Reverse circulation blowing-down device of wing boundary layer

A boundary layer and wing technology, applied in wings, aircraft parts, transportation and packaging, etc., can solve the problems of inability to actively adjust the flight status, the principle of the shock blowing scheme is unknown, and the acceleration of the viscous bottom layer, etc., to achieve light weight, Low energy consumption and the effect of suppressing flow separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

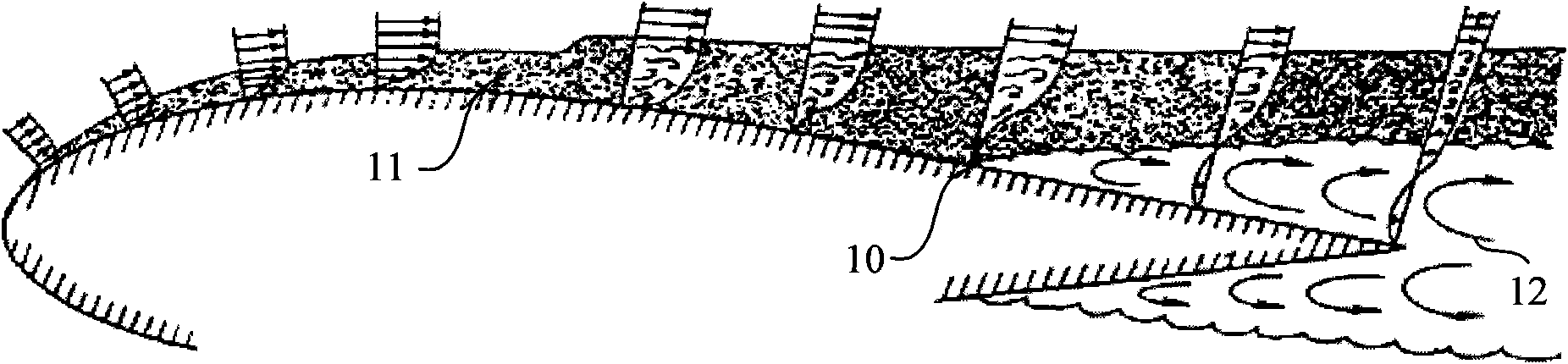

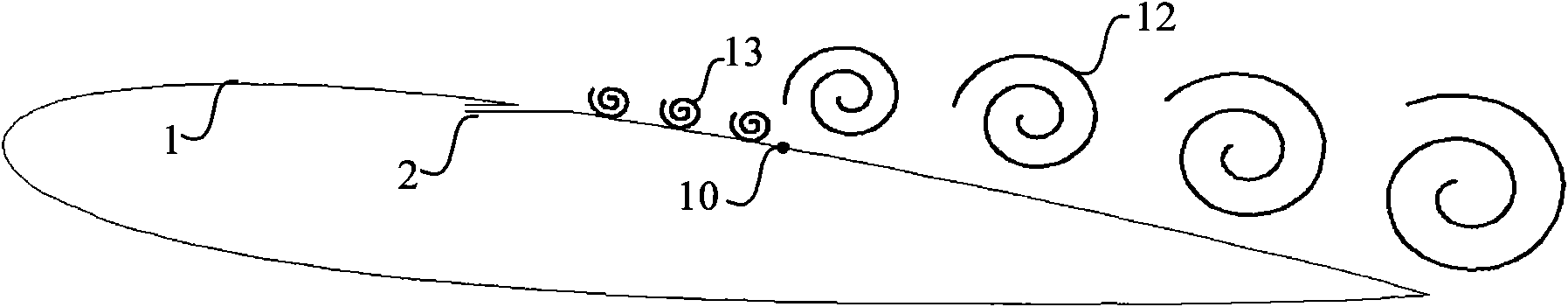

[0038] Such as figure 2 As shown, after the separation point 10 on the wing 1, a clockwise-rotating separation vortex 12 has occurred, and the present invention produces a counterclockwise vortex 13 opposite to the separation vortex 12 at the blowing slot 2 of the wing 1, and uses the counterclockwise vortex 13 to weaken and counteract the flow separation vortex 12; at the same time, the high-speed airflow blown out also increases the flow velocity of the bottom layer, and the two are used together to better eliminate flow separation.

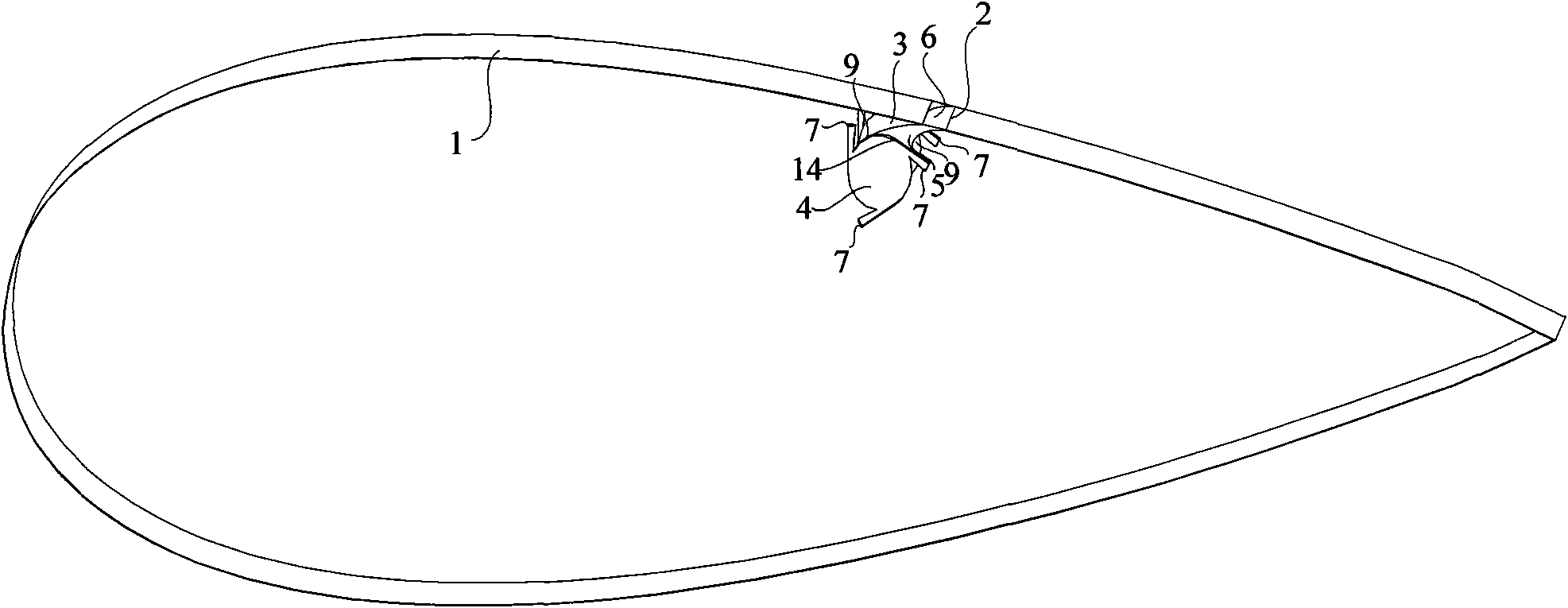

[0039] The present invention is a kind of airfoil boundary layer anti-circulation amount blowing device, such as image 3 , Figure 4 As shown, it includes blowing channel 3 , cyclone 4 and sealing connection platform 5 .

[0040] Have blowing slot 2 on the surface of wing 1, described blowing slot 2 is positioned ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com