Supersonic velocity continuous variable mach number spray pipe based on center body

A center body and Mach number technology, applied in the field of supersonic continuously variable Mach number nozzles, can solve the problems of flow field airflow deflection angle, inability to finely evaluate the performance of the intake port, velocity stratification and poor Mach number uniformity, etc. The effect of good field quality, good flow field quality and reliable technical means

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

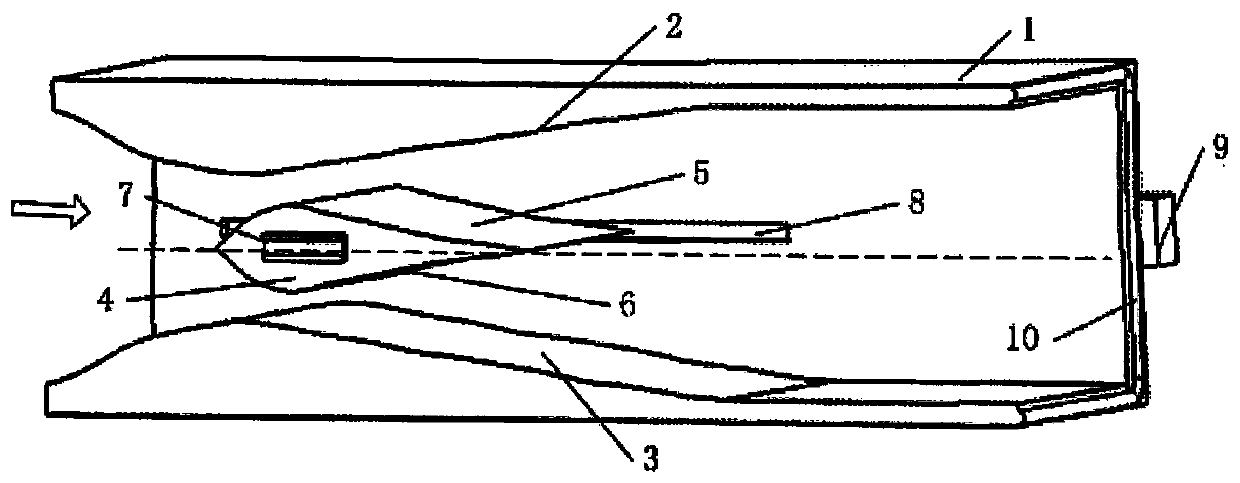

[0028] In the supersonic continuously variable Mach number nozzle based on the center body of this embodiment, when the nozzle diffuser profile is designed, the throat area lower than Mach number 1.5 is selected as the reference area of the nozzle throat, and the characteristic line method is used to design Diffusion section profile in the range of Mach number 2.0 to 3.5; Widoshinsky method is used in the profile design of nozzle contraction section; area law is used in the center body profile design, and the characteristic line method is considered comprehensively And Widowshinski's method, finally realize the continuous change of the flow area of the nozzle after adding the center body, and place the sound velocity line near the throat of the nozzle.

[0029] The outlet cross-section of the supersonic continuously variable Mach number nozzle based on the central body of this embodiment is 0.6m×0.6m, and every time the central body changes by about 15mm, the Mach number ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com