Method for designing ultrasonic-speed turning flow channel

A supersonic flow and design method technology, applied in the direction of mechanical equipment, fluid flow, etc., can solve the problems of shock wave generation, uncontrollable internal flow field parameters, no supersonic speed and no shock wave turning channel, etc., and achieve the goal of improving the quality of the flow field Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] According to an embodiment of the present invention, a supersonic turning channel is obtained by the following method.

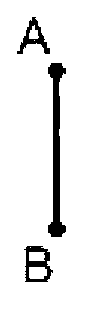

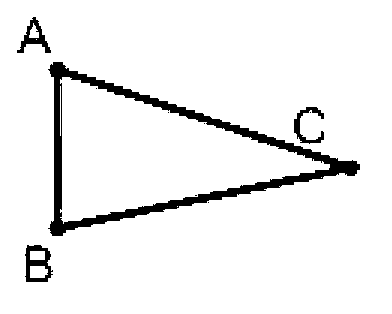

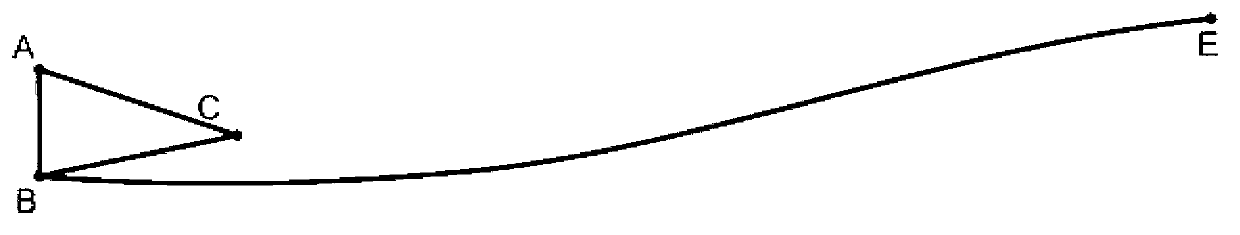

[0036] like figure 1 As shown, first, according to the structural design requirements of the supersonic turning channel, that is, the geometric constraints of the outlet flow field parameters, the inlet boundary AB of the supersonic channel wall curve is determined, where A is the second inlet boundary point of the inlet boundary AB, and B is the inlet boundary AB The first entry boundary point of . Then according to the coordinates of the second inlet boundary point A and the first inlet boundary point B of the inlet boundary AB, the Mach number and the flow direction angle, the coordinates of the vertex C of the inlet influence domain and the Mach number and sum of the vertex C are determined by the method of characteristic lines flow direction angle. Then, according to the coordinates, Mach number and flow direction angle of each point between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com