Throat structure capable of improving Reynolds number of tube wind tunnel test

A ducted wind tunnel and Reynolds number technology, which is used in aerodynamic testing, machine/structural component testing, measuring devices, etc., can solve problems such as low test Reynolds number and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with examples, but the embodiments of the present invention are not limited thereto.

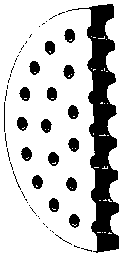

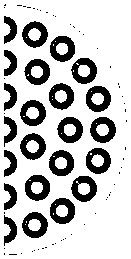

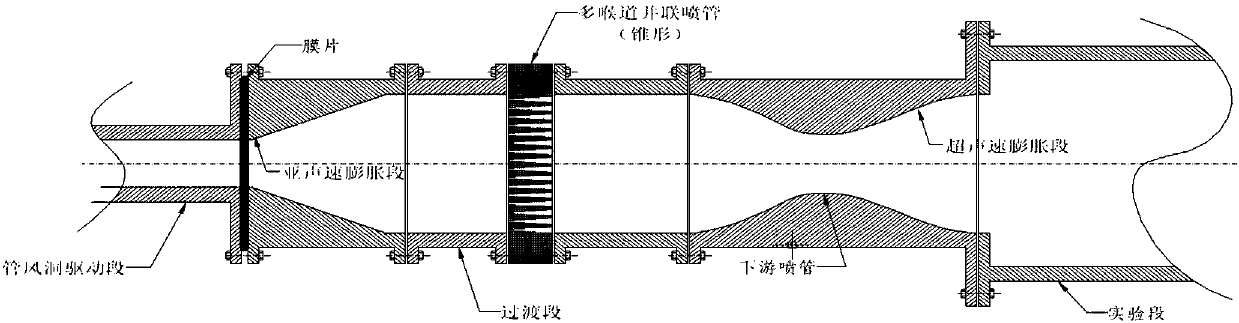

[0020] like figure 1 As shown, the present invention provides a throat structure for increasing the Reynolds number of the tube wind tunnel test. The upstream subsonic expansion section is directly connected to the pulse-type wind tunnel body, and the downstream throat and supersonic expansion section are used to generate Airflow conditions. Throat structure work starting process of the present invention is described as follows:

[0021] When the diaphragm ruptures or the fast valve opens, the high-pressure gas in the driving section of the tube wind tunnel enters the double-nozzle-multi-throat structure at subsonic speed under the action of the expansion wave, and first reaches the The speed of sound is further accelerated to supersonic speed, and a mixed layer structure is formed at the outlet of the mu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com