System and method for roasting siderite

A siderite and roasting technology, applied in the field of smelting, can solve the problems of workers' physical injury and environmental pollution, and achieve the effect of reducing physical injury and pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

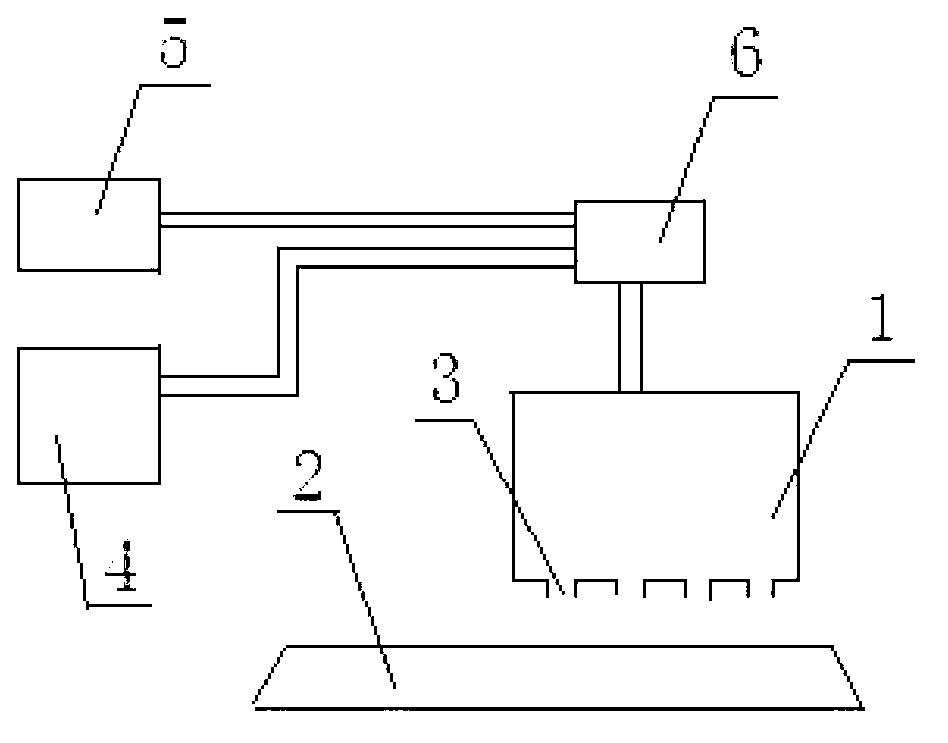

[0049] Embodiment 1 of the present invention provides a kind of system of roasting siderite, see figure 1 , the system consists of:

[0050] A belt sintering machine, the belt sintering machine includes an ignition device 1 and a bucket car 2 for transporting siderite, the bottom of the ignition device 1 has a flame outlet 3, and the ignition device 1 is located at the bottom of the bucket truck 2 Above, there is a space between the bucket car 2;

[0051] The system also includes: a gas supply device 4, an air supply device 5, and a mixing device 6; the gas supply device 4 is connected to the mixing device 6, the air supply device 5 is connected to the mixing device 6, and the mixing device means 6 connected to said ignition means 1;

[0052] The gas supply device is used to deliver gas to the mixing device;

[0053] said air supply means for delivering air into said mixing means;

[0054] The mixing device is used to mix the coal gas sent by the gas supply device and the ...

Embodiment 2

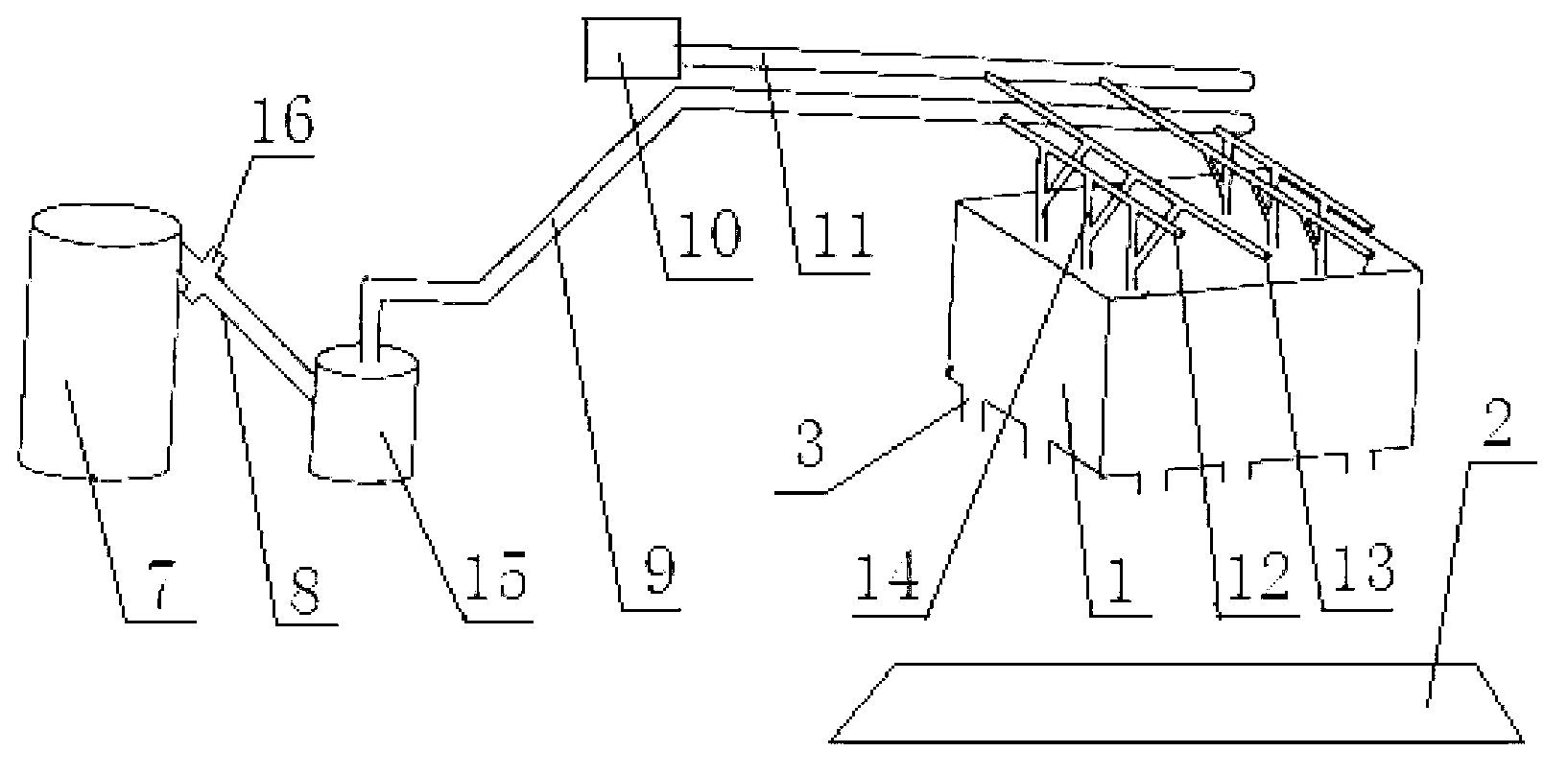

[0059] Embodiment 2 of the present invention provides another system for roasting siderite, see figure 2 , the system consists of:

[0060] A belt-type sintering machine, the belt-type sintering machine includes an ignition device 1 and a bucket car 2 for transporting siderite, the bottom of the ignition device 1 has evenly distributed flame ports 3, and the ignition device 1 is located in the bucket There is a distance of 20 centimeters between the top of the car 2 and the bucket car 2;

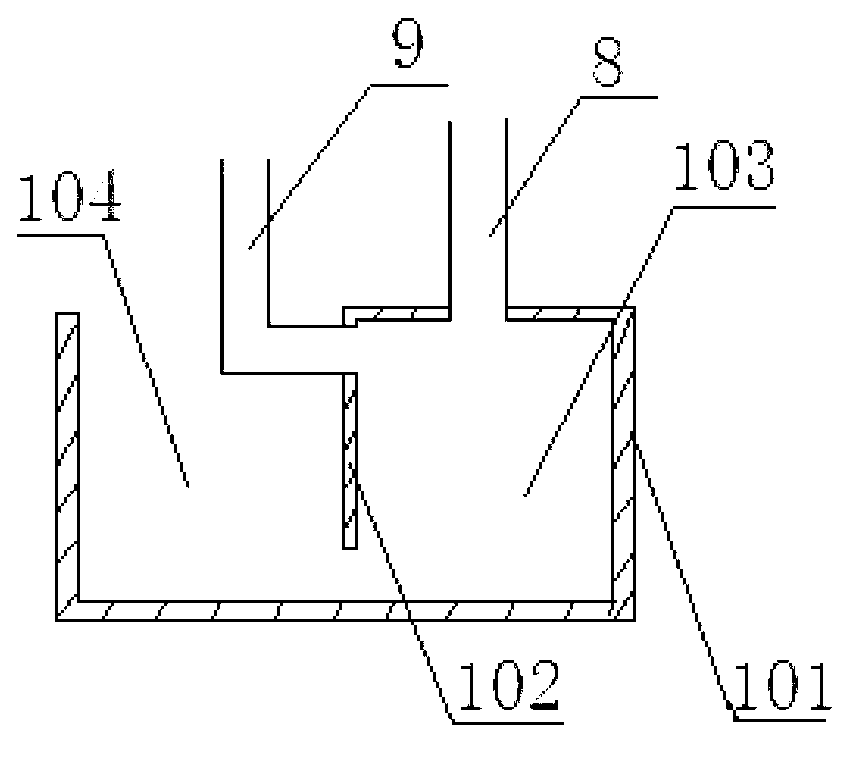

[0061] The system also includes: a gas generating component 7, a first delivery pipeline formed by connecting the first delivery branch pipe 8 and the second delivery branch pipe 9, a blower 10, and a second delivery pipeline 11; wherein, the gas production component 7 and the first delivery branch pipe 8 are connected, and the air outlet of the blower 10 is connected with the second conveying pipeline 11;

[0062] Wherein, the coal gas generating component 7 is connected with the first d...

Embodiment 1

[0078] For embodiment one, embodiment three of the present invention provides a kind of method for roasting siderite, see Figure 4 , the method includes:

[0079] Step S101: delivering gas to the mixing device through the gas supply device, and delivering air to the mixing device through the air supply device;

[0080] Step S102: the gas and air are mixed in the mixing device, and the mixed gas is sent to the ignition device of the belt sintering machine for combustion;

[0081] Wherein, in the mixed gas, the proportion of coal gas is 1 / 3-1 / 2; preferably, in the mixed gas, the proportion of coal gas is 1 / 2, that is, coal gas and The ratio of air is 1:1;

[0082] Step S103: The flame generated by combustion is sprayed to the siderite cart of the belt sintering machine through the flame nozzle at the bottom of the ignition device, so as to roast the siderite in the cart.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com