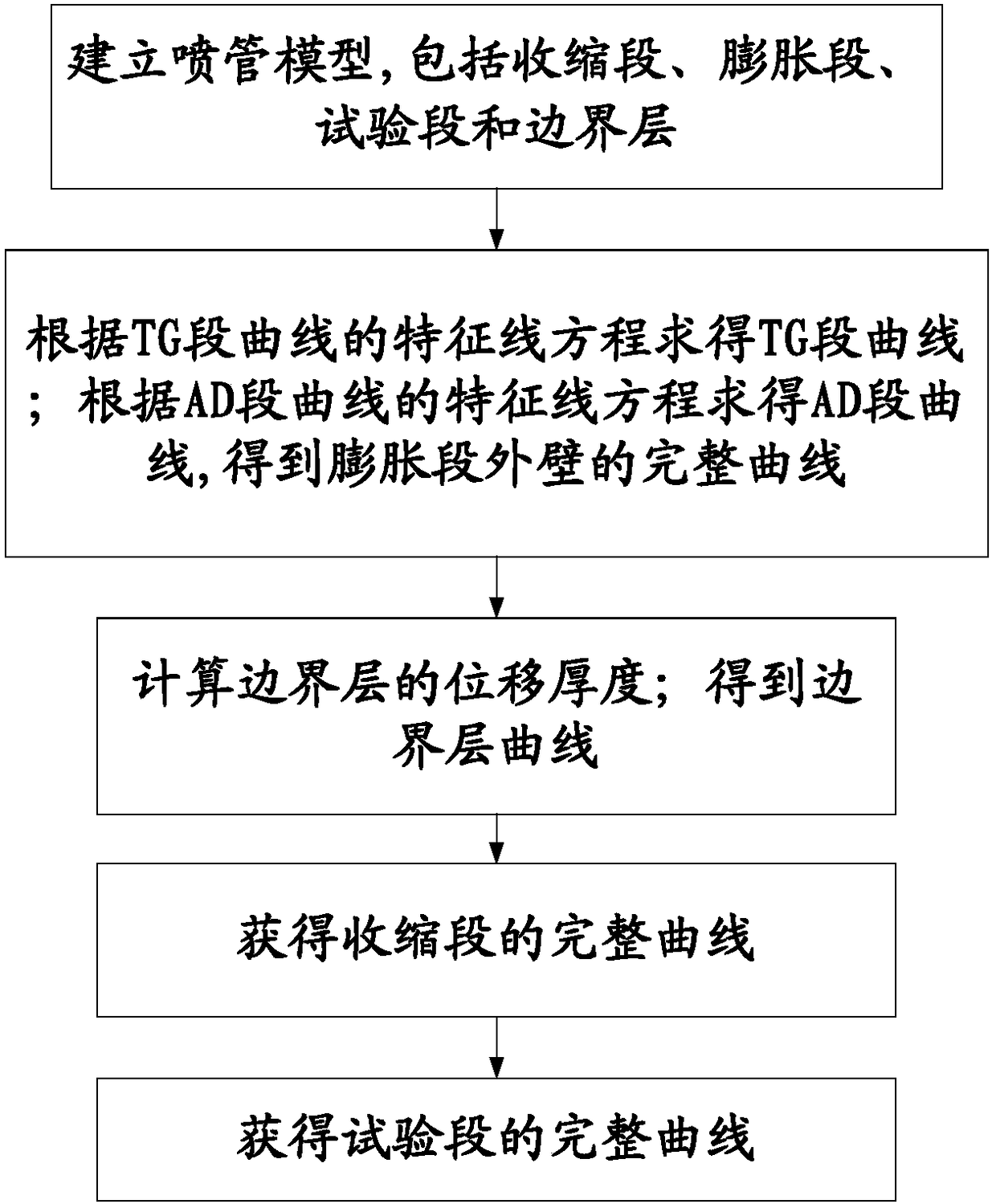

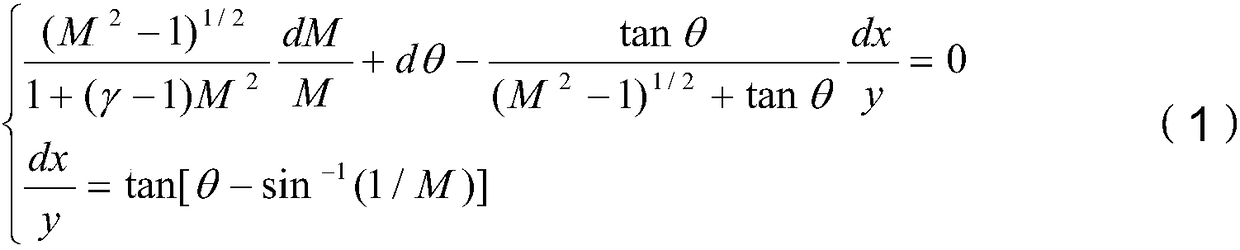

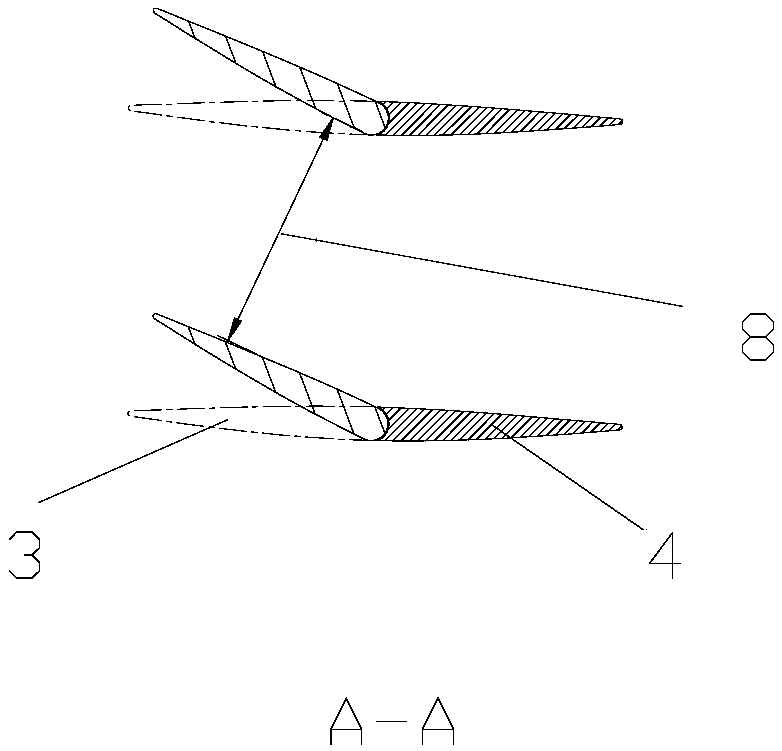

Supersonic velocity integrated spray pipe design method

ActiveCN108182319AGood flow field qualityContinuous slopeGeometric CADDesign optimisation/simulationDeflection angleAirflow

The invention discloses a supersonic velocity integrated spray pipe design method and relates to the field of wind tunnel tests. The method includes the following steps of 1, creating a spray pipe model, wherein the model includes a retraction segment, an expansion segment, a testing segment and a boundary layer; 2, figuring out a TG segment curve according to a characteristic line equation of theTG segment curve, figuring out an AD segment curve according to a characteristic line equation of the AD segment curve, and correspondingly obtaining a complete curve of the outer wall of the expansion segment; 3, calculating the displacement thickness of the boundary layer to obtain a boundary layer curve; 4, obtaining a complete curve of the retraction segment; 5, obtaining a complete curve ofthe testing segment. By means of the method, a testing area is enlarged, and the parameters such as a Mach number root-mean-square deviation, an axial Mach number gradient and an airflow-deviation angle of the testing segment are all in line with national military-standard advanced indexes.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

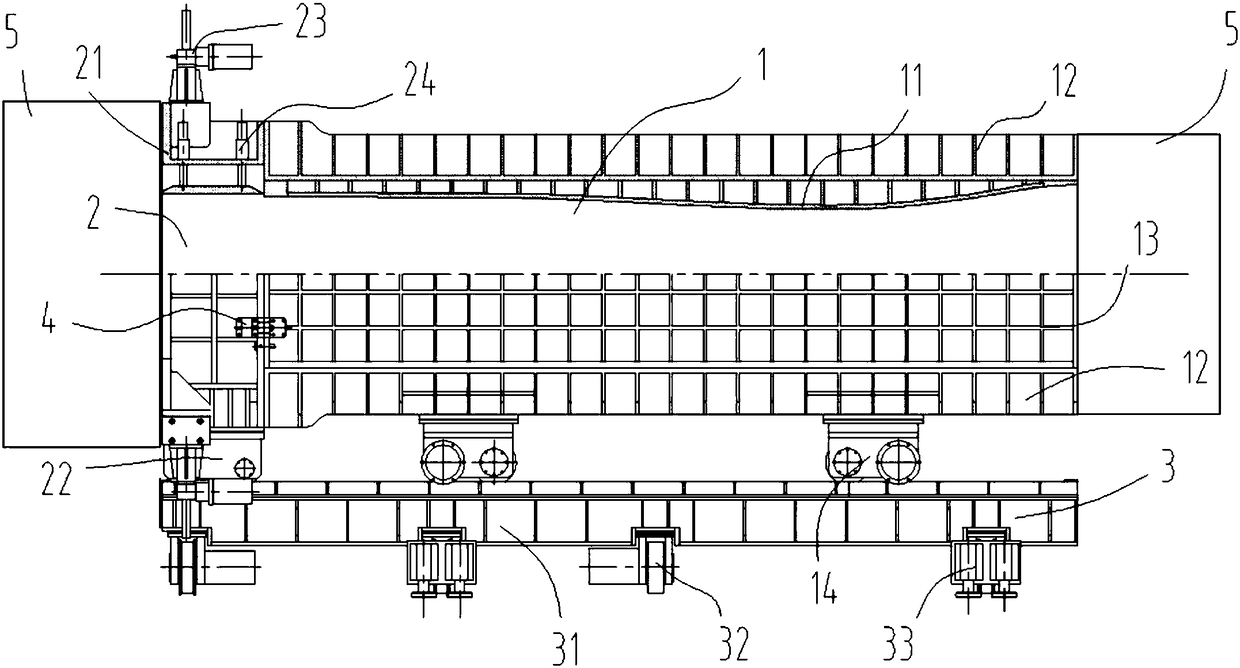

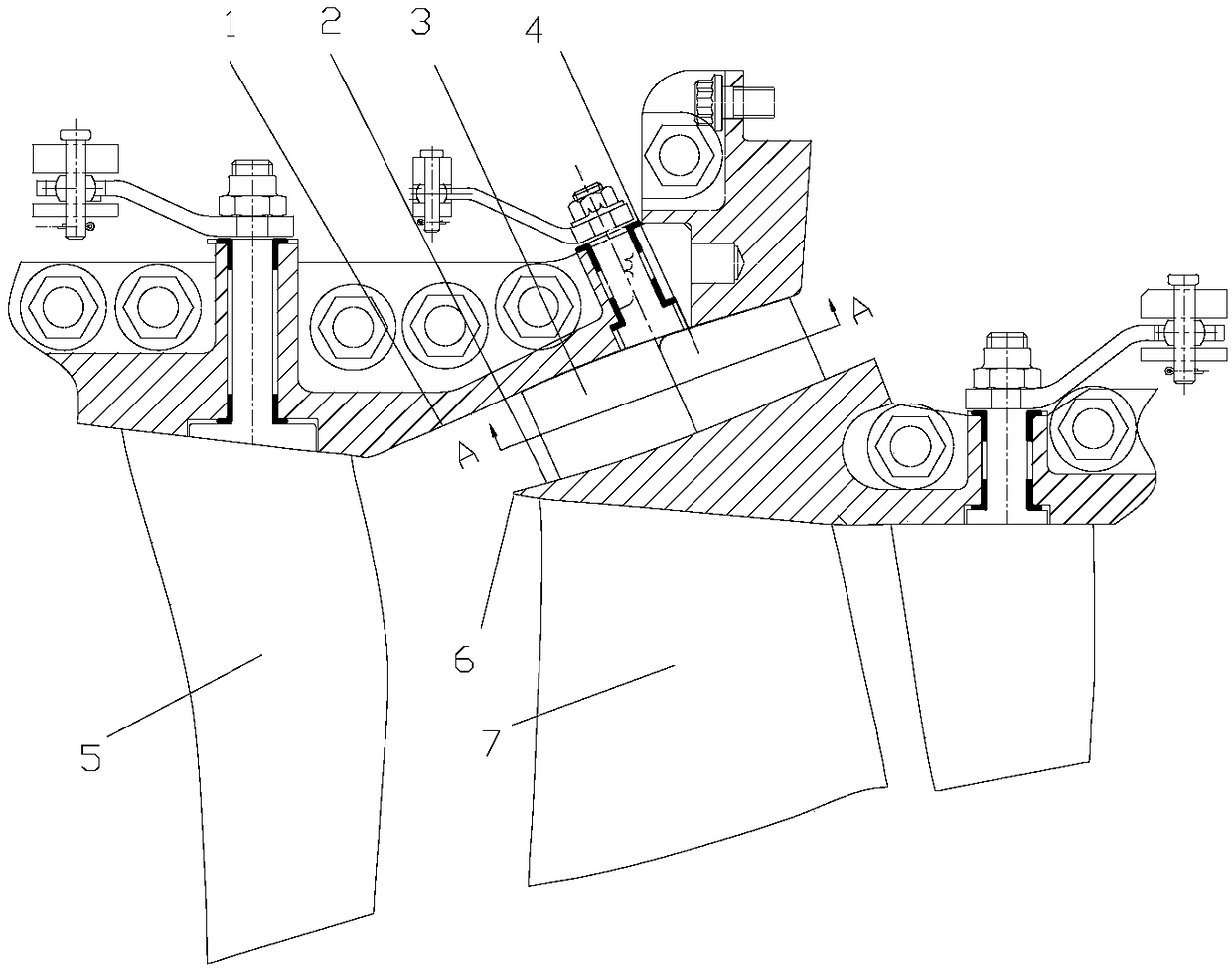

Large wind tunnel nozzle test section integrated device

ActiveCN108519209AEliminate step wavesImprove flow field qualityAerodynamic testingAerospace testingEngineering

The invention discloses a large wind tunnel nozzle test section integrated device, and relates to the technical field of aerospace testing. The large wind tunnel nozzle test section integrated devicecomprises an nozzle test integrated section, an outlet flange section, a support frame car, a thread pin and wind tunnel devices; the support frame car is horizontally placed on the ground; the nozzletest integrated section is placed horizontally on the upper surface of the support frame car, and the axial direction of the nozzle test integrated section is identical to the longitudinal directionof the support frame car; the outlet flange section is coaxially fixed and installed in an axial outlet end of the nozzle test integrated section; the outlet flange section and the nozzle test integrated section are fixedly connected through the threaded pin; the wind tunnel devices are coaxially and fixedly mounted on the axial inlet end of the nozzle test integrated section and the axial outer end of the outlet flange section. The large wind tunnel nozzle test section integrated device adopts the modular design, is low in processing and manufacturing cost, is high in economy; driving is achieved by a wheel set, guiding and positioning is achieved by a guide rail; the operation is simple, and the safety is high; and the precise positioning design reduces the labor cost, and the disassembly and assembly is convenient. .

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

Low-temperature wind tunnel system

InactiveCN111413061AGuarantee job stabilityReduce adverse effectsAerodynamic testingAir cycleEngineering

The invention relates to a low-temperature wind tunnel system. The system includes: a refrigeration device configured to generate a cryogenic gas, a gas pipeline provided with a test section, an atomization spraying device, and an airflow driving device configured to drive the air in the air conveying pipeline to advance to the test section by utilizing the low-temperature air generated by the refrigerating device, wherein the airflow driving device is an ejector, the refrigerating device generates low-temperature gas through air circulation refrigeration, the low-temperature gas serves as a main flow of the ejector to be fed into the ejector, air in the air conveying pipeline is driven to advance to the test section along the air conveying pipeline and is mixed with air in the air conveying pipeline, so that the temperature of the test section is reduced. By adopting the low-temperature wind tunnel system, the adverse effect of freezing on an airflow driving device in the wind tunnelsystem can be effectively avoided, and the working stability of the wind tunnel system is effectively ensured.

Owner:COMAC +1

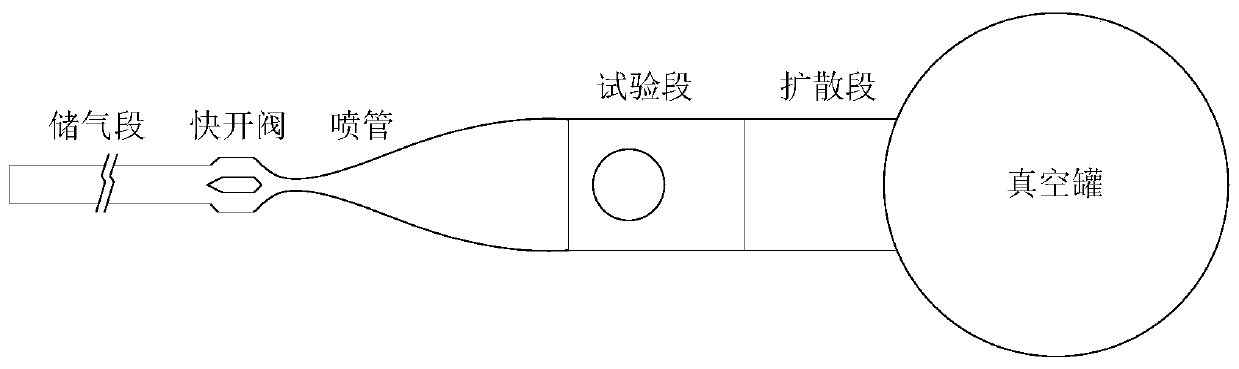

Ludwieg tube wind tunnel and high Mach number expansion method thereof

ActiveCN111426445ASimple methodImprove flow field qualityAerodynamic testingEnvironmental geologyStructural engineering

The invention discloses a Ludwieg tube wind tunnel and a high Mach number expansion method thereof, and belongs to the technical field of hypersonic speed wind tunnels. According to the invention, a stable section is added on the basis of a traditional Ludwieg tube wind tunnel; an inlet of the stable section is matched with an outlet of a quick-opening valve; an outlet of the stable section is matched with an inlet of a spray pipe; a stable subsonic flow field is formed between the wind tunnel quick-opening valve and a spray pipe section; meanwhile, a throat specification replaceable spray pipe matched with the stable section is designed, and due to the addition of the stable section, the operation mach number of the wind tunnel can be expanded to a high mach number only by replacing spraypipes with different throat specifications on the premise of not changing other parts of the wind tunnel. Through the technical scheme of the invention, the high mach number expansion of the Ludwiegtube wind tunnel can be realized. The method for expanding the high Mach number wind tunnel is simple and economical, a good test flow field is easy to obtain, and in addition, the method can also beused as a method for improving the quality of the flow field of the Ludwieg tube wind tunnel.

Owner:AERODYNAMICS NAT KEY LAB +1

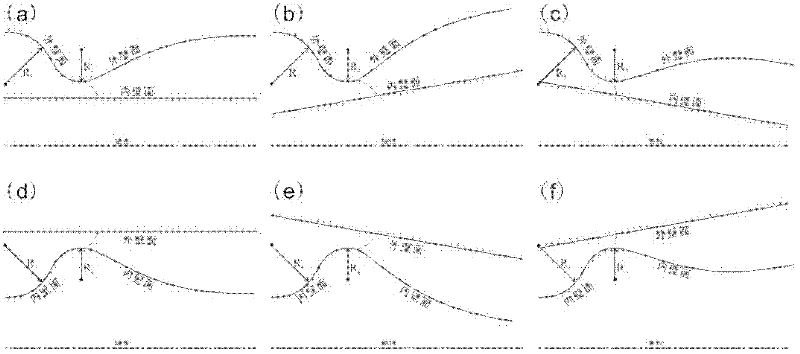

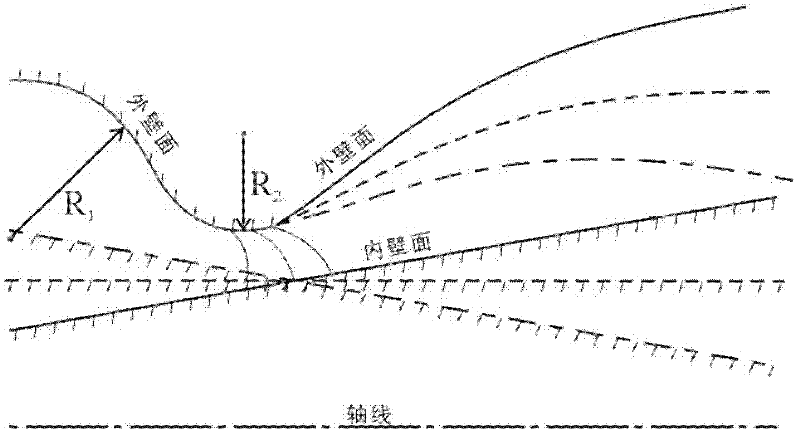

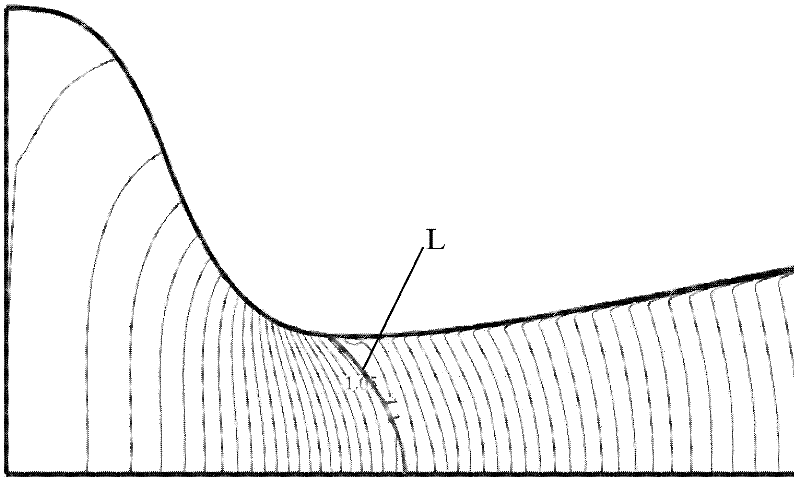

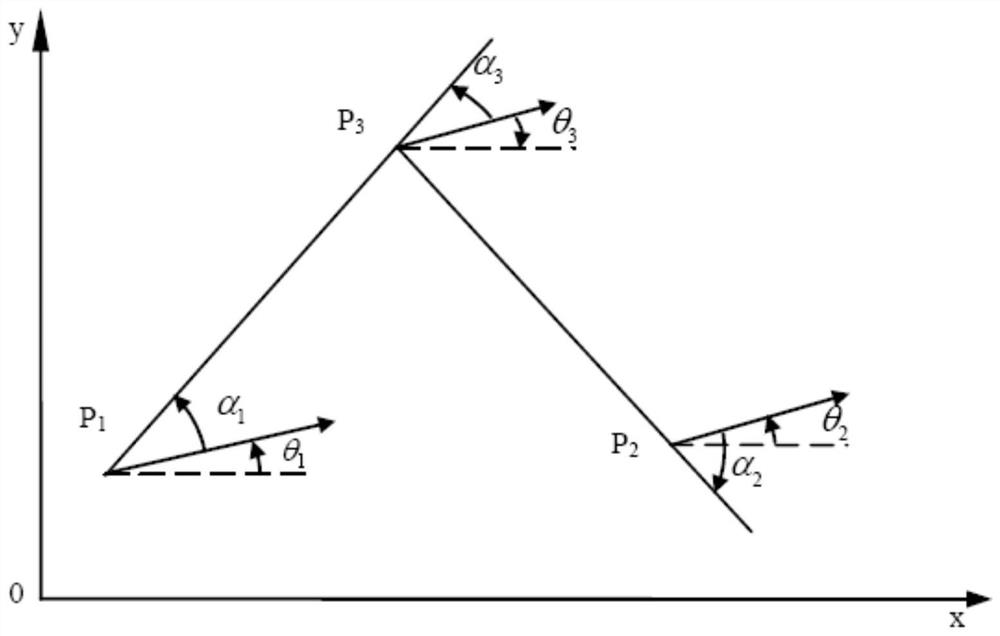

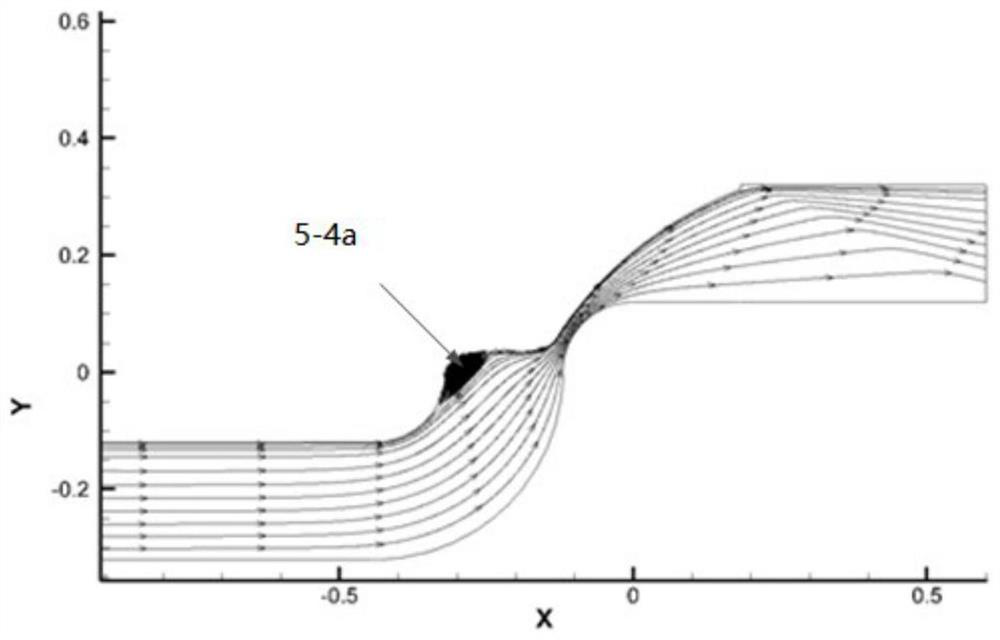

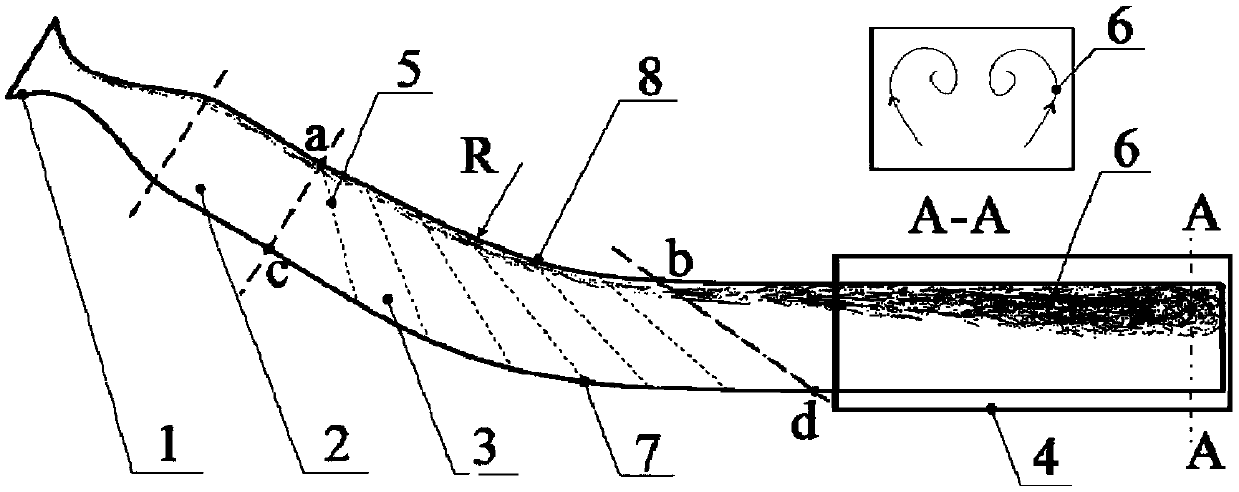

Method for designing ultrasonic-speed turning flow channel

The invention provides a method for designing an ultrasonic-speed turning flow channel. The method comprises the following steps of: determining the inlet boundary of the wall surface curve of the ultrasonic-speed flow channel according to the geometric constraint of the design structure of the ultrasonic-speed flow channel; determining the one-sided wall surface curve of the ultrasonic-speed flow channel according to the geometric constraint of the design structure of the ultrasonic-speed flow channel; determining the opposite-side wall surface curve which corresponds to the one-sided wall surface curve by adopting the method of characteristics; and determining the wall surface curve of the ultrasonic-speed flow channel according to the parameters of an outlet flow field. Due to the adoption of the method, the shock-free ultrasonic-speed flow channel of the whole flow field can be obtained, and a better flow field environment can be provided for the aerodynamic and structural design of an ultrasonic-speed wind tunnel, an ultrasonic-speed ejector and an ultrasonic-speed aircraft.

Owner:NAT UNIV OF DEFENSE TECH

External culvert structure adapted to variable incoming flow angle low loss adjustable support plate

InactiveCN108252823AReduce flow lossImprove flow field qualityJet propulsion plantsEngineeringBypass ratio

The invention belongs to the field of design of a core drive fan and a high pressure compressor in a gas turbine type engine, and provides an external culvert structure adapted to a variable incomingflow angle low loss adjustable support plate. A second external culvert inlet is located on a casing between the outlet of a CDFS (5) and the inlet of a high pressure compressor rotor (7), and an external culvert support plate of a second external culvert adopts a segmented adjustable structure. According to the external culvert structure adapted to the variable incoming flow angle low loss adjustable support plate, the second external culvert between the CDFS and the high pressure compressor is redesigned, and the inlet position of the second external culvert, an upper flow passage of the second external culvert, a lower flow passage of the second external culvert and a support plate structure of the second external culvert are specially designed, so that the air entraining content requirement under different bypass ratios can be realized under the condition that the high pressure compressor has better quality of an inlet flow field; and the flow losses in the second external culvertcan be well controlled under different incoming flow angles to ensure the better quality of an outlet flow field of the second external culvert.

Owner:AECC SICHUAN GAS TURBINE RES INST

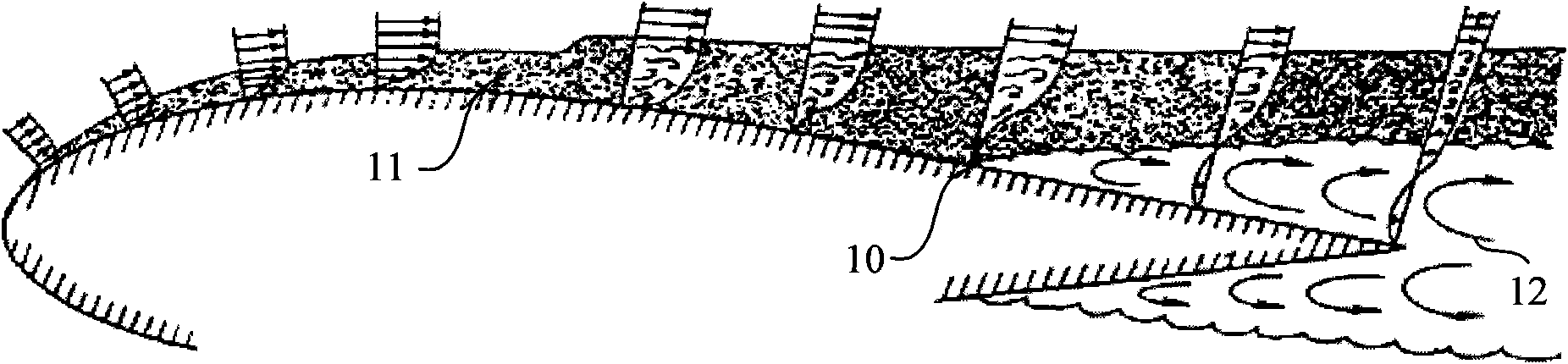

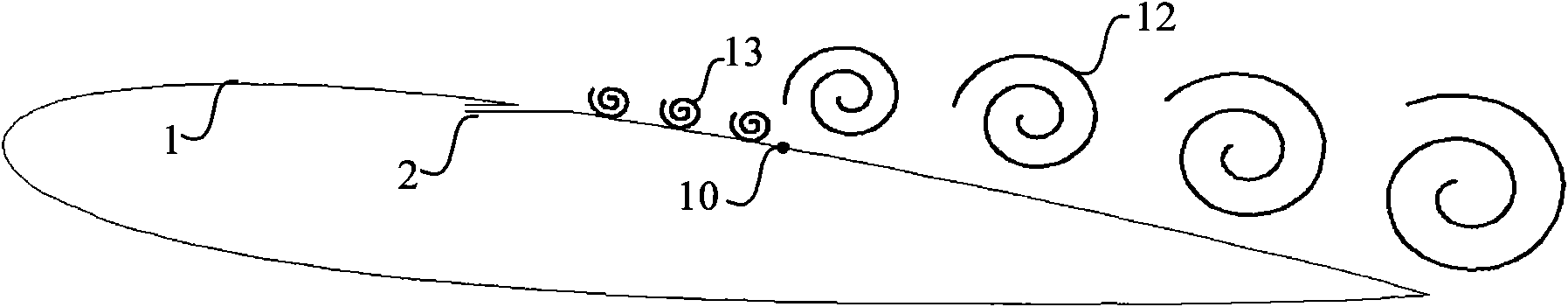

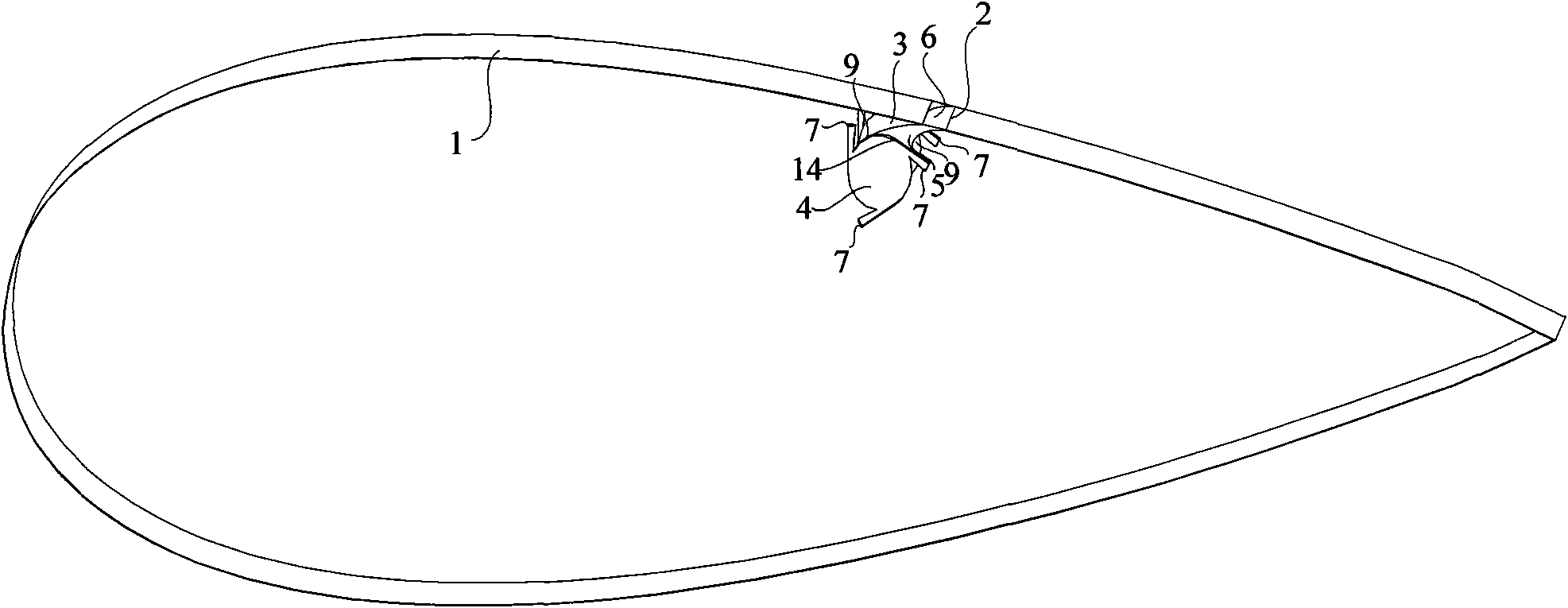

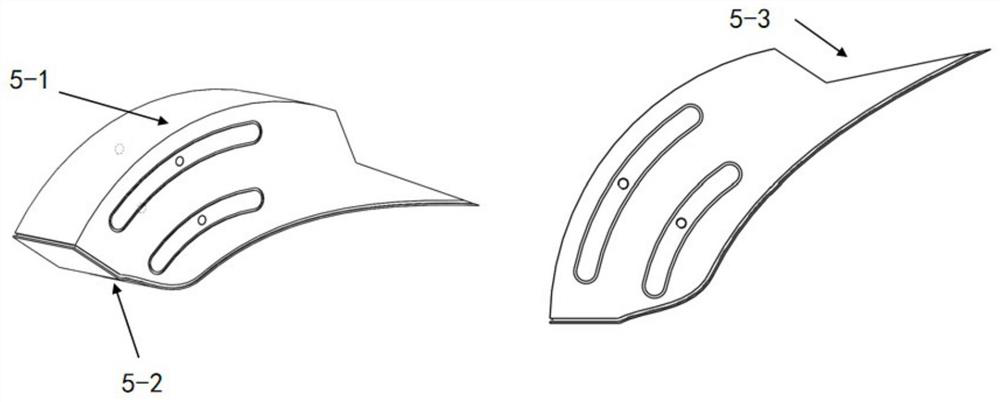

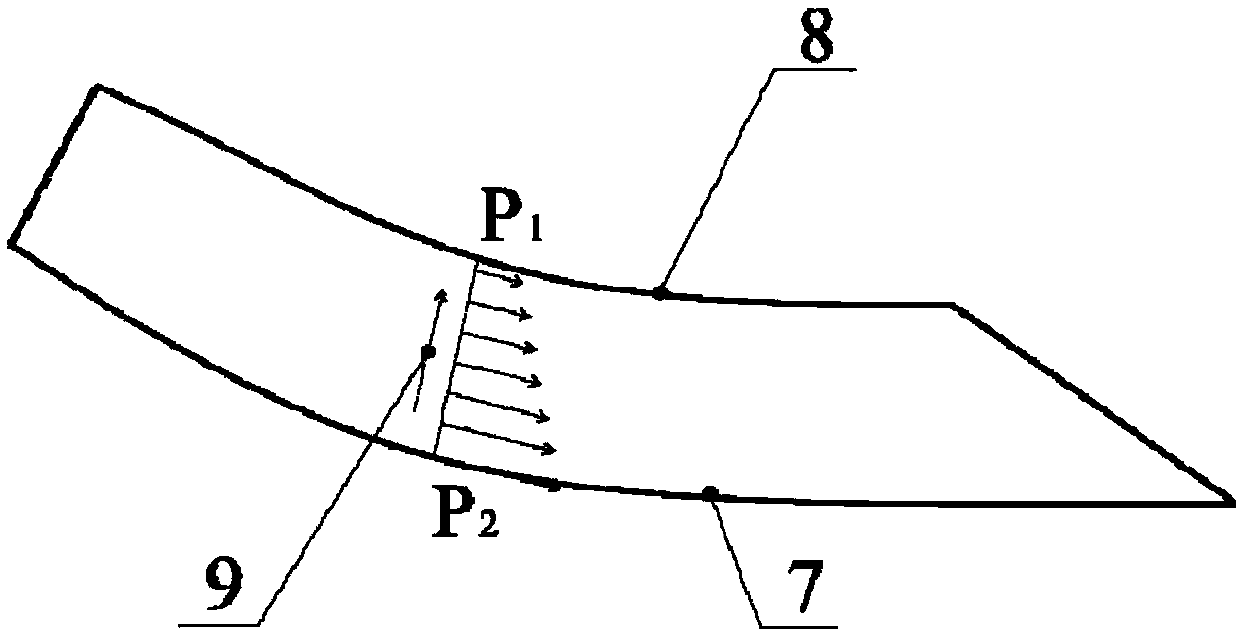

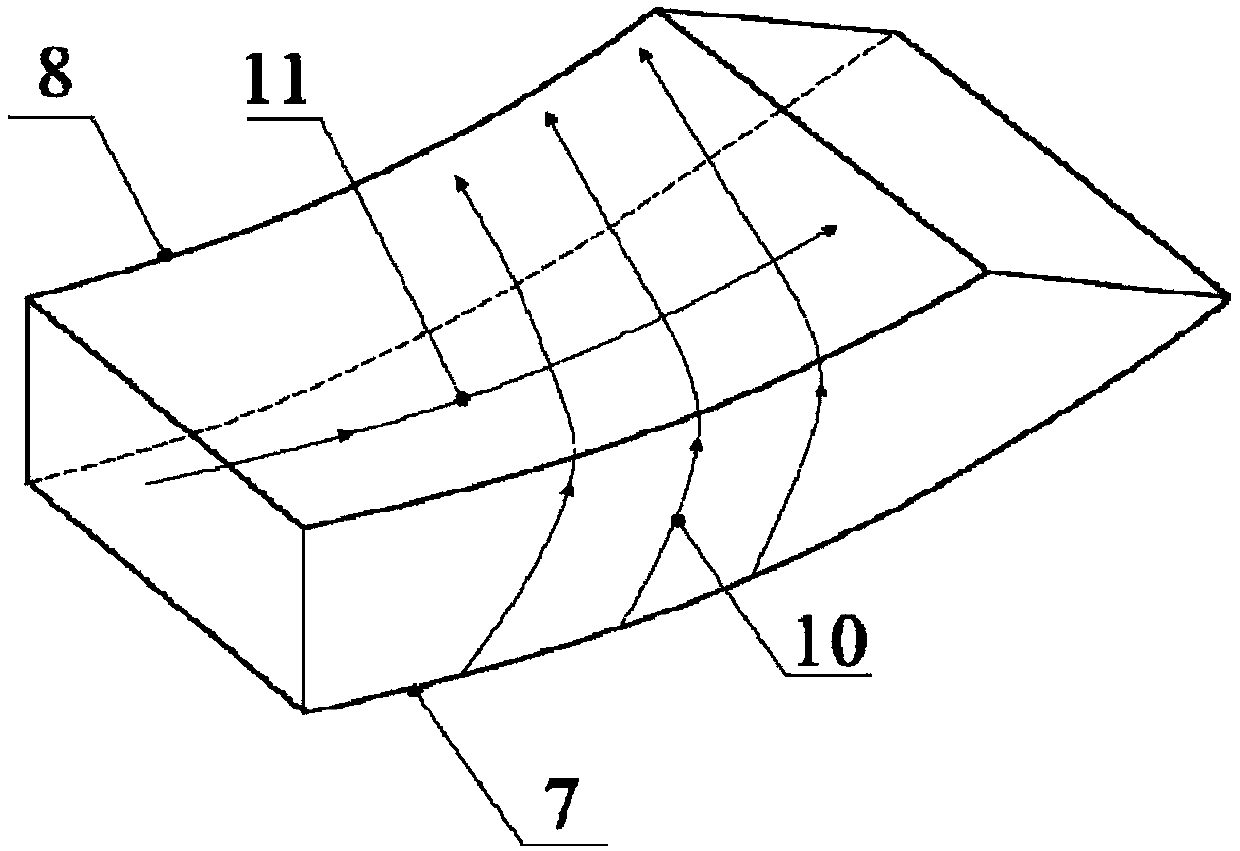

Reverse circulation blowing-down device of wing boundary layer

InactiveCN101633406AInhibition of flow separationImprove flow field qualityHeat reducing structuresEngineeringCircular cavity

The invention discloses a reverse circulation blowing-down device of a wing boundary layer, comprising a blowing passage, whirlcones and an end surface, wherein wing surfaces are provided with blowing slits, the blowing passage is in the shape of a curved surface and comprises a circular arc surface and a curved surface, wherein one end of the curved surface is smoothly connected with the circular arc surface, the other end of the curved surface is connected with the blowing slits and is tangent with the wing surfaces, and the tangent positions are processed with chamferings; the blowing passage is perpendicular to both ends of the plane of wings or the middle of the blowing passage is connected with the whirlcones, and the radius and the wall thickness of the circular arc surface are equal to that of circular cavities of the whirlcones; the whirlcones positioned on both ends of the blowing passage are sealed with the surfaces and the curved surfaces of the wings by the end surface and are provided with tangential air inlets, and the air flow rotating directions of the whirlcones are reverse to a bypass flow whirlpool. Compared with a common independent blowing scheme, the reverse circulation blowing device of the wing boundary layer better restrains the flow separation, can thoroughly eliminate the separation areas under small blowing quantity and enhance the flow field quality.

Owner:BEIHANG UNIV

Current stabilizer

The invention discloses a current stabilizer, which comprises a shell, a first plate body, a deformable container, an air source and a controller, wherein the first plate body is arranged in the shellto divide a closed cavity into a first cavity and a second cavity which are mutually communicated, the deformable container is disposed within the first cavity and defines a gas chamber within the deformable container for containing gas, the gas chamber has a gas preload, the deformable container is configured to contract when the gas preload is less than a circulating liquid pressure within theshell, and to expand when the gas preload is greater than the circulating liquid pressure within the shell, the gas source is communicated with the gas chamber through a gas chamber connecting pipe, the controller is respectively connected with the gas source and the gas chamber, and the controller controls the gas source to provide gas to the gas chamber according to the pressure in a circulatingfluid loop so as to form gas prepressing. According to the current stabilizer provided by the embodiment of the invention, the flow and pressure fluctuation in the circulating fluid loop can be effectively absorbed, so that the stable flow of the circulating fluid in the circulating fluid loop is ensured, and the quality of a flow field is improved.

Owner:STATE POWER INVESTMENT CORP RES INST

Spray pipe section structure and method for realizing continuous variable mach number wind tunnel

ActiveCN113295369ATurn fasterImprove flow field qualityAerodynamic testingWind energy generationRotational axisEngineering

The invention provides a spray pipe section structure and method for realizing a continuous variable mach number wind tunnel. The spray pipe section structure comprises a protective shell, a spray pipe section upper wall face, a spray pipe section lower wall face, a spray pipe section side wall, a rotary spray pipe, a rotary shaft, a driving device and a transmission force arm. The positions of the spray pipe section upper wall surface and the spray pipe section lower wall surface are fixed and are used for connecting a downstream experiment section and an upstream stable section of the spray pipe section structure. When the rotating spray pipe rotates around the rotating shaft under the transmission action of the transmission force arm and the power action of the driving device, self-adaptive backflow areas are formed at the upstream position and the downstream position of the rotating spray pipe, and the self-adaptive backflow areas are used for generating pneumatic wall faces, so that flowing in a flow field where the rotating spray pipe is located is kept smooth. The lower wall surface of the rotary spray pipe and the lower wall surface of the spray pipe section form a throat part, airflow reaches sound velocity at the throat part, and when the rotary spray pipe is rotated, the deflection angle is adjusted by changing the position of the throat part, so that the sound velocity reaches a specific Mach number based on the deflection angle, and the continuous variable Mach number wind tunnel is realized.

Owner:NAT UNIV OF DEFENSE TECH

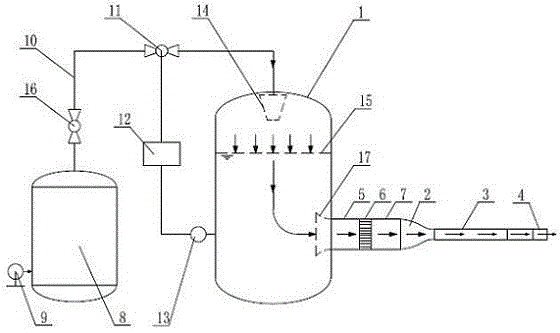

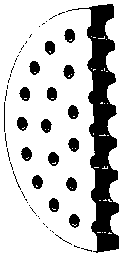

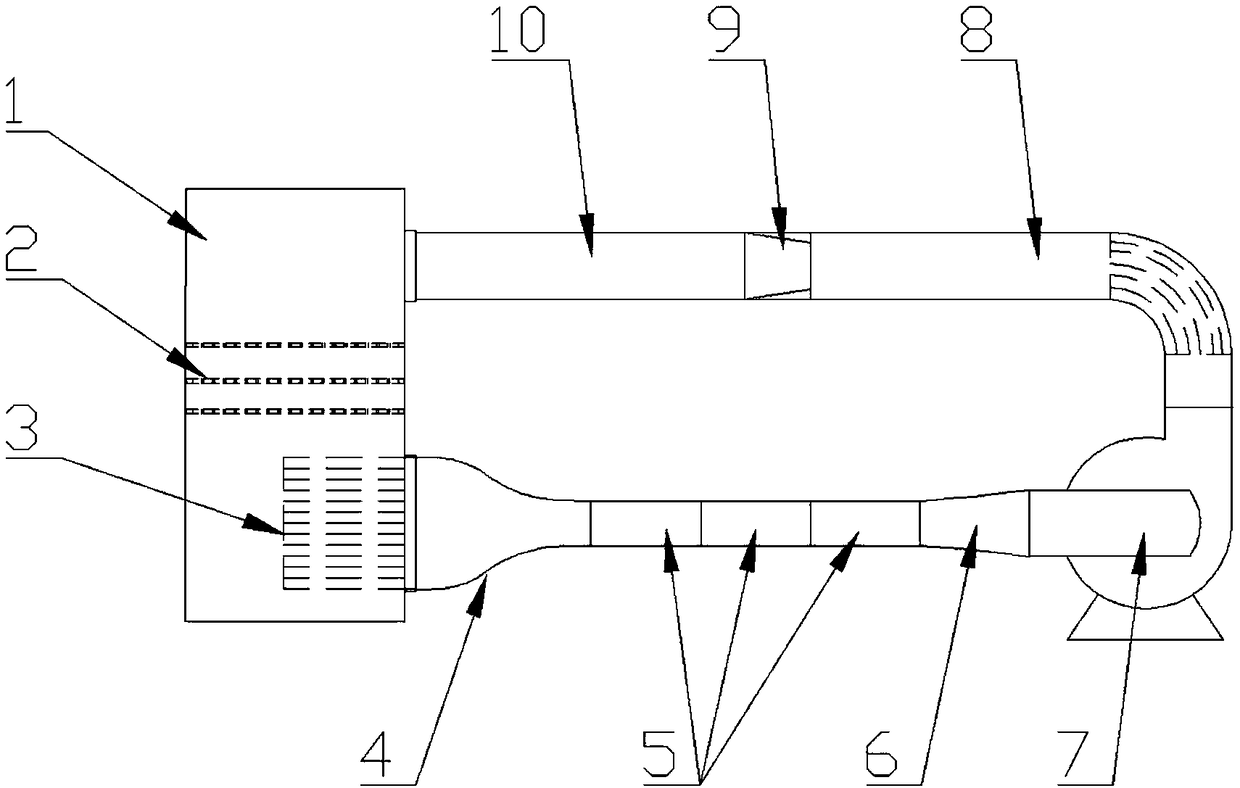

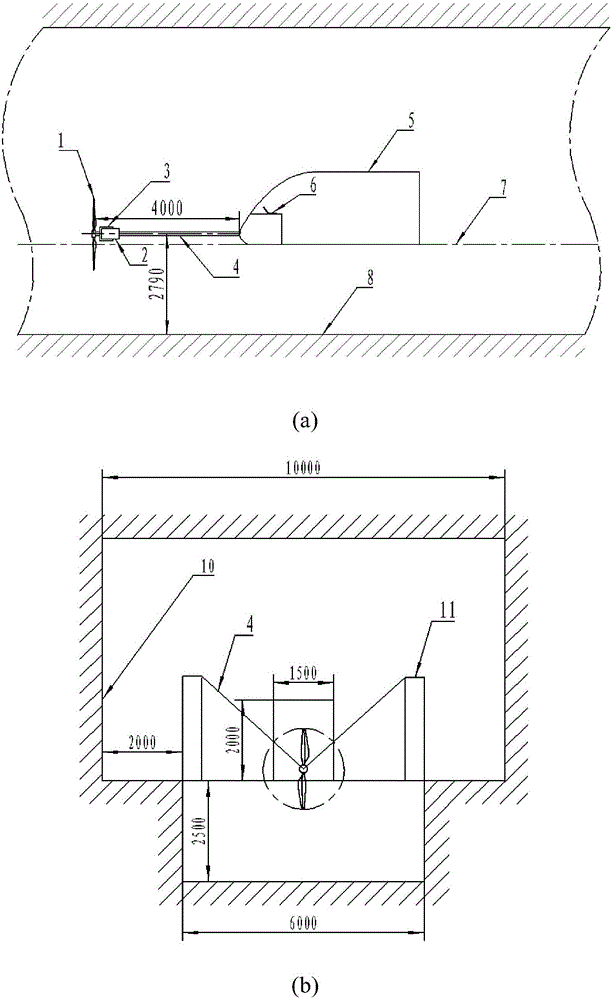

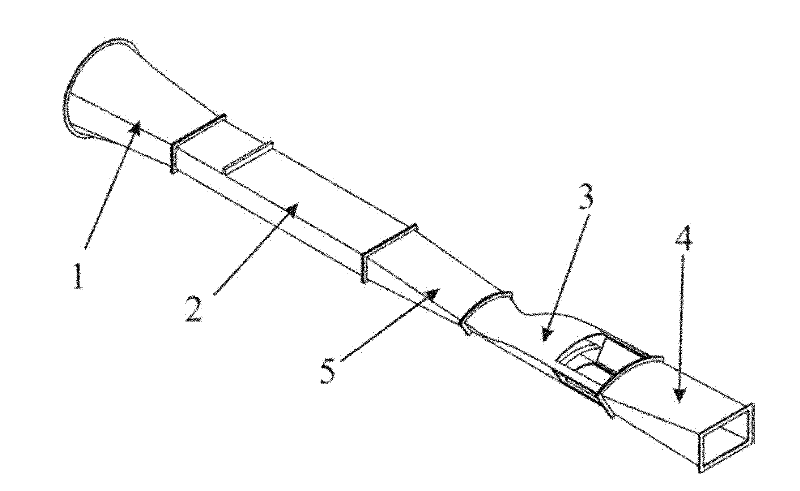

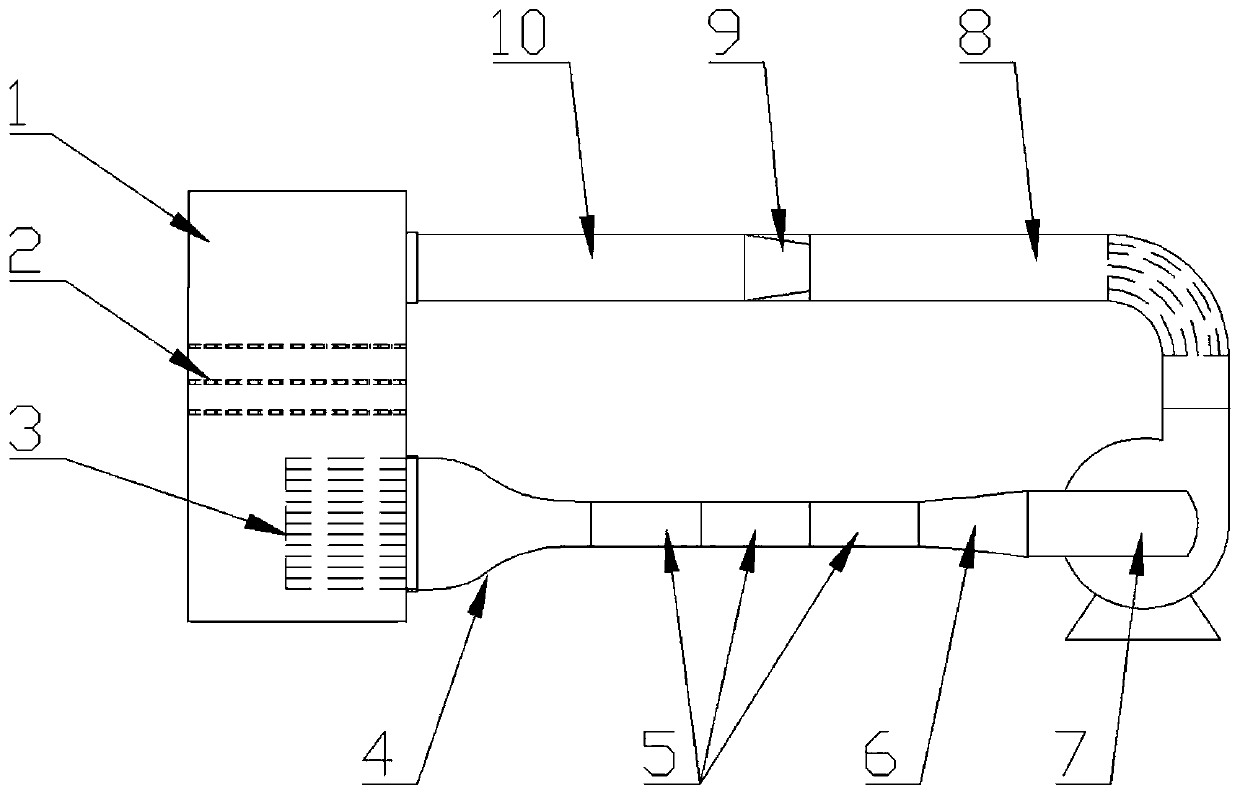

Low-turbulence compact circulating water tunnel experimental device

The invention discloses a low-turbulence compact circulating water tunnel experimental device, comprising a water tank (1), a centrifugal pump (7), and a porous plate (2) and a honeycomb screen (3) which are disposed in the water tank (1). The water tank (1) has a water inlet at the upper part and a water outlet at the lower part at the same side. The porous plate (2) is installed between the water inlet and the water outlet. The honeycomb screen (3) is installed at the water outlet, and has an outlet successively connected a contraction section (4), an experimental section (5) and an expansion section (6). The outlet of the expansion section (6) is connected to the inlet of the centrifugal pump (7). The outlet of the centrifugal pump (7) is successively connected with a backflow section(8), a round-to-square section (9) and a diverging section (10). The outlet of the diverging section (10) is connected to the water inlet of the water tank (1). The hydrodynamic design used by the invention greatly reduces the turbulence of a flow field in the experimental section. The whole experimental device has a compact structure, a small occupied space and low manufacturing cost, which greatly improves the applicability of the water tunnel experimental device.

Owner:XI AN JIAOTONG UNIV

Single-pair supersonic flow direction vortex generation device

ActiveCN109655271AAvoid pollutionSimple structureInternal-combustion engine testingShock waveFully developed

The invention discloses a single-pair supersonic flow direction vortex generation device. The device comprises a laval nozzle, a transition section, a vortex generation section and a test window whichare sequentially connected. A uniform supersonic flow is formed through the laval nozzle and the transition section and enters the vortex generation section, the side wall boundary layer is induced to form transverse flow by means of radial pressure gradient, a pair of large-scale flow direction vortices are generated on one side of a pipeline, and through the design of wave elimination, a uniform and background-free supersonic core flow and a fully-developed single-pair supersonic flow vortex can be generated in the test window. The vortex generation device has the advantages of being simplein structure, convenient to integrate with an existing test bed and display a flow field, and effectively avoiding the pollution of a background wave system to the flow field. In addition, the flow channel area of a test device is gradually increased, and an additional vortex generation device is not needed, so that the requirement of a direct-connected test bed on the plugging degree of a modelis more easily met, a feasible test device is provided for researching the interference mechanism of a shock wave string and the supersonic flow direction vortices in a scramjet engine.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

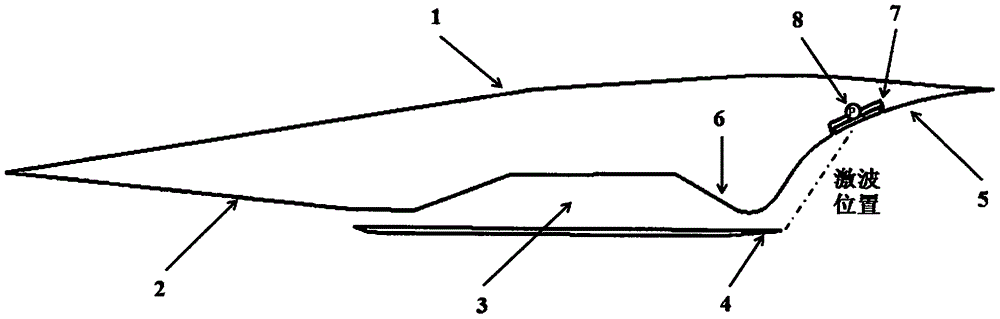

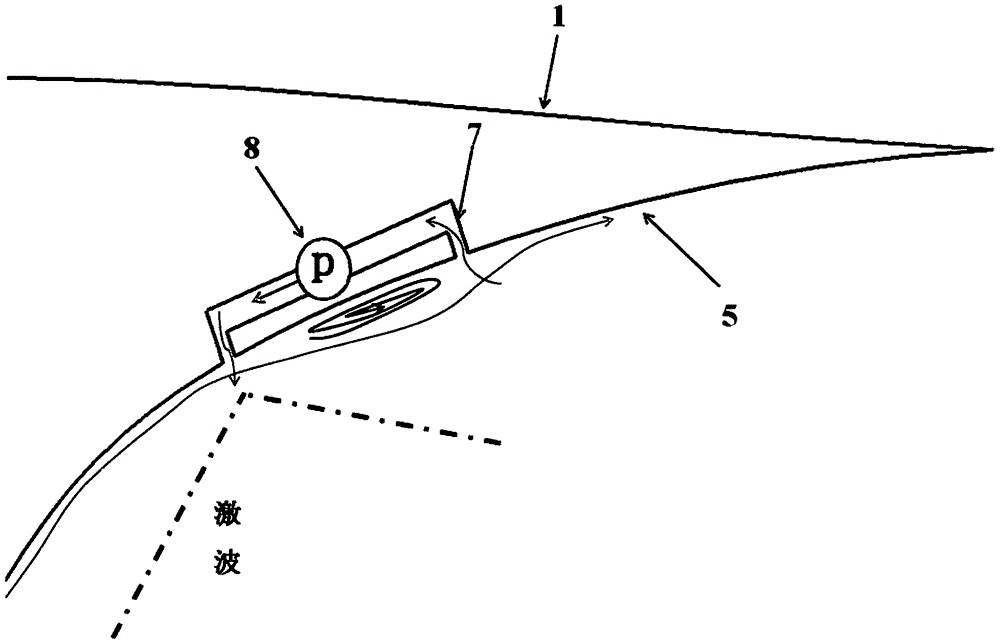

Pressurization flow control device-containing SERN structure for TBCC

InactiveCN106014683AImproved transonic thrust performanceEliminate separationEfficient propulsion technologiesJet propulsion plantsShock waveEngineering

The invention relates to a pressurization flow control device-containing SERN structure for a TBCC. The SERN structure comprises a lower wall surface of a single expansion ramp nozzle, a contraction section of the single expansion ramp nozzle and a single expansion ramp nozzle single-side expansion section, and further comprises the pressurization flow control device arranged on the single expansion ramp nozzle single-side expansion section, wherein the pressurization flow control device comprises a U-shaped communicating pipeline and a supercharger arranged on the U-shaped communicating pipeline; besides, a front port of the U-shaped communicating pipeline is positioned in front of an intersection point of an oblique shock wave and the single expansion ramp nozzle single-side expansion section; and a back port of the U-shaped communicating pipeline is arranged at the back of the intersection point of the oblique shock wave and the single expansion ramp nozzle single-side expansion section. According to the SERN structure, airflow flowing through the communicating pipeline is pressurized, extra airflow in a diverging zone is extracted and then is ejected from the front port at a relatively high speed, so that the separation zone range is greatly decreased and even eliminated, the shock wave is moved forwards, the static pressure distribution of a main flow is changed, and the working condition of overexpansion operation is improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Multiphase flow vertical-type water hole with bi-directional flowing function

The invention discloses a multiphase flow vertical-type water hole with a bi-directional flowing function. The multiphase flow vertical-type water hole comprises a power section, a backflow section, alower rectifying section, a lower diameter-variable section, a work section, an upper diameter-variable section, an upper rectifying section and an upper tank. In work, a second water pump is closed,a first water pump is started, a fluid in the water hole flows to the lower rectifying section, the lower diameter-variable section, the work section, the upper diameter-variable section and the upper rectifying sectionsequentially along the backflow section and then enters the upper tank for closed circulation; or the first water pump is closed, the second water is started, the fluid in the water hole flows to the upper rectifying section, the upper diameter-variable section, the work section, the lower diameter-variable section and the lower rectifying section sequentially along the upper tank and then enters the backflow section for closed circulation. According to the multiphase flow vertical-type water hole, the mode that the first water pump and the second water pump are arranged inparallel is adopted, the movement direction of the fluid is conveniently and rapidly converted; and water replenishing connecting pipes and particle solution connecting pipes are evenly distributed on the lower diameter-variable section and the upper diameter-variable section, the influences of flowing separation on the experimental result are prevented from water replenishment, and through adding of bubbles and particles, multiphase flowing is achieved.

Owner:HEBEI UNIV OF TECH +1

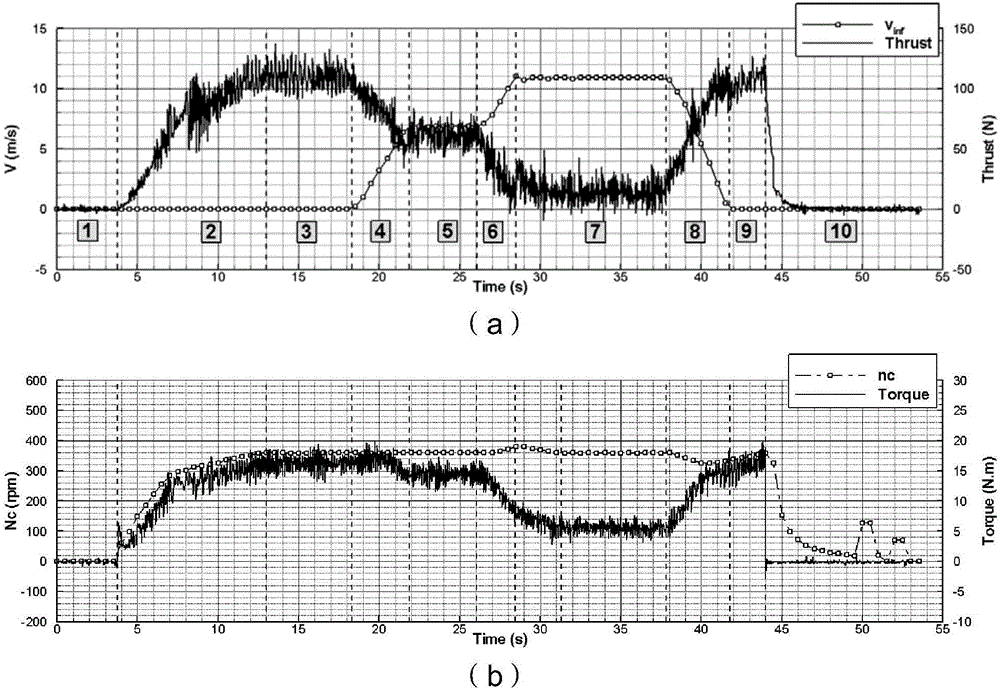

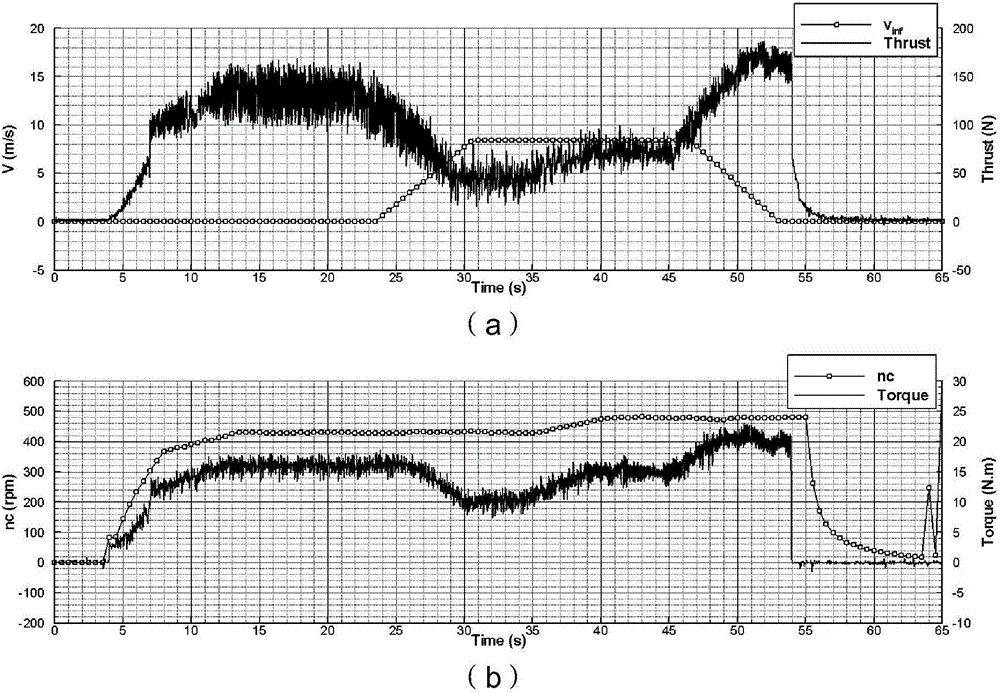

Dynamic response characteristic test method for air propeller electric propulsion system

ActiveCN106813891AIncreased cross-sectional areaGood flow field qualityAerodynamic testingElectric machineryPropeller

The invention relates to a dynamic response characteristic test method for an air propeller electric propulsion system. The method comprises: a ground test system of an electric aircraft propeller is constructed; a trailer is accelerated to be at a steady-state speed at different accelerated speeds, the acceleration state is kept for a period of time, and a tensile force and a torque of the propeller and a rotating speed of the motor are measured; the speed of the trailer is kept to be constant, the rotating speed of a motor is adjusted, and a tensile force and a torque of the propeller are measured; and the influence on the rotating speed of the motor by a trailer speed change as well as influences on the tensile force and torque of the propeller by the trailer speed change or motor rotating speed change is analyzed. The test method has the following advantages: the trailer speed can be controlled precisely; the trailer system has the large accelerated speed; the marching speed of the propeller can be changed; and the dynamic response characteristic of the propulsion system can be simulated when gust happens. The speed regulation characteristic of the electric propulsion system of the propeller can be measured by changing the rotating speed instruction of the motor. The test method is suitable for a dynamic response characteristic test of a propulsion system of a low-speed electric propeller aircraft.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

Three-freedom-degree flapping-wing comprehensive experiment platform

InactiveCN102338690BUp and down flutterSweep forward and backwardAerodynamic testingFlapping wingThree degrees of freedom

The invention discloses a three-freedom-degree flapping-wing comprehensive experiment platform which comprises a rack, a driving motor, a transmission mechanism, flapping wings and a control system, wherein a box-type structure is adopted under the rack and is used for installing the driving motor and the control system; two universal bearings are symmetrically arranged by a cross beam supported by vertical columns, so that one pair of flapping wings have three rotating freedom degrees; and the transmission mechanism transmits the rotation of the driving motor to the flapping wings to realize three-freedom-degree compound flapping, and measures the flapping force and the torque characteristic of the flapping wings by a sensor. According to the three-freedom-degree flapping-wing comprehensive experiment platform, any three-freedom-degree preset flapping law of the up-down flapping, the front-back sweeping and twisting can be accurately realized, and the direct real-time measurement is carried out on the force and moment in the flapping process. The three-freedom-degree flapping-wing comprehensive experiment platform is suitable for analysis and verification of the wind tunnel test for the complex moving law of the flapping wings.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

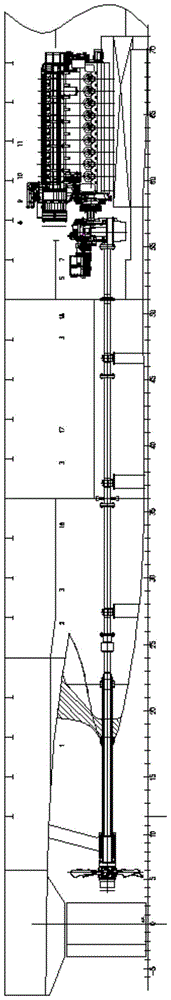

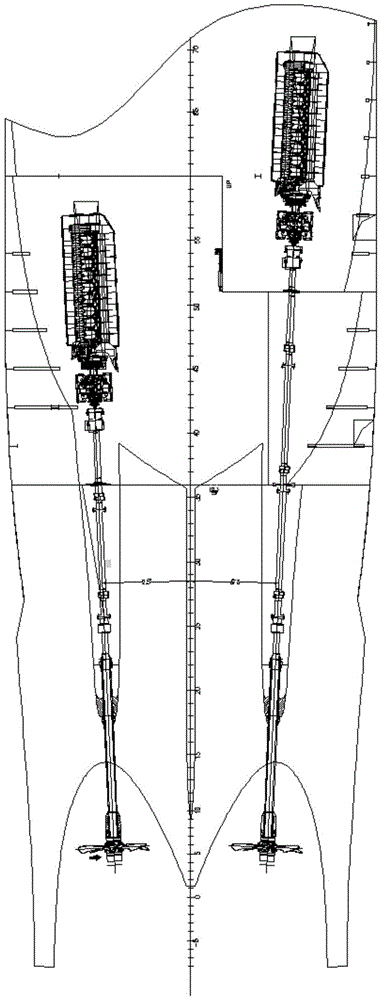

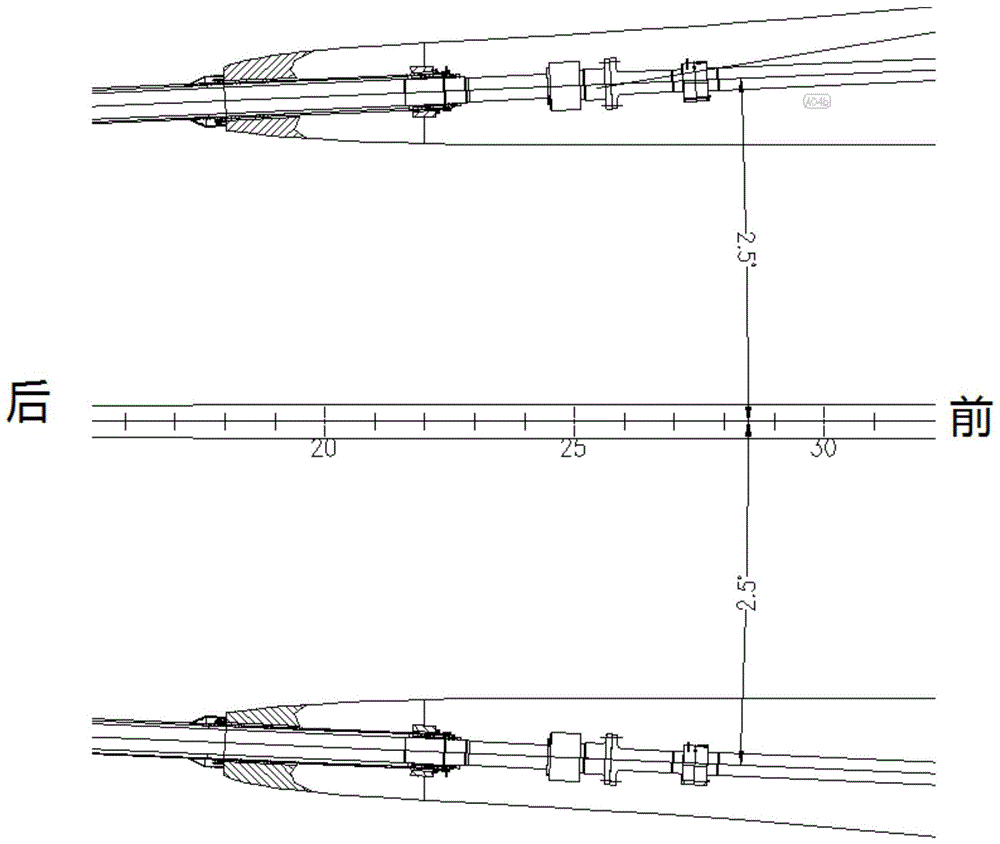

Stern structure for internal rotation double-paddle ship

InactiveCN105730603AReduce the excitation forceImprove the quality of the tail flow fieldWatercraft hull designHydrodynamic/hydrostatic featuresWater flowEngineering

The invention relates to a stern structure for an internal rotation double-paddle ship. The stern structure comprises a pair of small tail fins. In a vertical view, each small tail fin is arranged at a horizontal inclination angle from front to back towards the central axis of a hull, and a pair of supporting shafts in the small tail fins incline at the same angle. The small tail fins inclining inwards conform to the direction of a flow field of a stern, tail water flow separation is reduced, and therefore resistance is reduced. In addition, pre-rotational flow with the rotating direction opposite to that of paddles act on the paddles, so that the rear tail flow rotation of the paddles is weakened or eliminated, and the effects of tail flow energy loss reduction and propelling efficiency improvement are achieved. By the adoption of the stern structure, the tail flow field is effectively improved, the propeller exciting force is reduced, the propeller first-stage exciting force under designed draft is reduced to be below 1.5 kPa, and the ship comfort is improved; the structure is relatively simple, the structure and the size of a tail attaching body are not additionally arranged or changed, and optimization and implementation are better facilitated; and the economical efficiency and rapidness are better considered.

Owner:SHANGHAI MERCHANT SHIP DESIGN & RES INST

Supersonic velocity continuous variable mach number spray pipe based on center body

PendingCN111487030AIncrease changeTo avoid the disadvantage of slow changeAerodynamic testingInlet channelMarine engineering

The invention discloses a supersonic velocity continuous variable mach number spray pipe based on a center body. The spray pipe is a spray pipe box body, the upper surface of the spray pipe box body is a two-dimensional molded surface I, and the lower surface of the spray pipe box body is a symmetrical two-dimensional molded surface II. The center body is arranged on the center line of the box body and is symmetrical up and down, sliding grooves are formed at the left side and the right side of the center body, and the correspondingly-matched sliding rails are installed at the left side and the right side of the spray pipe box body. The center body can move forwards and backwards on the center line of the spray pipe box body through the cooperation of the sliding grooves and the sliding rails, a moving control mechanism is arranged outside the spray pipe box body to control the moving position and the moving speed of the center body, and sealing shrouds are arranged on the front end face and the rear end face of the spray pipe box body. The spray pipe adopts a sliding center body spray pipe technology, the Mach number of a wind tunnel can be changed from 2.0 to 3.5 or from 3.5 to 2.0 within 3 seconds, so that the high-speed wind tunnel can be ensured to have good flow field quality, and a reliable technical means is provided for the performance assessment and evaluation of an air inlet channel under the supersonic speed Mach number changing condition.

Owner:INST OF HIGH SPEED AERODYNAMICS OF CHINA AERODYNAMICS RES & DEV CENT

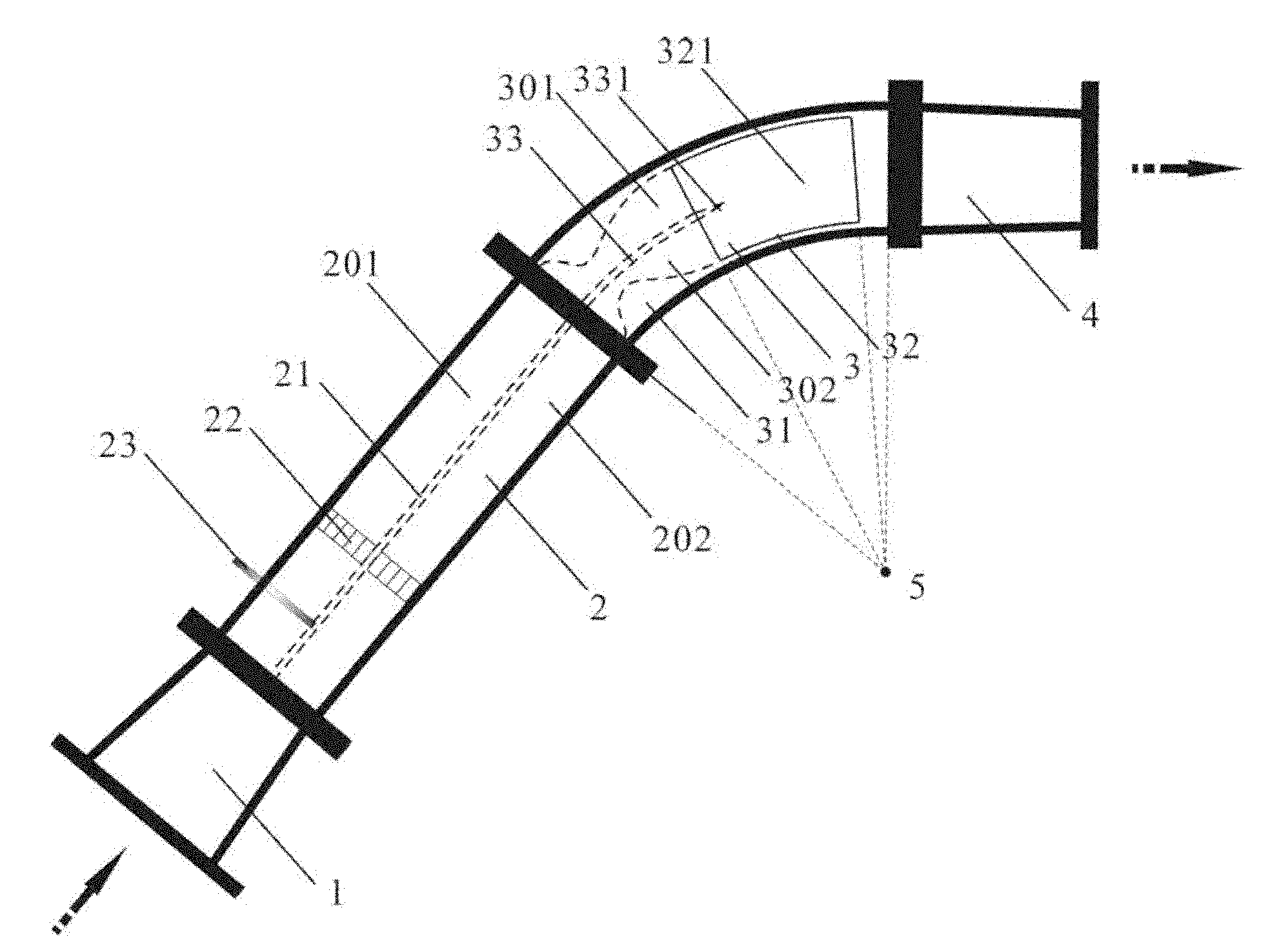

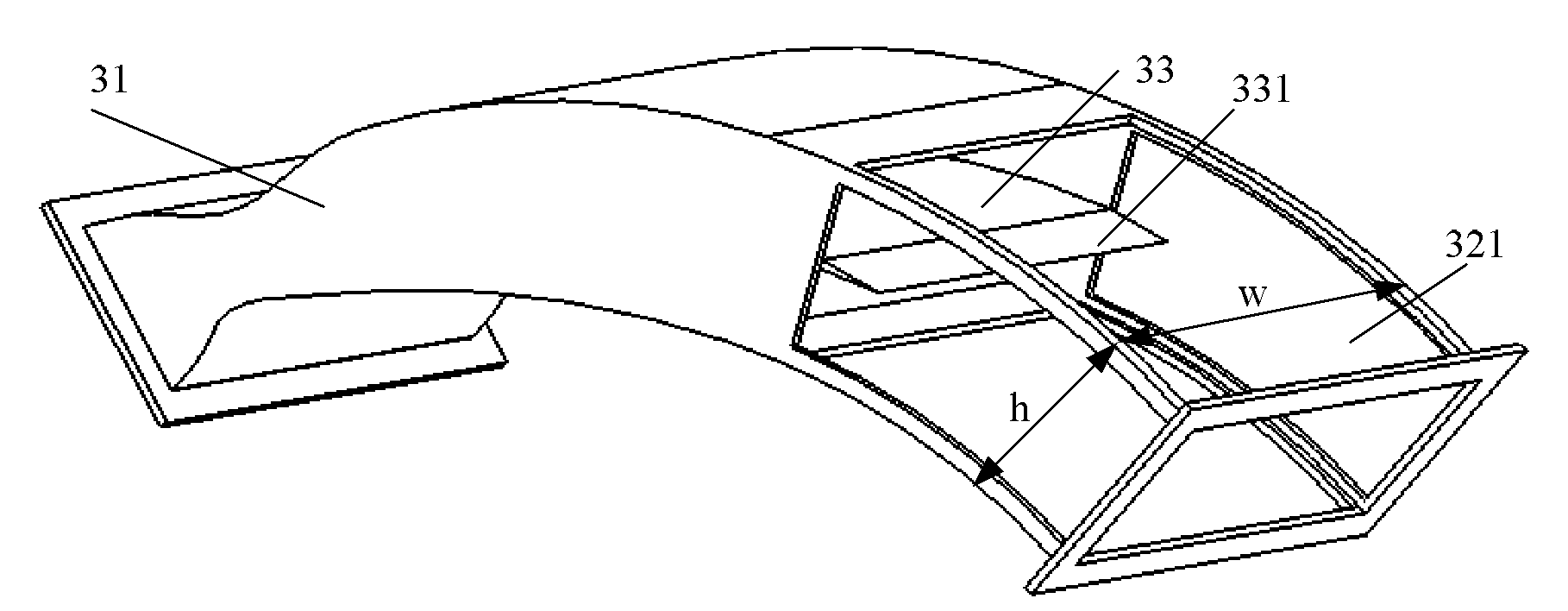

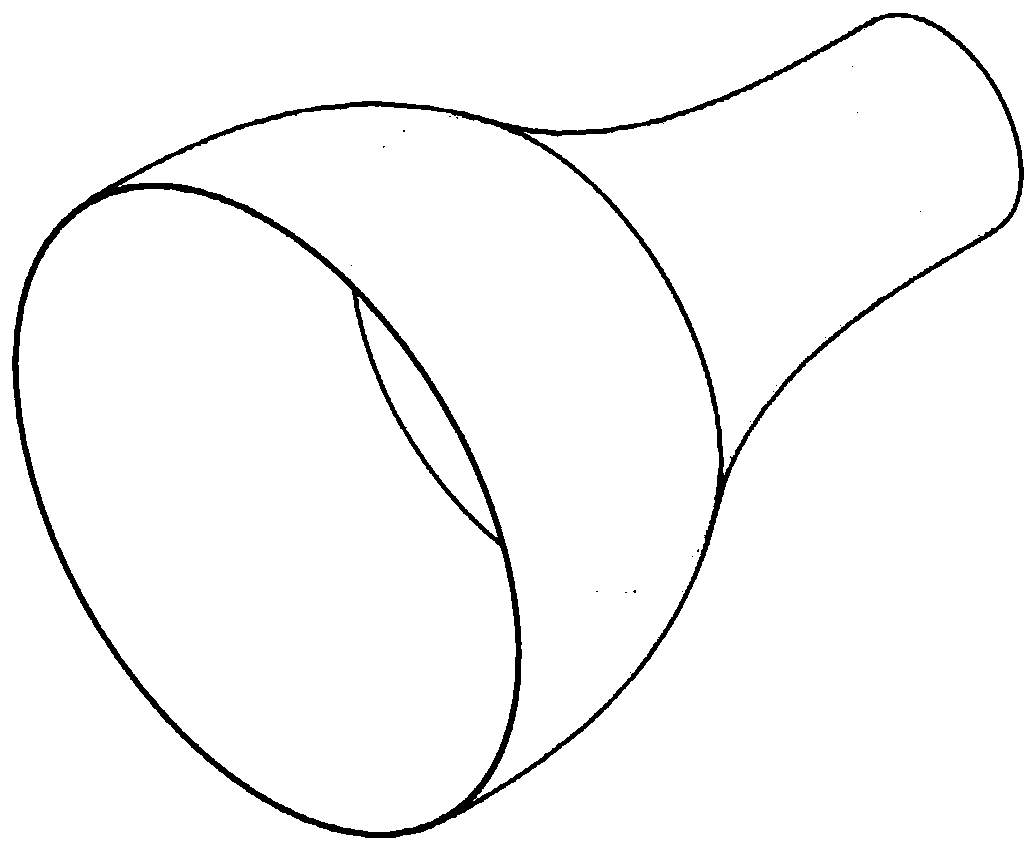

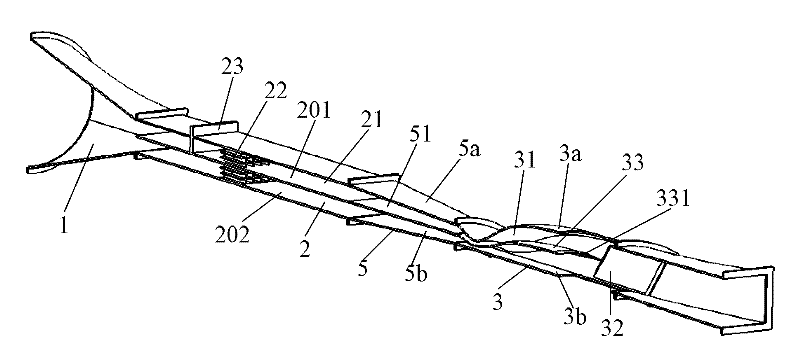

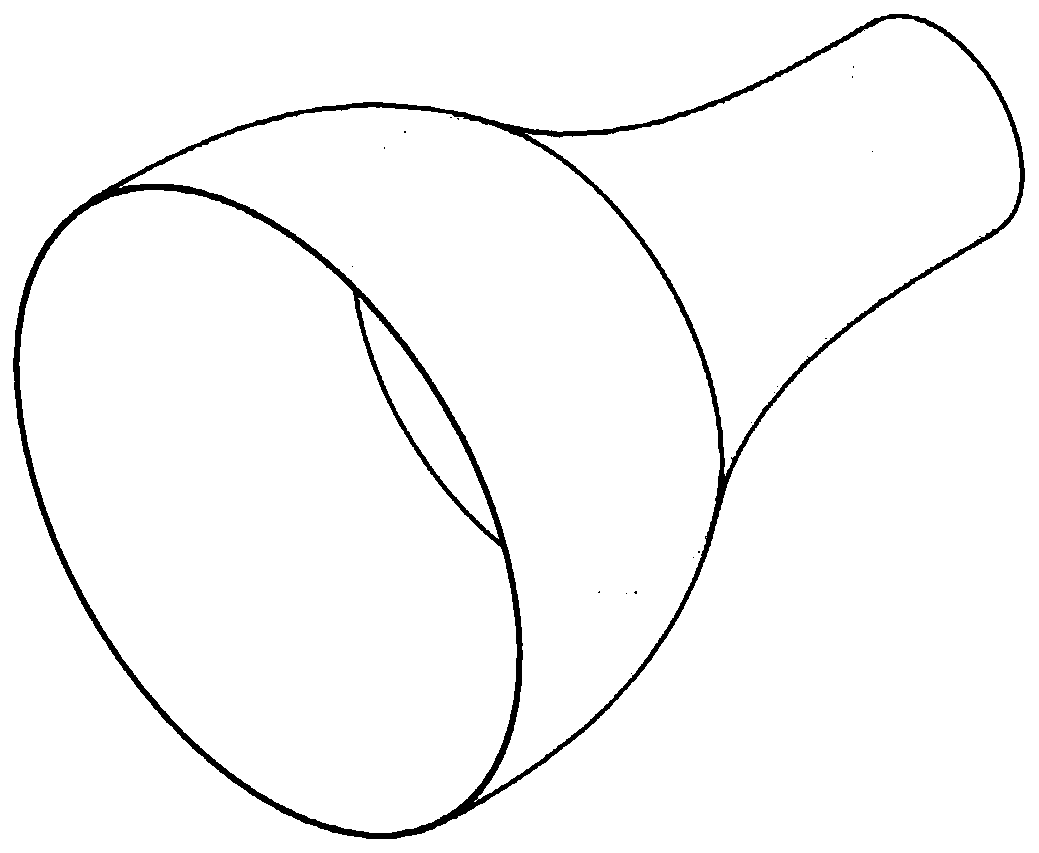

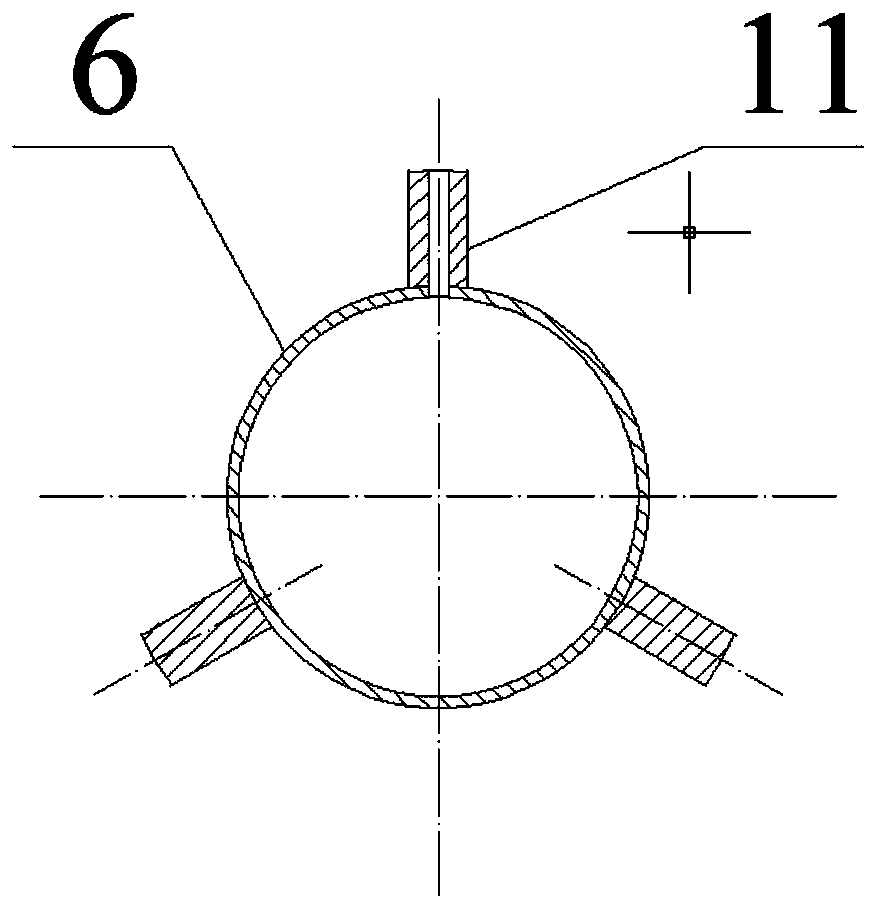

Supersonic-speed axisymmetric mixing layer wind tunnel

ActiveCN101975653BEasy to implementOptical non-contact testing technology facilitatesAerodynamic testingEngineeringSupersonic speed

The invention provides a supersonic-speed axisymmetric mixing layer wind tunnel which is characterized by comprising a transition section (1), a stabilization section (2) and a spray pipe experimental section (3), wherein the transition section is used for introducing an airflow; the stabilization section is provided with a first partition board (21) which divides the introduced airflow into two airflows; the spray pipe experimental section is connected at the downstream part of the stabilization section (2) and forms a fan-shaped axisymmetric structure relative to an axis (O) of revolution; the cross section of the peripheral wall of the spray pipe experimental section (3) is in a sector ring shape; a transparent window is formed on the peripheral wall; a spray pipe part (31) and a mixing experimental section (32) are formed on the spray pipe experimental section (3); and a second partition board (33) is arranged in the spray pipe part and the mixing experimental section is used for forming an axisymmetric mixing layer. By using the supersonic-speed axisymmetric mixing layer wind tunnel, the supersonic-speed axisymmetric mixing layer flow field of a totally-circular flow channel can be simulated and implementing the optical non-contact testing technology becomes convenient.

Owner:NAT UNIV OF DEFENSE TECH

A low-turbulence compact circulating water tunnel experimental device

The invention discloses a low-turbulence compact circulating water tunnel experimental device, comprising a water tank (1), a centrifugal pump (7), and a porous plate (2) and a honeycomb screen (3) which are disposed in the water tank (1). The water tank (1) has a water inlet at the upper part and a water outlet at the lower part at the same side. The porous plate (2) is installed between the water inlet and the water outlet. The honeycomb screen (3) is installed at the water outlet, and has an outlet successively connected a contraction section (4), an experimental section (5) and an expansion section (6). The outlet of the expansion section (6) is connected to the inlet of the centrifugal pump (7). The outlet of the centrifugal pump (7) is successively connected with a backflow section(8), a round-to-square section (9) and a diverging section (10). The outlet of the diverging section (10) is connected to the water inlet of the water tank (1). The hydrodynamic design used by the invention greatly reduces the turbulence of a flow field in the experimental section. The whole experimental device has a compact structure, a small occupied space and low manufacturing cost, which greatly improves the applicability of the water tunnel experimental device.

Owner:XI AN JIAOTONG UNIV

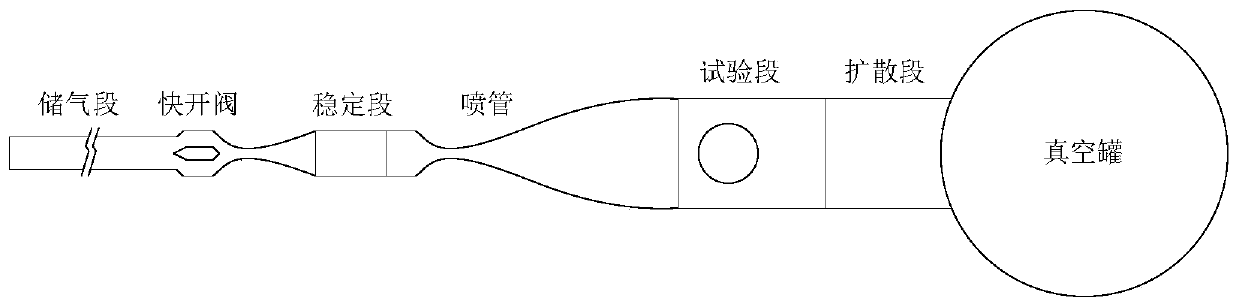

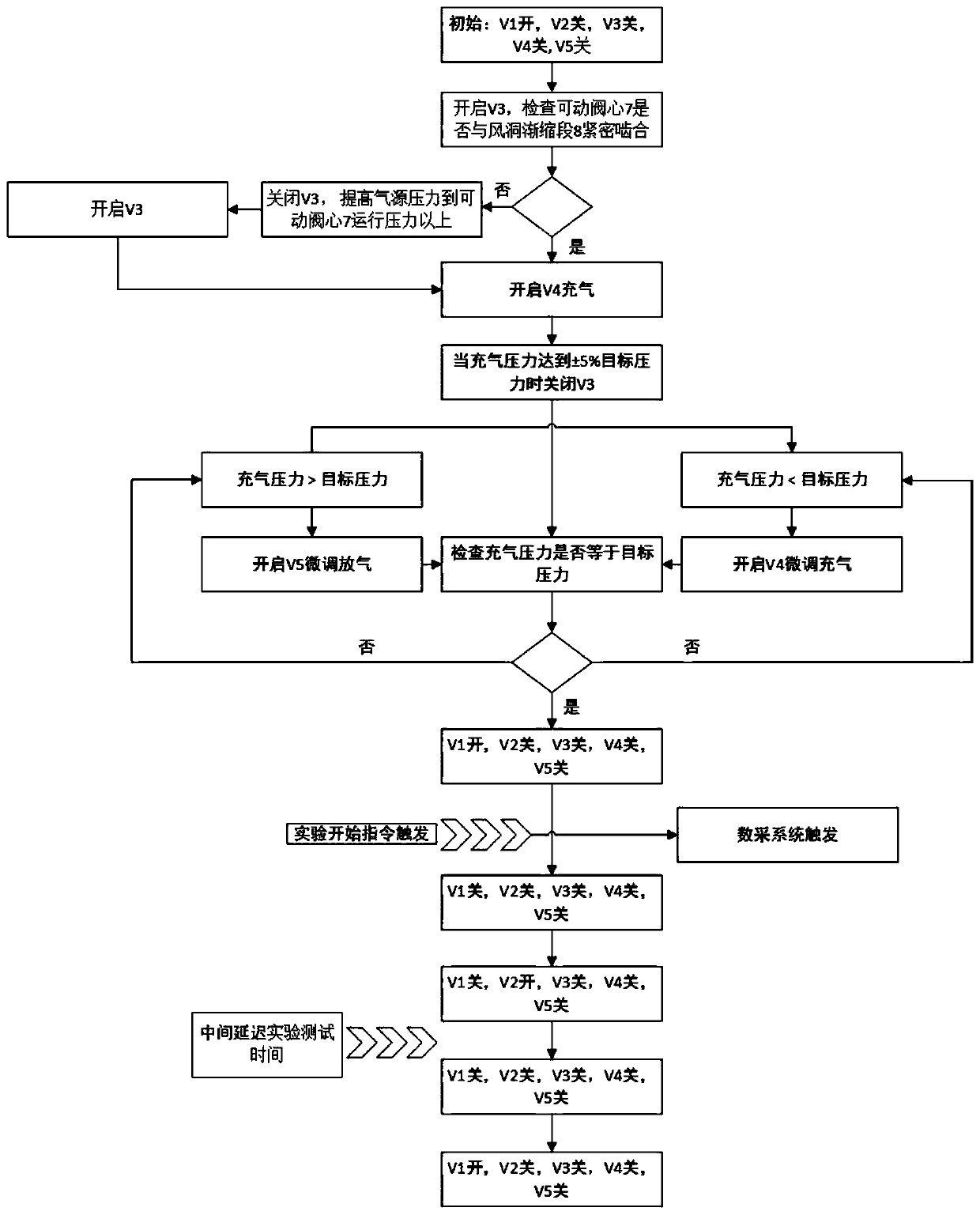

Hypersonic transient impulse type wind tunnel start-stop control system and method

ActiveCN110362123AGuaranteed opening and closing speedImprove stabilityAerodynamic testingFluid pressure control using electric meansStart stopReciprocating motion

The invention discloses a hypersonic transient impulse type wind tunnel start-stop control system and method, and belongs to the field of wind tunnel experiment. The system comprises a valve core base(5) which is internally provided with a cylindrical cavity (6), multiple support rib plates (11), a movable valve core (7), a first pipeline which penetrates through the transient impulse type wind tunnel pipe wall and is used for controlling the air pressure in a transient impulse type wind tunnel gas storage section (4), and a second pipeline which sequentially penetrates through the transientimpulse type wind tunnel pipe wall and the support rib plates and used for controlling the air pressure in the cylindrical cavity (6). The invention also provides the corresponding transient impulse type wind tunnel start-stop control method. The reciprocating movement of the movable valve core can be controlled by controlling the gas pressure difference between the left and right sides of the movable valve core through the first pipeline and the second pipeline so that that start and stop of the transient impulse type wind tunnel can be controlled, the aerodynamic response speed is fast, thestart and stop speed of the wind tunnel is ensured, start and stop of the wind tunnel can be repeatedly controlled and the operation economy of the hypersonic transient impulse type wind tunnel and the flow field quality of the wind tunnel test can be improved.

Owner:HUAZHONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com