Combined workshop collocation method for electrolytic aluminium production

A configuration method and electrolytic aluminum technology are applied in the field of transportation design of general plans of industrial enterprises, which can solve the problems of increased road paving area and pipeline laying length, increased material transportation distance, and increased production and operation costs, so as to reduce infrastructure investment and production. The effect of operating cost, transportation efficiency improvement, and transportation distance reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

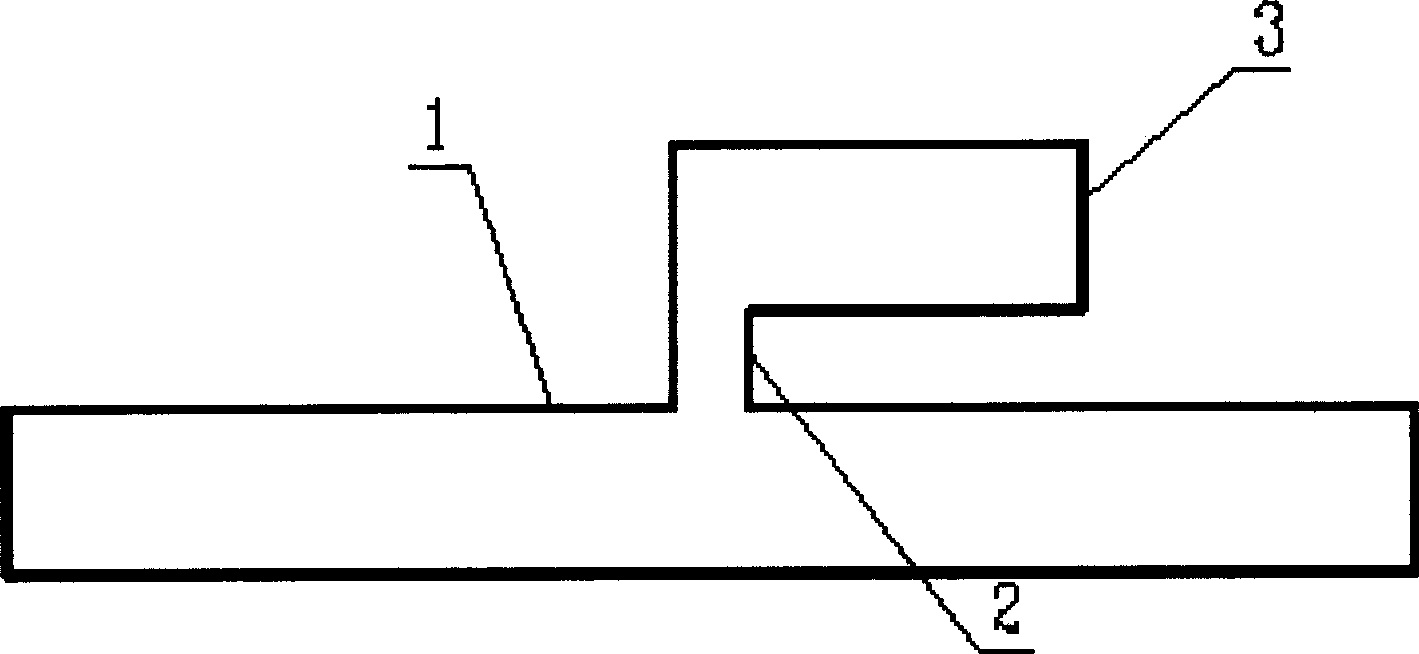

[0007] Embodiments of the present invention: as attached figure 1 As shown, when configuring the combined factory building for electrolytic aluminum production, firstly adjust the vertical design of the factory area or adjust the process design so that the elevation of the liquid aluminum casting operation plane of the casting workshop (3) is basically the same as that of the electrolysis workshop (1). Then set a vertical corridor (2) in the central channel area of the electrolysis workshop (1) to connect the liquid aluminum casting operation plane of the casting workshop (3). The corridor (2) can be designed with walls / No wall, covered / uncovered form, and the length of the corridor (2) should meet the fire protection, ventilation, safety, and hygiene requirements between the two processes of the electrolysis workshop (1) and the foundry workshop (3). The general length is set to 12m to 20m, the width of the corridor (2) is generally two to three electrolytic column spacing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com