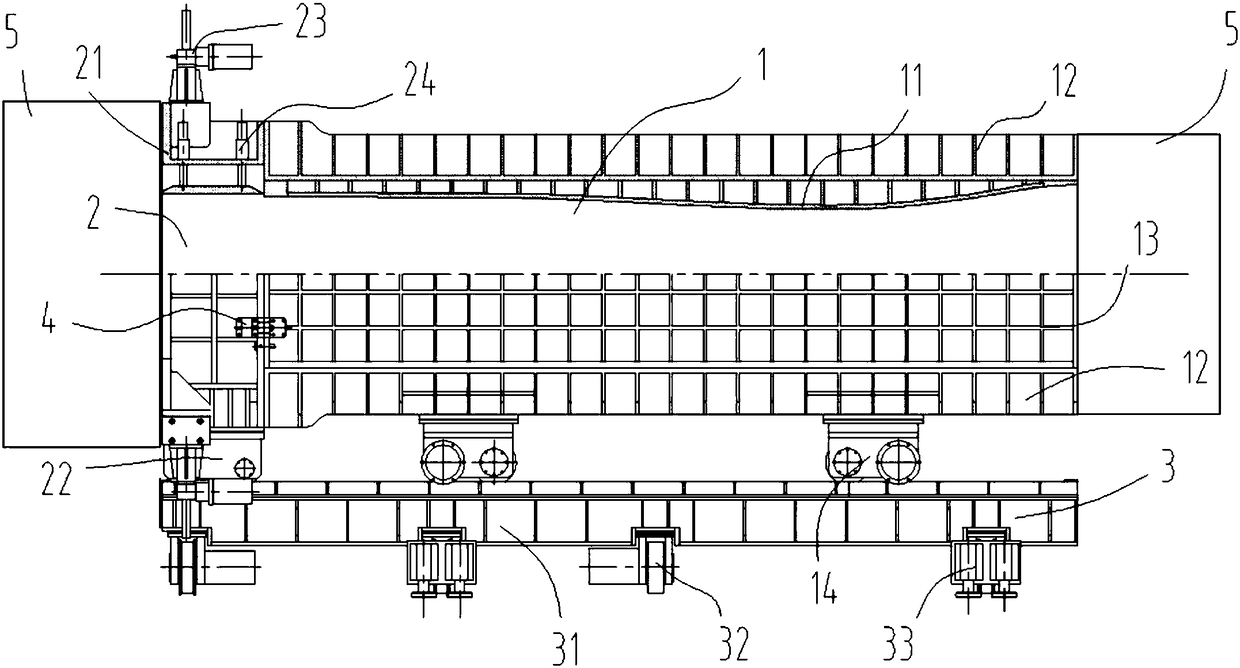

Large wind tunnel nozzle test section integrated device

A technology of test section and nozzle, applied in the field of aerospace test, can solve the problems of limited effect and low efficiency of wind tunnel test, and achieve the effects of convenient disassembly and assembly, reduced labor cost and high economy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

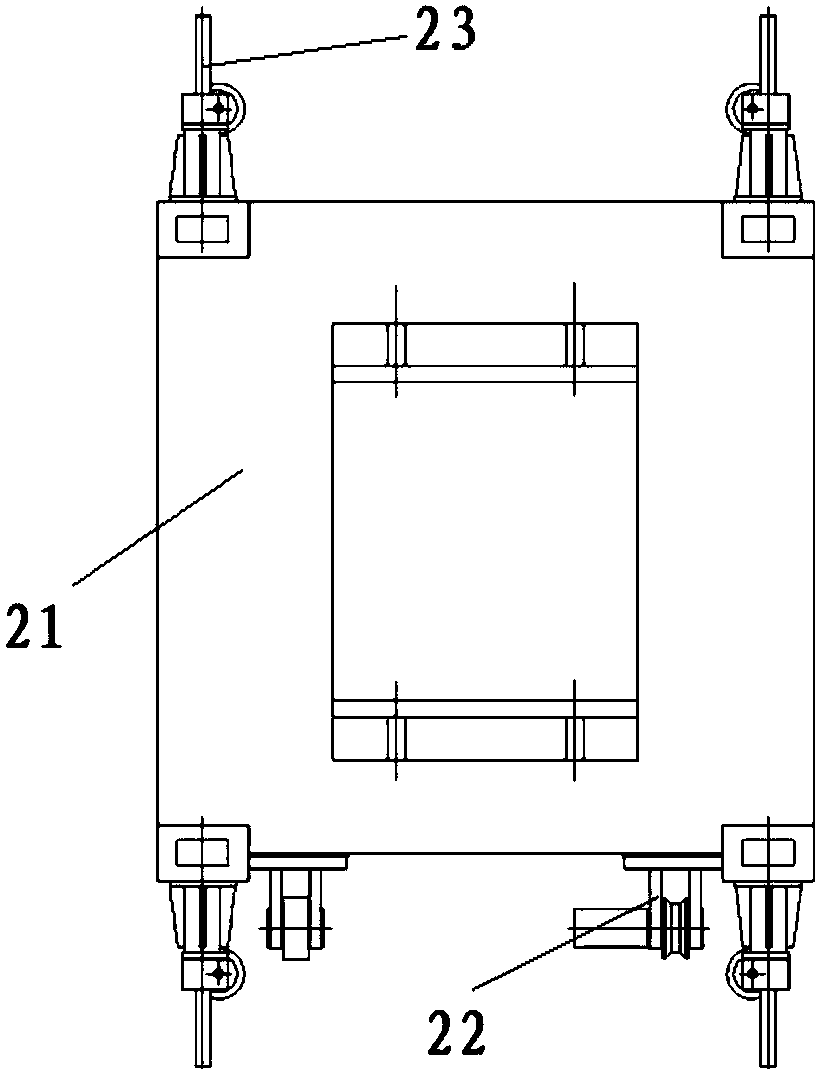

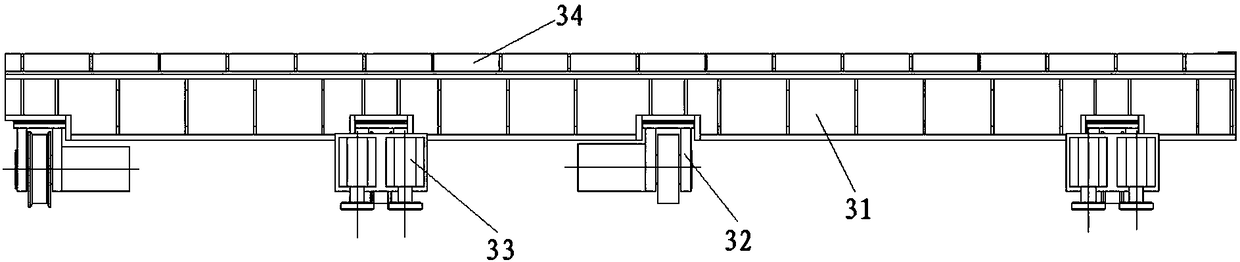

[0021] The invention provides a large-scale wind tunnel nozzle test section integration device, which adopts the design of combining the traditional supersonic nozzle and the test section, and eliminates the seam at the joint between the original nozzle and the test section, thereby eliminating the seam The step wave at the place improves the quality of the flow field in the wind tunnel test area; the modular design is adopted, the manufacturing cost is low, compatible with the existing wind tunnel equipment, does not affect the wind tunnel test production, the transformation cost is low, and the economy of the whole device is high ;The integrated section of the nozzle test, the outlet flange section and the frame car are replaced and placed by driving the wheel set to walk on the track. The guide positioning is accurate, the operation is simple,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com