Patents

Literature

47results about How to "Stir evenly and thoroughly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

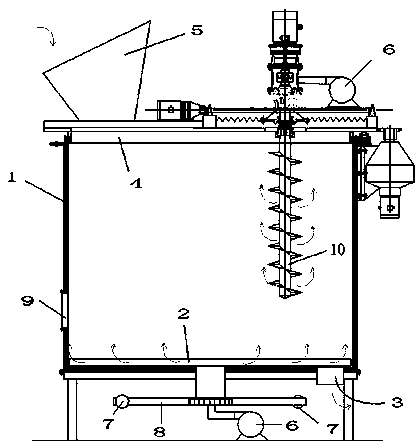

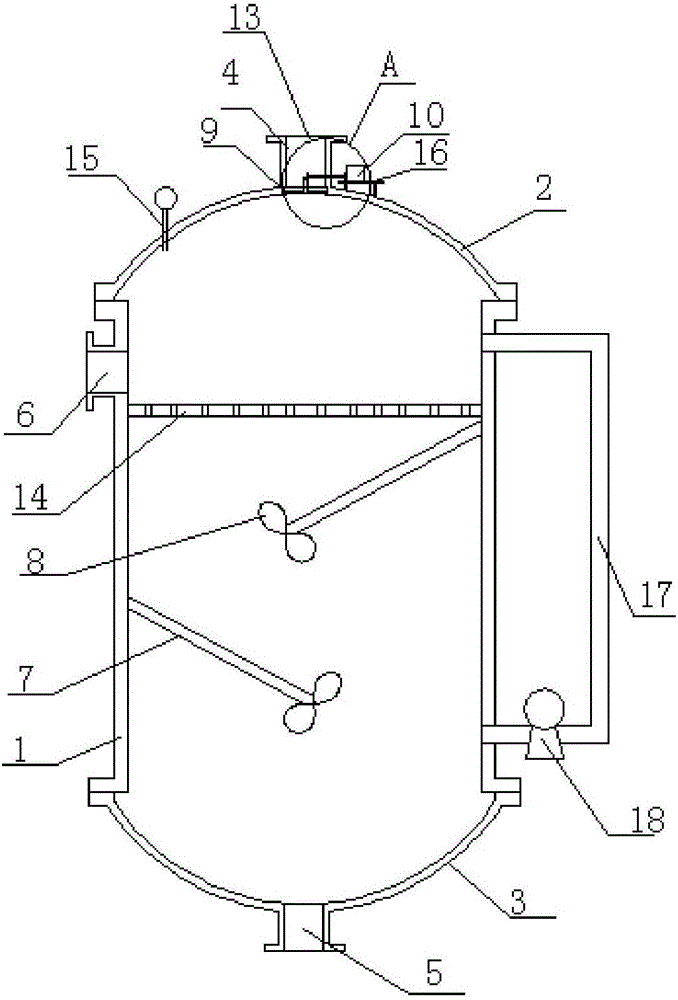

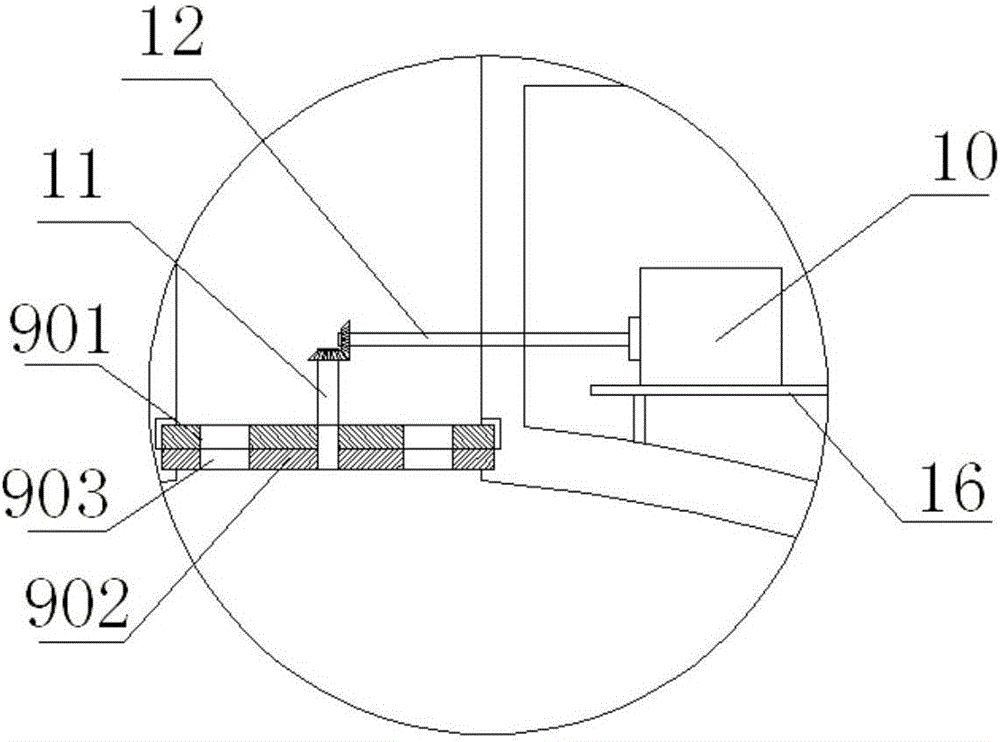

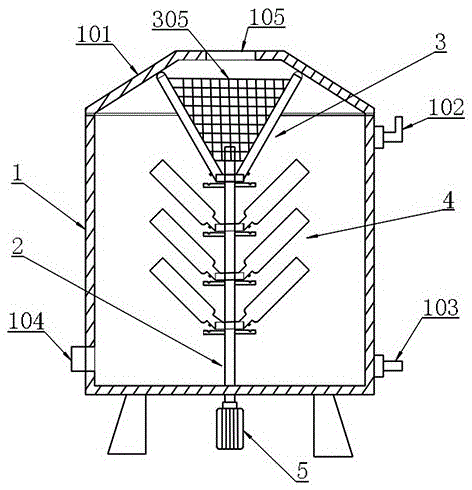

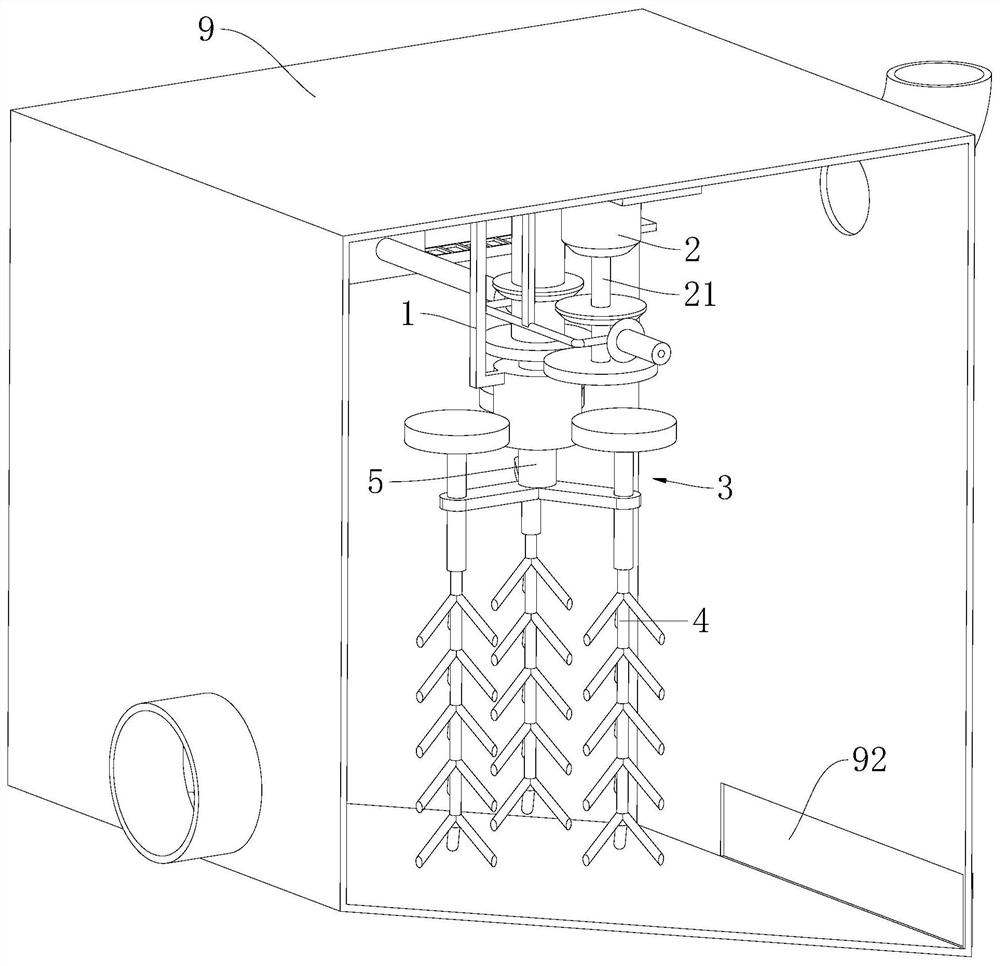

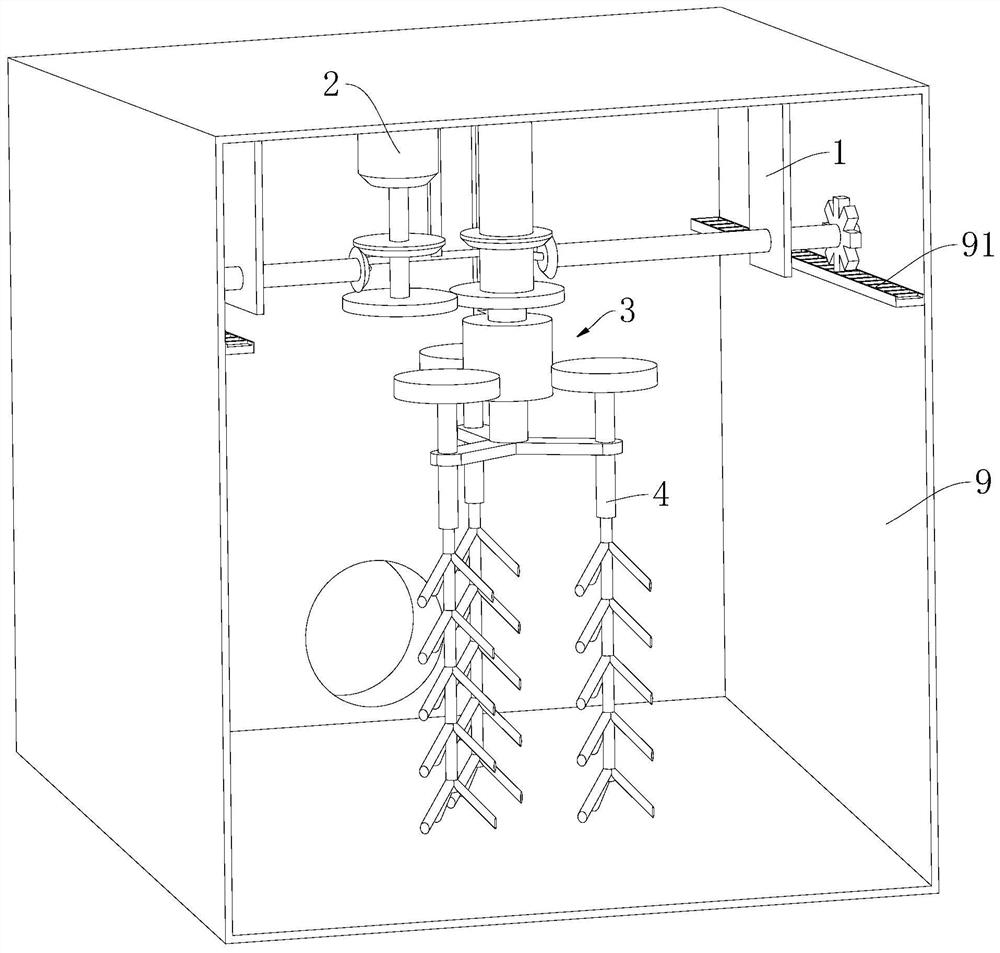

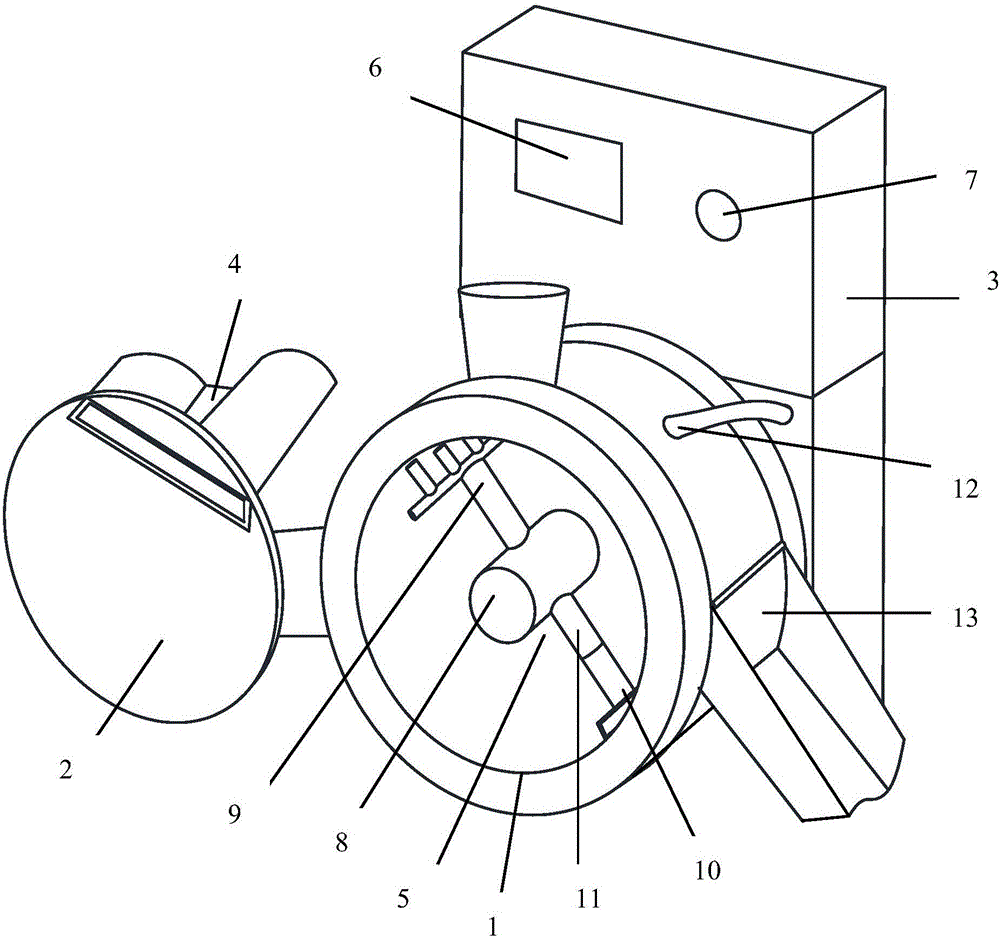

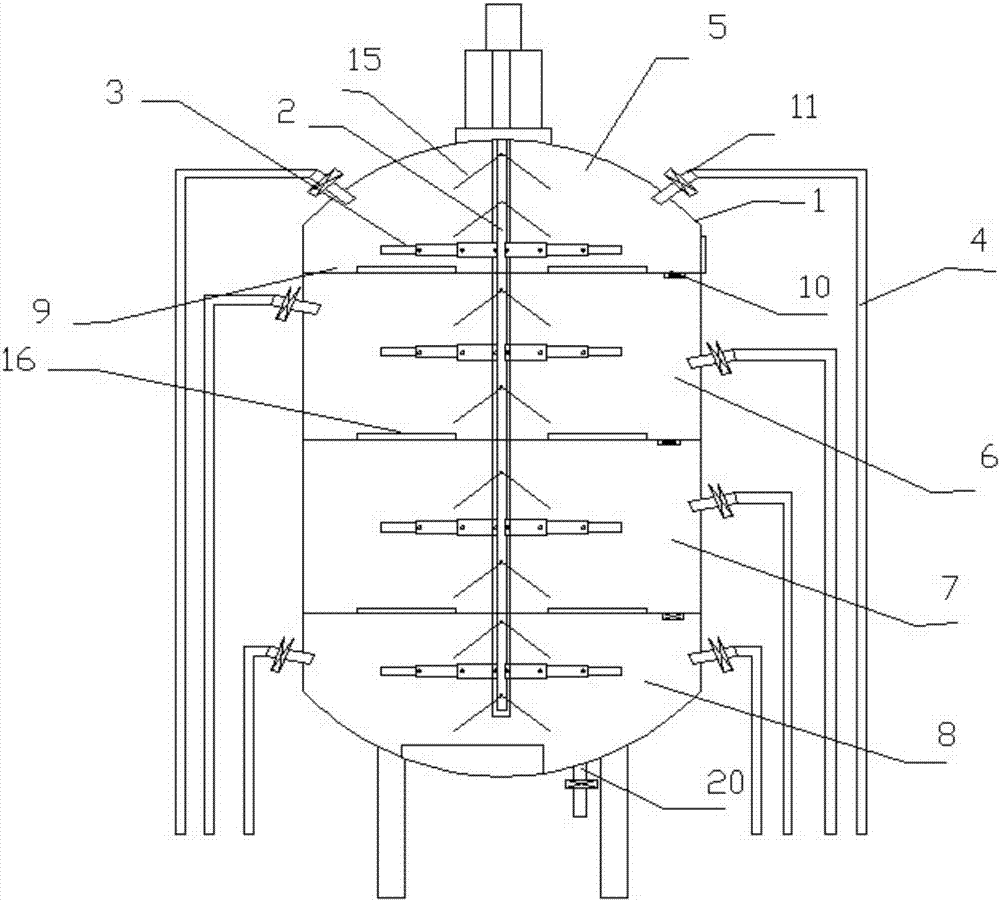

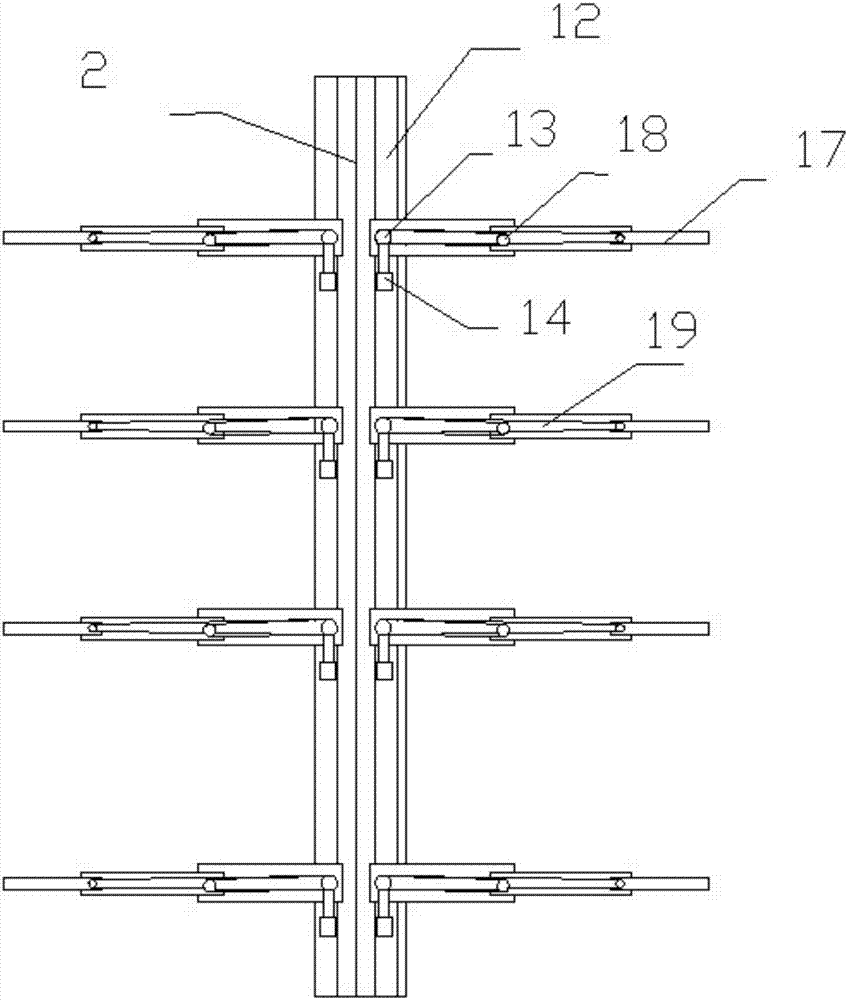

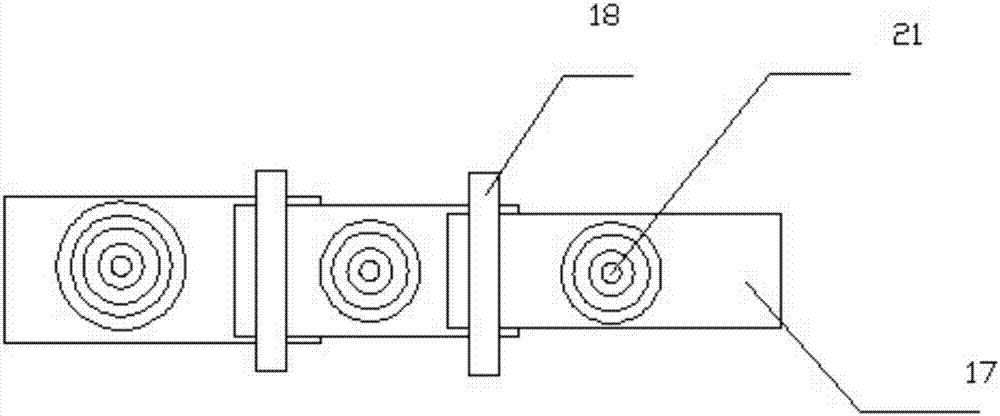

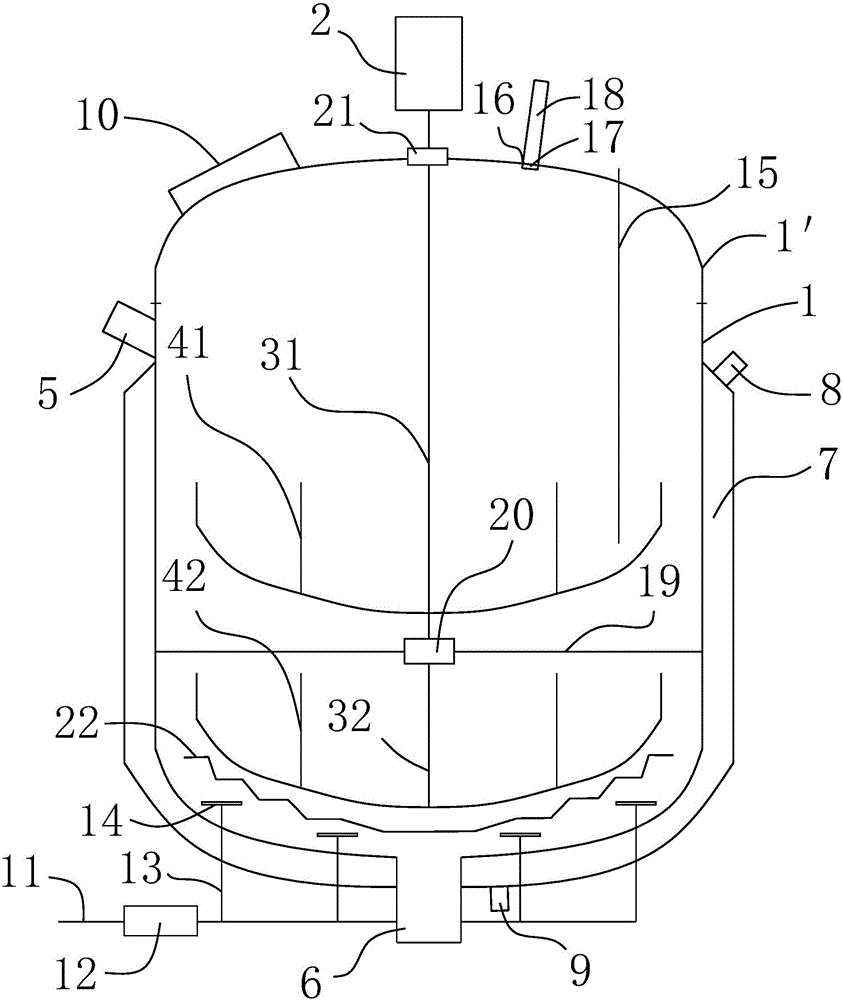

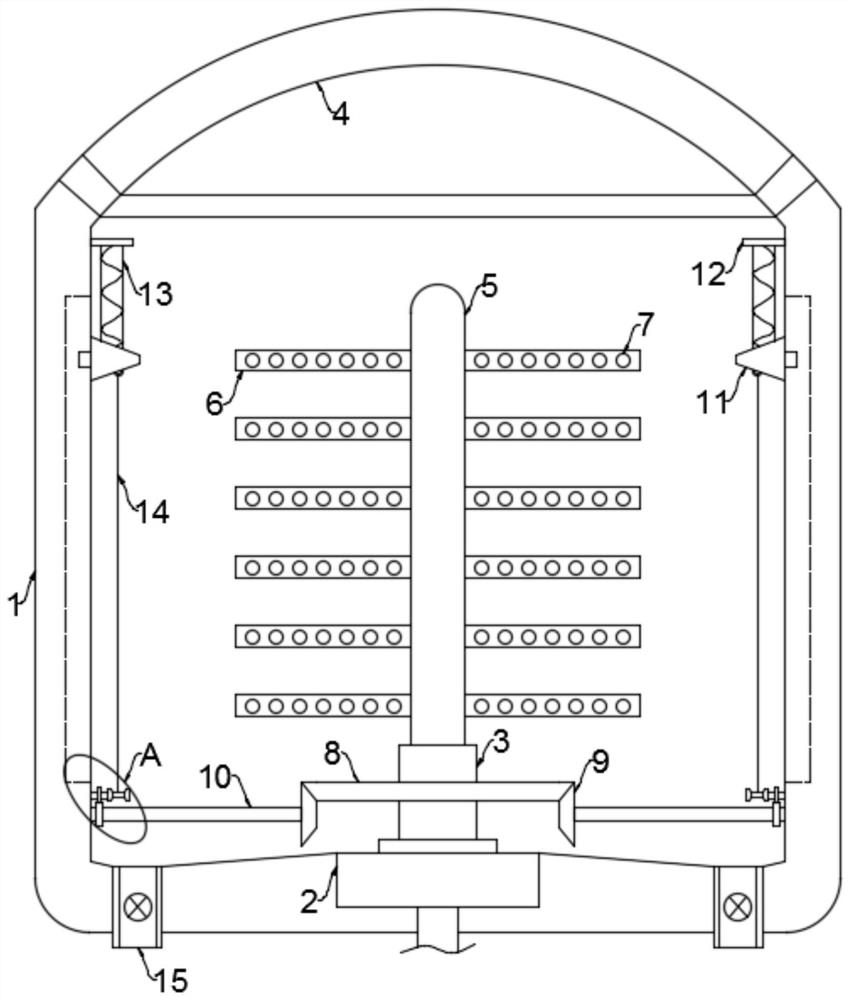

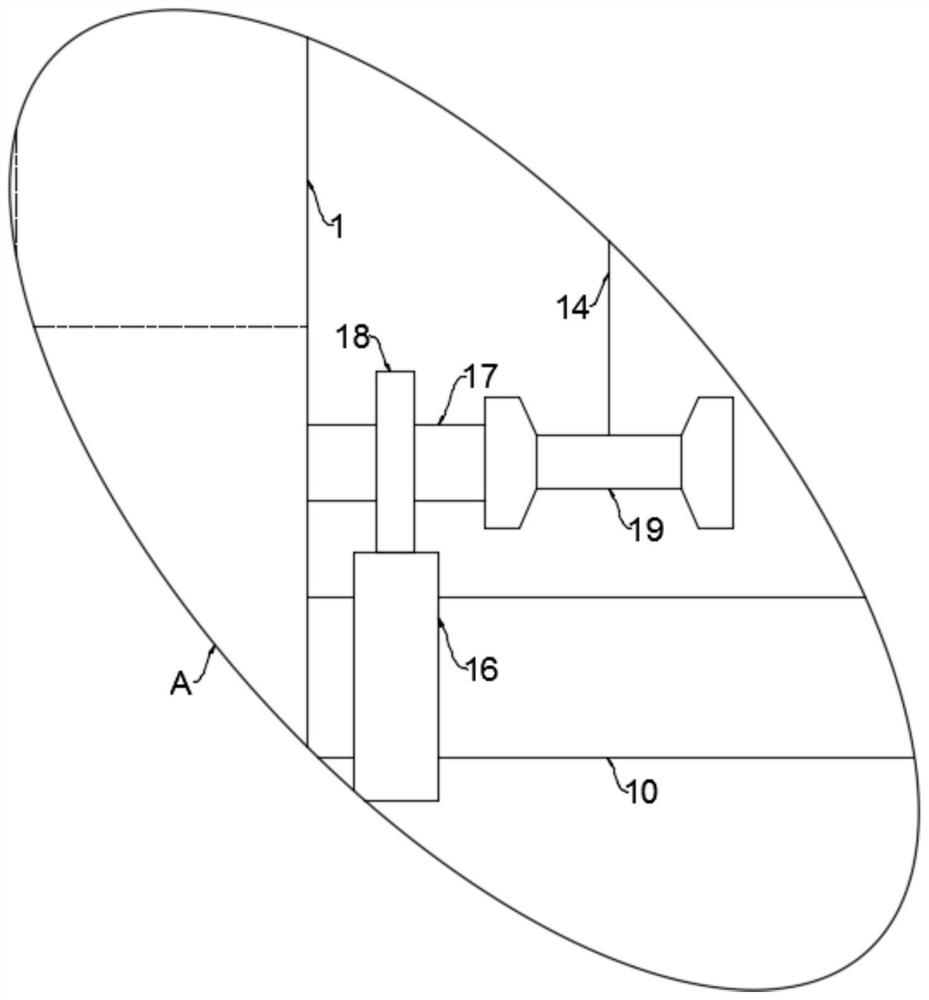

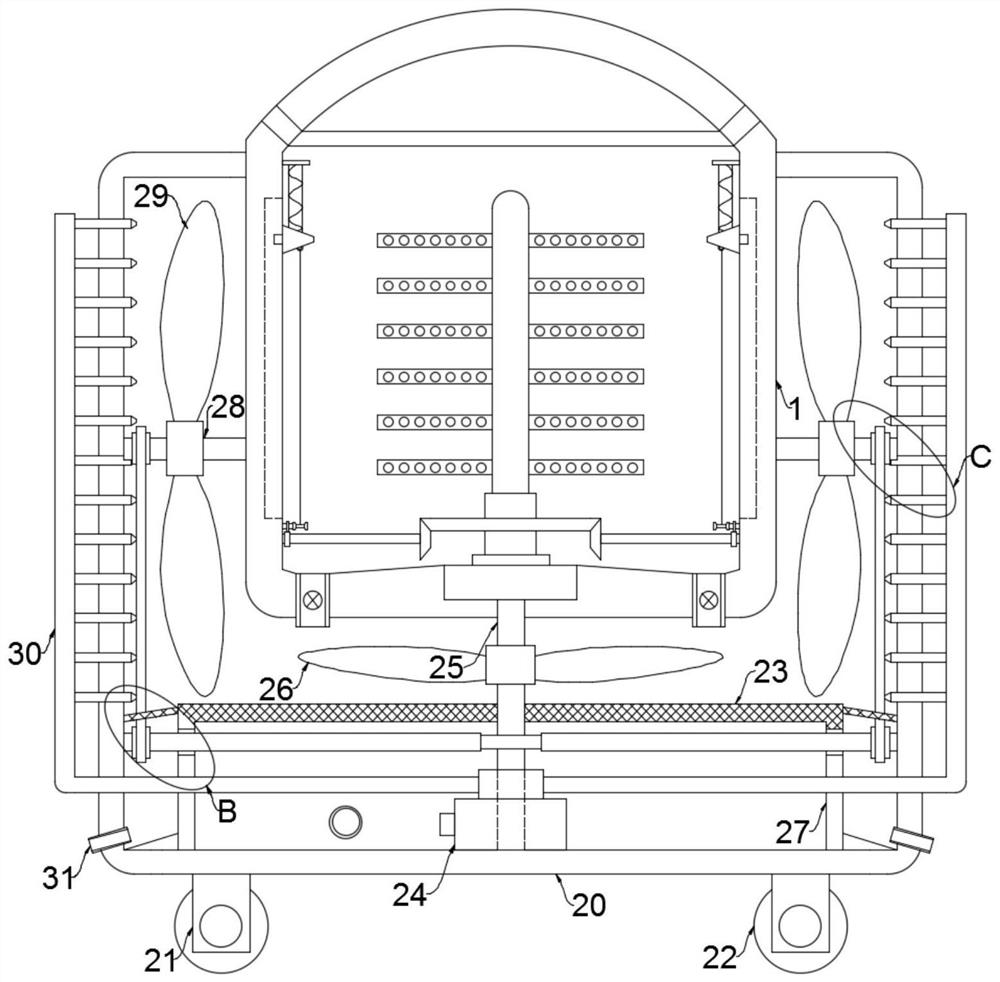

Fermentation tank

ActiveCN103667015AImprove discharge efficiencySave powerBioreactor/fermenter combinationsBiological substance pretreatmentsRadial motionAgricultural engineering

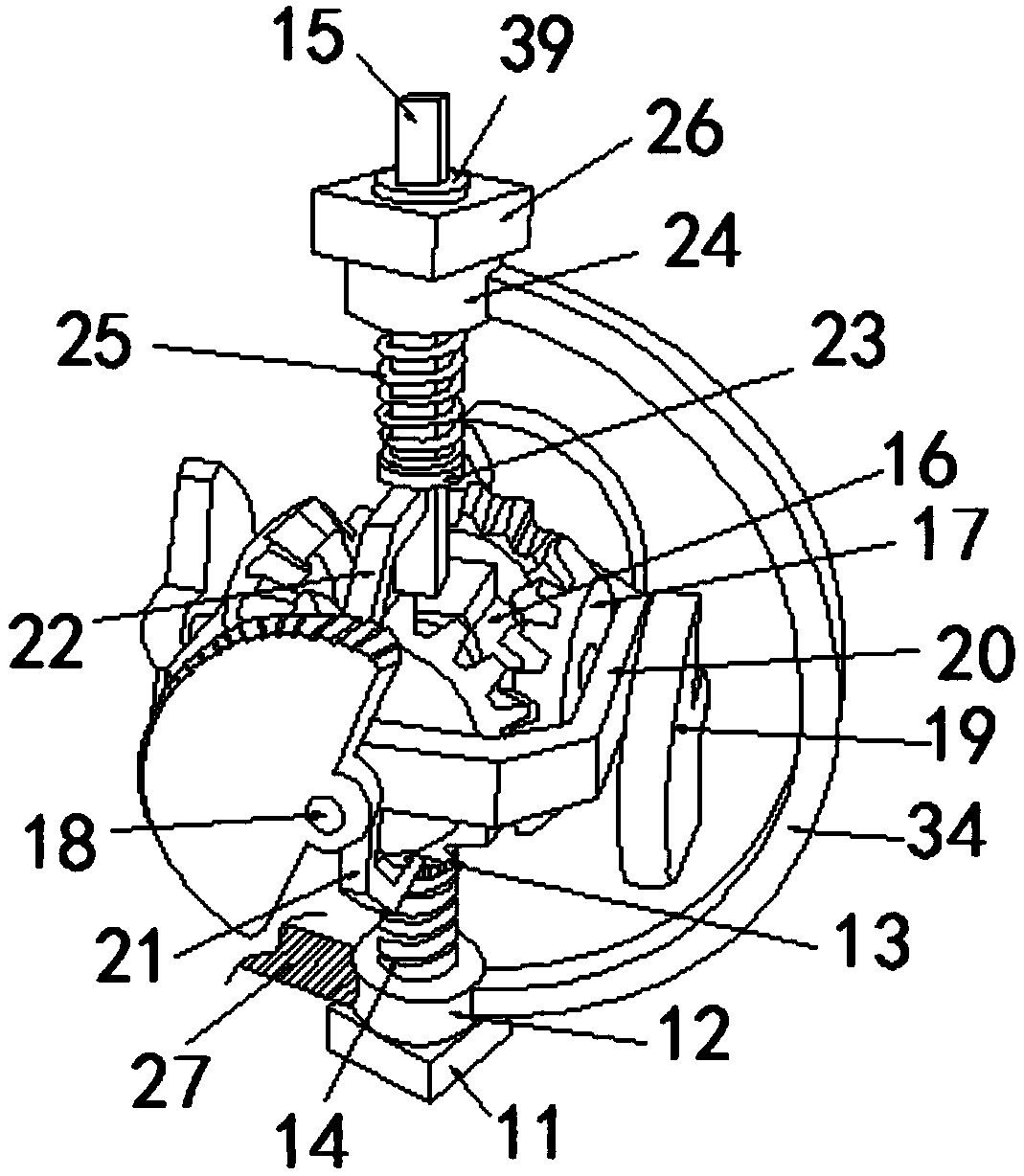

The invention discloses a fermentation tank which comprises an upper cover, a feeding device, a tank body, an air blasting device, an air extracting device, a stirring device and a discharging device, wherein the upper cover is arranged at the upper end of the tank body, a sealing device is arranged between the upper cover and the tank body, the feeding device is mounted on the upper cover, and the discharging device is arranged at the bottom of the tank body; the upper cover can rotate within a certain angle in a reciprocating manner and / or rotate for 360 degrees; the rotation of the upper cover drives the stirring device to rotate; and a slide track is mounted on the upper cover, and the stirring device can move in the radial direction of the slide track. According to the fermentation tank, rotation of the upper cover and the stirring device as well as the radial motion of the stirring device are driven with smaller power consumption, comprehensive stirring without dead angle of a fermented material in the fermentation tank is achieved under the condition of small power consumption; the discharging device is improved scientifically, with the combination of the improvement of the discharging device, the power consumption is reduced more comprehensively, and power required by discharging is reduced remarkably; and the fermentation tank is particularly suitable for vertical stirring of large-scale and supersized solid material fermentation tanks.

Owner:麦行

High-efficient paper pulp stirring device for industrial paper making

InactiveCN106237897AExtended service lifeImprove stirring efficiencyRotary stirring mixersTransportation and packagingPulp and paper industry

Owner:鄂星峄

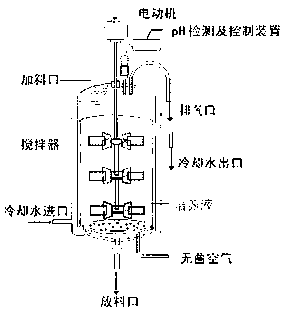

Reaction kettle with device for preventing liquid volatilization and pollution

InactiveCN105903423AStir well and thoroughlyNot volatileChemical/physical/physico-chemical stationary reactorsFeed devicesPollutionControl engineering

The invention provides a reaction kettle with a device for preventing liquid volatilization and pollution. The reaction kettle comprises a reaction kettle main body and a doser, wherein the reaction kettle main body comprises a kettle body, an upper cover and a lower cover; a feeding port is arranged on the upper cover; a discharging port is arranged on the lower cover; a liquid inlet is arranged on a side wall at the upper end of the kettle body; an inclined stirring rod is arranged on the side wall in the kettle body; a liquid distributing plate is arranged in the kettle body between the liquid inlet and the inclined stirring rod; the lower end and upper end of the kettle body are connected with each other through a circulating liquid pipeline on the outer side of the kettle body; the doser is arranged on the feeding port; the doser comprises a dosing separating plate and a motor; the dosing separating plate comprises an upper separating plate and a lower separating plate; corresponding circular holes are formed on the upper separating plate and the lower separating plate; a rotating shaft is arranged at the axis of the dosing separating plate; the rotating shaft is matched with the motor through a conical gear. The reaction kettle with the device for preventing liquid volatilization and pollution provided by the invention can prevent the organic volatile liquid from volatilizing from the feeding port while adding the solid material and can ensure the safety of the working environment.

Owner:TIANJIN TIANYUAN MACHINERY MFG

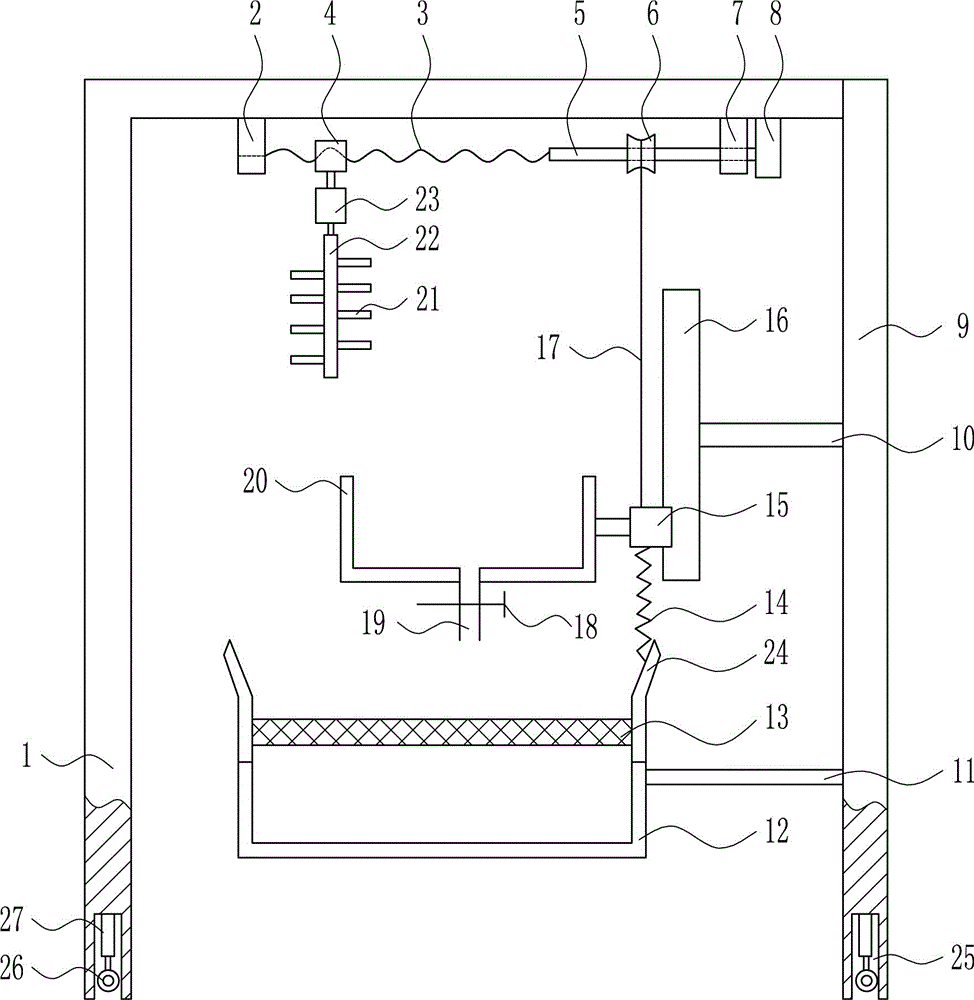

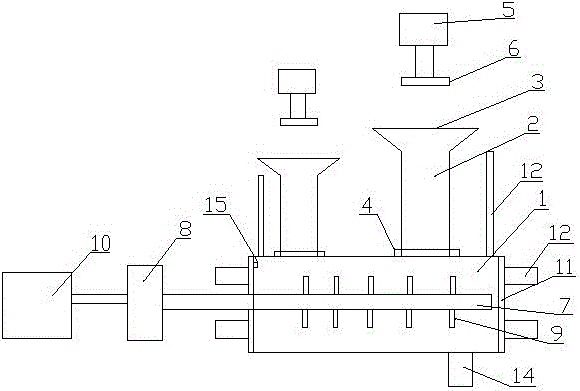

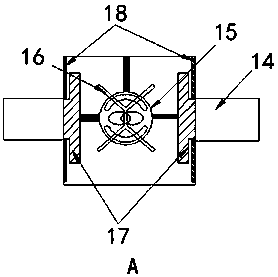

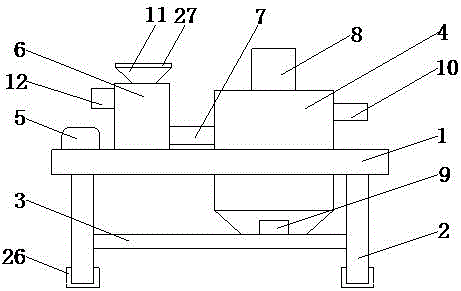

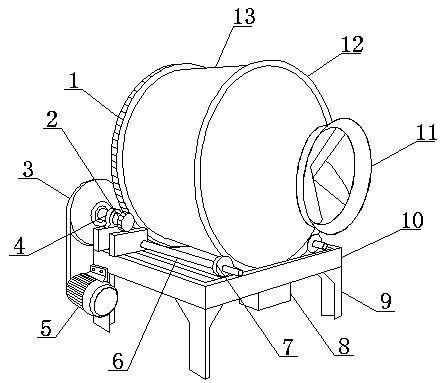

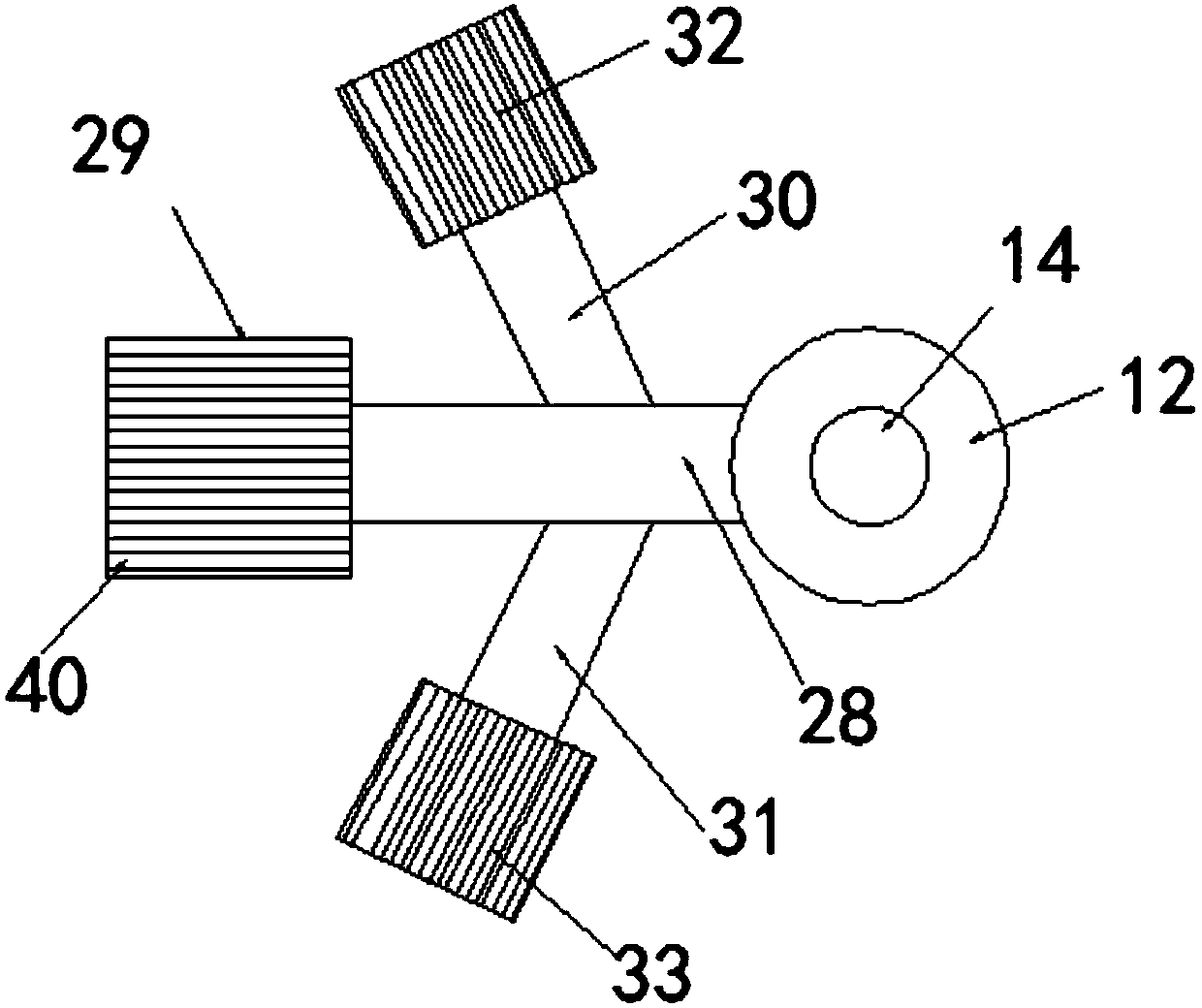

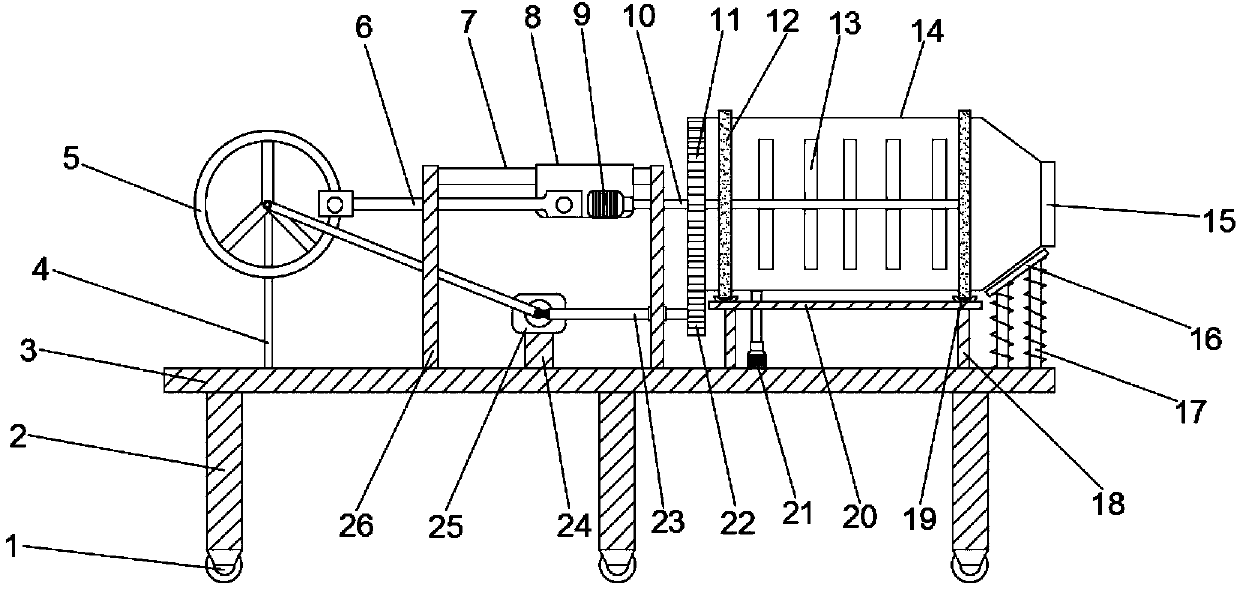

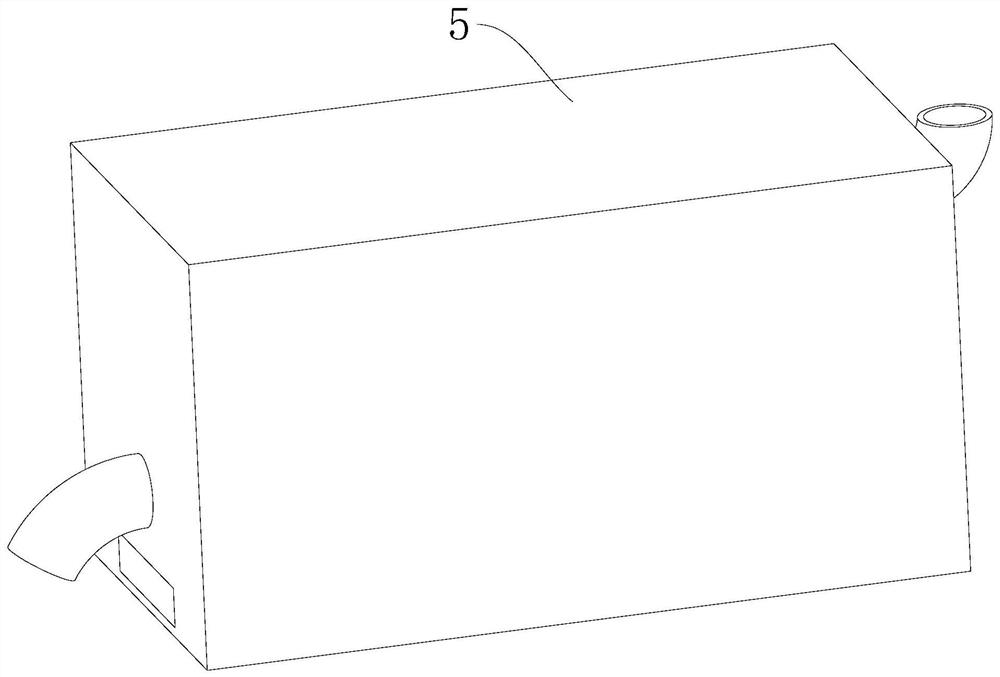

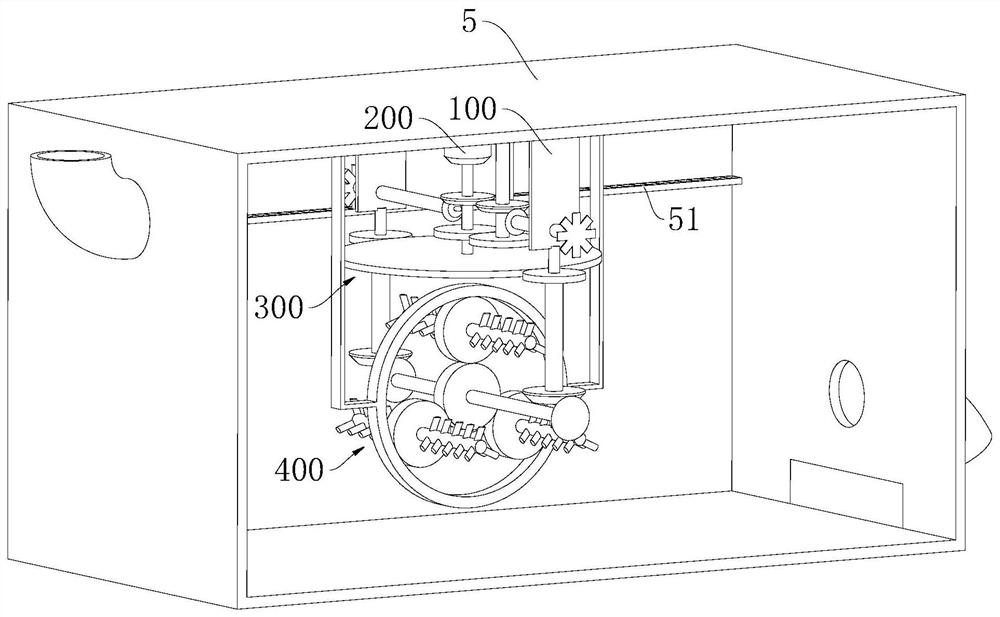

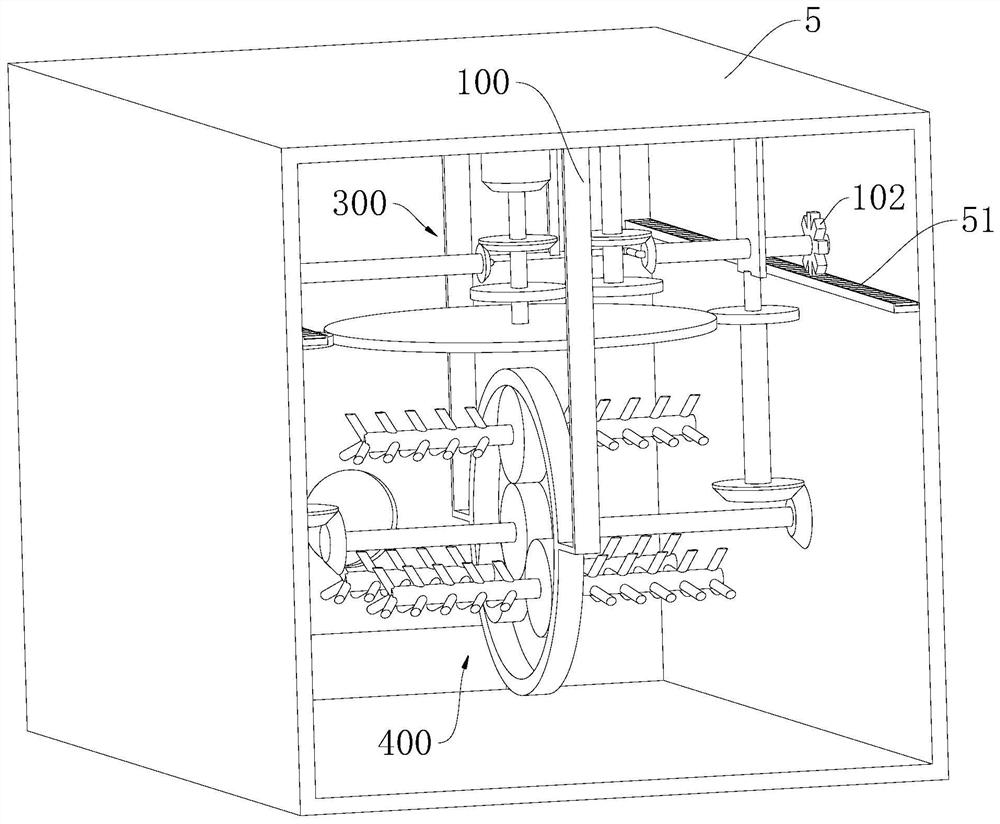

Raw material batching device for injection molding materials

The invention provides a raw material batching device for injection molding materials. The raw materials are stirred by a stirring cylinder which is arranged transversely. Two feeding cylinders used for feeding waste material particles and fresh material particles respectively are arranged on the stirring cylinder; the feeding cylinders are transparent so that the volume of the materials can be observed clearly, volume scale observation scales are arranged on the feeding cylinders, and thus observation is more convenient; after the feeding cylinders are filled with the materials, the materials are compressed tightly through circular push-down plates, and then the materials enter the stirring cylinder to be stirred; a stirring shaft can stir in a rotary mode as well as slide transversely, so that the materials are stirred more uniformly and more completely, and batching can be conducted well; in addition, the side walls of the stirring cylinder are provided with filtering layers, and small-size dust in the raw materials can be sucked through air sucking pipes. The raw material batching device is simple in structure and easy to operate, batching can be conducted efficiently and rapidly, and the raw material batching device is applicable to production.

Owner:WUHU LANBO PLASTIC

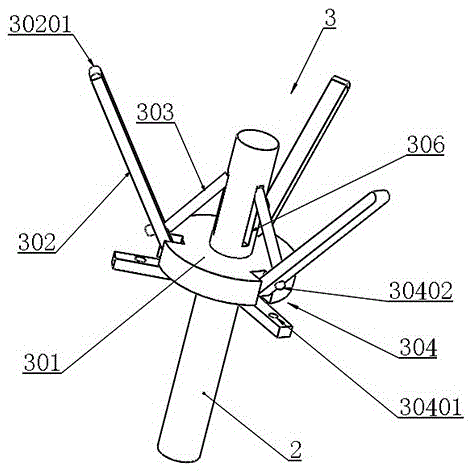

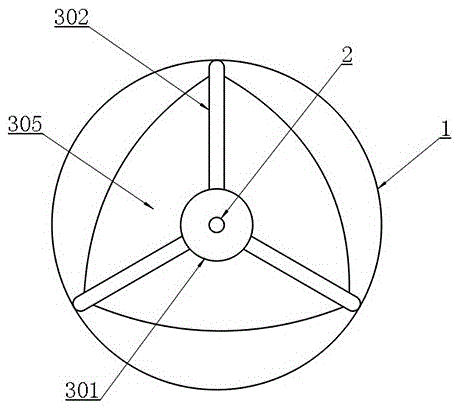

Stirring device for investment casting of wax liquid

ActiveCN105597598ASimple structureGood effect of removing impuritiesTransportation and packagingRotary stirring mixersWaxInvestment casting

The invention belongs to the technical field of investment casting equipment and particularly relates to a stirring device for investment casting of wax liquid. The stirring device comprises a stirring device main body, and further comprises a stirring column arranged in the stirring device main body, wherein a filter screen unit capable of being folded through elastic pull force, and a stirring rod unit are arranged on the stirring column in sequence from top to bottom. The stirring device provided by the invention can be used for filtering the wax liquid to remove impurities before stirring, and has the advantages of simple and effective structure, good impurity removing effect, uniformity and completeness in stirring and convenience for washing an inner wall of the device.

Owner:HUZHOU NANFENG MACHINERY MFG

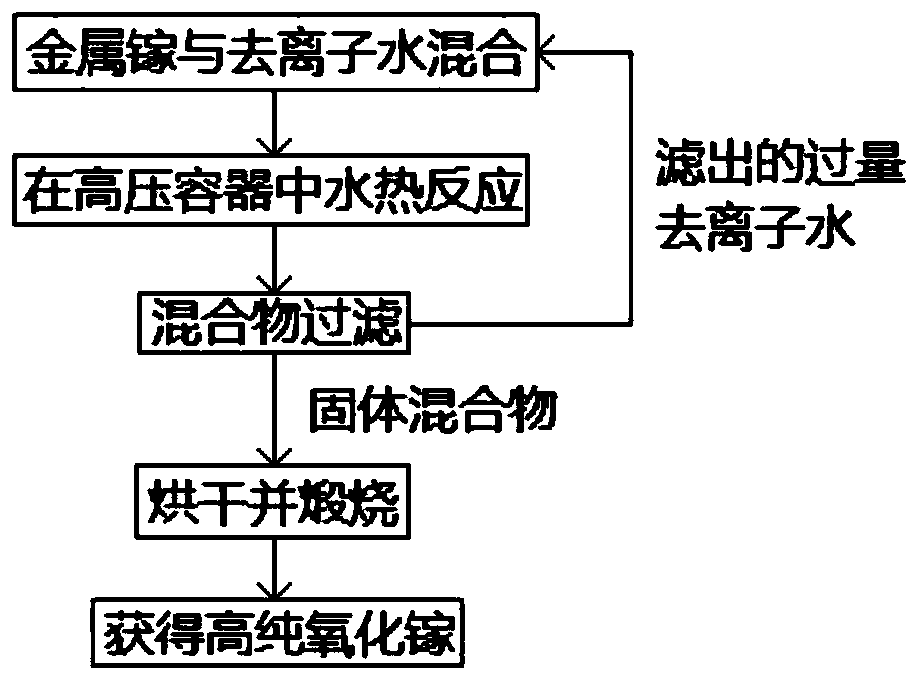

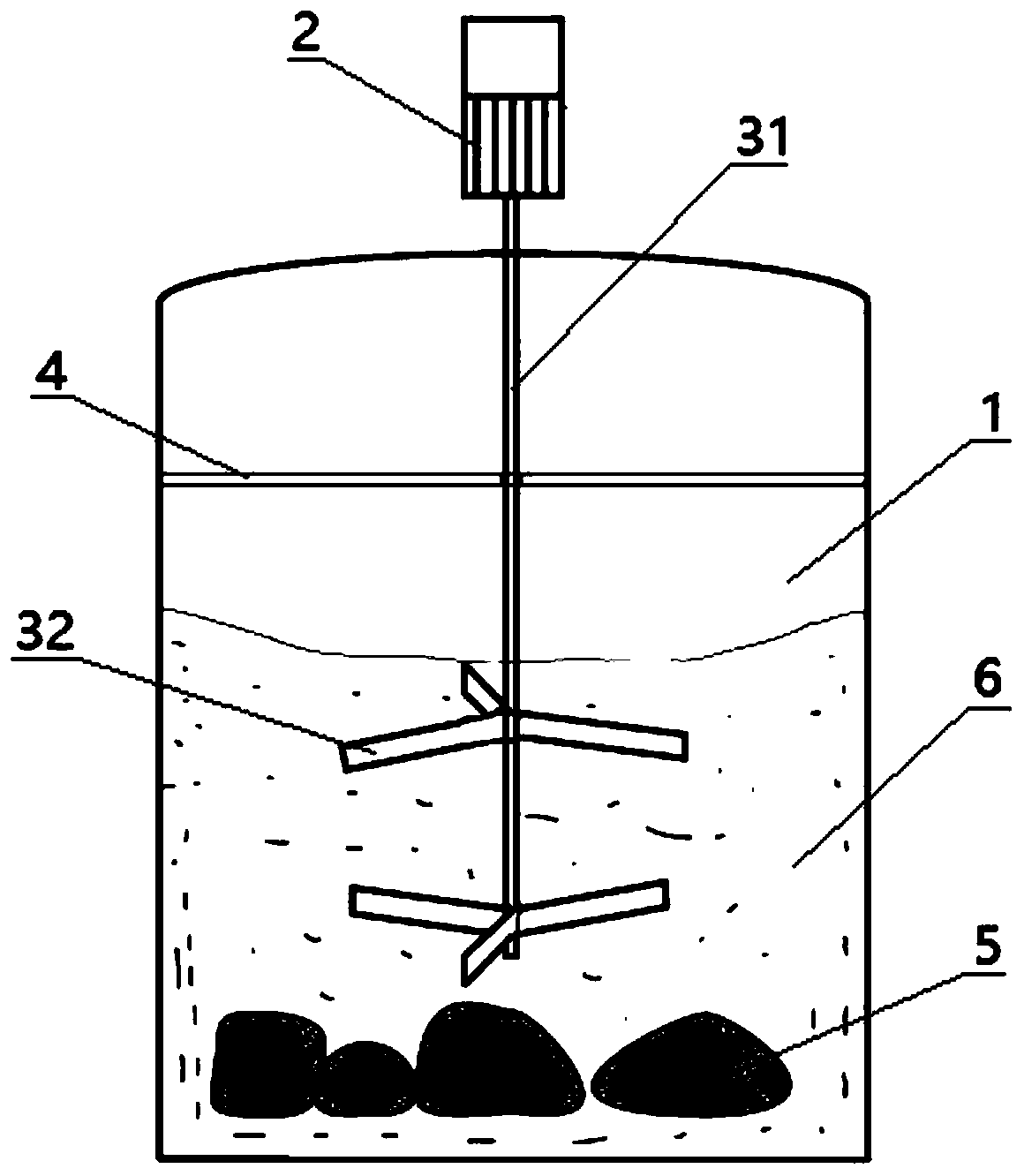

Preparation method and preparation device for high-purity gallium oxide

InactiveCN110627112AFully contactedImprove reaction efficiencyGallium/indium/thallium compoundsCalcinationMetal

The invention discloses a preparation method for high-purity gallium oxide. The method includes the following steps: mixing metal gallium and water for a reaction to generate a mixture; filtering themixture, and performing drying; and performing calcination on the mixture to generate the gallium oxide. According to method, gallium oxide hydroxide and gallium oxide are prepared through ahigh-temperature hydrothermal reaction, drying is performed and calcination is performed to make the gallium oxide hydroxide decomposed into gallium oxide and water, and after the water is evaporated and escaped, the high-purity gallium oxide is obtained. The present application also provides a preparation device for preparing the high-purity gallium oxide.

Owner:CNBM CHENGDU OPTOELECTRONICS MATERIAL

Detection device for preservative content in powder food

InactiveCN107817156AStir wellStir evenly and thoroughlyPreparing sample for investigationTesting foodEngineeringHeat balance

The invention discloses a detection instrument for the content of preservatives in powdered food, which comprises an inner tube of the detection instrument, an outer wall of the detection instrument, and a sealing cover. The top of the test instrument is provided with the sealing cover, wherein, the upper part of one side of the inner tube of the detection instrument is provided with a feed port, and the feed port penetrates the outer wall of the test instrument and extends to the side of the outer wall of the test instrument, The lower part of the other side of the inner tube of the detection instrument is provided with a discharge port, and the discharge port penetrates through the lower part of the other side of the outer wall of the detection device and extends to the side of the outer wall of the detection device. A motor 1 is arranged inside, and the bottom of the motor 1 is provided with a partition, and the bottom of the partition is provided with an air rod. Beneficial effects: the balance of stirring and the uniformity of heat are improved, the accuracy of detection is increased, and the detection accuracy is improved.

Owner:WUXI X RES PROD DESIGN & RES

Paint processing equipment for construction

InactiveCN107998926AAdjustable distanceReduce intensityRotary stirring mixersTransportation and packagingMotor driveReciprocating motion

The invention relates to paint processing equipment for construction. The equipment comprises an upper cover box, a motor, handles, supporting feet, a main rotating rod, a main stirring paddle and supporting legs, wherein the motor is arranged in the middle of the upper surface of the upper cover box, the handles are arranged on the two sides of the motor, and the handles are fixedly connected tothe upper surface of the upper cover box; the output end of the motor is connected with the main rotating rod through a coupler, and auxiliary stirring paddles are arranged on the two sides of the main stirring paddle, so that paint is uniformly stirred; the motor which is a servo motor drives the main stirring paddle and the auxiliary stirring paddles to reciprocate and stir the paint, so that stirring is more uniform and thorough, and the stirring efficiency is improved; meanwhile, the distances between the main and auxiliary stirring blades can be adjusted, so that the applicability of theequipment is improved, and popularization and application are facilitated; the supporting legs are arranged to replace handheld stirring, so that the working intensity of workers is reduced; the distance between the supporting legs is adjustable, so that the applicability of the equipment is not influenced; tool cloth is arranged between the supporting legs for shielding, so that the phenomenon that the paint is splashed in the stirring process is avoided.

Owner:赵孝利

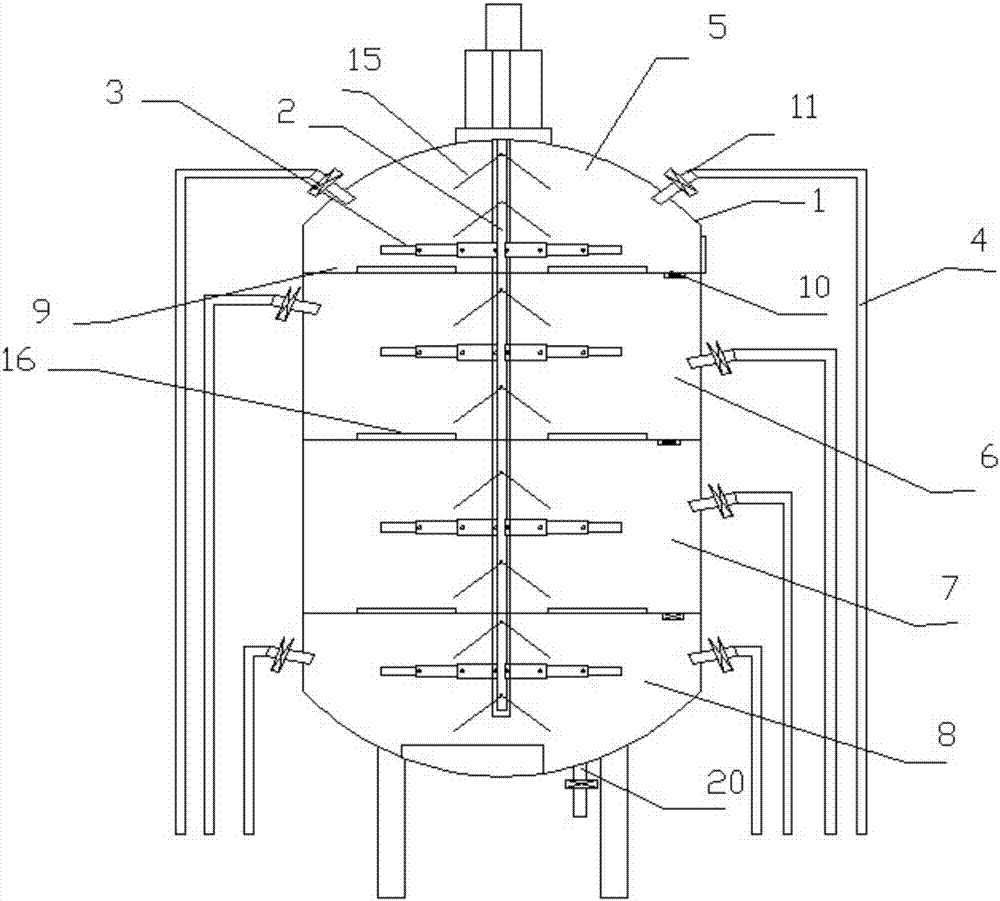

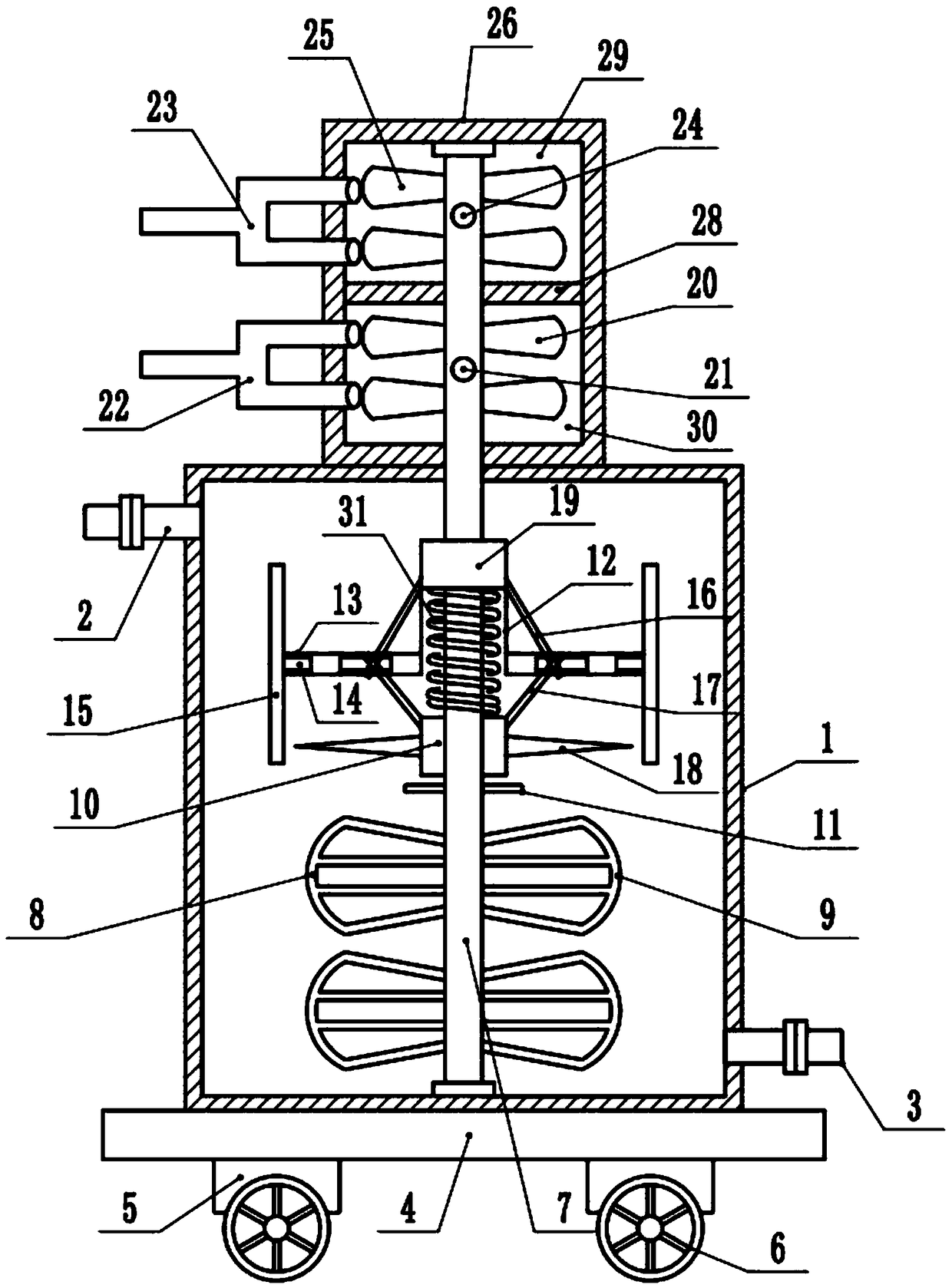

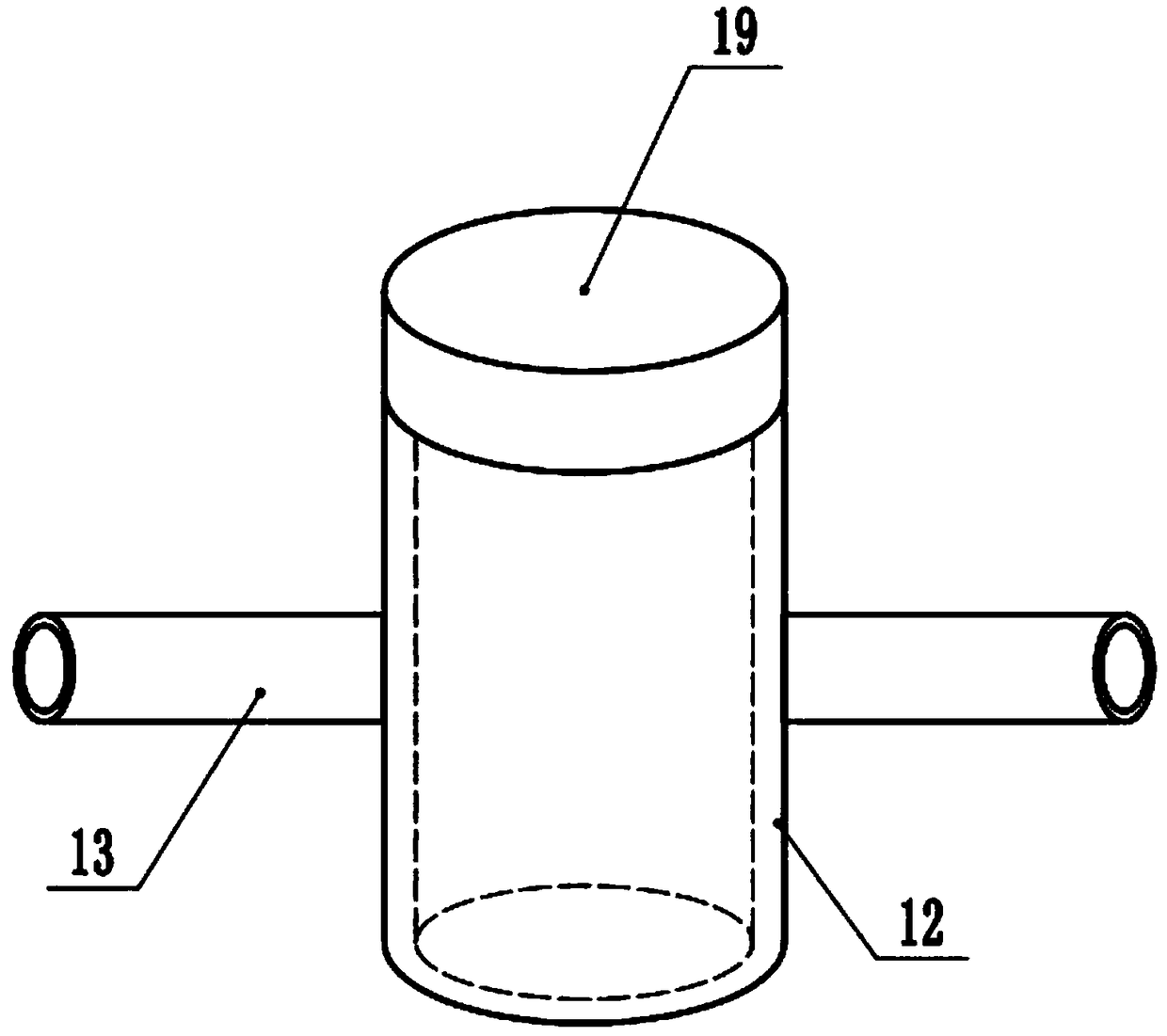

Automatic feeding reaction kettle for producing liquid barium-zinc heat stabilizer

PendingCN107252669AIncrease productivityImprove feeding efficiencyChemical/physical/physico-chemical stationary reactorsFeed devicesEngineeringZinc

The invention discloses an automatic feeding reaction kettle for producing a liquid barium-zinc heat stabilizer. The automatic feeding reaction kettle comprises a shell and a mixing device, wherein the mixing device comprises a mixing shaft and a blade; the blade is fixedly arranged on the mixing shaft; the mixing shaft extends into the shell; the shell is divided into four layers, which are a top layer, an upper middle layer, a lower middle layer and a bottom layer separately; the mixing shaft penetrates through the top layer, the upper middle layer, the lower middle layer and the bottom layer; a feeding hole is formed in each layer; the feeding holes are connected with delivery pipes; the delivery pipe connected with the feeding hole in the top layer is connected with a water suction pump; one end of the delivery pipes connected with the feeding hole in the upper middle layer is connected with the water suction pump and the other one is connected with a blast blower; the delivery pipe connected with the feeding hole in the lower middle layer is connected with the blast blower; the delivery pipe connected with the feeding hole in the bottom layer is connected with the blast blower. The automatic feeding reaction kettle for producing the liquid barium-zinc heat stabilizer is capable of automatically feeding, and is simple in feeding, time-saving and labor-saving, and the production efficiency is improved.

Owner:德清县东来化学有限公司

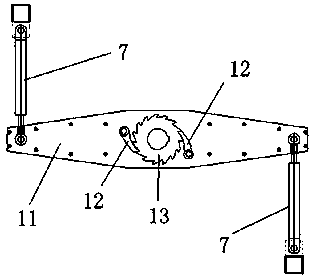

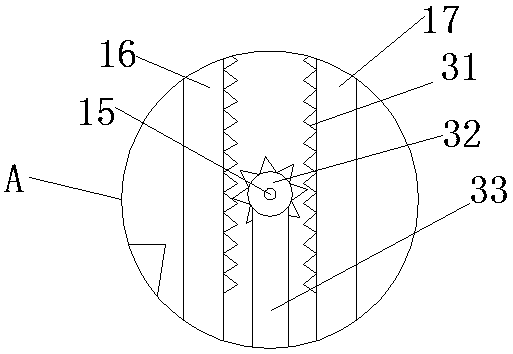

Pulp stirring device capable of achieving bidirectional stirring

InactiveCN106823882AStir evenly and thoroughlyIncrease contact areaRotary stirring mixersTransportation and packagingDrive wheelMotor drive

The invention relates to the technical field of paper making equipment, and discloses a pulp stirring device capable of achieving bidirectional stirring. The pulp stirring device comprises a base and a cylinder, the cylinder is installed on the upper surface of the base through a support rod, an inner groove is formed in the left side of the base, a first motor is installed on the inner wall of the left side of the inner groove, a drive wheel is fixedly connected to an output shaft of the first motor, a bearing is installed at the bottom of the left side face of the cylinder, and a connecting rod is inserted into the bearing. According to the pulp stirring device capable of achieving bidirectional stirring, the first motor, a second motor, a stirring shaft, stirring rods, a rotating shaft, fixing rods and a U-shaped frame are arranged, the first motor drives the stirring shaft to rotate to conduct transverse stirring on pulp, the second motor drives the rotating shaft to rotate to conduct longitudinal stirring on the pulp, a vortex formed by transverse stirring and longitudinal stirring is dispersed, then stirring is conducted, therefore, the condition that stirring cannot be conducted due to the fact that the pulp generates agglomerates or rotates along with the flow speed is prevented, and the effect that stirring is more uniform and thorough is achieved.

Owner:王琳

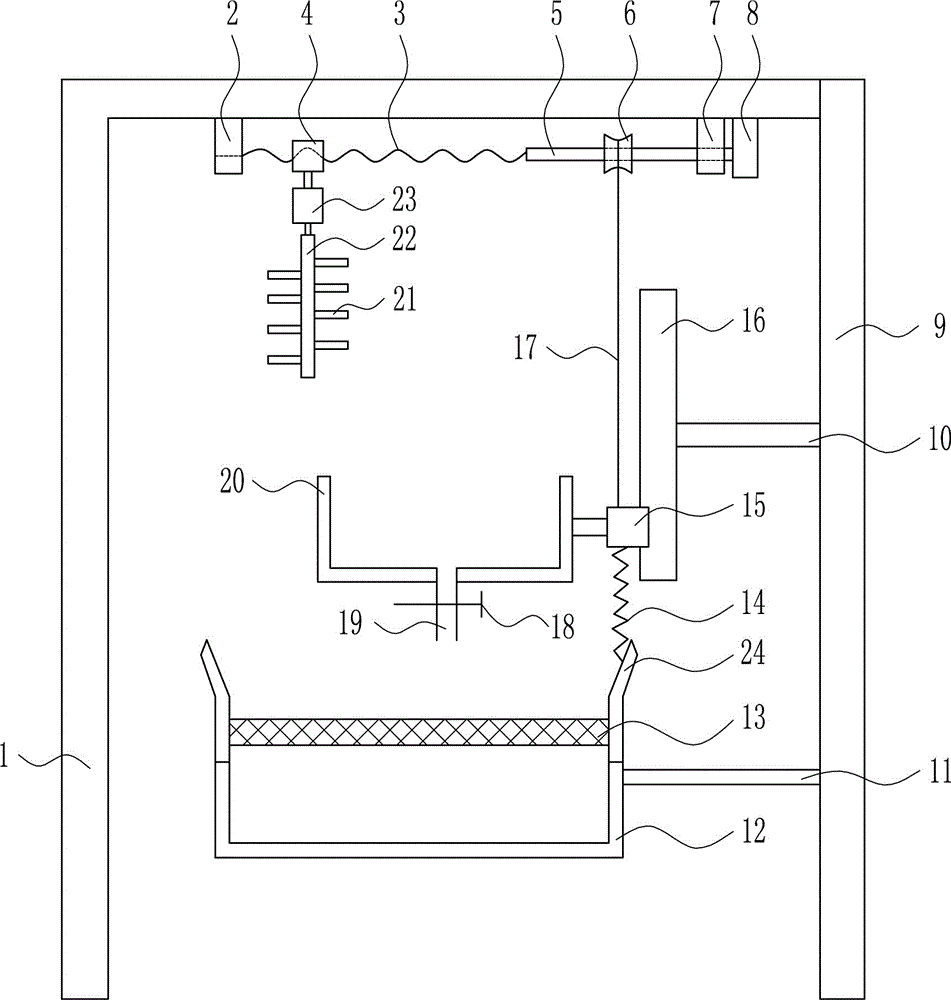

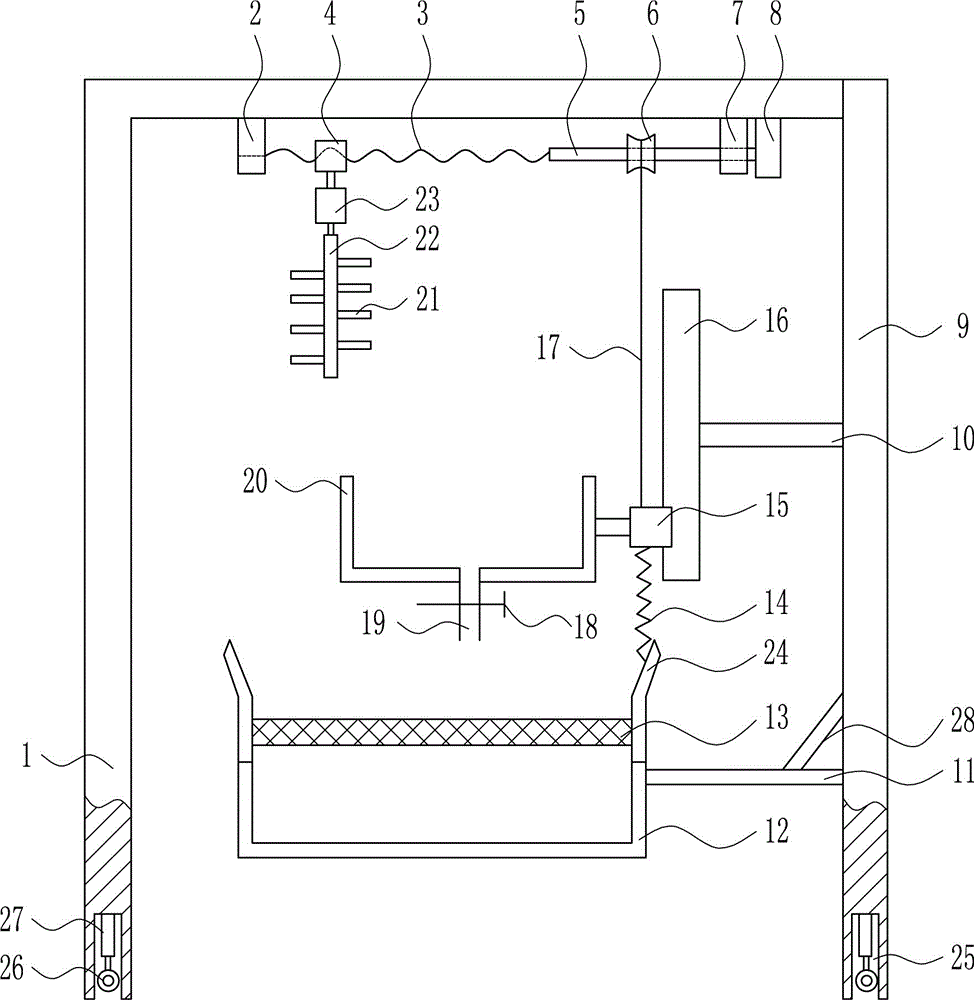

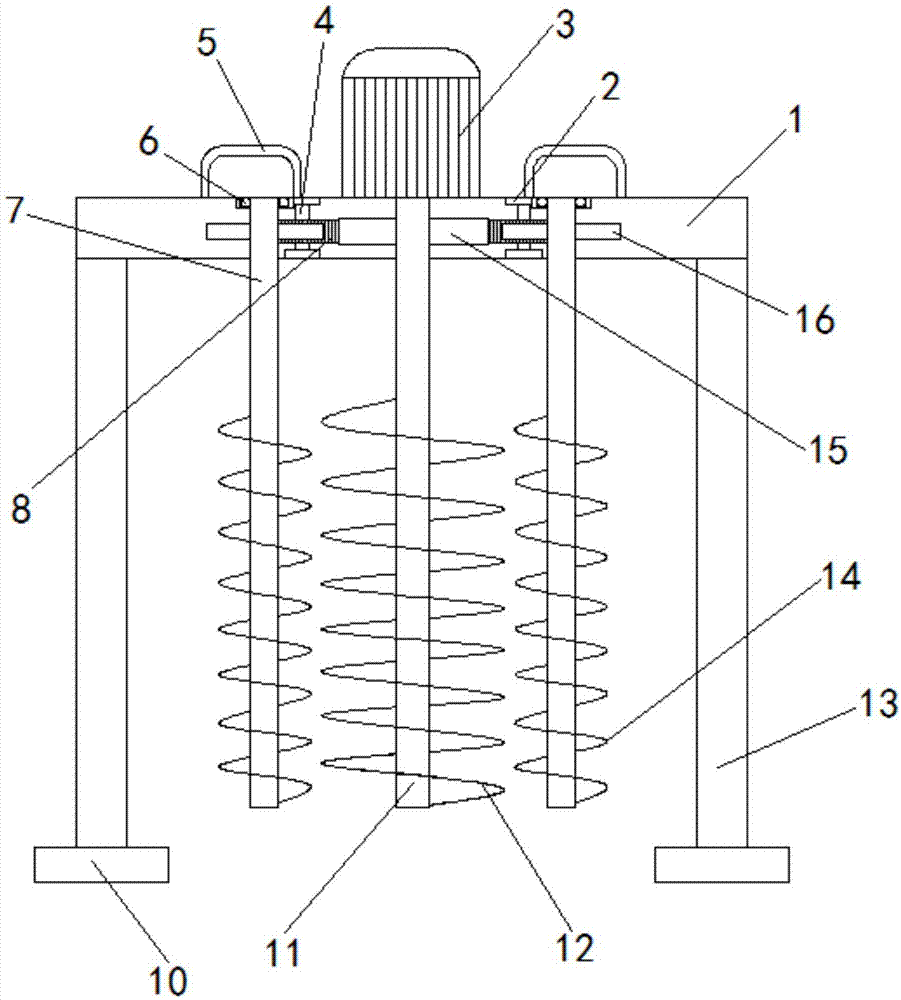

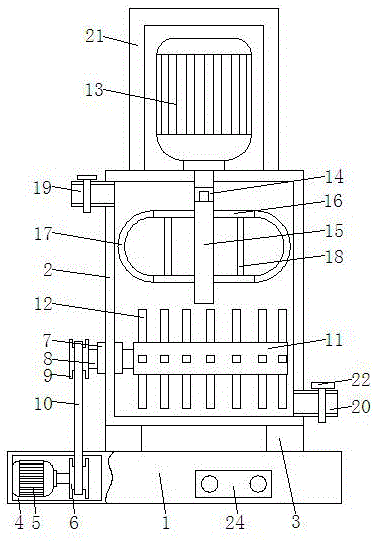

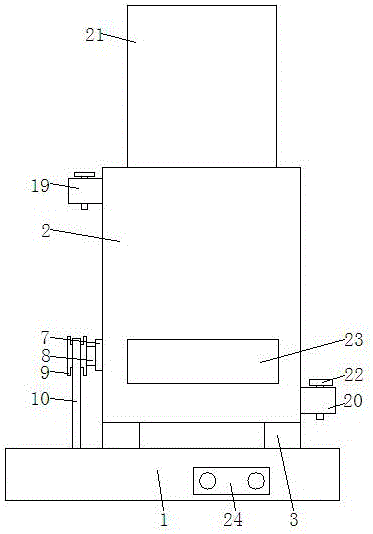

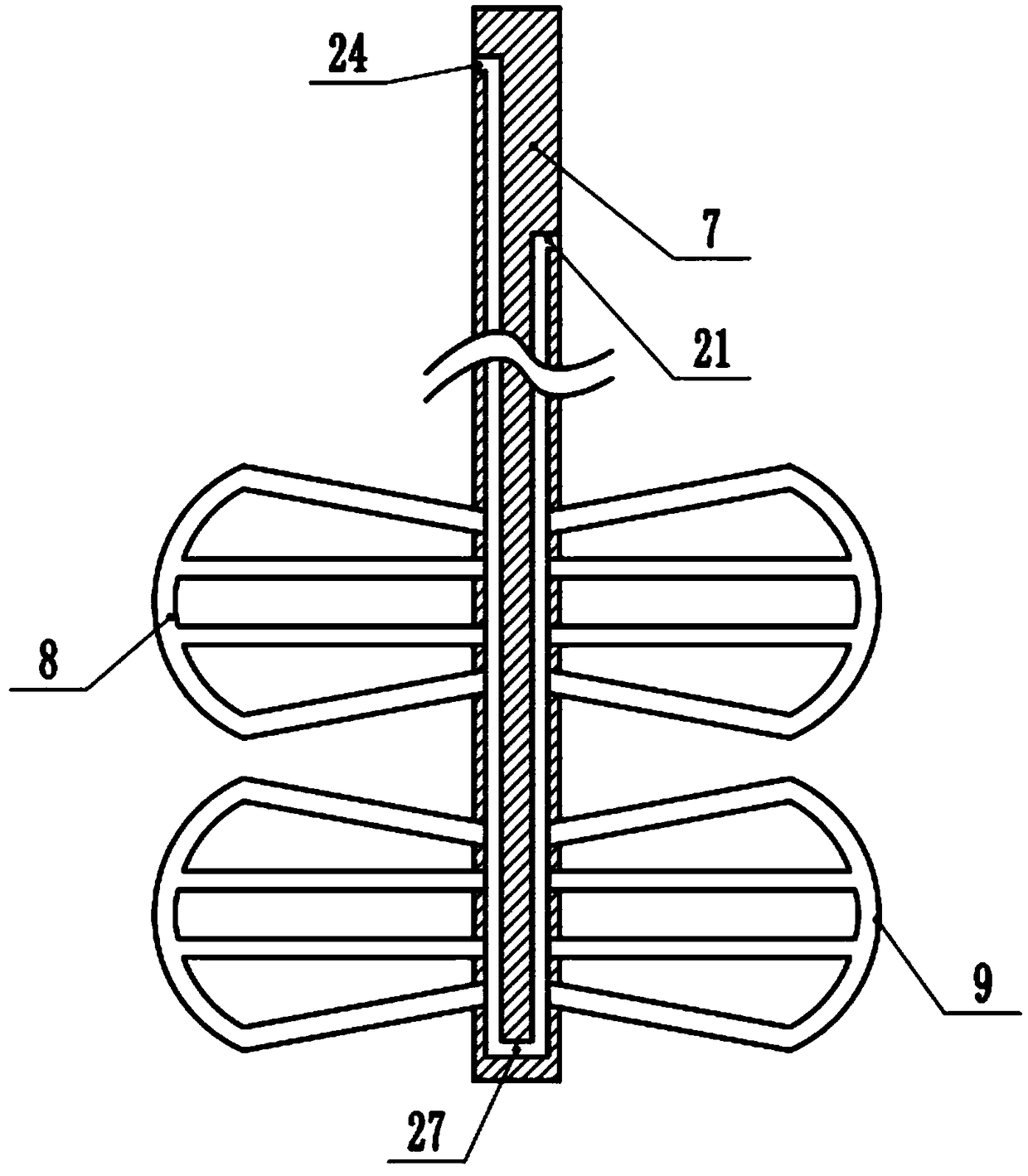

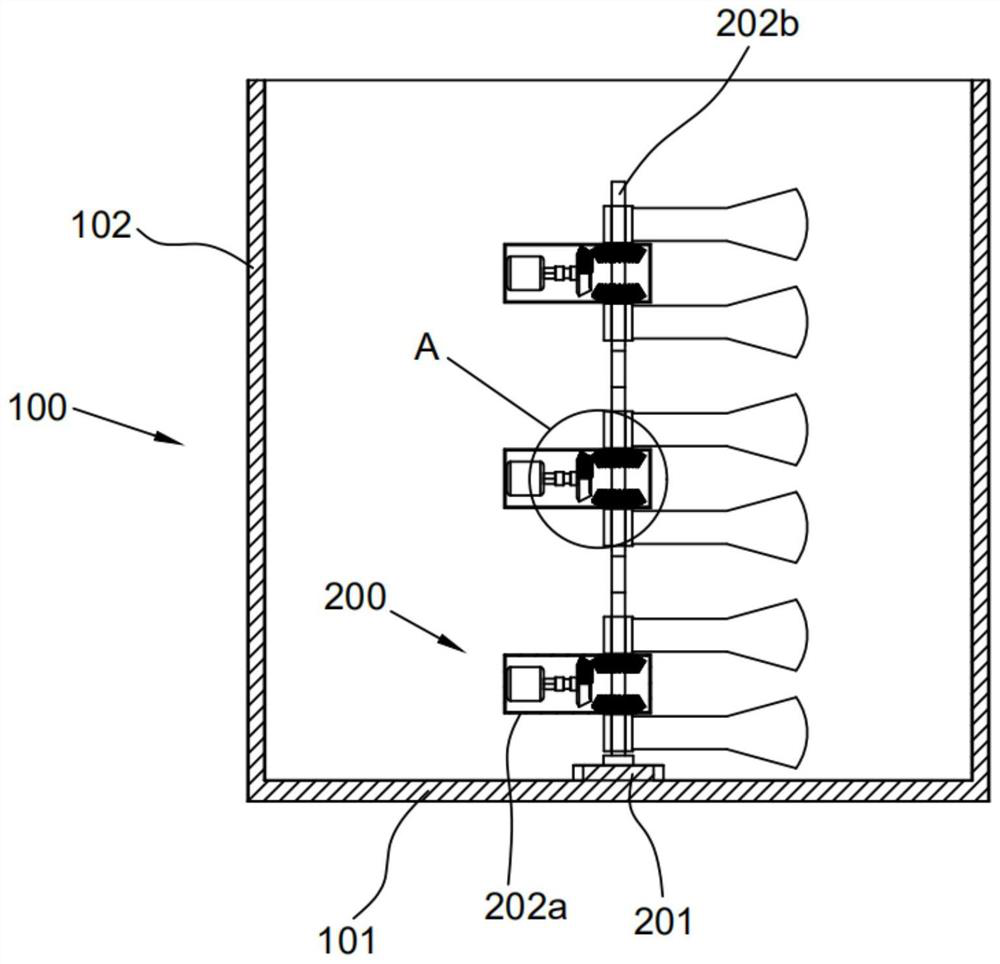

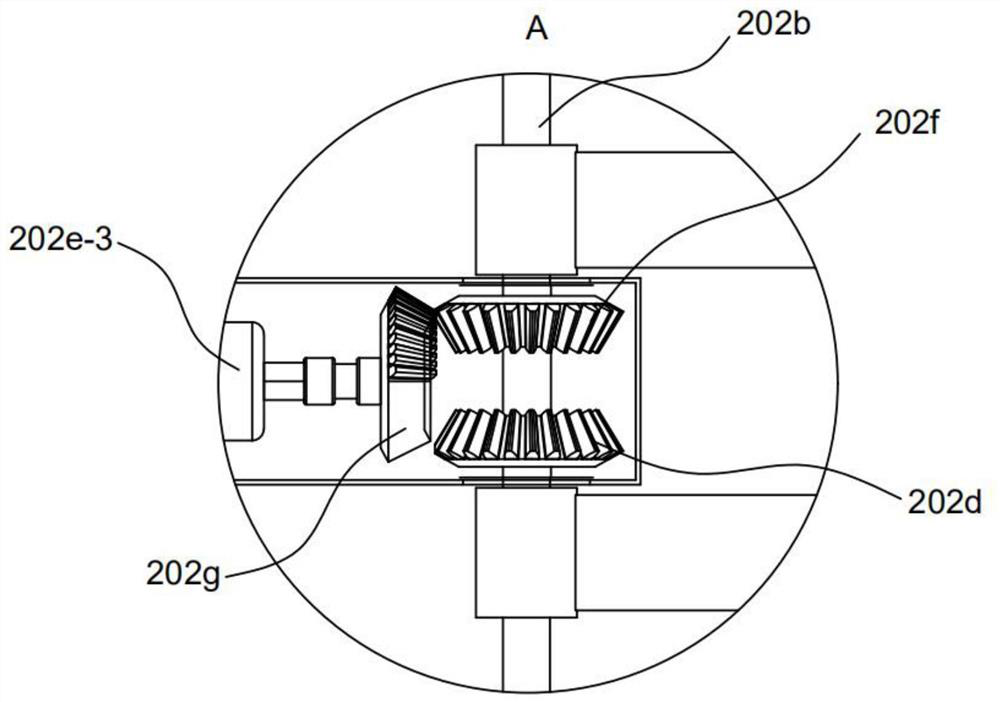

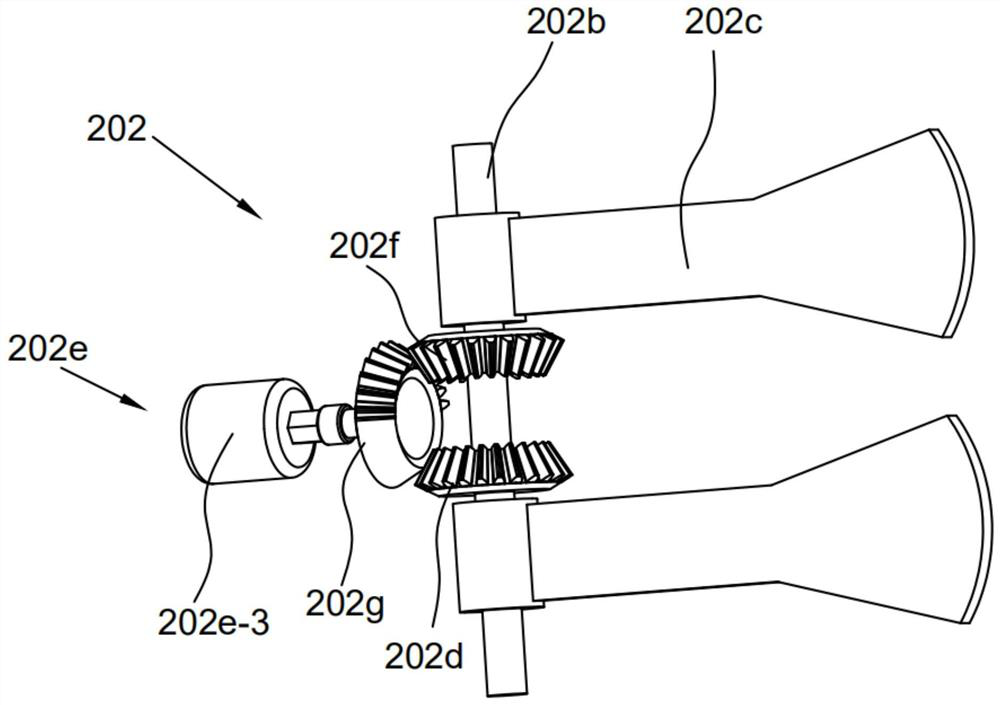

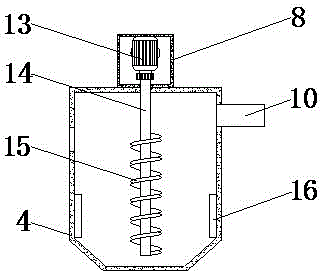

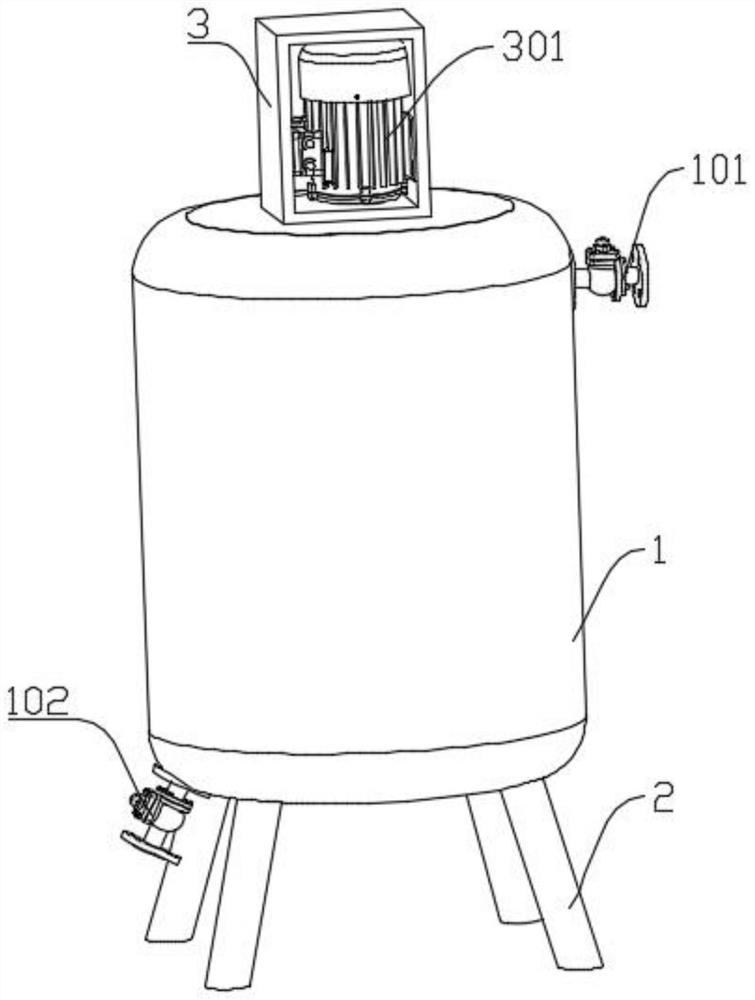

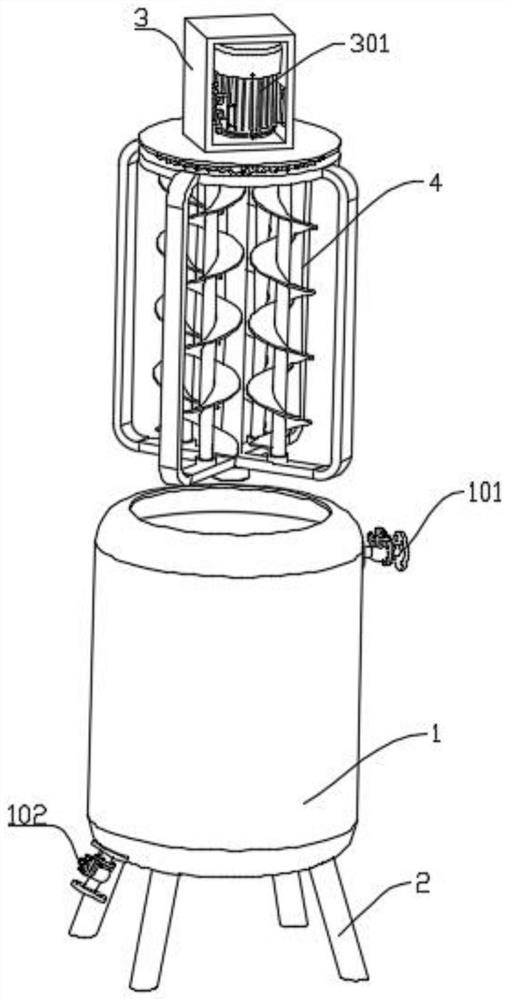

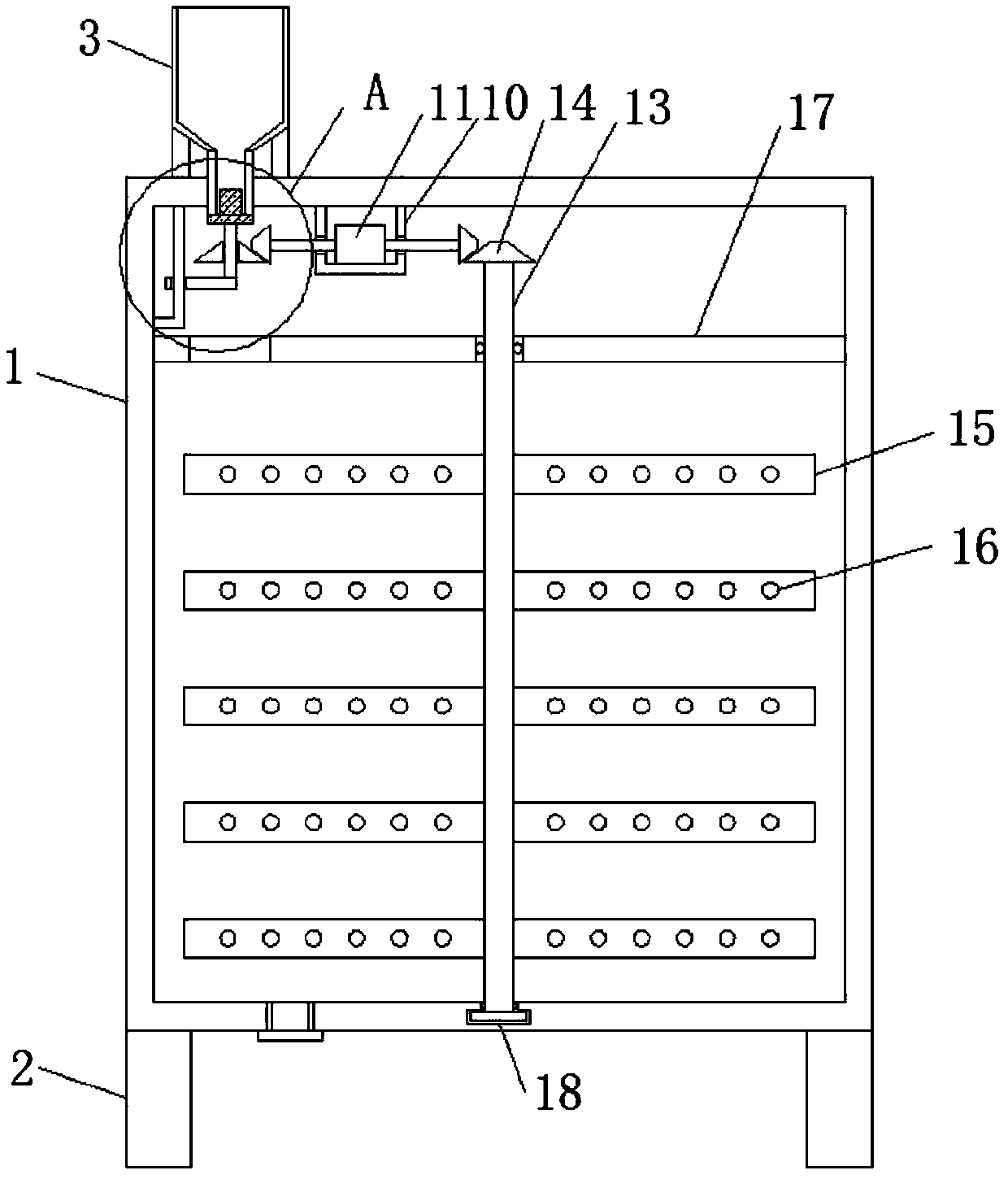

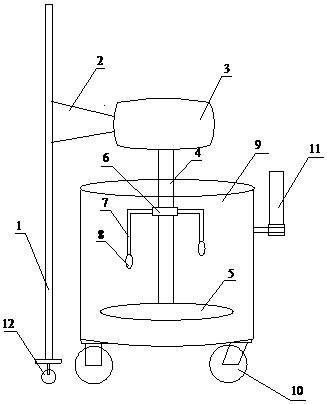

Microbial fermentation device for biotechnology

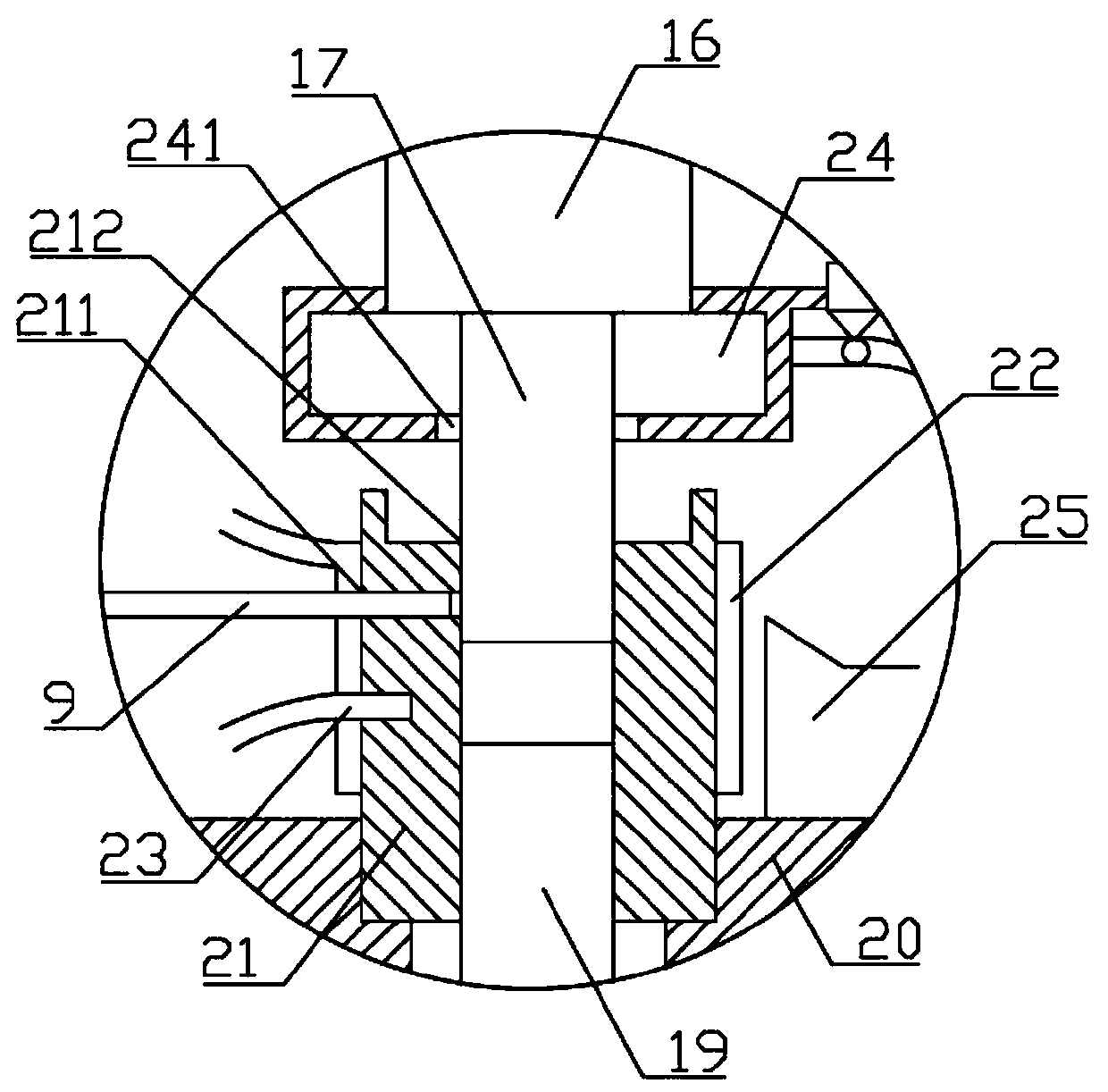

InactiveCN108660057AReasonable structureInnovative designBioreactor/fermenter combinationsBiological substance pretreatmentsAgricultural engineeringFermentation broth

The invention discloses a microbial fermentation device for biotechnology. The microbial fermentation device comprises a base; a fermentation box is installed at the upper end of the base; a driving box is installed in the middle of the upper end of the fermentation box; a rotating block is installed in the middle of a stirring shaft positioned in the fermentation box; a sleeve is installed at theouter side of the lower end of the rotating block; guide cylinders are respectively installed at the middle parts of the two ends of the sleeve; a guide rod is installed in the middle of each guide cylinder; telescopic rods are hinged between the inner sides of the guide rods and the rotating block; fixed connecting rods are hinged with the lower ends of the inner sides of the guide rods; a lifting block is hinged with the lower ends of the fixed connecting rods; a left heat dissipation frame pipe is installed at the left end of the stirring shaft positioned at the bottom end of the fermentation box; a right heat dissipation frame pipe is installed at the right end of the stirring shaft positioned at the bottom end of the fermentation box. The microbial fermentation device not only can conveniently control the temperature inside the fermentation box, but also can conveniently control the rotation speed of the stirring shaft, thereby realizing the scraping of the upper layer surface box wall of fermentation liquid by a scraper blade, and facilitating the cleaning of a fermentation tank in the later stage; the microbial fermentation device for biotechnology is high in practicality.

Owner:苏州朝霞生物科技有限公司

Stirrer and smelting furnace with stirrer

ActiveCN111678353AStir evenly and thoroughlyImprove mixing uniformityStirring devicesCharge treatment typeElectric machineryDrive motor

The invention discloses a stirrer and a smelting furnace with the stirrer. The stirrer comprises a traveling support, a driving motor, a transmission structure and stirring paddles, wherein the driving motor is arranged on the traveling support, an output shaft of the driving motor is connected with the stirring paddles through the transmission structure and drives the stirring paddles to rotate,and a first traveling wheel and a second traveling wheel are respectively arranged on two sides of the traveling support; and the output shaft of the driving motor is respectively connected with the first traveling wheel and the second traveling wheel through the transmission structure, drives the first traveling wheel and the second traveling wheel to synchronously rotate, and drives the traveling support and the stirring paddles arranged on the traveling support to horizontally move. The driving motor is arranged to control the two traveling wheels to rotate on guide rails, so that the traveling support is driven to travel in the smelting furnace, the smelting furnace can be stirred, and the stirring is more uniform and thorough.

Owner:湖南森科有色金属有限公司

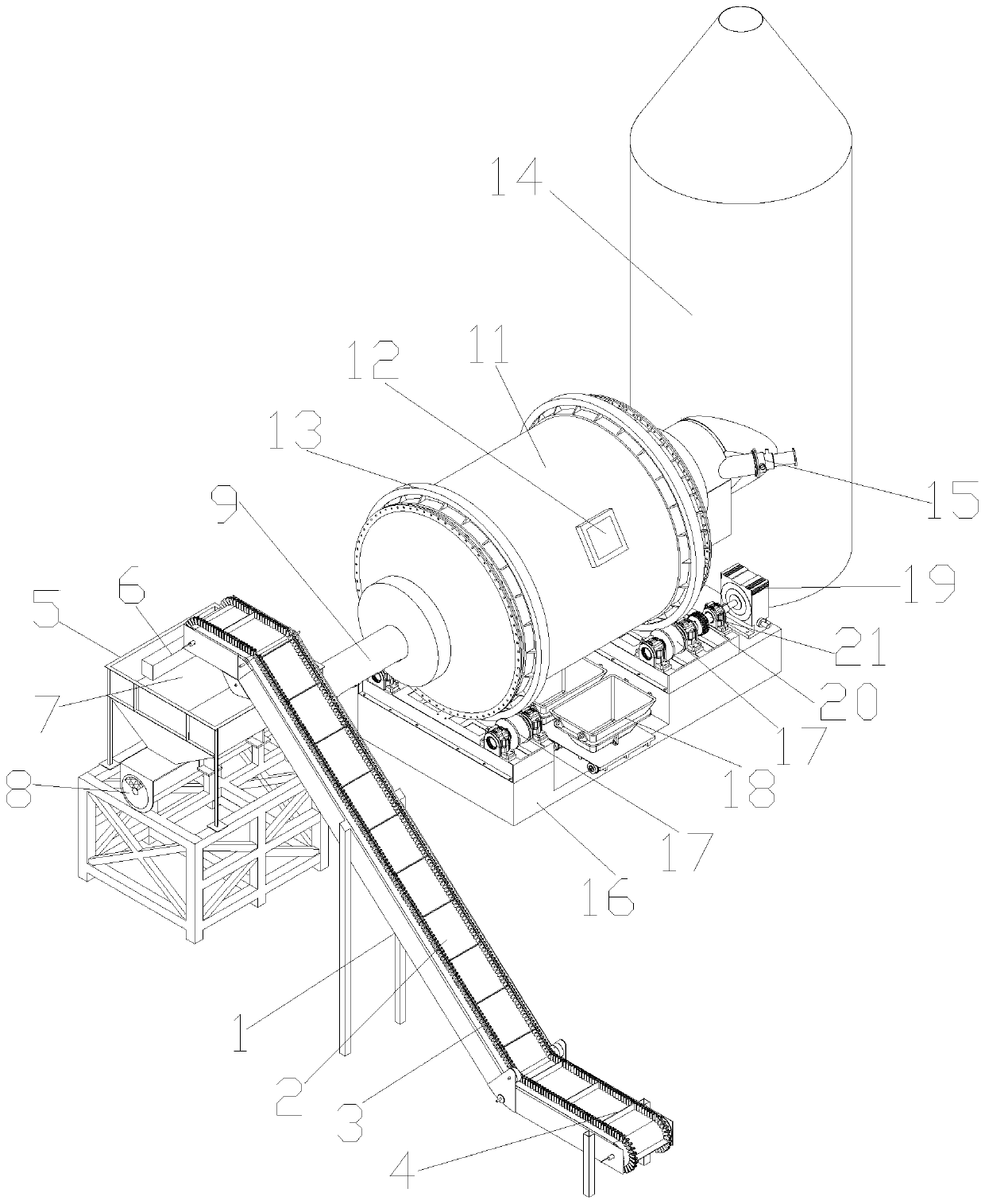

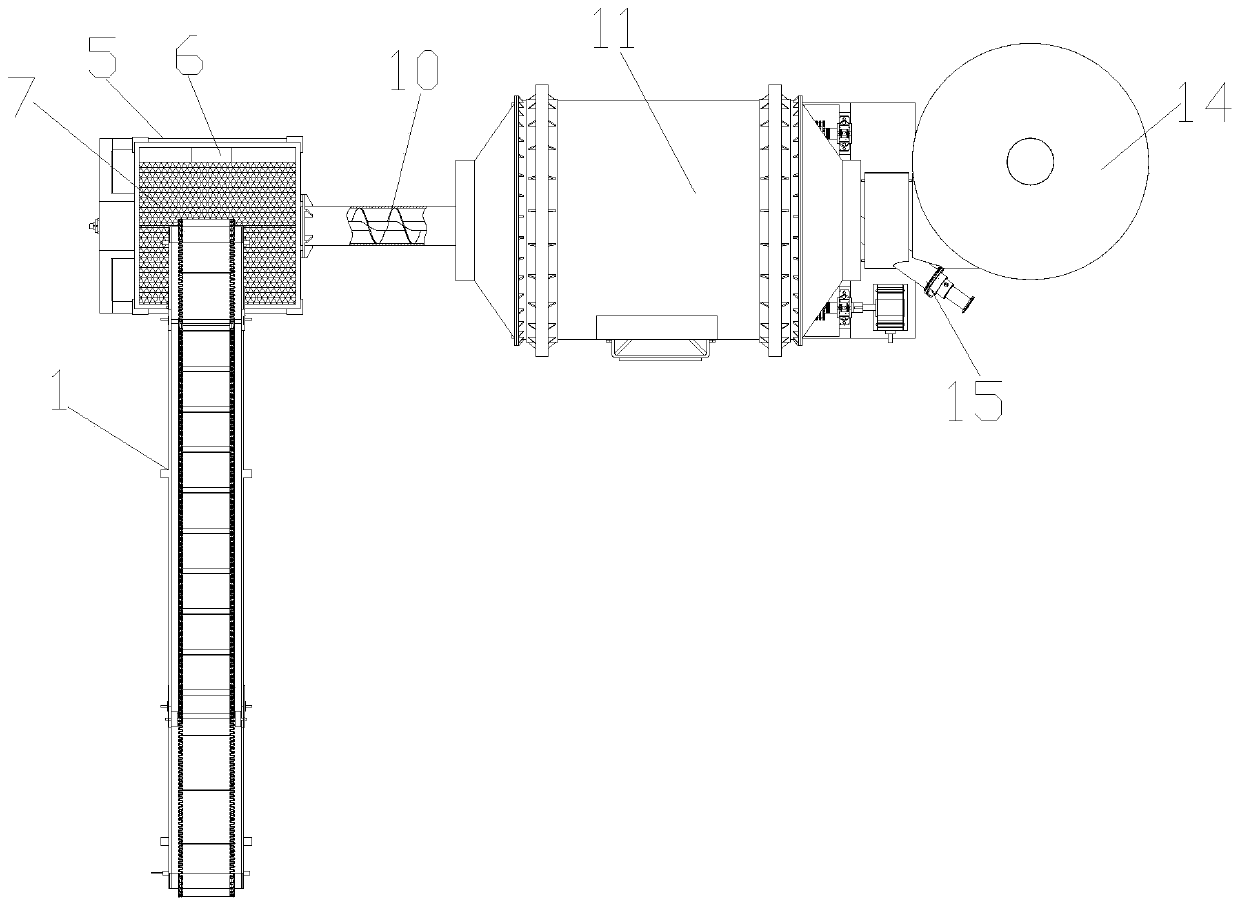

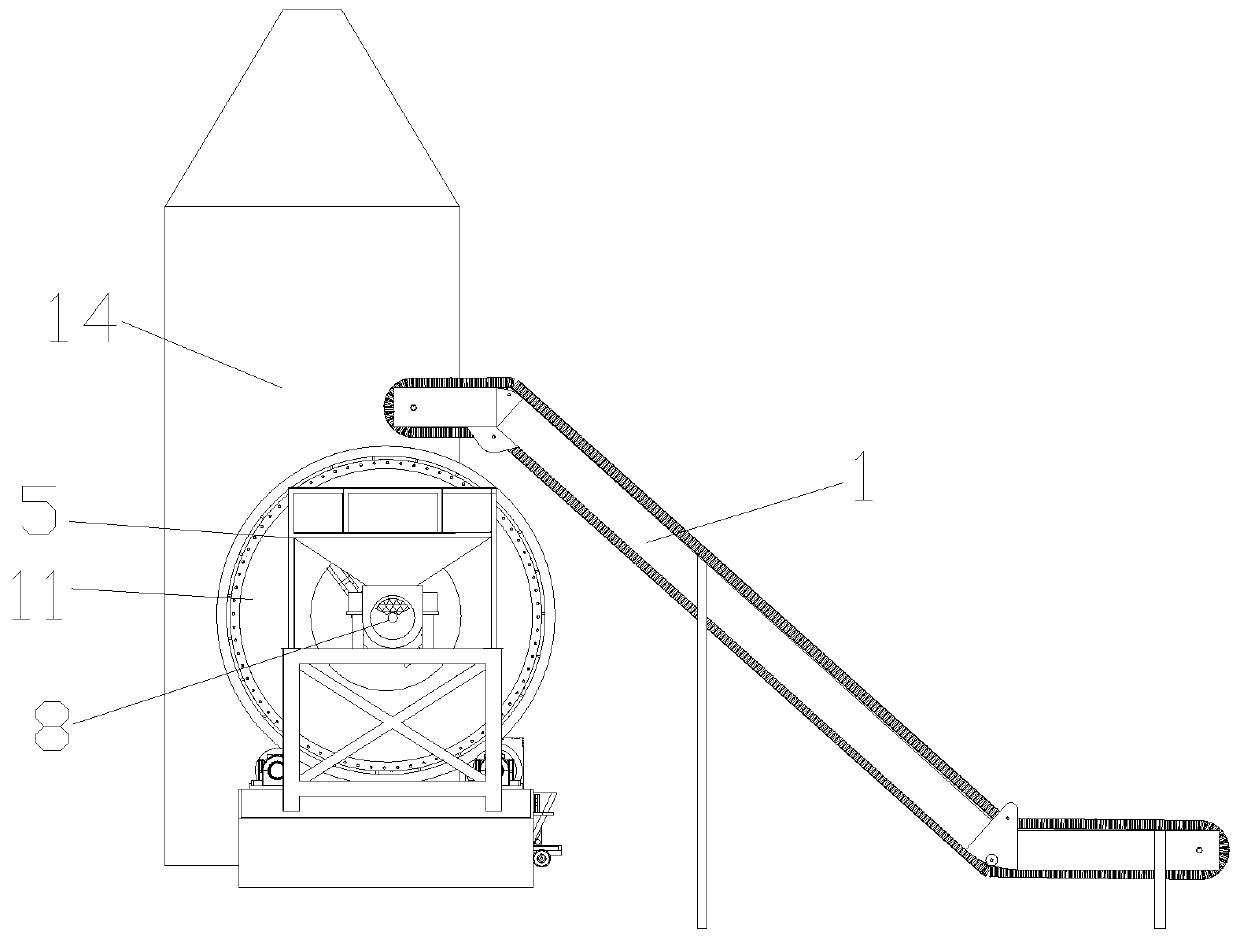

Smelting furnace feeding stirring conveyor for casting

InactiveCN111121458AQuality assuranceEasy to addCharge manipulationCharge treatment typeLiquid metalMechanical engineering

The invention discloses a smelting furnace feeding stirring conveyor for casting. The conveyor involves a smelting furnace, a stirring mechanism and a feeding mechanism; the feeding mechanism comprises a first supporting frame, a conveying belt is arranged on the first supporting frame, and a conveying mechanism is arranged below the top end of the conveying belt; the conveying mechanism comprisesa receiving chamber, the bottom of the receiving chamber communicates with a conveying pipe, and a pushing mechanism is arranged in the conveying pipe; the stirring mechanism comprises a stirring tank, the conveying pipe communicates with the stirring tank, supporting rollers are arranged below the two ends of the stirring tank, and one of the supporting rollers is provided with a driving gear ring through a connecting shaft; and a discharging port in the stirring tank communicates with a feeding port in the smelting furnace. According to the conveyor, raw materials needing to be added are conveyed into the conveying mechanism at the upper end, so that adding is convenient, and feeding is easy and convenient; and the raw materials which are evenly stirred can be rapidly conveyed into thesmelting furnace to be smelted, so that the quality of smelted liquid metal is guaranteed.

Owner:安徽依格尔精密铸造有限公司

Sludge stirring device

InactiveCN113058454AStir wellStir evenly and thoroughlyRotary stirring mixersTransportation and packagingThermodynamicsSludge

The invention provides a sludge stirring device, which comprises a stirring pool and a working module, wherein the stirring pool comprises a barrel bottom and a barrel wall surrounding the barrel bottom; the working module comprises a mounting base arranged at the center of the barrel bottom, the mounting base is connected with a plurality of stirring units, and the plurality of stirring units are vertically arranged and detachably connected; a plurality of stirring units are used for comprehensively stirring the interior of the stirring tank, so that the sludge is more uniformly and thoroughly stirred; the stirring units are detachably connected, the stirring blades are detachably connected with the rotating shaft, and when elements are damaged or the density of the stirring blades is adjusted, replacement is more convenient; and the stirring directions of the stirring blades can be staggered, so that the sludge can be uniformly stirred more easily.

Owner:新沂市新南环保产业技术研究院有限公司

Food stir-baking device

The invention discloses a food stir-baking device which comprises a pot body, a pot cover, an electric control cabinet, a feeding hole, an agitator, a main motor, an electromagnetic heating coil, an operation panel and a host, wherein the main motor, the electromagnetic heating coil and the operation panel are connected with the host respectively; the operation panel is arranged at the upper part of the front surface of the electric control cabinet; the transversely arranged front end of the pot body is hinged with the pot cover; the electric control cabinet is arranged at the back end of the pot body; the feeding hole is arranged in the pot cover; the agitator is arranged in the center of a pot body inside the pot body and runs through the center to be connected with the main motor arranged inside the electric control cabinet; the main motor drives the agitator to rotate; the electromagnetic heating coil is arranged at the periphery of the pot body; after being electrified, the electromagnetic heating coil heats the pot body. The food stir-baking device has the beneficial effects of compact, convenient and flexile structure, having of import significance, automation, quick temperature rise, uniform temperature, uniform and thorough agitation, no adhesion to the pot body, replacement of manual stir-baking and uniform standardization of a taste.

Owner:PENGLAI HUIYANG FOOD

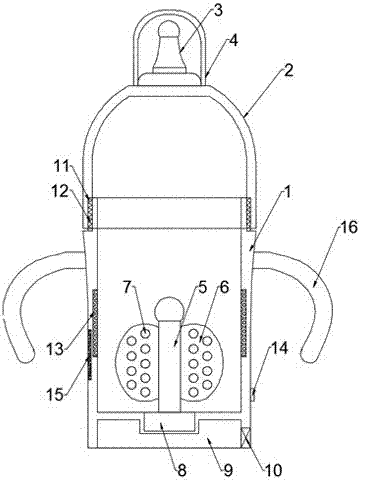

Novel feeding bottle for baby

InactiveCN107510611AJudgment temperatureEasy to operateFeeding-bottlesDomestic articlesBiochemical engineeringCircular surface

The invention discloses a novel feeding bottle for a baby. The feeding bottle comprises a bottle body and a bottle cap, wherein an inner screw thread is arranged on the inner circular surface of the opening end of the bottle cap; a nipple is arranged at the top end of the bottle cap; a protective cover is arranged outside the nipple; an outer screw thread, which is matched with the inner screw thread, is arranged on the outer circular surface of the opening end of the bottle body; a stirring shaft is arranged on the bottom wall of an inner cavity of the bottle body; a plurality of stirring blades are arranged on the side face of the stirring shaft; a motor and a storage battery are arranged in the bottom of the bottle body; the storage battery is arranged at the lower end of the motor; the stirring shaft is fixedly connected to the motor by virtue of a motor shaft; an electric heating sheet is embedded in the sidewall of the interior of the bottle body; the electric heating sheet and the motor are electrically connected to the storage battery; a thermometer is arranged on the outer circular sidewall of the bottle body; a temperature measuring probe of the thermometer is in communicating connection to the inner cavity of the bottle body; a power interface and a switch button are arranged on the sidewall of the bottom of the bottle body; and the switch button is arranged at the upper side of the power interface. The feeding bottle provided by the invention is simple to operate, uniform and thorough in stirring and rapid in stirring; secondary heating processing can be conducted; and temperature in the bottle body can be intuitively judged, so that the baby can drink milk at an expropriate temperature.

Owner:张强

Reaction kettle for producing liquid barium-zinc heat stabilizer

PendingCN107213860AIncrease productivityImprove feeding efficiencyChemical/physical/physico-chemical stationary reactorsEnergy based chemical/physical/physico-chemical processesElectrical resistance and conductanceHeat resistance

The invention discloses a reaction kettle for producing liquid barium-zinc heat stabilizer, which comprises a shell, an agitator, and a heater, the agitator comprises an agitating shaft and blades, the blades are fixed on the agitating shaft, the agitating shaft extends into the shell, a feed inlet and a discharge outlet are arranged on the shell, the heater is embedded in the blades, the heater comprises heating resistance wires and wires, the heating resistance wires are coiled in the blades, the wires are connected to a power supply, the agitating shaft is provided with vertical slide ways, the blades are fastened in the vertical slide ways by means of sliding shafts, pneumatic cylinders are mounted on the agitating shaft, and the other ends of the pneumatic cylinders are connected to the sliding shafts of the blades. When the reaction kettle for producing liquid barium-zinc heat stabilizer disclosed by the invention is utilized to prepare liquid barium-zinc heat stabilizer, the agitator can move up and down, consequently, substances can be promoted to be uniformly heated, reaction is thorough, the heat preservation time is shortened, and the production efficiency is increased.

Owner:德清县东来化学有限公司

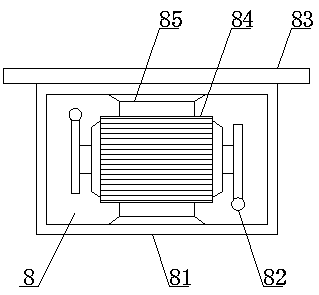

High-efficiency pet food stirring device

The invention discloses a high-efficiency pet food stirring device and relates to the technical field of feed stirring. The high-efficiency pet food stirring device comprises a supporting plate, wherein supporting legs are symmetrically mounted at the bottom of the supporting plate; a support plate is arranged between the supporting legs; two sides of the support are fixedly connected with the opposite side of the supporting legs; a stirring box is mounted at the top of the support plate; the top of the stirring box penetrates through the supporting plate and extends to the upper side of the supporting plate; a controller and a feeding box are sequentially arranged at the top of the supporting plate and positioned at the left side of the stirring box from the left to right. According to the high-efficiency pet food stirring device, due to the adoption of the second motor, a second rotating shaft connected onto the second motor, and crushing blades connected onto the second rotating shaft, the foods can be crushed, and the device has a crushing function. Therefore, the foods can be uniformly and completely stirred, the working efficiency is improved, livestock is conveniently fed, and the production income is increased.

Owner:无锡市友盟投资管理有限公司

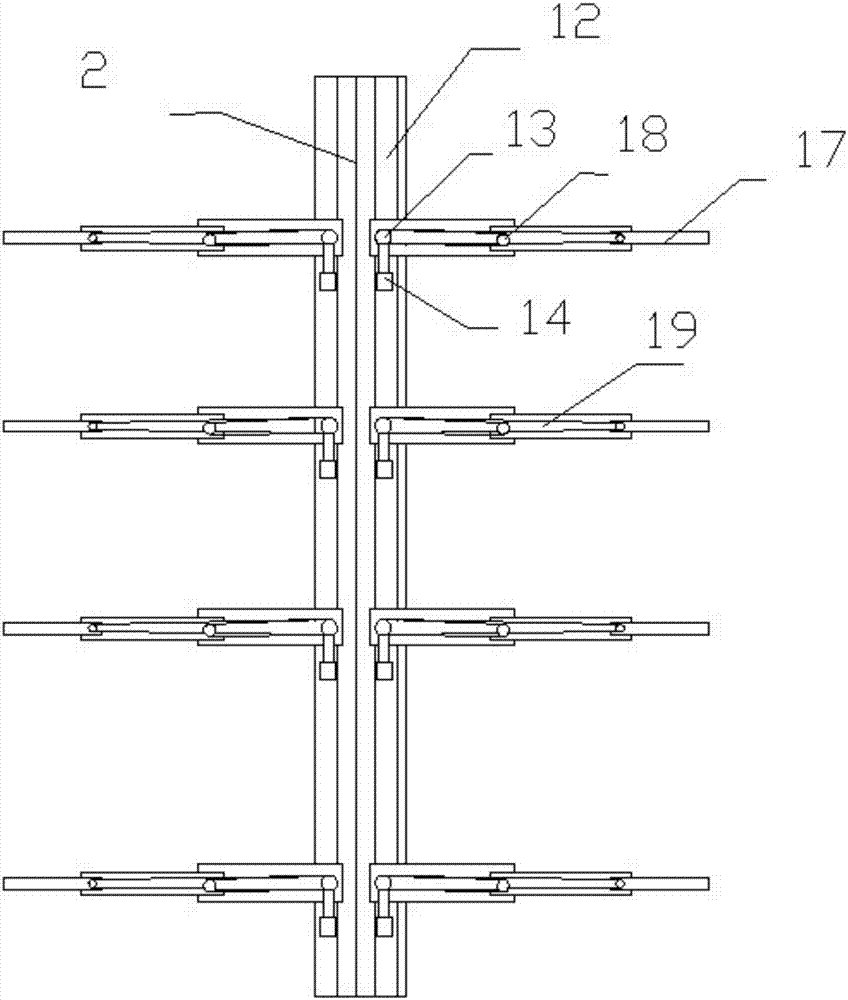

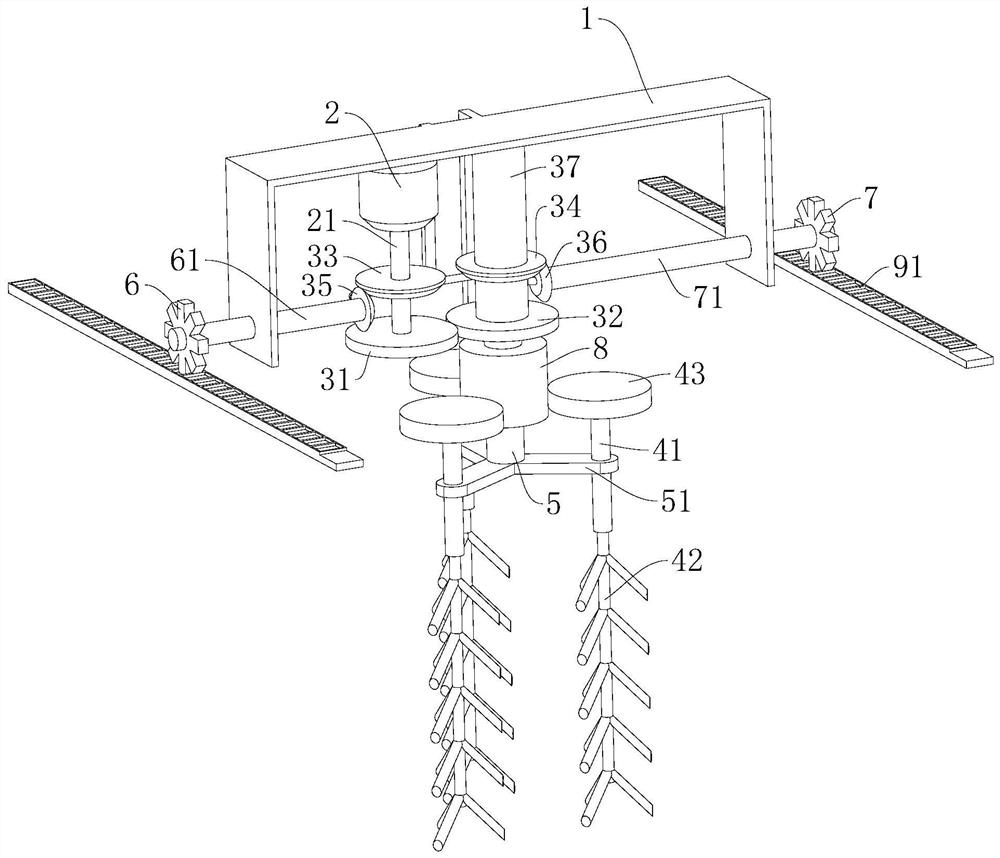

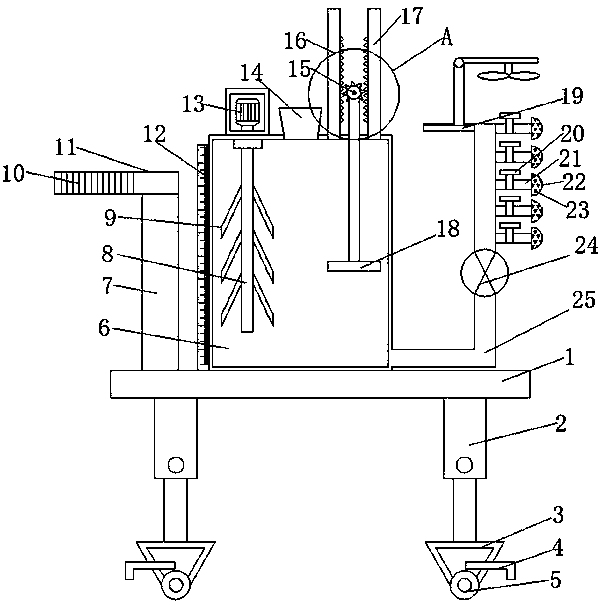

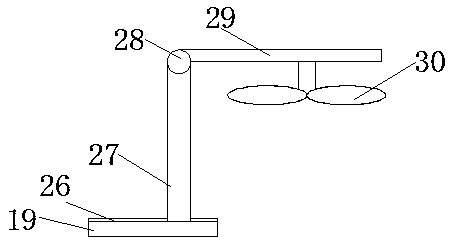

Spraying vehicle for agricultural pesticide spraying

InactiveCN108575964AEasy to useEasy to moveRotary stirring mixersTransportation and packagingReciprocating motionAgricultural engineering

The invention provides a spraying vehicle for agricultural pesticide spraying, and relates to the field of agricultural equipment. The spraying vehicle comprises a vehicle body, wherein a strut is fixedly mounted on the top of the vehicle body, a push handle is fixedly mounted at one end of the strut, and anti-skid stripes are arranged inside the push handle; a stirring chamber is fixedly formed in the top of the vehicle body, a graduated scale is fixedly mounted on the left side of the stirring chamber, and a feed hopper is fixedly mounted on the top of the stirring chamber. According to thespraying vehicle for agricultural pesticide spraying, an electric telescopic rod is arranged, and height of the spraying vehicle can be adjusted according to height of plants, so that a pesticide is sprayed uniformly and thoroughly; spray holes are formed, accordingly, the pesticide can be sprayed uniformly, and too many or too few pesticides can be avoided; moving is convenient by rollers, and the spraying vehicle is more convenient during use; a push-pull rod can be driven by a second motor to reciprocate vertically in the stirring chamber to perform stirring, liquid pesticide can be more fully stirred, material deposition is prevented, and the liquid pesticide is stirred more uniformly.

Owner:周琼

Stirrer having vibration function and used for building

InactiveCN108501219AStir evenly and thoroughlyImprove performanceCement mixing apparatusArchitectural engineeringChassis

The invention discloses a stirrer having a vibration function and used for a building. The stirrer comprises a support mounted below a chassis frame, wherein a stirring barrel is arranged above the chassis frame, a material port is formed in the right end of the stirring barrel, a rotating frame is arranged on the periphery of the right end of the stirring barrel, and a vibrator is mounted on thestirrer for the building. When the stirrer for the building is used for stirring concrete, a switch of the vibrator can be turned on, then, the vibrator can drive the whole stirrer for the building tovibrate, and accordingly, when the concrete is stirred, the vibrator can vibrate the concrete in the stirring barrel, so that stirring is more thorough and uniform; when the stirrer for the buildingis used, concrete stacked on the inner wall of the stirring barrel can be vibrated off because of vibration of the vibrator, so that the stirrer for the building is cleaned more thoroughly after use,and the use performance of the stirrer for the building is improved.

Owner:芜湖市涵润智能科技有限公司

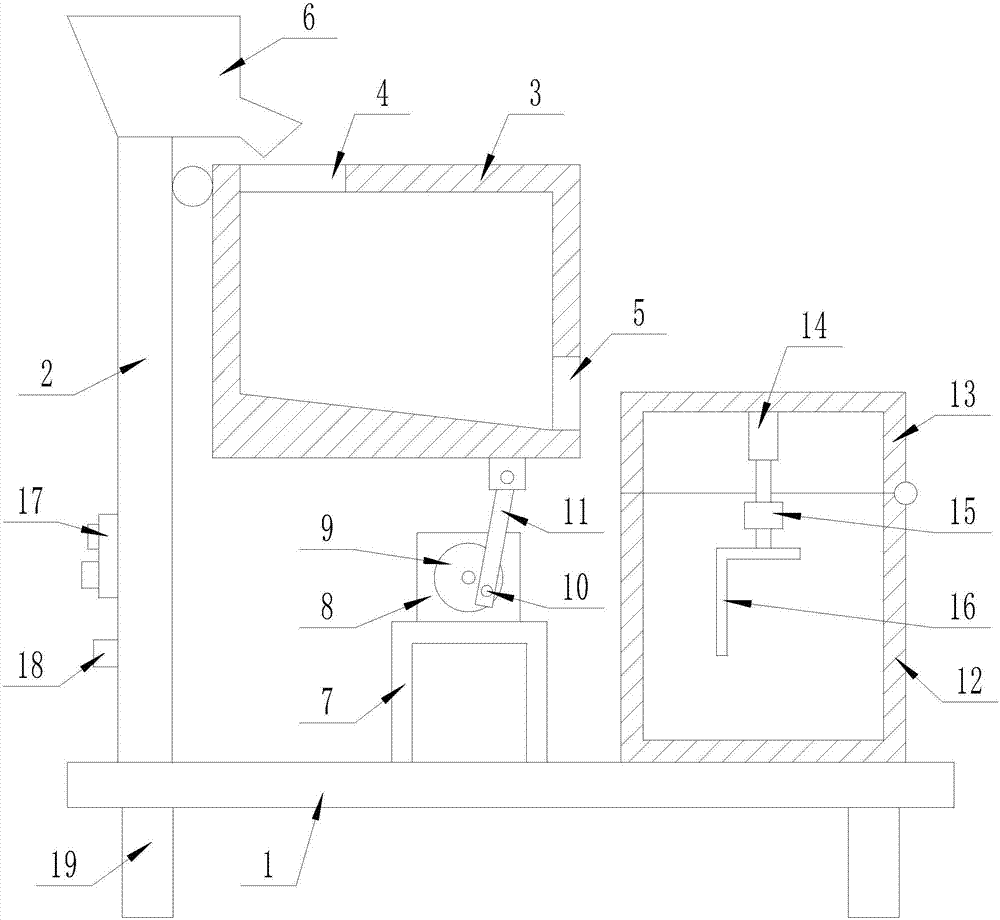

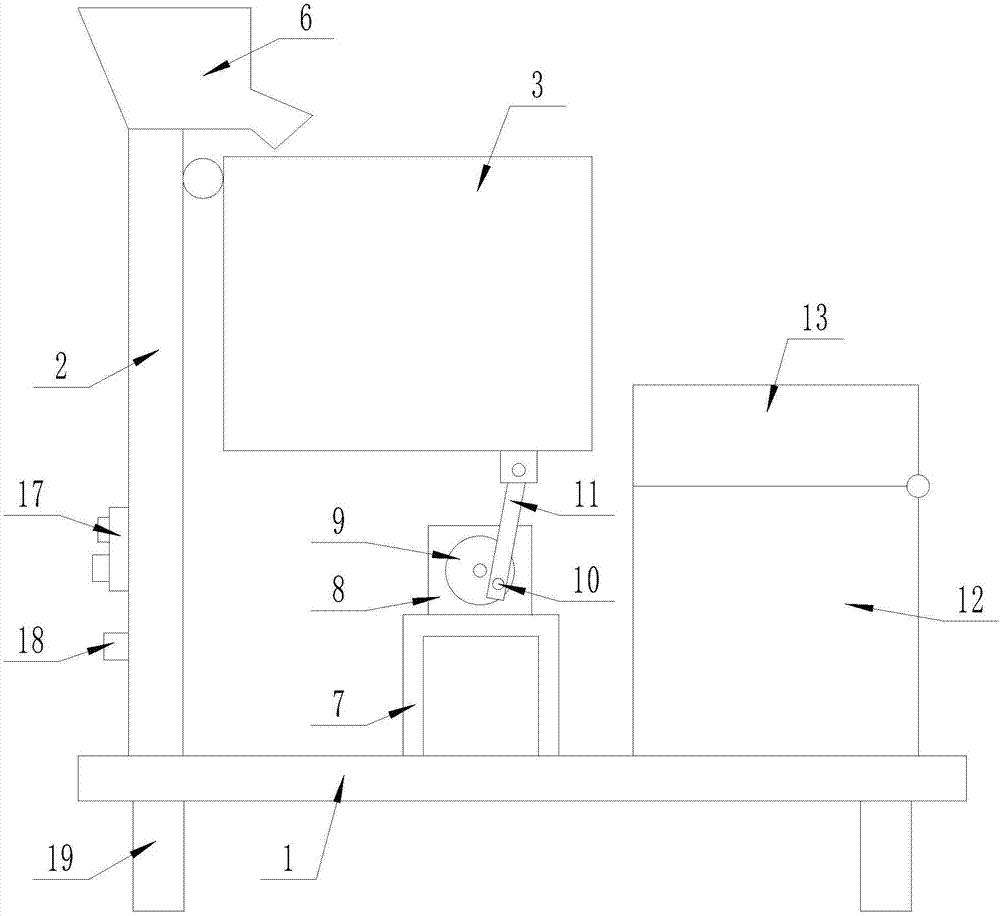

Flower cultivating soil stirring device

InactiveCN107308853AStir evenly and thoroughlyTransportation and packagingRotary stirring mixersCircular discLap joint

The invention discloses a flower cultivating soil stirring device. The device comprises a rectangular pedestal, a door-shaped supporting rack is arranged at the left side of the upper surface of the rectangular pedestal, a rectangular jittering box body is hinged to the surface of the right side of the door-shaped supporting rack, the left side of the upper surface of the rectangular jittering box body is provided with a material inlet, the lower end of the side surface of the rectangular jittering box body is provided with a discharging opening, the upper surface of the door-shaped supporting rack is provided with a feeding hopper lap-jointed to the material inlet, a motor fixing rack is arranged on the upper surface of the rectangular pedestal and positioned below the rectangular jittering box body, the upper surface of the motor fixing rack is provided with a first rotating motor with the rotating end being horizontal, the rotating end of the first rotating motor is provided with a rotating disc, and the edge of the front surface of the rotating disc is provided with a rotating circular rod. The device preliminarily jitters flower cultivating soil in the flower cultivating soil stirring process to break large soil blocks, and stirs and mixes the broken soil to form flower cultivating soil, so the flower cultivating soil is uniformly and thoroughly stirred.

Owner:闫淑军

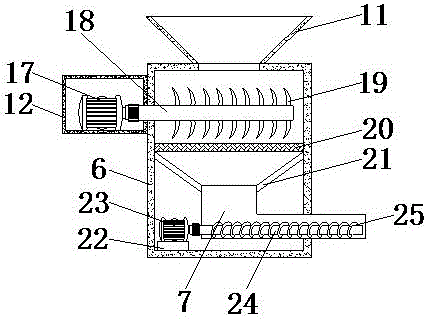

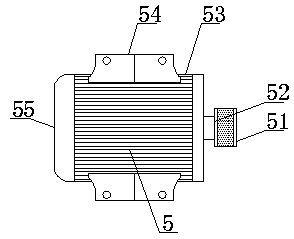

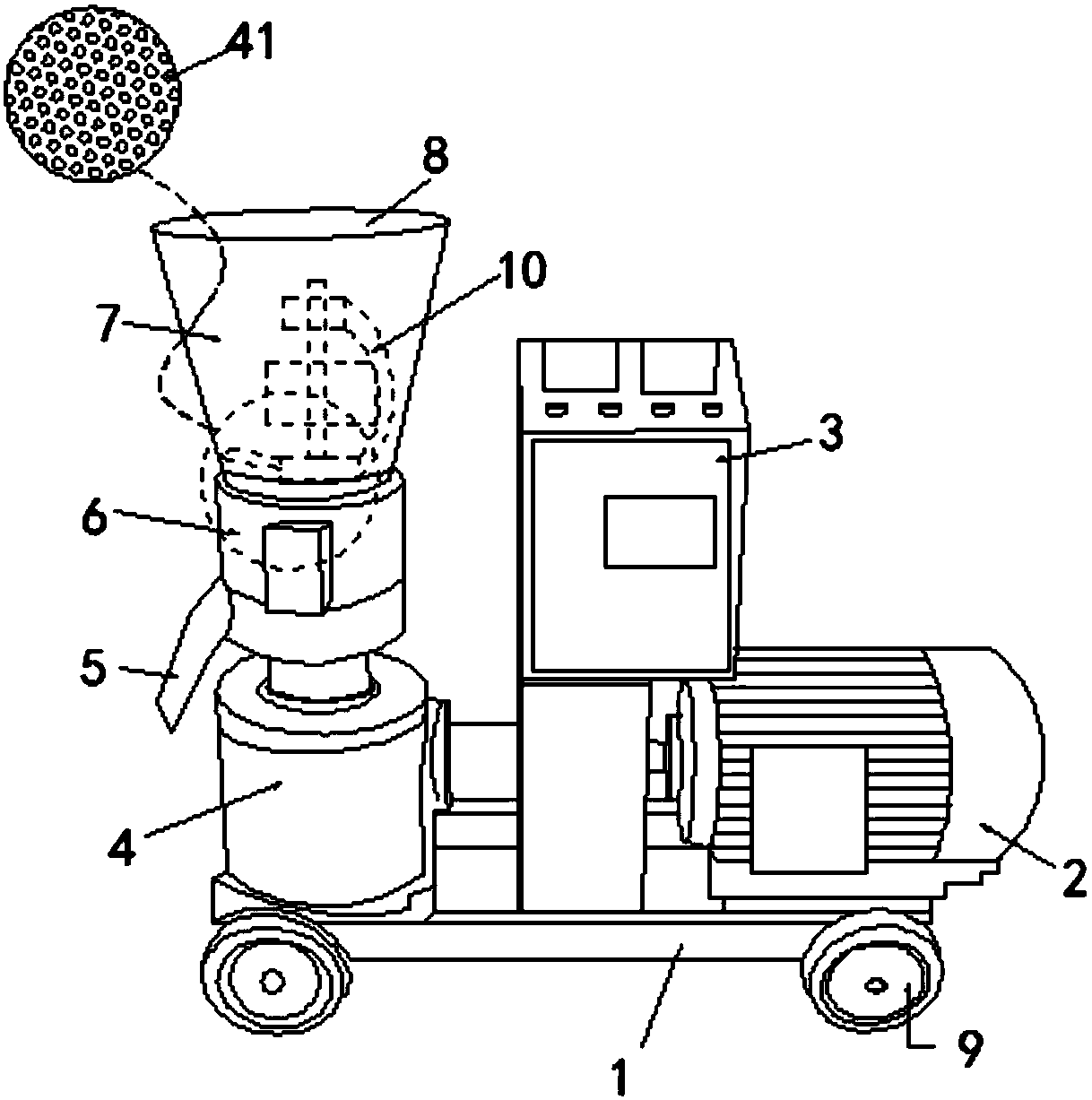

High-efficiency poultry feed stirring granulator

PendingCN108097166AStir evenly and thoroughlyImprove stirring efficiencyFeeding-stuffGranulation in stationary drums/troughsEngineering

The invention discloses a high-efficiency poultry feed stirring granulator. The granulator comprises a base, a motor 1, an operating machine, a decompression gear box, a discharging port, a feed machine stirring tank, a discharging hopper, a feeding inlet and a plurality of wheels. The bottom of the base is provided with a plurality of the wheels. The top of the base is orderly provided with the decompression gear box, the operating machine and the motor 1 from left to right. The top of the decompression gear box is provided with the feed machine stirring tank. The lower part of one side, faraway from the operating machine, of the feed machine stirring tank is provided with the discharging port. The top of the feed machine stirring tank is provided with the discharging hopper. The top ofthe discharging hopper is provided with the feeding inlet. A stirring device is arranged in the discharging hopper. A fixing column 1 is arranged in the stirring device and is located at the top in the feed machine stirring tank. The high-efficiency poultry feed stirring granulator improves the stirring efficiency of the poultry feed granulator and improves the yield and quality of the feed.

Owner:潘钰

A reaction device for printing and dyeing chemical industry

ActiveCN103894133BEasy to passDeliver faster and more evenlyMixer accessoriesChemical/physical/physico-chemical stationary reactorsChemical industryChemical reaction

The invention relates to a reaction device for a printing and dyeing chemical industry. The reaction device comprises a tank body, a tank cover, a gas heating device, and a plurality of escape pipes inserted into the tank body from the bottom, wherein the escape pipes are connected with the exhaust end of the gas heating device; an exhaust plate is arranged at the end part of each escape pipe, inserted into the tank body; an electric heating tube fixed inside the tank body is arranged below an agitator blade above the exhaust plate. On one hand, the escape pipes are communicated to the bottom of the tank body of the reaction device, the heated inert gases are conveyed to the inside of the tank body by using the escape pipes, and hot gases are dispersed through a diffuser plate, so that the heat can be quickly transferred to the material inside the tank body to heat the material; on the other hand, the electric heating tube arranged inside the tank body can directly heat the material, and the material generates convection due to the characteristic that the gases input by the escape pipes quickly move upwards, so that the heat of the electric heating tube is more quickly and more uniformly transferred to the material.

Owner:SUZHOU RUNHONG TRADING

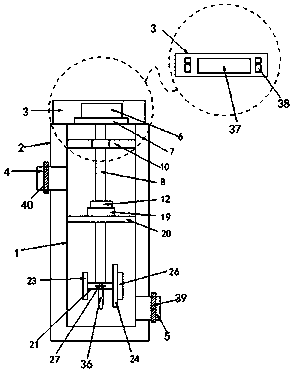

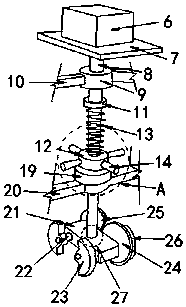

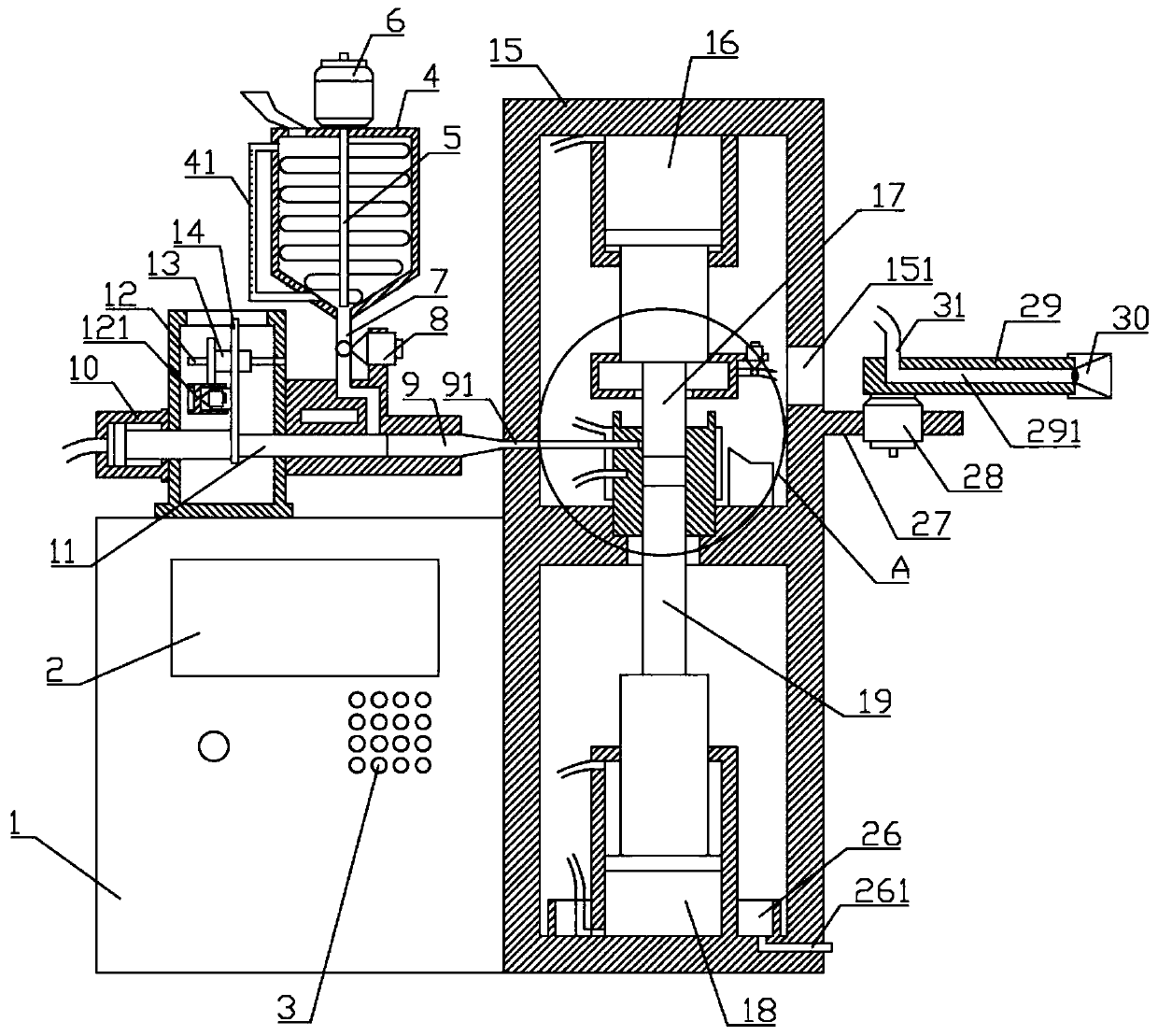

Cold-pressing sintering method and cold-pressing sintering apparatus for Bi2O3 ceramic

The invention relates to the technical field of low-temperature sintered ceramics, and especially relates to a cold-pressing sintering method and a cold-pressing sintering apparatus for a Bi2O3 ceramic. The apparatus comprises a control box, a feeding device and a sintering device which are fixedly connected together, the sintering device comprises a shell, an upper forming hydraulic machine is fixedly mounted on the upper end surface of the shell, the main shaft of the upper forming hydraulic machine is fixedly provided with an upper mold core, a lower forming hydraulic machine is fixedly mounted at a position, corresponding to the upper forming hydraulic machine, of the lower end surface of the shell, the main shaft of the lower forming hydraulic machine is fixedly provided with a lowermold core, the sidewall of the shell is provided with a mounting table, a mold is detachably mounted on the mounting table, and the outer wall of the mold is provided with a heating mechanism. The cold-pressing sintering method and the cold-pressing sintering apparatus for a Bi2O3 ceramic can realize the high-density Bi2O3 ceramic, and the processed Bi2O3 ceramic has the advantages of high yield,clean surface and realization of industrial batch streamline production.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Stirrer and self-cleaning intelligent environment-friendly concrete stirring device

PendingCN112917685AStir evenly and thoroughlyStir thoroughlyHollow article cleaningCement mixing apparatusElectric machineGear wheel

The invention discloses a stirrer and a self-cleaning intelligent environment-friendly concrete stirring device. The stirrer comprises a stirrer body, a double-shaft motor is fixedly mounted on the stirrer body, a rotating roller is rotationally mounted on an upper driving shaft of the double-shaft motor through a rotating shaft, and a plurality of stirring rods are fixedly mounted on the rotating roller. Two transmission gears are mounted between the rotating shaft and the stirrer body through two transmission mechanisms, two scraping plates are mounted on the stirrer body through two sliding mechanisms, and two fixing plates are fixedly mounted on the stirrer body. The stirrer and the self-cleaning intelligent environment-friendly concrete stirring device have the advantages that concrete can be uniformly and thoroughly stirred by adopting a mode of matching transverse scraping type stirring and longitudinal overturning type stirring, concrete attached to the inner wall of the stirrer can be automatically scraped during stirring, automatic flushing and cleaning can be performed after stirring is completed, waste is avoided, environment protection is achieved, and the automation degree is high.

Owner:FUJIAN XINDA MACHINERY

Building construction concrete mixer

InactiveCN110271100AEasy to operateEasy to moveDischarging apparatusCement mixing apparatusArchitectural engineeringBuilding construction

A building construction concrete mixer comprises a first supporting plate. Six fixed plates arranged in a rectangular shape are arranged below the first supporting plate, and every two adjacent fixed plates are symmetric about the center line of the first supporting plate. A universal wheel is arranged on the lower portion of each fixed plate. A first fixed rod, two parallel third fixed rods and four second fixed rods arranged in a rectangular shape are sequentially arranged on the upper surface of the supporting plate from left to right. A rotating disc is arranged on the side, away from the first supporting plate, of the first fixed rod, and the first fixed rod is rotationally connected with the rotating disc through a first rotating shaft. A fixed block is arranged between the two third fixed rods. The upper surface of the fixed block is fixedly connected with a second rotating motor. The second rotating motor is rotationally connected with the first rotating shaft on the rotating disc through a belt. The building construction concrete mixer is convenient to operate and move, discharging is rapid, diversified mixing manners are achieved, and mixing is uniform and thorough.

Owner:湖北乾奥建设工程有限公司

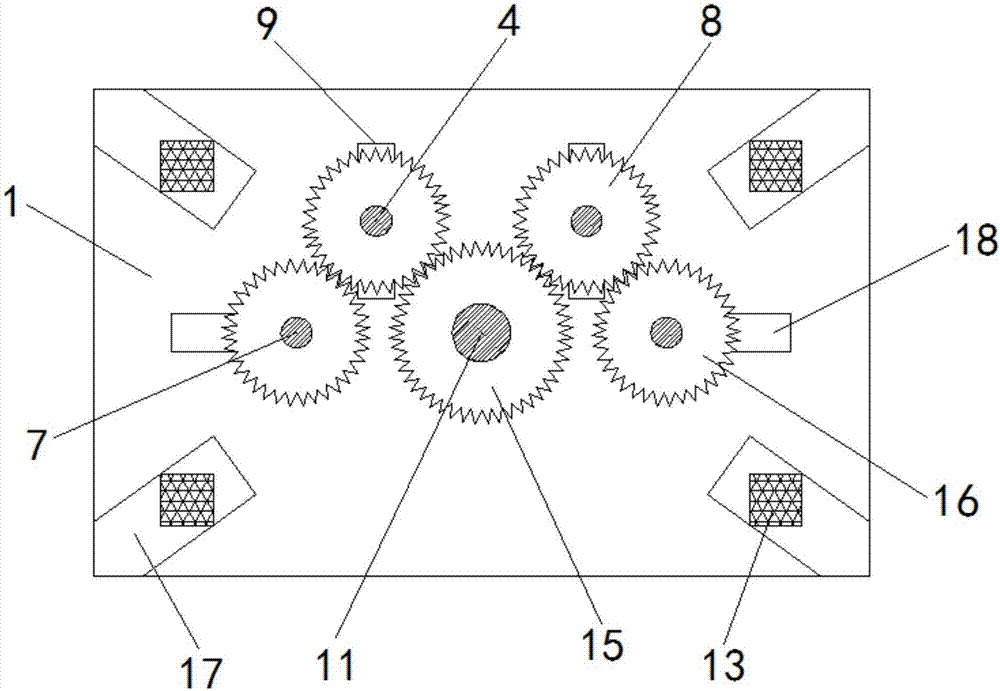

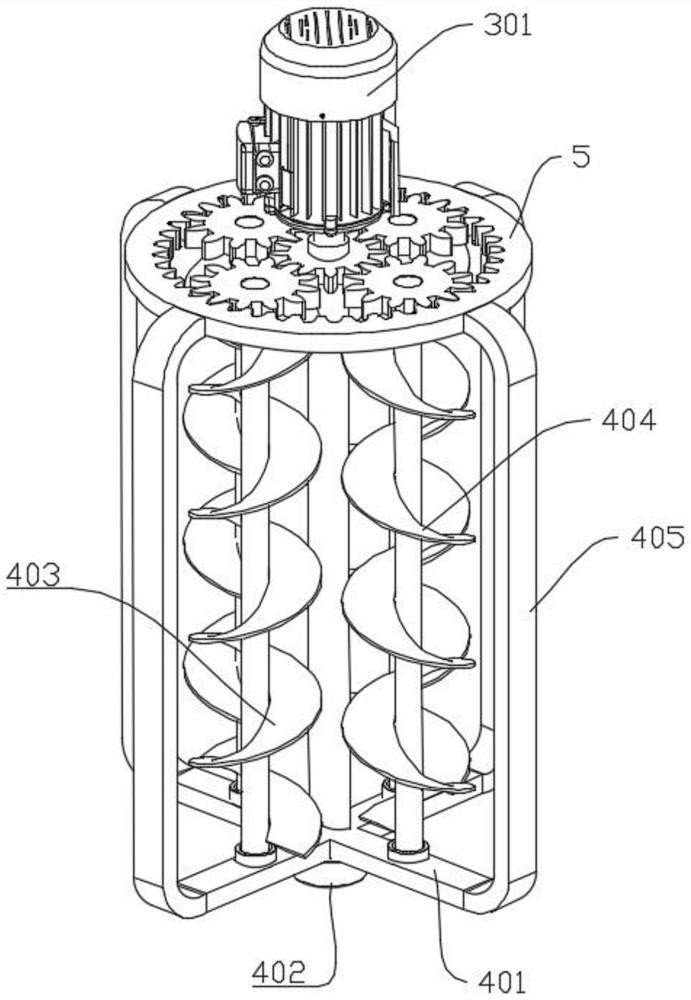

Migration-resistant environment-friendly plasticizer production device

PendingCN114177874ASolve the stratification of raw materialsStir evenly and thoroughlyRotary stirring mixersTransportation and packagingProcess engineeringPlasticizer

The invention belongs to the technical field of plasticizer production equipment, and particularly relates to a migration-resistant environment-friendly plasticizer production device which comprises a reaction kettle, a stirring part and a gear part, supporting legs are fixedly connected to the four corners of the bottom of the reaction kettle, and a fixing seat is fixedly connected to the top of the reaction kettle. By arranging the reaction kettle, the supporting legs, the servo motor, the stirring piece and the gear piece, four stirring blades are driven by the servo motor and the gear piece to rotate in the reaction kettle, the four stirring blades are identical in pairs and are symmetrically arranged, one pair of stirring blades rotates forwards, the other pair of stirring blades rotates backwards, and the stirring blades are driven by the servo motor to rotate in the reaction kettle; the problem of raw material layering is solved, stirring is uniform and thorough, the inner wall scraper frame can scrape off raw materials adhered to the inner wall of the reaction kettle, uneven mixing caused by the fact that the raw materials are adsorbed to the inner wall is avoided, and the reaction kettle is reasonable in overall design structure and suitable for reaction stirring during plasticizer production.

Owner:ZHEJIANG GREAT CHEM SCI & TECH

Efficient stirring device for pesticide production

InactiveCN107790028AStir wellEasy to addTransportation and packagingRotary stirring mixersPulp and paper industryRaw material

The invention discloses an efficient stirring device for pesticide production. The efficient stirring device comprises a device body of a cavity structure and is characterized in that support legs aremounted on two sides of the bottom of the device body, a feeding hopper is mounted on one side of the top of the device body, a vertical guide pipe is connected to the bottom of the feeding hopper, one end of the guide pipe extends into the device body, the bottom-end inner wall of the guide pipe is provided with a sealing plug, a screw is connected to the bottom of the sealing plug, a first gearsleeves the screw, a limit plate vertical to the screw is connected to one side of the bottom of the screw, a limit rod is mounted on the top inner wall, close to one side of the of the feeding hopper, of the device body and slidably connected with the limit plate, a support is mounted on the top inner wall of the device body, and a double-shaft motor is mounted on the support. The efficient stirring device has the advantages that the device is reasonable in design, pesticide stirring can be performed conveniently while pesticide raw materials are added during pesticide production, even and thorough pesticide stirring can be achieved, and pesticide production efficiency can be increased effectively.

Owner:阳新五林农业服务有限公司

Stirring device and smelting furnace with stirring device

InactiveCN111678352AStir evenly and thoroughlyImprove mixing uniformityStirring devicesCharge composition/stateElectric machineDrive shaft

The invention discloses a stirring device and a smelting furnace with the stirring device. The stirring device comprises a walking support, a driving motor, a transmission structure and a stirring mechanism. The driving motor is arranged on the walking support, the walking support can drive the driving motor and the stirring mechanism to horizontally move under the driving action of the driving motor, the stirring mechanism comprises a driving shaft and a stirring paddle, an output shaft of the driving motor is connected with the driving shaft through the transmission structure, the driving shaft extends horizontally and is perpendicular to the moving direction of the walking support, and the driving shaft rotates to drive the stirring paddle to rotate around the driving shaft. The drivingmotor is arranged to control two walking wheels to rotate on a guide rail, so that the walking support is driven to walk in the melting furnace, the interior of the smelting furnace can be completelystirred, and stirring is more uniform and thorough.

Owner:临沂欧邦机电设备有限公司

Novel plastic construction stirring machine

PendingCN107653765AReasonable designStir evenly and thoroughlyRoads maintainencePhysicsElectric machinery

The invention relates to the technical field of plastic raw material stirring construction, in particular to a plastic field construction stirring machine which comprises a material cylinder and a rack, wherein a sliding track is arranged on the rack; a stirring motor is mounted on the sliding track through a motor base; the output shaft of the stirring motor is connected with a stirring shaft; astirring roller is mounted at the bottom end of the stirring shaft; a fixing sleeve is arranged in the middle of the stirring shaft; a plurality of stirring claws of different lengths are arranged onthe fixing sleeve; stirring blades are arranged at end parts of the stirring claws; a universal brake wheel is mounted at the bottom of the material cylinder; a telescopic handle is mounted on the side surface of the material cylinder. The novel plastic construction stirring machine is reasonable in design, materials at different depths in different directions can be uniformly mixed, and stirringcan be implemented uniformly and thoroughly; the material cylinder can be moved, the materials can be rapidly transferred, the conveying problem after stirring is solved, and the materials can be conveniently transferred.

Owner:济南锐硕机电科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com