Preparation method and preparation device for high-purity gallium oxide

A preparation device and gallium oxide technology, applied in chemical instruments and methods, inorganic chemistry, gallium/indium/thallium compounds, etc., can solve the problems of long process flow, complex process, unfavorable preparation of gallium oxide, etc., to improve reaction efficiency, Agitate for full effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

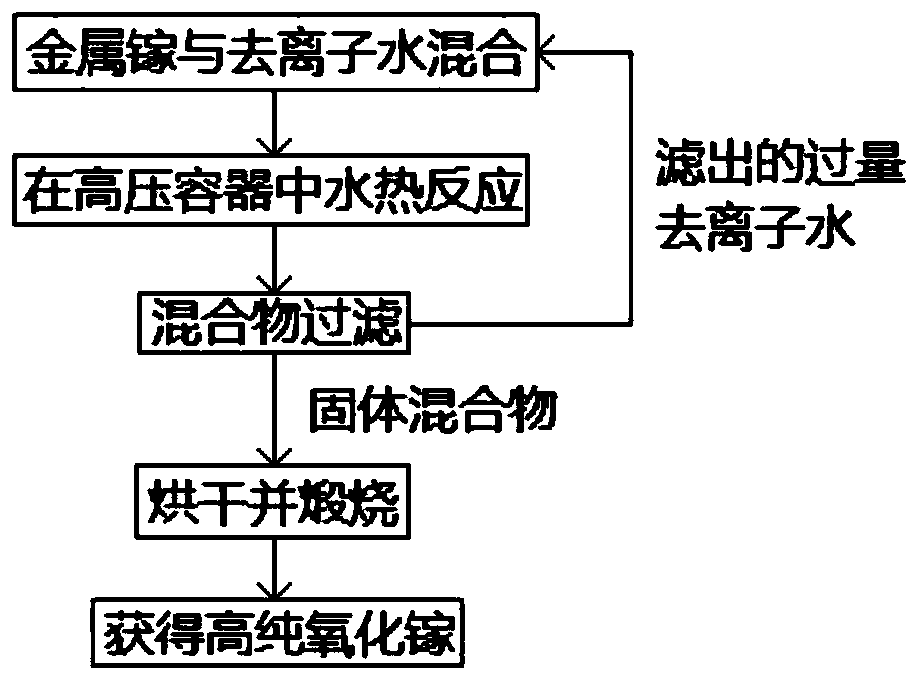

[0030] Please refer to figure 1 , the present embodiment provides a preparation method of high-purity gallium oxide, comprising the following steps:

[0031] Take metal gallium of 4N purity and mix it with deionized water, the mass ratio of gallium to water is 1:2-1:8;

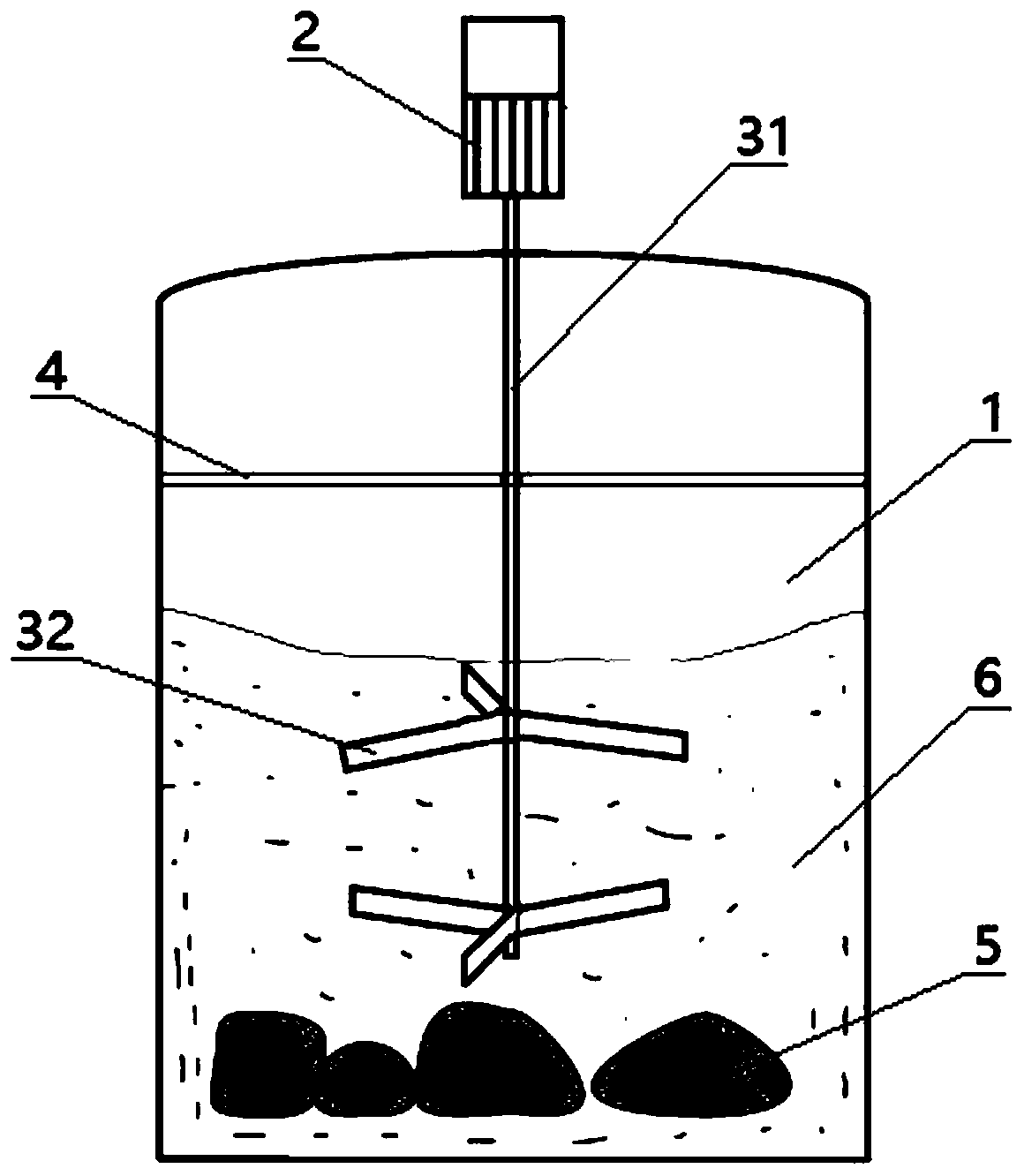

[0032] Put the mixture of gallium and water into a high-pressure reaction vessel, keep stirring at a temperature of 150-250°C, and perform a hydrothermal reaction for 1-1.5 hours to generate a mixture of gallium oxyhydroxide and gallium oxide;

[0033] The mixture is filtered, and the filtered solid is dried; the filtrate is mixed with deionized water and used as a raw material;

[0034] The solid mixture is calcined at 700-800°C for 1-2h, and the gallium oxyhydroxide decomposes to form gallium oxide.

[0035] The 4N purity described in this application is the representation method of the purity of the equivalent reagent, that is, the purity of 99.99%.

[0036] When metal gallium and high-temperature water ...

Embodiment 1

[0043] Take 4N pure gallium metal and mix it with deionized water, the mass ratio of gallium to water is 1:2;

[0044] Put the mixture of gallium and water into a high-pressure reaction vessel, continuously stir at 150°C, and perform a hydrothermal reaction for 1.5 hours to generate a mixture of gallium oxyhydroxide and gallium oxide;

[0045] The mixture is filtered, and the filtered solid is dried; the filtrate is mixed with deionized water and used as a raw material;

[0046] The solid mixture was calcined at 700°C for 2 hours, and gallium oxyhydroxide was decomposed to form gallium oxide.

Embodiment 2

[0048] Take metal gallium with 4N purity and mix it with deionized water, the mass ratio of gallium to water is 1:4;

[0049] Put the mixture of gallium and water into a high-pressure reaction vessel, continuously stir at 180°C, and perform a hydrothermal reaction for 1.4 hours to generate a mixture of gallium oxyhydroxide and gallium oxide;

[0050] The mixture is filtered, and the filtered solid is dried; the filtrate is mixed with deionized water and used as a raw material;

[0051] The solid mixture was calcined at 730°C for 1.8h, and gallium oxyhydroxide was decomposed to form gallium oxide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com