Stern structure for internal rotation double-paddle ship

A stern and ship technology, which is applied in the field of stern structure design, can solve problems such as optimization difficulties and many appendages at the tail, and achieve the effects of improving propulsion efficiency, improving tail wake, and optimizing implementation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

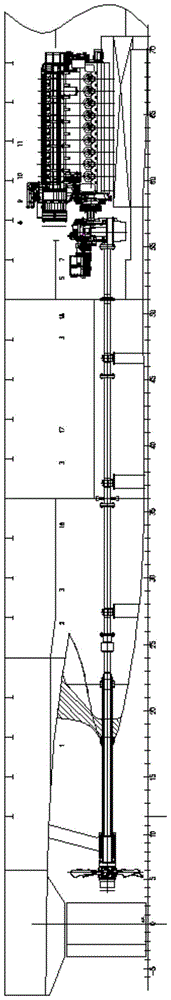

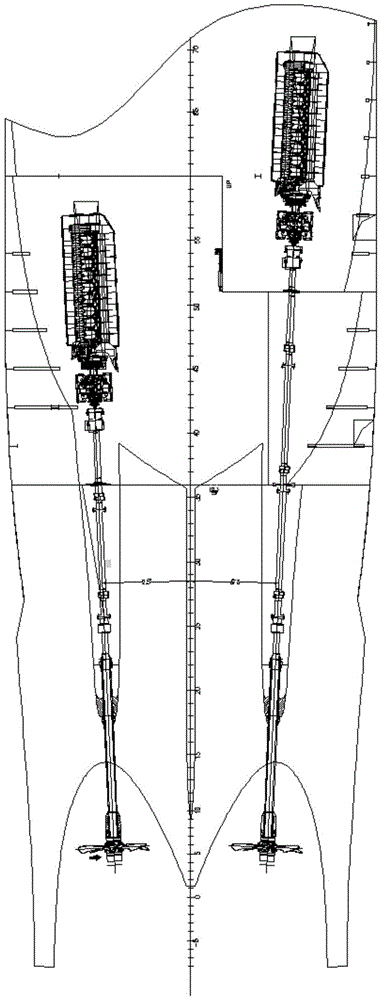

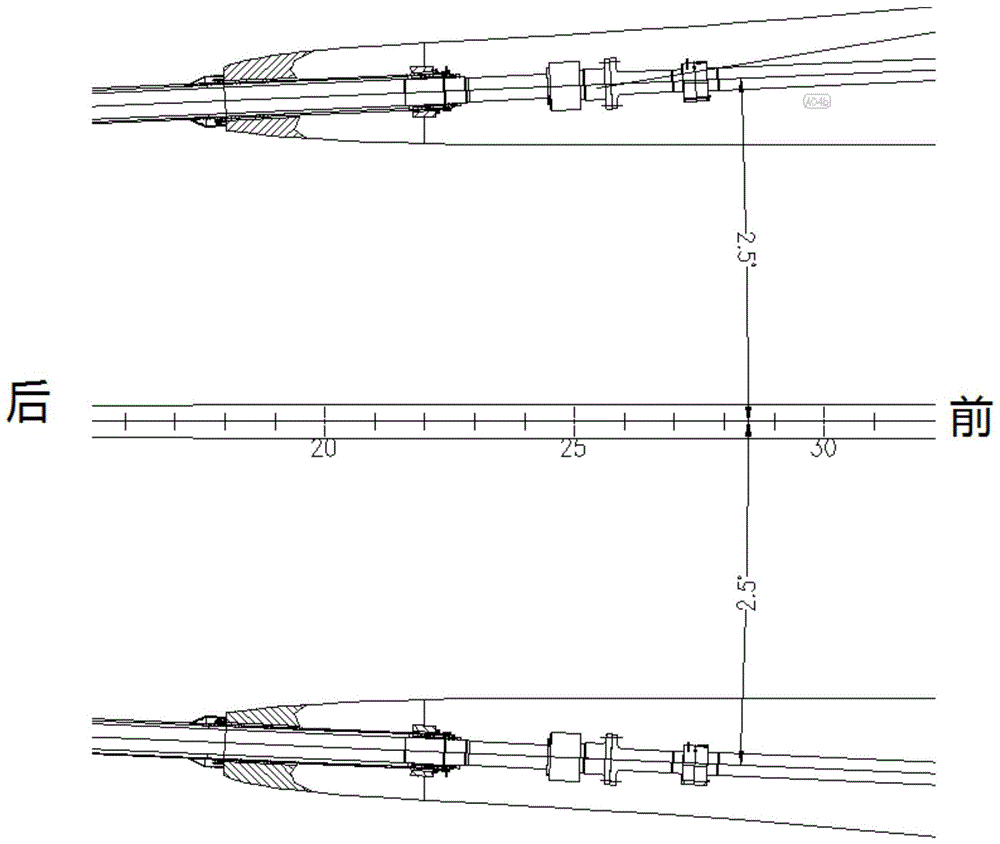

[0031] see Figure 1-Figure 4 , a stern structure of an internally rotating double propeller ship, comprising a pair of small tail fins of the internally rotating double propellers, which have a horizontal inclination to the central axis of the hull from front to rear, and the inclination direction of the small tail fins is in line with the direction of the stern flow field Correspondingly, the separation of the tail water flow is reduced, thereby reducing the drag.

[0032] see figure 1 , the rear end of the support shaft at the rear of the small skeg is connected to the hull through a single shaft bracket. The small tail fin is smoothly drawn out on the line of the main hull, the size of the rear end just wraps around the paddle shaft, and the shape of the front end takes into account the layout of the gearbox; the length of the small tail ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com