Supersonic free vortex mixing layer wind tunnel

A vortex mixing and supersonic technology, applied in the field of wind tunnel, can solve the problems of reducing the turbulence degree of incoming flow, high Reynolds number, obvious side wall effect, etc., to achieve uniform transition, reduce shock wave intensity, and good two-dimensional characteristics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

[0046] The outer peripheral wall referred to in this paper refers to the peripheral wall that is located farther away from the position of the free vortex center in the wind tunnel structure, and the inner peripheral wall refers to the peripheral wall that is located closer to the location of the free vortex center in the wind tunnel structure. side wall.

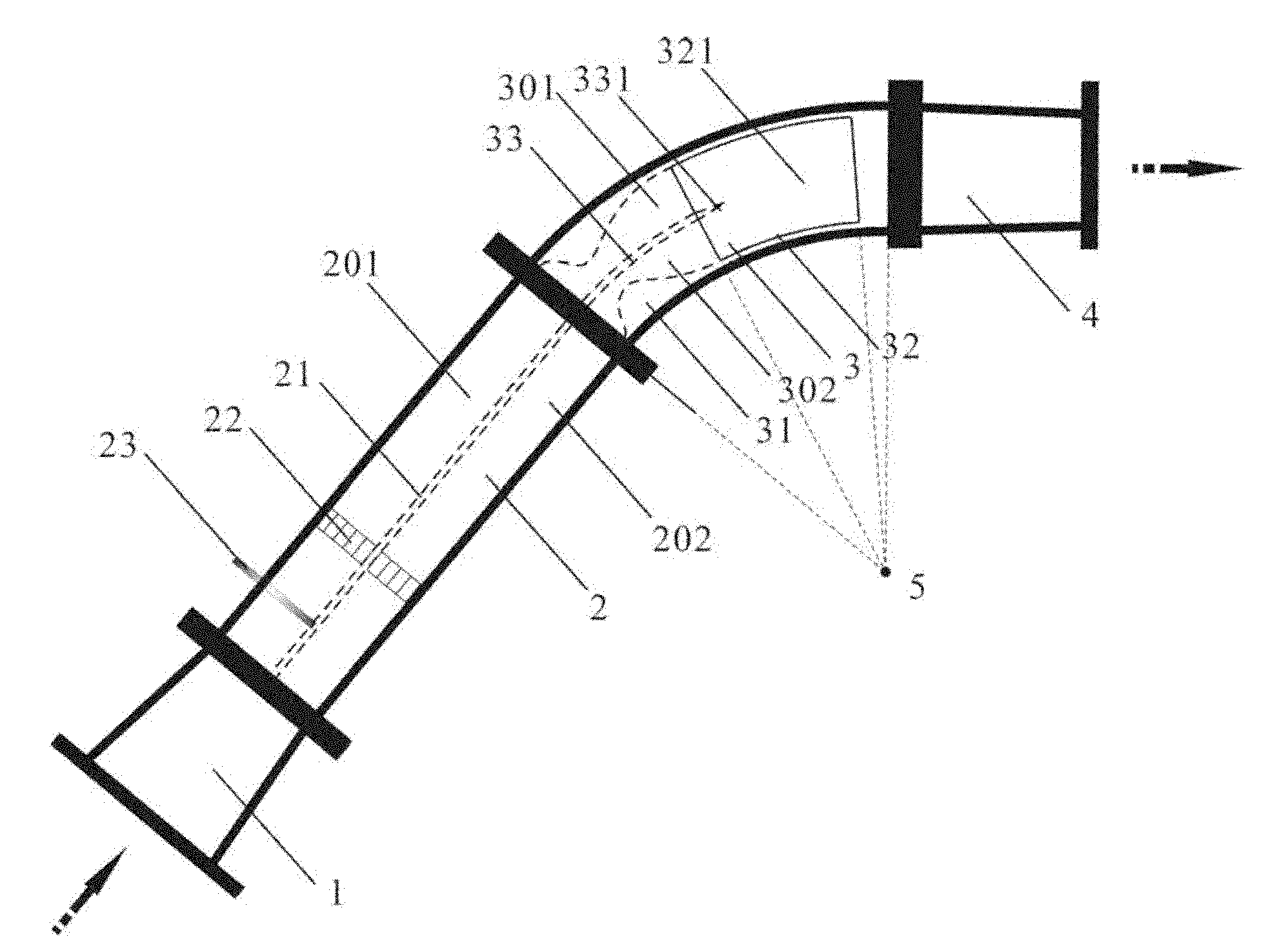

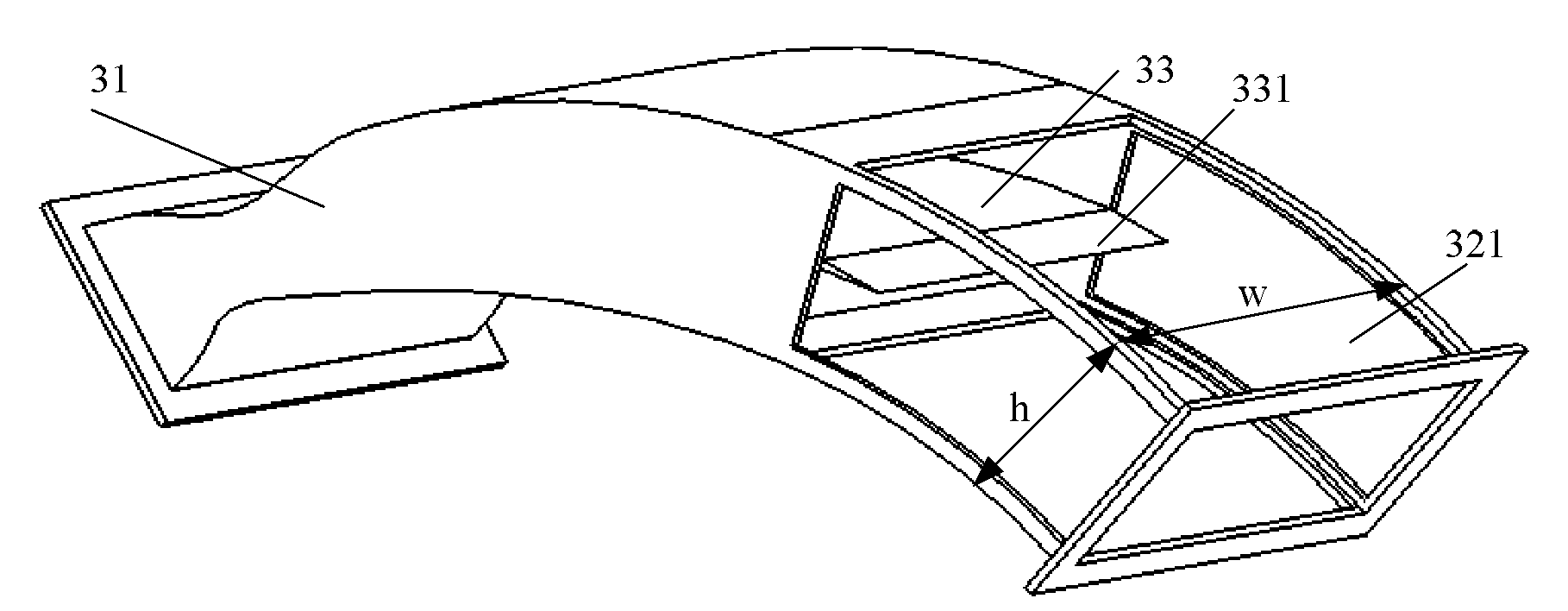

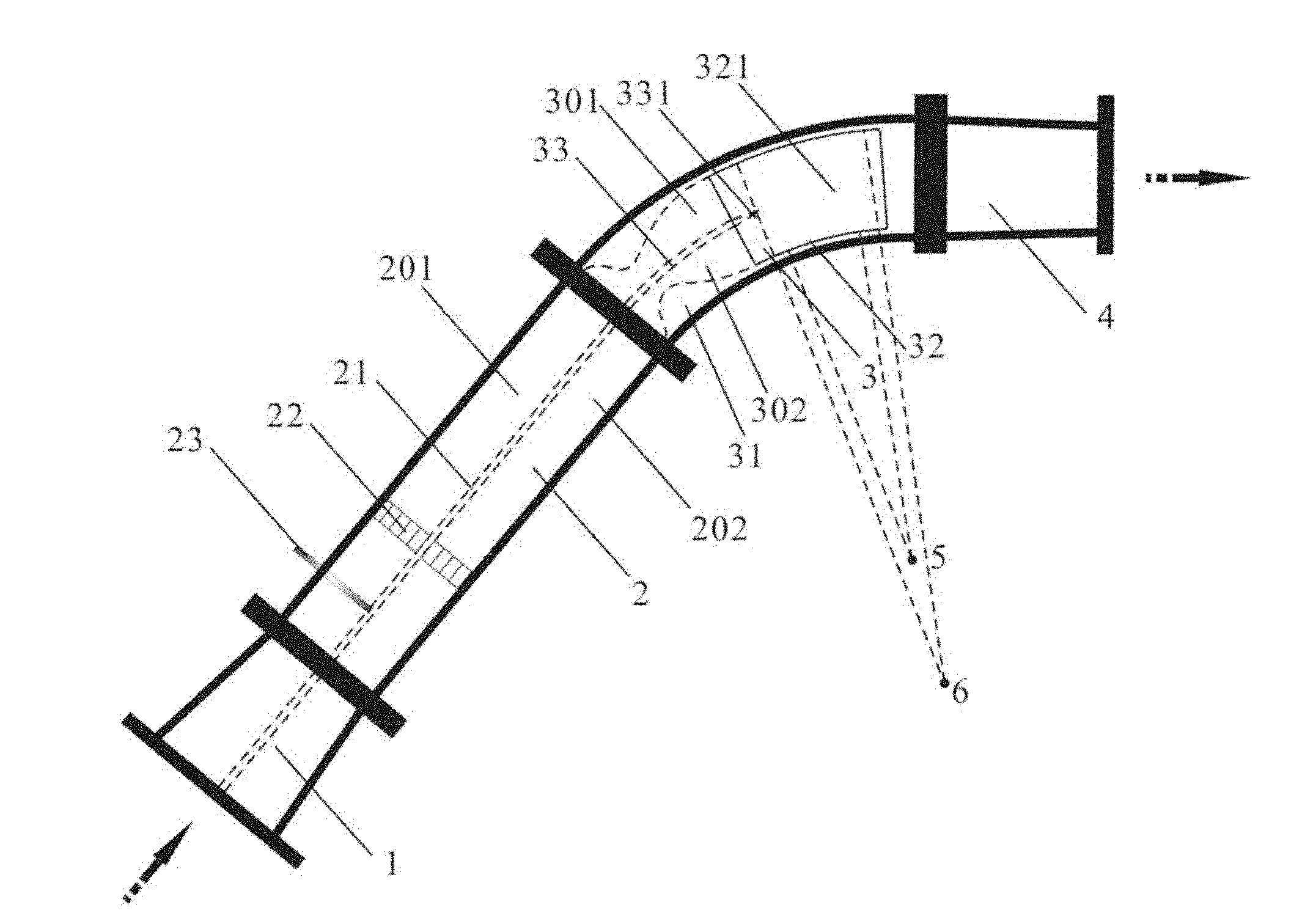

[0047] see figure 1 , shows the overall structure of a supersonic free vortex mixed layer wind tunnel according to the present invention, the supersonic free vortex mixed layer wind tunnel of the present invention mainly consists of a transition section 1, a stable section 2, a nozzle test section 3 and a diffuser section 4 end-to-end connections. Transition section 1 is used to introduce air f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com